Hi-Velocity RPM-E User manual

Manufactured By

Module-RPM-E-Refrigerant-Module-Installation-052020Module-RPM-E-Refrigerant-Module-Installation-052020

RPM-E Refrigerant Module

Installation Manual

Small Duct High Velocity Heating, Cooling and Home Comfort Systems

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

*IMPORTANT: The freeze control serves the purpose

of preventing severe icing of the coil in the event of

an undercharge or low load on the coil. This piece of

equipment must be used at all times. Lack of use of

the freeze-stat will result in RPM-E related warranty

issues being voided.

A

A1

B

B1

COIL

Module RPM-E

Refrigerant Module Installation

Rough Opening Sizes A or B A1 or B1

RPM-E 50 113/4”L X 131/4”H

(298mm X 337mm)

113/4”L X 9”W

(298mm X 229mm)

RPM-E-70 163/4”L X 131/4”H

(425mm X 337mm)

163/4”L X 9”W

(425mm X 229mm)

RPM-E-100 223/4”L X 131/4”H

(578mm X 337mm)

223/4”L X 9”W

(578mm X 229mm)

Refrigerant Modules (RPM-E)

The RPM-E series cooling module can be used with the Hi-

Velocity Fancoil, installed in many dierent positions. It is pre-

piped with an adjustable, heat pump ready, thermal expansion

valve and comes with a bleed port, sight glass, suction and liquid

line access ports, freeze-stat, and two L brackets for mounting.

The RPM-E comes as a complete module and must be installed

in the vertical position on the return air side of the fancoil; the

unit cannot be turned on its side and is a draw through unit

only. The module oers multi-position airow congurations for

horizontal, highboy, or counter-ow congurations. (Fig. RPM-

01)

The TXV (Thermal Expansion Valve), sight glass, access ports,

and freeze-stat* are already installed and are accessible through

an easy to remove access hatch. The liquid and suction lines have

male solder connections at a standard width making connections

to the condenser lines quick and easy.

Fig. RPM-01 - RPM-E Cooling Module Congurations

When installing, follow the recommendations shown in

Table 01, demonstrated in Fig. 01. For example, a horizontal

application could use A to B while highboy applications could

use A to B1. Do not use a combination of A to A1 or B to B1, as

this would bypass the cooling coil completely. A1 is not to be

used for outlet airow. The knock-outs can be removed with a

screw driver and hammer. Use caution when opening the knock-

outs, ensuring you do not damage the coil surface.

Congurations

Important: If side A1 is going to be used in your selected

conguration, the extended drain pan must be removed.

RPM-E Drain Pan Extension

The RPM-E Drain Pan Extension (DPE) is to be removed for up

ow (vertical) return air applications (avoid installing the RPM-E

in counter ow applications).

The lower knockout can now be removed, using a screwdriver

and hammer (Fig-RPM-03). Use caution when removing knockouts

ensuring you do not damage the coil inside the module.

To remove the pre-installed DPE, rst remove left side access

panel of the RPM-E Module. Remove the 3 - ¼ ” screws that hold

the DPE in place, remove the DPE and replace ¼” screws into the

coil support (Fig. RPM-02). Replace the left side access panel.

-2--2-

Right Wrong

A to B B1 to A1

A to B1 B to A1

A1 to B A to A1

A1 to B1 B to B1

B to A

B1 to A

Table RPM-01 - RPM-E Cooling Module Congurations

Fig-RPM-02 - Remove DPE

Fig-RPM-03 - Remove Knockout

*IMPORTANT: The freeze control serves the purpose

of preventing severe icing of the coil in the event of

an undercharge or low load on the coil. This piece of

equipment must be used at all times. Lack of use of

the freeze-stat will result in RPM-E related warranty

issues being voided.

A

A1

B

B1

COIL

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

Locate the outdoor unit in a suitable location, as close as

possible to the fan coil. Maintain the clearances recommended by

the manufacturers of the outdoor unit, to ensure proper airow.

The outdoor unit must be installed level, in a properly supported

location. A liquid line lter/drier is recommended to be installed.

Outdoor Unit Installation

Make all connections to the outdoor unit with rain tight conduit

and ttings. Most building codes require a rain tight disconnect

switch at the outdoor unit as well (always check local codes). Run

the proper size copper wires to the unit, and connect as per the

manufacturer’s recommendations.

Ensure that the outdoor unit is setup for a TX system. If not, a

hard start kit may be required.

Wiring - Outdoor Unit

-3--3-

Mounting the RPM-E

Fig. RPM-04 - Mounting Brackets

(76mm)

(76mm)

(76mm)

(76mm)

Two L mounting brackets are shipped loose for attaching the

RPM-E to the fan coil, along with two sided foam tape for an air

seal between the units. When mounting the cooling coil to the

fancoil (Fig. RPM-04), ensure that no screws puncture the drain

pan or coil. It is advised that no screws be placed within 3 inches

(76mm) from the bottom of the coil. This will prevent the drain

pan from being accidentally pierced. It is also advised that care be

taken when placing screws in the top left side of the cooling coil

(when looking at the access hatch), as this is where the top most

extent of the cooling coil is located. See Specication Pages for

the dimensions of the fan coil units and cooling modules.

Fig. RPM-05 - Secondary drain pan

Capped

Cleanout

P-Trap

Secondary

Drain

Primary

Drain

Drain Connections, P - Trap &

Secondary Drain Pan

The primary condensate drain must have a minimum 3”

P-Trap installed (Fig. 05). The drain line must run at a slope of

¼” per foot in the direction of the drain. RPM-E modules come

with a ¾” male CPVC primary and secondary outlet. It is good

practice to install a clean out right above the P-Trap. Using a

“tee tting” and cap in the P-Trap’s construction can be used as

the clean out and as a way to prime the P-Trap if it ever dries out.

A wet P-Trap is important. A dry P-Trap can be detrimental to

proper drainage. If code requires a secondary drain line, run the

secondary line using the same method as primary. Otherwise,

capping o the secondary drain line is acceptable. Do not run the

secondary drain line to the secondary drain pan or use it as a vent

to atmosphere! An equipment stand/riser or rubber equipment

mat may be necessary to elevate the module o of the ground to

allow for a P-Trap.

Any installation that has the potential of property damage

due to condensate must have a secondary drain pan installed. If

the unit is installed in a high heat and/or high humidity location,

extra insulation around the unit casing may be required. This will

prevent excessive condensate from forming on the outer surface

of the casing.

Important: Piping the condensate lines on a return side cooling

coil can be dramatically dierent, be sure to read info below.

Module RPM-E

Refrigerant Module Installation

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

Pipe Sizing

When sizing refrigerant piping,

follow the outdoor unit

manufacturer’s recommendations.

Run the pipes in the most direct route possible, taking into

account structural integrity and building details. If the evaporator

is located above the condenser, slope any horizontal runs toward

the condenser. If the condenser is located above the evaporator,

a P-trap must be installed at the bottom of the vertical riser. For

long vertical risers, additional P-traps must be installed for every

twenty feet (6m). For lines running over 50’ (15m), a suction line

accumulator must be installed. Lines running over 100’ (30m) are

not recommended. All lines should be piped so as not to restrict

access to the front panels, lter section, or electrical enclosure.

Piping the RPM-E

Only refrigerant grade pipe and ttings are to be used with

Hi-Velocity Systems. Plumbing ttings may contain wax or other

contaminants which are detrimental to the proper operation of

the system. Insulate the suction line with 3/8” (9.53mm) insulation

such as Armaex. In high heat areas, 1/2” (12.7mm) insulation

may be needed. If the lines are run in an area where temperatures

could exceed 120°F (49°C) or runs longer than 50’ (15.24m), then

the liquid line may need to be insulated as well. Support the pipe

every 5 feet (1.52m), or whatever local code states.

Brazing & Pressure Testing

The RPM-E comes pre-piped with the coil assembly. With the

RPM-E, the Liquid and Suction lines are the only brazing that need

to be done at the fan coil. For charging and brazing, remove the

front access panel of the RPM-E (Fig. RPM-06). With the access

panel removed, the coil assembly will be accessible. Wet rag the

liquid and suction line (or use a heat dissipating paste) to ensure

no overheating occurs to the pre-piped coil assembly. Excess heat

may damage the RPM-E components.

Fig. RPM-06 - Remove Front Access Panel

Once the system has been brazed it must be pressure tested.

Pressure testing must be done with nitrogen and not refrigerant.

Typically, pressures are tested to the maximum operating pressure

that the system will see. Allow the system to hold the nitrogen

charge for at least 15 minutes to ensure there are no leaks. Check

with local codes for proper testing procedures.

After the piping is installed and all components have been

brazed together, a vacuum pump must be used to evacuate the

system from both the low and high side to 1500 microns (200

pa). Add pressure to the system to bring the pressure above zero

psig. After allowing the refrigerant to absorb moisture, repeat the

above procedure. Evacuate the system to 500 microns (67 pa) on

the second evacuation, and ensure that the system holds at the

vacuum pressure. If not, check for leaks and evacuate again. At

this point open service valves on pre-charged condensing units,

and add refrigerant to the system if necessary.

Evacuating

The use of an electronic leak detector is recommended, as it is

more sensitive to small leaks under the low pressures.

Once the system has been determined clean and ready for

charging, refrigerant can be added. The service valves on the

condenser must be open at this point. Never leave the system

unattended when charging. With the system running, slowly

add refrigerant. The typical operating point of an RPM-E coil is

that of a saturated suction temperature of 38-40°F (3-4°C) and a

suction line temperature of 42-44°F (6-7°C). In order to prevent

overcharging during this stage, refrigerant should be added in

steps. This will allow time for the system to settle and prevent

‘overshooting’ the ideal charge. Condenser pressures and

temperatures remain similar to those in a conventional forced air

system. It is recommended that the coil be charged on a high load

day at the compressor’s highest speed.

Charging

-4--4-

Most system start ups require only an adjustment to the

refrigerant level of the system. Should further renement be

required, the TXV may be adjusted. A clockwise turn of the

superheat valve (the direction in which the cap is screwed on) will

result in a closing of the valve while a counterclockwise turn (the

direction in which the cap was unscrewed) will result in opening

of the valve. Always note system conditions before adjusting the

valve and allow 5 minutes for the system to settle before making

any further adjustments. Never adjust the TXV more than one

quarter turn at a time.

Module RPM-E

Refrigerant Module Installation

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

Freeze Stat

The RPM-E series cooling coil comes equipped with an anti-

freeze control mounted on the suction line. This freeze control

serves the purpose of preventing severe icing of the coil in the

event of an undercharge or low load on the coil. This piece of

equipment must be used at all times. Lack of use of the

freeze-stat will result in RPM-E related warranty issues

being voided. During start-up, it is acceptable to jumper across

the Freeze-Stat. This will prevent the freeze-stat from shutting

the system o while charging a new system that may be low

on refrigerant. Once charged and running, this jumper must be

removed and the Freeze-Stat connected to the FZ and FZ terminals

on the Printed Circuit Board. Should wiring needs arise in which

the outdoor unit is controlled through another means of wiring,

the Freeze-Stat should be connected in series on the supply side

of the control wiring.

Heat Pumps

Traditionally, SDHV systems have been charged to special

guidelines when used in conjunction with heat pumps. This

charging procedure involved charging the units to normal cooling

capacities and reviewing the operation in heating mode. If head

pressures were found to be impinging on the high head pressure

limits, a small amount of refrigerant was removed to prevent the

unit from shutting down. The cause of high head pressures in

heating mode is due to the disparity in sizes of the indoor and

outdoor coils, along with the lower airow rates of SDHV systems.

The RPM-E coil can operate at a level that is dierent from

most other conventional system coils. Typically, superheat levels

are low, 2-4°F of superheat. Adjustment of the valve also diers

somewhat. Rather than having a large eect on the range of

superheat, adjustment of the valve has a larger eect on the

system pressures; superheat maintaining a fairly constant point.

Opening the valve will increase suction pressures and decrease

liquid pressures, while closing the valve will decrease suction

pressures and raise liquid pressures.

Bi-Flow Receiver

The Bi-Flow Receiver is designed

for use with heat pump systems,

up to 5 tons, and with any typical

refrigerants. The receiver allows

refrigerant a location to migrate to

during the heating cycle, minimizing

head pressures. During cooling mode,

the receiver is empty, allowing the full

refrigerant charge to be utilized for

cooling.

The receiver is a horizontal tank with a pair of dip tubes

extending to the bottom of the tank. These two tubes allow for

liquid refrigerant to be drawn from the tank regardless of the

direction of ow. For this reason, the receiver must be mounted

so that the inlet/outlets of the tank come out of the top of the

unit. Mounting brackets are located at the base of the unit for

secure mounting. The receiver is to be located on the liquid line of

the system, anywhere between the indoor and outdoor coils. As

the unit is of a bi-ow design, it does not matter which end faces

towards the indoor coil.

The inlet/outlet ports are constructed of steel and require the

use of a 35-45% Silver Solder and Flux for brazing. The use of

standard copper to copper solders may result in diculty brazing

and the potential for a failure at the weld. Ensure that the tank is

protected from overheating while brazing and that any remaining

ux is cleaned from the unit. If installing outdoors, ensure that the

receiver is insulated and protected from the elements.

With the introduction of newer, larger heat pumps, this issue

is more likely to be experienced. While some heat pump units

may still be charged in the traditional method, the amount of

refrigerant that is required to be removed for heating mode may

leave the system drastically undercharged for cooling mode. For

this reason it is highly recommended that a Bi-Flow Receiver be

used with heat pump applications.

Charging Cont’d

-5--5-

Typical Operating Ranges

Saturated Suction Temperature 38 - 40°F (3 - 4°C)

Suction Line Temperature 42 - 44°F (6 - 7°C)

Superheat 2 - 4°F (1 - 2°C)

Suction Line Pressure R-22 60 - 72 psig

R-410a 110-124 psig

Liquid Line Pressure R-22 160-210 psig

R-410a 250-300 psig

Module RPM-E

Refrigerant Module Installation

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

-6--6-

Troubleshooting the TXV

When issues arise that bring the function of the TXV into

question, factors must be looked into before replacement.

Inspect the TXV for signs of damage. This may be from a pinched

equalizer line to a burnt valve. These issues will have an adverse

aect on the operation of the valve. Should the equalizer line be

pinched, the valve will no longer be able to supply the proper

amount of refrigerant to the coil. A burnt valve may have an eect

on the refrigerant charge of the TXV bulb or the seal of the valve.

This may again cause an improper amount of refrigerant to be

metered by the valve or cause the valve head to become seized.

The TXV bulb location and mounting should also be inspected.

The bulb should be securely mounted on the top half of the

suction line. If the bulb is loose or on the lower half of the line, the

bulb will not properly sense the refrigerant temperature and will

not meter the proper amount of refrigerant. Ensure that the bulb

is also properly insulated, as a lack of insulation will expose the

bulb to conditions well outside those of the coil. This will cause an

overfeed of refrigerant to the system.

Should the installation of the valve be proper, and no damage

is evident, inspect the operation of the valve. If the TXV bulb

is removed and held in ones hand, the valve should react

accordingly. This sudden increase in heat will open the valve. This

will cause a rise in suction pressure and a drop in liquid pressure.

Should nothing happen, the valve is likely seized and will need to

be replaced.

and outdoor unit, on and o. This often takes the form of very

short and frequent on cycles. There are many factors that may

contribute to short cycling of the refrigerant system. These issues

can generally be broken down between airow related issues,

refrigerant issues, and installation issues.

Low airow rates are one of the most common causes of short

cycling. As the airow rate is lowered across the cooling coil, the

coil pressure drops along with it. This lowers the temperature of

the coil and may cause the freeze-stat to trip. As the system settles,

the freeze-stat closes and the cycle begins again, as the unit

does not run long enough for the space to become adequately

conditioned. Ensure that the proper amount of airow is provided

to the coil. Check for proper air ows and return air practices.

Improperly charged systems run the risk of short cycling as well.

An undercharged system will react much the same as a system

with low airow. If the charge is low enough, it may trip out on

low pressure. If a system is overcharged, it may trip out on high

head pressure. Ensure that the system charge is within the bounds

described in section “Piping the RPM-E”.

System set-up and installation should be checked as well.

Piping practices should be within the bounds described in section

“Piping the RPM-E” and within the realms of the outdoor unit

manufacturer. Extreme and often unnecessary adjustment of

the TXV can create conditions similar to an undercharged coil. A

poorly placed T-stat, such as underneath a vent, can cause short

cycling. This happens due to the T-stat being satised very shortly

after the unit has begun to operate.

Short Cycling

Short cycling is the unnecessary running of the indoor

Specications RPM-E-50 RPM-E-70 RPM-E-100

Matching Fan Coil

HE-Z/HE-B/HE-50/51

HV-50/51/52

LV-50

HE-Z/HE-B/HE/HV-70/71

LV-70 HE-Z/HE-B/HE/HV-100/101

Part Number 20090200050 20090200070 20090200100

Tons(1) 1.5 - 2.0 (5.3 - 7.0 kW) 2.5 - 3.0 (8.8 - 10.6 kW) 3.5 - 5.0 (12.3 - 17.6 kW)

Refrigerant Type R-410A R-410A R-410A

TX Cooling MBH(2) 18-24 (5.3-7.0 kW) 30-36 (8.8-10.6 kW) 42-60 (12.3-17.6 kW)

Latent Cooling MBH 6.8-8.9 (2.0-2.6 kW) 11.7-13.7 (3.4-4.0 kW) 16.0-22.2 (4.7-6.5 kW)

Fin Material Aluminum Aluminum Aluminum

Tubing Material Copper Copper Copper

Type of Fins .006 Al (0.1524mm) .006 Al (0.1524mm) .006 Al (0.1524mm)

Hydronic

Connection

Sizes

Liquid Line (Lq) 3/8”(9.5mm) 3/8”(9.5mm) 3/8”(9.5mm)

Suction Line (S) 7/8” (22.3mm) 7/8” (22.3mm) 7/8” (22.3mm)

Drain Connection 3/4”M CPVC (19mm) 3/4”M CPVC (19mm) 3/4”M CPVC (19mm)

TXV with Built in Check Valve & Bypass Yes Yes Yes

Site Glass Yes Yes Yes

Access Ports Yes Yes Yes

Freeze Stat Yes Yes Yes

Shipping Weight 48 lbs (22kg) 59 lbs (27kg) 74 lbs (34kg)

Module Size (L x W x H) 19 1⁄4”x 14 5⁄8”x 18 1⁄2”

(489mm x 371mm x 470mm)

24 1⁄4” x 14 5⁄8” x 18 1⁄2”

(616mm x 371mm x 470mm)

32” x 14 5⁄8” x 18 1⁄2”

(813mm x 371mm x 470mm)

MBH - Thousand British Thermal Units per Hour

TX - Thermal Expansion

TXV - Thermal Expansion Valve

(2) Smaller condensers may be matched to the fan coil when needed (match TXV to condenser size)

(1) Minimum ofMinimum of four HE outletsfour HE outlets per ton of cooling needed. (2" Duct = Minimum per ton of cooling needed. (2" Duct = Minimum eight outletseight outlets per ton)per ton)

Module RPM-E

Refrigerant Module Installation

www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.© 1995-2020 Energy Saving Products Ltd.

Module RPM-E

Refrigerant Module Installation

-7--7-

• Inoperative parts must be returned to Energy Saving Products Ltd. with an ESP RMA Form that

includes model, serial number, and a detailed description of the entire problem. Inoperative parts

must be returned in testable condition.

• This warranty does not cover shipping costs to and from the factory, labor costs or any other cost

associated with the installation of the replacement part.

• Energy Saving Products Ltd. is not liable for any other damages, personal injury, or any other losses

of any nature.

• The liability of Energy Saving Products Ltd. is limited to and shall not exceed the cost of pre-approved

replacement parts.

WARRANTY

AThree (3) Year Limited Warranty is extended on Electric Strip Heaters.

A Five (5) Year Limited Warranty is extended on all components in products manufactured exclusively

by Energy Saving Products. These components include Motors, WEG Controller, Circuit Boards, Dampers,

Zoning Controls, Blowers, Motor & Blower Assemblies, Heating Coils, Chilled Water Coils, and Air

Conditioning Coils. Note: If any product is installed in or exposed to a corrosive environment, warranty

will be void.

Energy Saving Products Ltd. is proud to oer a limited warranty. This warranty applies strictly to the rst

purchaser at wholesale level and only to the fan coil unit and module. It does not include connections, attachments

and other products or materials furnished by the installer.

TERMS & CONDITIONS

• Any repair performed under warranty must be approved by Energy Saving Products Ltd. for this

warranty to be valid.

This warranty replaces all other warranties expressed or implied.

www.hi-velocity.com

• Should there be multiple consecutive failures of a single part, warranty will not be considered unless

a contractor has contacted Energy Saving Products Ltd. Technical Department for assistance, and

received a tech code.

Follow these steps for Service or Repair:

1. Contact the installer of the product or a licensed service company

2. Contact the distributor

3. Contact Energy Saving Products Ltd. Mon-Fri 8 am – 4:30 pm MT 1-888-652-2219

This warranty excludes any damages caused by changes, relocation to, or installation in a new site. This warranty

does not cover any defects caused by failure to follow the installation and operating instructions furnished with

the fan coil. This warranty does not cover defects caused by failing to adhere to local building codes and following

good industry standards. Failure to correctly install the fan coil, or material related to the unit, may result in

improper system performance and/or damages and will void this warranty. This warranty does not cover material

installed in or exposed to a corrosive environment. This warranty does not cover products subjected to abnormal

use, misuse, improper maintenance, or alteration of the product. Using the fan coil and/or module as a source of

temporary heating/cooling during construction will void this warranty.

Products sold by Energy Saving Products but manufactured by others, will carry the original

manufacturer’s warranty.

TM

Energy Saving Products Ltd, established in 1983, manufactures the Hi-Velocity

SystemsTM product line for residential, commercial and multi-family markets. Our facilities

house Administration, Sales, Design, Manufacturing, as well as Research & Development

complete with an in-house test lab. Energy Saving Products prides itself on Customer

Service and provides design services and contractor support.

For all of your Heating, Cooling and Indoor Air Quality needs, the Hi-Velocity System

is the right choice for you!

Phone: 780-453-2093

Fax: 780-453-1932

Toll Free: 1-888-652-2219

www.hi–velocity.com

Hi-Velocity HE-Z Fan Coils,Hi-Velocity HE-Z Fan Coils, GreenGreen TechnologyTechnology

Build Smart, BreatheBuild Smart, Breathe EasyEasy

Small Duct Heating, Cooling and IAQ Systems

This manual suits for next models

3

Table of contents

Other Hi-Velocity Control Unit manuals

Popular Control Unit manuals by other brands

HumanTechnik

HumanTechnik MA-1 operating instructions

Animal Factory Amplification

Animal Factory Amplification Coma Reactor user manual

ABB

ABB REC650 ANSI Product guide

Rockwell Automation

Rockwell Automation 2711P-RPA installation instructions

Honeywell

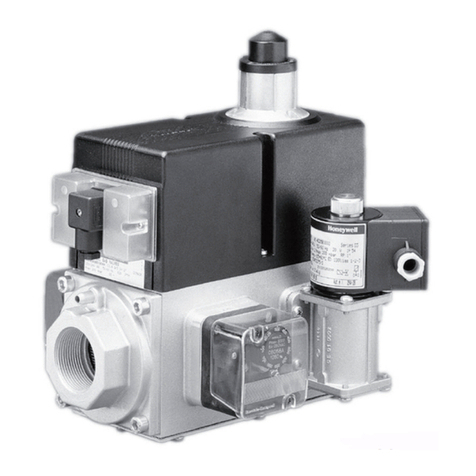

Honeywell VQ400 Series manual

Roger Technology

Roger Technology B70/1DC Instruction and warnings for the installer

Nice

Nice mindy TT1N Instructions and warnings for the fitter

Johnson Controls

Johnson Controls System 350 Y350R Technical bulletin

YASKAWA

YASKAWA MECHATROLINK Sigma 2 Series user manual

GOK

GOK Caramatic Switch Two Assembly and operating manual

GEM

GEM 695 operating instructions

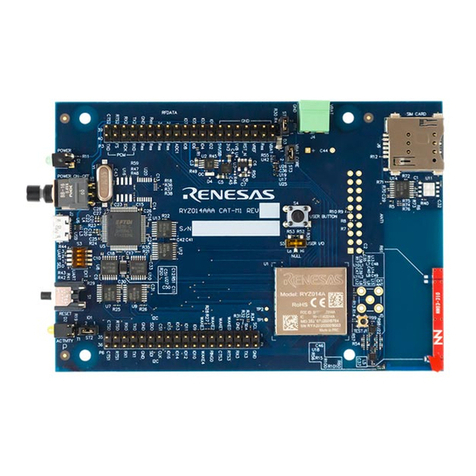

Renesas

Renesas RYZ014 manual