Sperry instrument ADT-222A User manual

(

SUBJECT

GROUND

EQUIPMENT

MANUAL

PN

4030935, 4039390

LIST

OF

CHAPTERS

General

Information

and

Operating Instructions

Description

Operating Instructions

Specifications

Installation

and

Removal

Handling

and

Mounting

Equipment

and

Materials

Installation

Procedures

Installation

Verification

Removal

from

Service

Storage

and

Shipping

Ma

intenance

Introduction

Performance Verification

Theory

of

Operation

Troubleshooting

Adjustment

and

Calibration

Repair

,

,

Special Tools, Fixtures,

and

Test

Equipment

. ,_»r

.,.,.,

.

CHAPTER-SECTION

1-0

1-1

1-2

1-3

2-0

2-1

2-2

2-3

2-4

2-5

2-6

3-0

3-1

3-2

3-3

3-4

3-5

3-6

3-7

To buy, sell, rent or trade-in this product please click on the link below:

http://www.avionteq.com/Honeywell-Sperry-ADT222A-4030935-911-Air-Data-Test-System.aspx

www.avionteq.com

or----------------------------------------------------------

I

----------------

GROUND'

EQUIPMENT

MANUAl,.

PN

4030935,4039390

FOREWORD

The

ADT-222A

Air

Data

Test

System,

Part

No.

4030935-XXX

and

4039390-XXX,

is

the

most

versatile,

accurate, easy

to

use,

air

data

test

instrument currently

available.

When

properly

and

effectively

used

it

can

substantially

reduce

test

and

calibration

times

and

overall costs of maintaining

air

data computers

and

instruments.

The

following

table

is

provided

as

a

definition

of

ADT-222A

configurations:

Nominal

Pneumatic

Voltage

Dash

No.

Calibration Port Required

-XXX

Medium

Location

(V

ac)

-901

Ai

r Front

115

-902

Air

Rear

115

-911

Ai

r Front

230

-912

Air

Rear

230

-SOl

N2

Front

115

-S02

N2

Rear

115

-Sl1

N2

Front

230

-S12

N2

Rear

230

This

manual

has

been

prepared to provide the operator with the information

necessary to operate

and

maintain the

ADT-222A.

A

full

description of the system

is

provided in Chapter 1 along with the system

specifications,

theory of

I operation,

and

manual

operating

instructions.

Chapter 2 contains the information

necessary to

install

the system

and

put

it

"on

line".

Chapter 2 also contains

instructions

for

removing

the

ADT-222A

from

service for storage

and

shipping.

Maintenance information, including

testing,

troubleshooting,

calibration,

and

repair

of the

ADT-222A,

is

contained in Chapter

3.

Acomplete

parts

list

is

provided in Chapter 4.

I

The

4030935-XXX

and

4039390-XXX

ADT-222A's

are identical

test

systems, except

4039390-XXX

contains

an

ASCII

interface

option

that

provides

capability

of

operating the

ADT-222A

automatically

under

control of

any

Automatic Test

Equipment

(ATE).

(Refer

to

Chapter 5.)

the

It

is

recommended

that

the operator read

and

familiarize himself with Chapters 1

and

2 before attempting

to

install

or operate the

ADT-222A.

Foreword

Page

1

Jun

15/S0

+~~!~~V

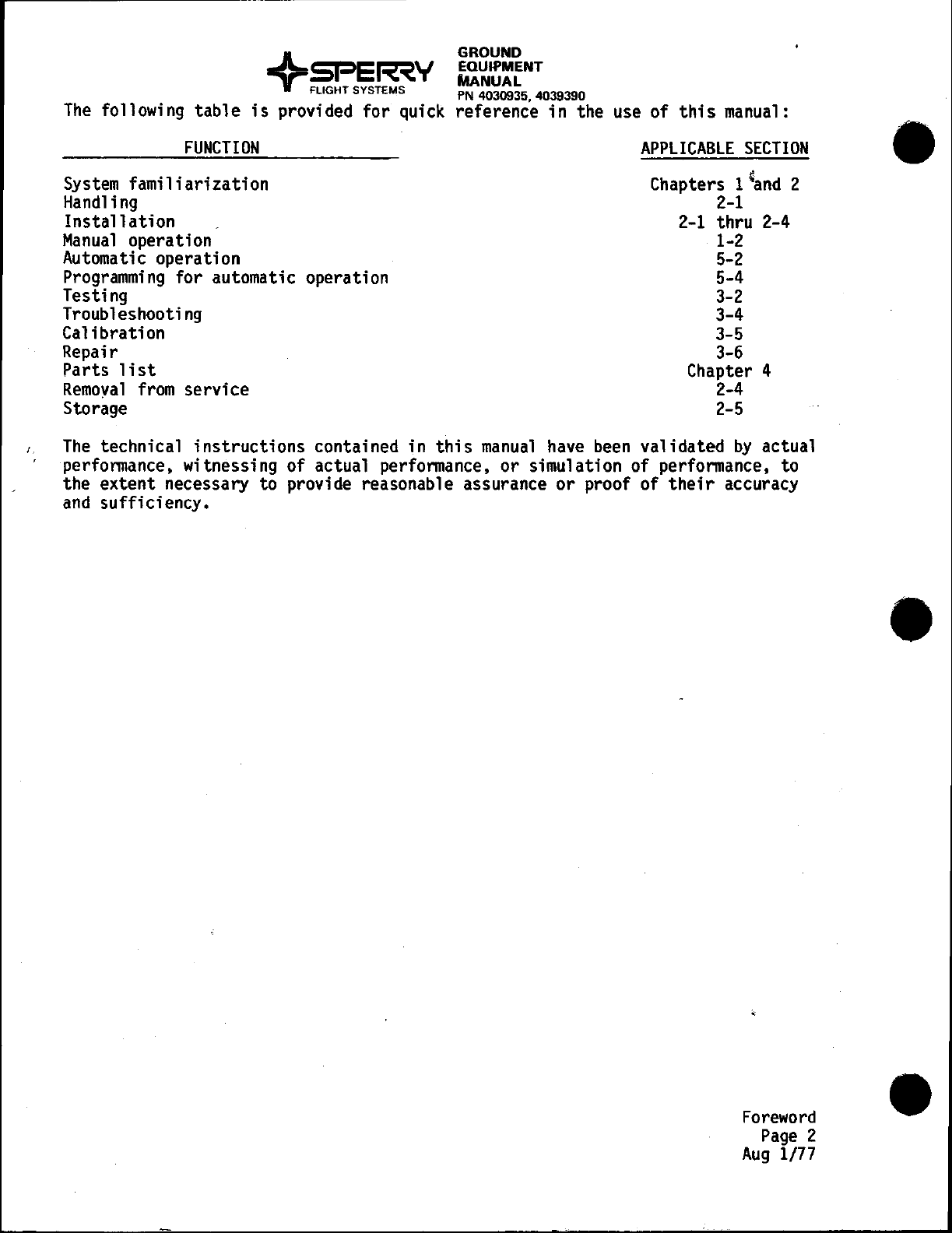

The

following table

is

provided for quick

FUNCTION

System

familiarization

Handling

Installation

Manual

operation

Automatic

operation

Programming

for automatic operation

Testing

Troubleshooting

Calibration

Repair

Parts

list

Remoyal

from

service

Storage

GROUND

EQUIPMENT

MANUAL

PN4030935,4039390

reference in the

use

of

this

manual:

APPLICABLE

SECTION

Chapters 1'and 2

2-1

2-1

thru

2-4

1-2

5-2

5-4

3-2

3-4

3-5

3-6

Chapter 4

2-4

2-5

/,

The

technical instructions contained in

this

manual

have

been

validated

by

actual

performance, witnessing of actual performance, or simulation of performance, to

the extent necessary

to

provide reasonable assurance

or

proof of

their

accuracy

and

sufficiency.

Foreword

Page

2

Aug

1/77

GROUND

EQUIPMENT

MANUAL

PN

4030935. 4039390

SERVICE

BULLETIN

LIST

In

the

serial

numbering

system assigned to the

ADT-222A,

the

first

three

numbers

of

the

seven-digit

serial

number

on

the

identification

plate

represent the date

of manufacture.

The

remaining

numbers

are a

four-digit

numeric sequence count

of

the item

as

manufactured.

Service

Bulletin

List (Page 1/2)

Feb

1/79

....----------~~~---

--

-----------------

I

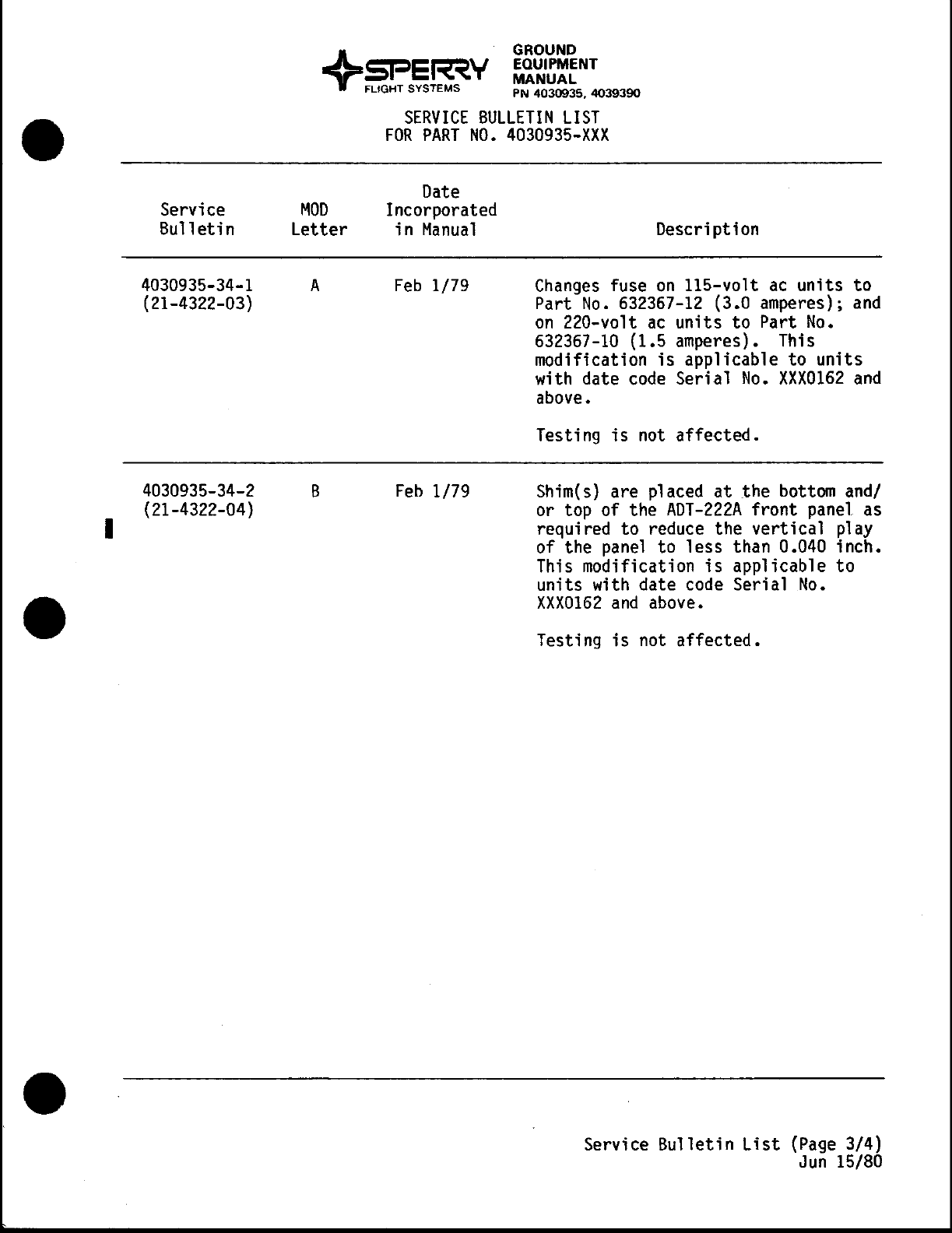

Service

Bull

eti

n

4030935-34-1

(21-4322-03)

4030935-34-2

(21-4322-04)

MOD

Letter

A

B

GROUND

EQUIPMENT

MANUAL

PN

4030935. 4039390

SERVICE

BULLETIN

LIST

FOR

PART

NO.

4030935-XXX

Date

Incorporated

in

Manual

Feb

1/79

Feb

1/79

Description

Changes

fuse

on

lIS-volt

ac

units to

Part

No.

632367-12

(3.0 amperes);

and

on

220-volt

ac

units

to

Part

No.

632367-10

(1.5 amperes). This

modification

is

applicable to

units

with date

code

Serial

No.

XXX0162

and

above.

Testing

is

not

affected.

Shim(s) are placed

at

the

bottom

and/

or top of the

ADT-222A

front panel as

required to reduce the

vertical

play

of the

panel

to

less

than 0.040 inch.

This modification

is

applicable

to

units with date

code

Serial

No.

XXX0162

and

above.

Testing

is

not

affected.

Service

Bulletin

List

(Page

3/4)

Jun

15/80

GROUND

EQUIPMENT

MANUAL

PN

4030935, 4039390

CHAPTER

1

GENERAL

INFORMATION

AND

OPERATING

INSTRUCTIONS

1-0

Aug

1/77

Chapter-

Section

1-1

1-2

1-3

GROUND

EQUIPMENT

MANUAL

PN

4030935,

4039390

CHAPTER

1

GENERAL

INFORMATION

AND

OPERATING

INSTRUCTIONS

Table of Contents

DESCRIPTION

1.

General

Description

2. Physical Description

3. Functional Description

OPERATING

INSTRUCTIONS

1.

General

2.

System

Initialization

3.

Measure

Mode

Operation

4. Control

Mode

Operation

5.

Leak

Test Operation

6.

Dynamic

Operation

7. Failure Procedures

8. Error

Messages

SPECIFICATIONS

1.

Leading

Particulars

2. Connections

and

Fittings

3.

Range

of Operation

4. Protection Limits

5.

Performance

Specifications

Page

1

2

5

1

5

8

9

11

13

14

15

1

2

2

4

4

1-0

Contents

Aug

1/77

I

Section

1.

1.

General

Description

GROUND

EQUIPMENT

MANUAL

PN

4030935. 4039390

Description

The

ADT-222A

Air

Data

Test

System

(figure 1-1)

is

a precise,

stable,

easy to

use

pressure control

system

designed to precisely simulate

and

accurately

measure

the

pneumatic

pressures associated with

an

aircraft

in

flight.

Its

operational

and

design features

were

selected to

meet

the needs of those

who

use,

repair,

or

manufacture precision

pneumatic

avionic equipment.

Conse-

quently,

it

is

ideally suited for laboratory, shop, or production use.

In

addition to

its

manual

operation

capability,

the

ADT-222A

is

available with

an

optional automatic

test

equipment

(ATE)

interface

which

allows

remote

slave operation of the

ADT-222A

by

an

ATE.

When

equipped with

this

option,

the

ADT-222A

is

fully

programmable

and

capable of being controlled

by

an

ATE

system

or

any

programmable

terminal

employing

an

IEEE

Standard

488-1975

interface.

Pressure

measurement

and

control

is

provided in terms of inches of

mercury

or

millibars;

altitude

in

feet

or meters;

and

airspeed in knots or kilometers/

hour, as selected

by

the operator. Aspecial purpose

digital

processor

operates in conjunction with

two

precision vibrating

diaphragm

digital

pressure sensors

and

electrically

controlled pressure regulation valves to

provide high speed control

and

measurement

response with readout displays

converted to the units desired

by

the operator.

I~

ADT-222A

Air

Data

Test

System

Figure

1-1

XX2

SERIES

HAVE

PNEUMATIC

CONNECTORS

ON

REAR PANEL

32315

A1

1-1

Page

1

Feb

1/79

+ GROUND

~E~\.J

EOUIPMENT

~I-

I~

....T

MANUAL

FLIGHT

SYSTEMS

PN

4030935.

4039390

When

used as a

transfer

standard, the

ADT-222A

accurately measures the

pressures applied to

its

input ports with

sufficient

resolution

and

stability

to

resolve a

I-foot

change in

altitude

at

60,000

feet.

Because of

its

extremely high

calibration

stability,

it

can

be

used to

calibrate

other

laboratory pressure standards

and

air

data

test

instruments as well as

air

data avionic equipment.

When

used as a pressure

controller,

the desired pressure

or

altitude

and

airspeed values are entered via

digital

lever

switches

on

the

front

panel.

Pressure

transition

rates

are selected

by

digital

thumbwheel

switches

on

the

front

panel

and

are precisely

controlled

to provide extremely

smooth

pressure

transitions

with

no

overshoot. A

single

pushbutton switch

initiates

control

to

the

newly

selected

values.

The

system will also respond to

dynamic

signals applied to a

dynamic

input

connector

on

the

rear

panel.

As

an

example, a function generator

can

be

used

to

superimpose sinusoidal pressure

waves

on

eitherP

s

or

Pt.

The

ADT-222A

employs

built-in-test

(BIT)

programming

and

hardware to monitor

its

own

operation,

detect

system

failures

and

improper

commands

from

the

operator,

and

shut

down

the system

when

a

fault

is

detected. This

BIT

capability

provides

fail-safe

operation

by

protecting the

unit

under

test

(UUT)

against possible hazards during

test.

Protection

is

provided against

UUT

damage

caused

by

either

operator

error

or

ADT-222A

failure.

The

operator

has

the option of

selecting

subsonic or supersonic protection

limits

to

match

the

capabilities

and

requirements of the

UUT.

In

addition to

electrical

power,

operation of the

ADT-222A

requires

an

exter-

nal

.pressure source

and

two

external

vacuum

sources.

The

exact requirements

for

all

of the inputs are

listed

in

Chapter

I,

section 3.

The

ADT-222A

is

calibrated

at

the factory for

use

with

either

dry

air

(-901, -902, -911,

-912)

or

dry nitrogen (-801, -802, -811, -812) as the pressure source.

The

calibration

medium

is

designated

by

a

front

panel decal.

2. Physical Description

The

ADT-222A

consists

of a

power

supply,

digital

control cards,

two

pressure

sensors,

and

two

pneumatic control systems

mounted

on

a

chassis.

The

front

panel contains operating controls

and

displays,

and

the

rear

panel contains

pressure

fittings

and

connectors for external control

and

test

equipment.

It

is

packaged in

an

aluminum

alloy enclosure designed for

either

rack

mounting

or

bench

top use. Dimensions, weight,

and

other leading

particulars

are

listed

in Chapter

I,

section

3.

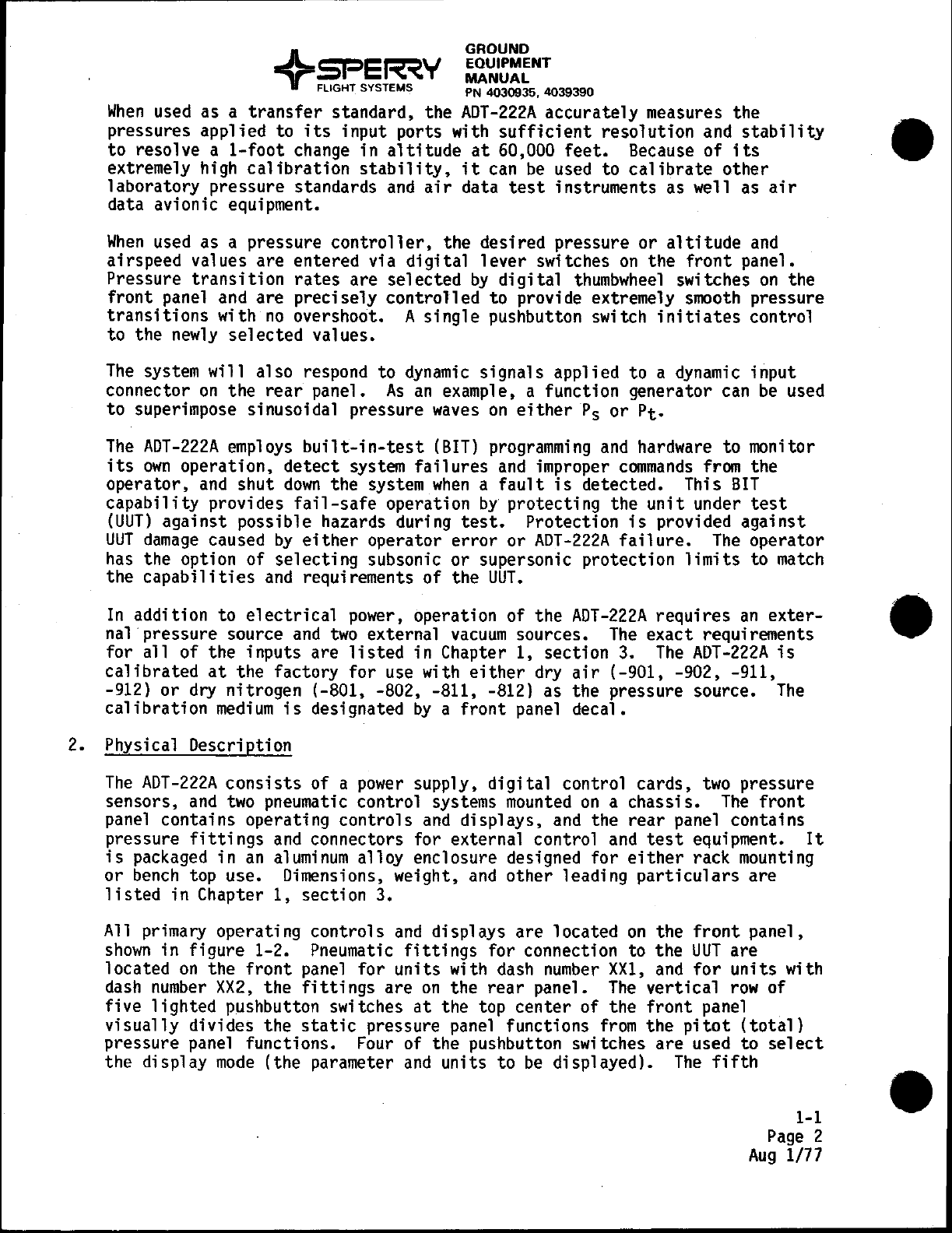

All

primary operating controls

and

displays are located

on

the

front

panel,

shown

in figure 1-2. Pneumatic

fittings

for connection to the

UUT

are

located

on

the

front

panel for

units

with dash

number

XXI,

and

for

units

with

dash

number

XX2,

the

fittings

are

on

the

rear

panel.

The

vertical

row

of

five

lighted

pushbutton switches

at

the top

center

of the

front

panel

visually

divides the

static

pressure panel functions

from

the

pitot

(total)

pressure panel functions.

Four

of the pushbutton switches

are

used to

select

the display

mode

(the parameter

and

units to

be

displayed).

The

fifth

1-1

Page

2

Aug

1/77

I

I

GROUND

EQUIPMENT

MANUAL

PN

4030935. 4039390

]lj

IjIj·lj

Ij·I91II[

0

tIIE,.c COIiIfdND ENTER

-I\l-

wtOLiT

-f\

\.-

~'::.~

J(c[C[~~

~

[D

D

)[C{C(C!

(~~f:~!..c

MT(

~

PRfCISIOfI

1tAT[

un

Co.MJC)

DISA8U

....

DYtrtMIIC

DlSoIoIU

SUBSONIC

ATE

CONtAOL.ASUIlf:

1llEASUM:

~R

IW'UT

~

LIMIT LIMIT

cpDDDDDDDDc::t}

'\

St&ITQI',

"'r

"'r

SttUTOfF

co."...

~

StAne

_

Oft

PlTOT

PIIIfSaIJIE

JUII

PAES!UU

Front

Panel

of

ADT-222A

Figure 1-2

32343

R1

pushbutton switch

is

used

to

select

either

English or metric

units

for

the

commands

and

displays.

The

horizontal

row

of eight lighted pushbuttons

contains the switches for turning the

power

on

and

off,

selecting

the

UUT

protection

limits,

and

controlling

the operational

modes

of the

ADT-222A.

With

the exception of the

RATE

COMMAND

controls,

the

static

pressure

functions,

on

the

left

side,

are identical to the

pitot

pressure functions,

on

the

right

side.

The

RATE

COMMAND

controls

are

ganged

digital

thumbwheel

switches.

The

control

on

the

static

pressure side contains four switches

and

thus controls four

digits;

a

fifth

digit

is

fixed

at

O.

The

control

on

the

pitot

pressure side contains only three switches

and

controls

three

digits.

These

controls

are

used

to specify the

transition

rate

to

be

used

when

changing pressures.

The

COMMAND

controls are

used

to

specify the next pressure

~o

be

supplied

to

the

UUT.

Each

control

is

a

set

of

six

ganged

digital

lever

switches.

Di

rectly

above

each

COMMAND

control

is

the pressure readout

di

spl ay.

Each

display

consists

of two,

three-digit.

gas

discharge tubes

mounted

side

by

side to provide a

six

digit

readout with a decimal point to the

right

of

each

digit.

Each

digit

in the display corresponds to the

digit

switch in the

COMMAND

control

directly

beneath

it.

These

are

situated

this

way

because in

responding to the

COMMAND

control the

ADT-222A

interprets

the placement of

the lighted decimal point of the

command

setting

to

be

in

the

same

digit

location

as

that

indicated

on

the

display.

1-1

Page

3

Jun

15/80

+ GROUND

~E~V

EQUIPMENT

.;;:;11- ..

~

~

T

MANUAL

FLIGHT SYSTEMS PN

4030935.

4039390

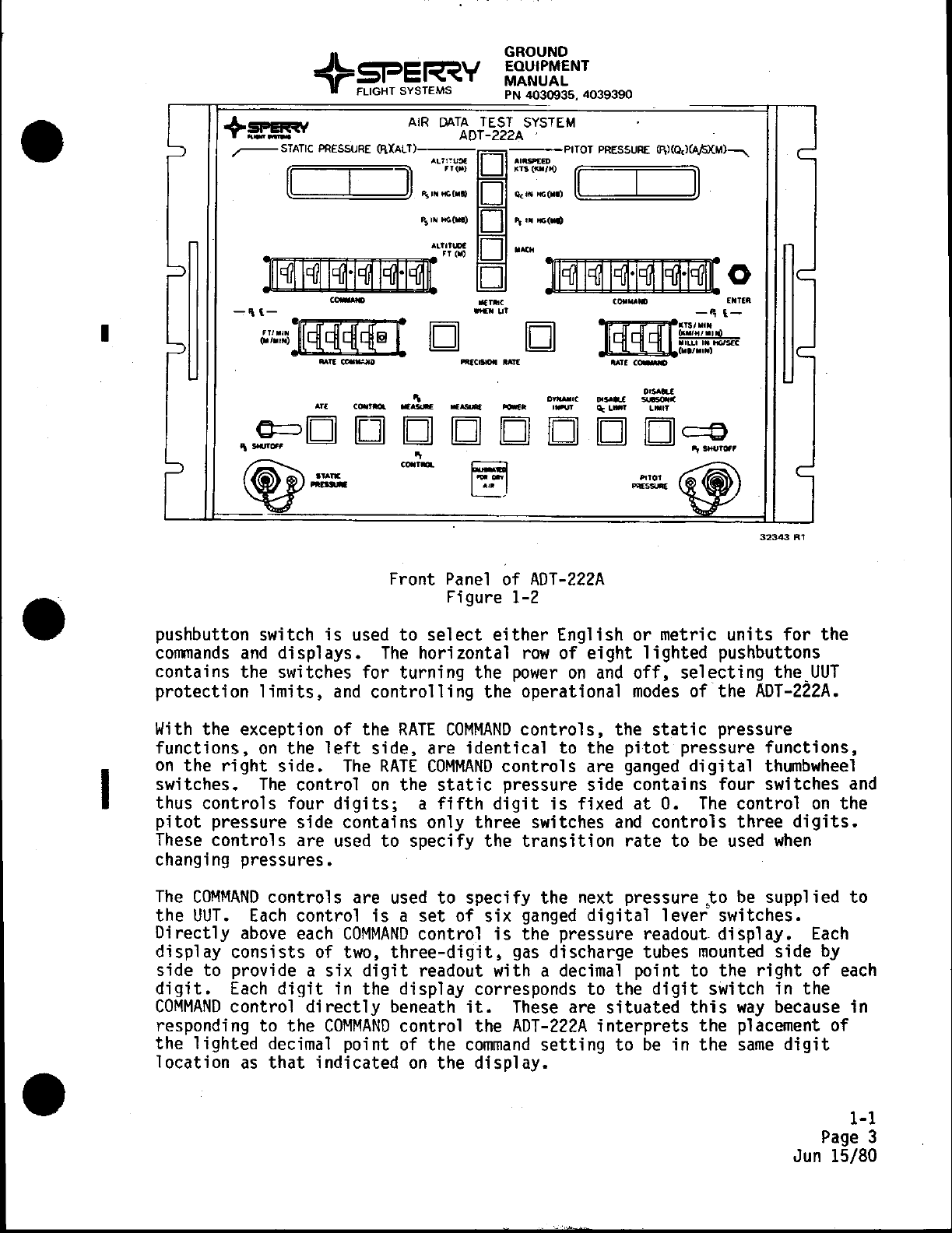

The

PRECISION

RATE

control for

each

side

is

a lighted pushbutton switch

located next to the

RATE

COMMAND

control

and

is

used

to

select

extra-precise

control of the pressure

transitions.

The

pneumatic

fitting

for

each

side

is

located

on

the front

panel

for

-XX1

units

and

on

the rear panel for

-XX2

units,

and

is

used

to pneumatically

connect the

UUT

to the

ADT-222A.

The

type of

fitting

used

is

listed

in

Chapter 1, section 3. A

manual

pneumatic

shutoff valve

is

provided for

each

fitting

for

isolating

the

UUT

from

the internal pressure

system

of the

ADT-222A.

The

manual

shutoff valves for

all

dash

numbers

are located

on

the

front panel.

The

lines

marked

Ps~and

Pt~are

the center

lines

of the sensors.

The

center

line

represents the

altitude

reference point (height)

at

which

all

pressures

are measured.

Fittings

for the pressure supply

and

vacuum

supplies are located

on

the rear

panel,

shown

in

figure 1-3, along with the

power

cord, fuse,

dynamic

input

connector

and

switch,

and

the

ATE

connector.

The

fittings

and

connectors

used

are

listed

in Chapter 1, section

3.

00

o 0

NOTE;

COVER PLATES FOR UNITS WITH

PITOT

AND

STATIC

PRESSURE

CONNECTION

ON

FRONT

PANEL.

.., ®

...

Cl..

...-

.....

Rear

Panel

of

ADT-222A

Figure

1-3

LJ

D ®

®

32316

1-1

Page

4

Aug

1/77

I

GROUND

EQUIPMENT

MANUAL

PN

4030935,4039390

Also

located

on

the

rear

panel

are

two

internal pressure regulator

controls.

The

pressure regulator controls are factory

set

and

should not

be

adjusted.

The

circuit

cards

and

major subassemblies are plug-in interchangeable for

quick

and

easy maintenance.

3.

Functional Description

The

pneumatic

system

of the

ADT-222A,

shown

in figure

1-4,

consists of

two

pneumatic paths, each containing a pneumatic control section

and

a measure-

ment

section.

The

sections are

isolated

from

each

other

and

from

the

UUT

connection

fittings

(P

s

andPt

ports)

by

solenoid operated valves. Extra

UUT

pneumatic

isolation

is

provided

by

manual

valves.

The

measurement

section of

either

path consists of a solenoid valve

at

each

end

of the section, a

30

cubic inch

volume

tank,

and

a pressure sensor.

The

pneumatic control section of

either

path consists of a pressure regulator for

the

inlet

supply pressure, pneumatic

line

and

fitting

for the

vacuum

supply,

and

a pneumatic servo control valve.

Both

paths join

at

the pressure supply

line

and

use

a

common

pneumatic

filter

and

solenoid valve

for

isolation

from

the pressure supply. .

There are

two

basic

modes

of operation: the

measure

mode

and

the control

mode.

In

the measure

mode

all

pressure

and

vacuum

supply

lines

are shut

off

and

the

pneumatic control section

is

shut

off

from

the

measurement

section.

The

measurement

section,

however,

is

open

to

the

test

ports.

Therefore, in the

measure

mode,

valves

Kl

and

K3

are

open

while valves

K2,

K4,

K5,

and

KG

are

closed.

In

the control

mode,

all

of the valves are

open

and

the pressures in both

paths are controlled

by

the respective pneumatic servo control valves,

CVl

and

CV2.

Operation of the

ADT-222A

is

controlled

by

a

system

control section

which

receives

instructions

from

the operator via the front

panel

controls or

from

an

ATE

via the optional

ATE

interface.

It

receives

measurement

data

from

the

sensors, performs the necessary calculations

and

conversions,

and

sends the

pressure values

to

the front

panel

for display.

In

the control

mode,

it

also

compares

the

measured

values

to

the input

commands

and

controls the pressure

control valves to obtain the desired response.

The

system control section also performs

all

BIT

functions

and

causes the

ADT-222A

to

either

shut

down

to

protect the

UUT,

or

just

ignore the input

commands,

whenever

an

equipment

failure

or

an

operator

error

is

detected.

A

more

detailed description of the operation of the

ADT-222A

is

contained in

Chapter

I,

section 2.

1-1

Page

5

Jun

15/80

I

I

GROUND

EQUIPMENT

MANUAL

PN

4030935,4039390

~DT-2ZzA------------------------------'

I X :

.----G)01~-~'Hl6ii'p_r<l

:

.,yac_

......

I

I

I~-«)()>--.L.,

~'!s

-,

.1

I

X :

I

I

I

I

I

»--i,~"

"""

I

I

I

..

I

........

I

I

. I

~--------------------------~---------

PNEUMATIC

DIAGRAM

o

AO..I

REGoULATOQ

@]

PNEUMATIC.

IIOLUME

(~

...

)

® SOLENOID

VALVE

0

~~¥~t':'~~~F

®

MANUAL

So.uTOo:!' @ PNEUMATIC.

O:ILTER

VALVE

Pneumatic

Diagram

Figure 1-4

E4030935-100-S(R2)

1-1

Page

6

Jun 15/80

1.

General

GROUND

EQUIPMENT

MANUAL

PN

4030935,4039390

Section 2. Operating Instructions

--~

This section contains

manual

operating procedures only. Refer to Chapter 5,

section 2 for procedures for automatic operation.

NOTE:

Before operating the

ADT-222A,

the user should

familiarize himself with subsections 7

and

8

of

this

section.

Before operating the

ADT-222A

it

is

helpful for the operator to understand

the general relationships

between

altitude,

airspeed,

and

pressure.

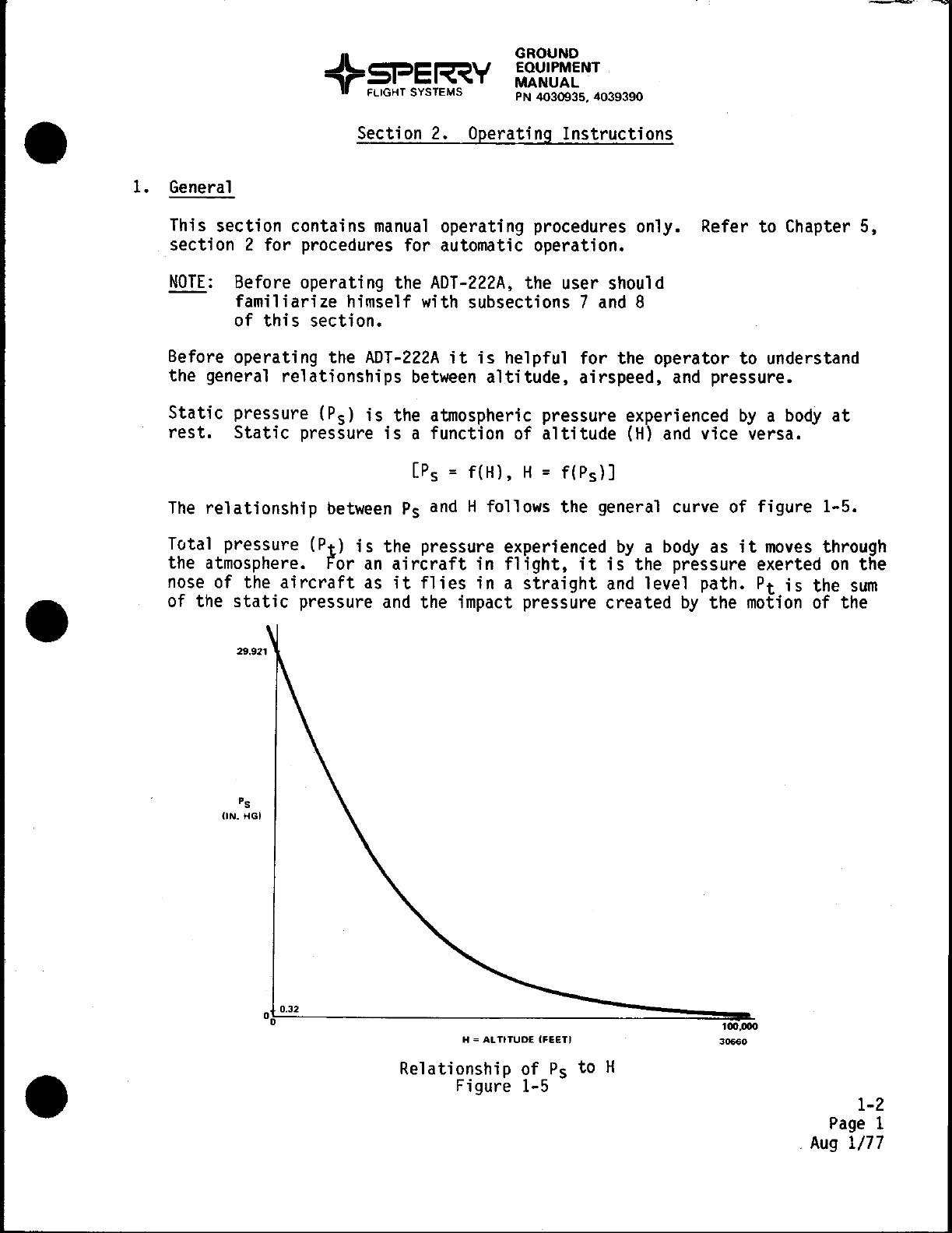

Static

pressure

(P

s)

is

the atmospheric pressure experienced

by

a

body

at

rest.

Static

pressure

is

a function

of

altitude

(H)

and

vice versa.

[P

s =f(H), H=

f(P

s)]

The

relationship

between

Ps

and

H follows the general curve of figure 1-5.

Total pressure

(P

t)

is

the pressure experienced

by

a

body

as

it

moves

through

the atmosphere.

For

an

aircraft

in

flight,

it

is

the pressure exerted

on

the

nose

of the

aircraft

as

it

flies

in a

straight

and

level path. Pt

is

the

sum

of the

static

pressure

and

the impact pressure created

by

the

motion

of the

'.

(IN.

HGI

10

-.3-2-

___

-==:::::::::::~~

o~ 100.000

H = ALTtTUDE (FEETI

Relationship of

Ps

to H

Figure 1-5

30660

1-2

Page

1

.

Aug

1/77

I

+ GROUND

sr=E~V

~':1~~~NT

FLIGHT

SYSTEMS

PN

4030935.

4039390

air.

Airspeed

(Vcl

is

a function of

the

impact pressure

(Qcl

and,

therefore,

a function of

the

relation

of

Pt

to

Ps-

Q

c = f(Vcl,

Vc

= f(Qcl

Pt = Ps +

Qc

Vc

=

f(Pt

-Psl

The

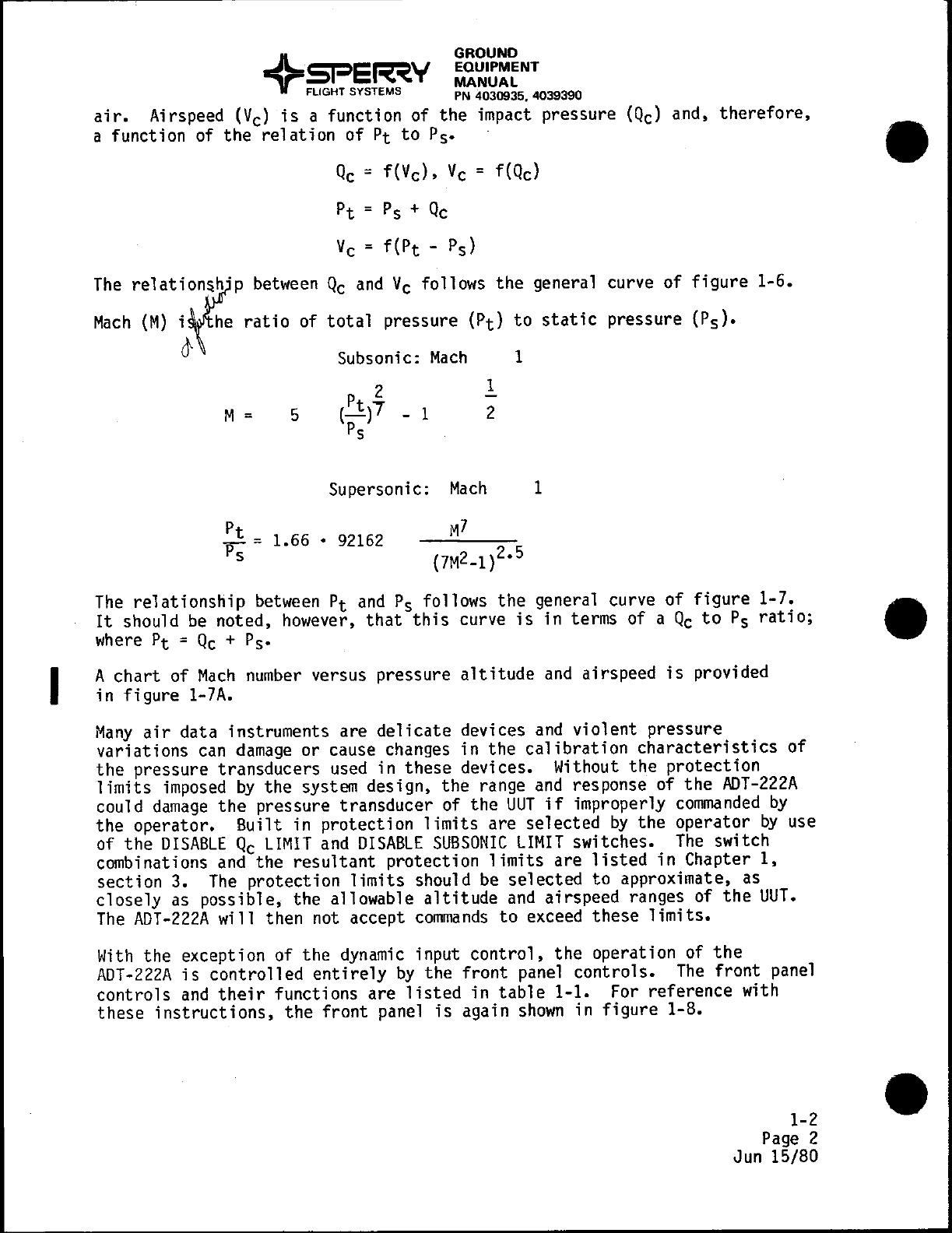

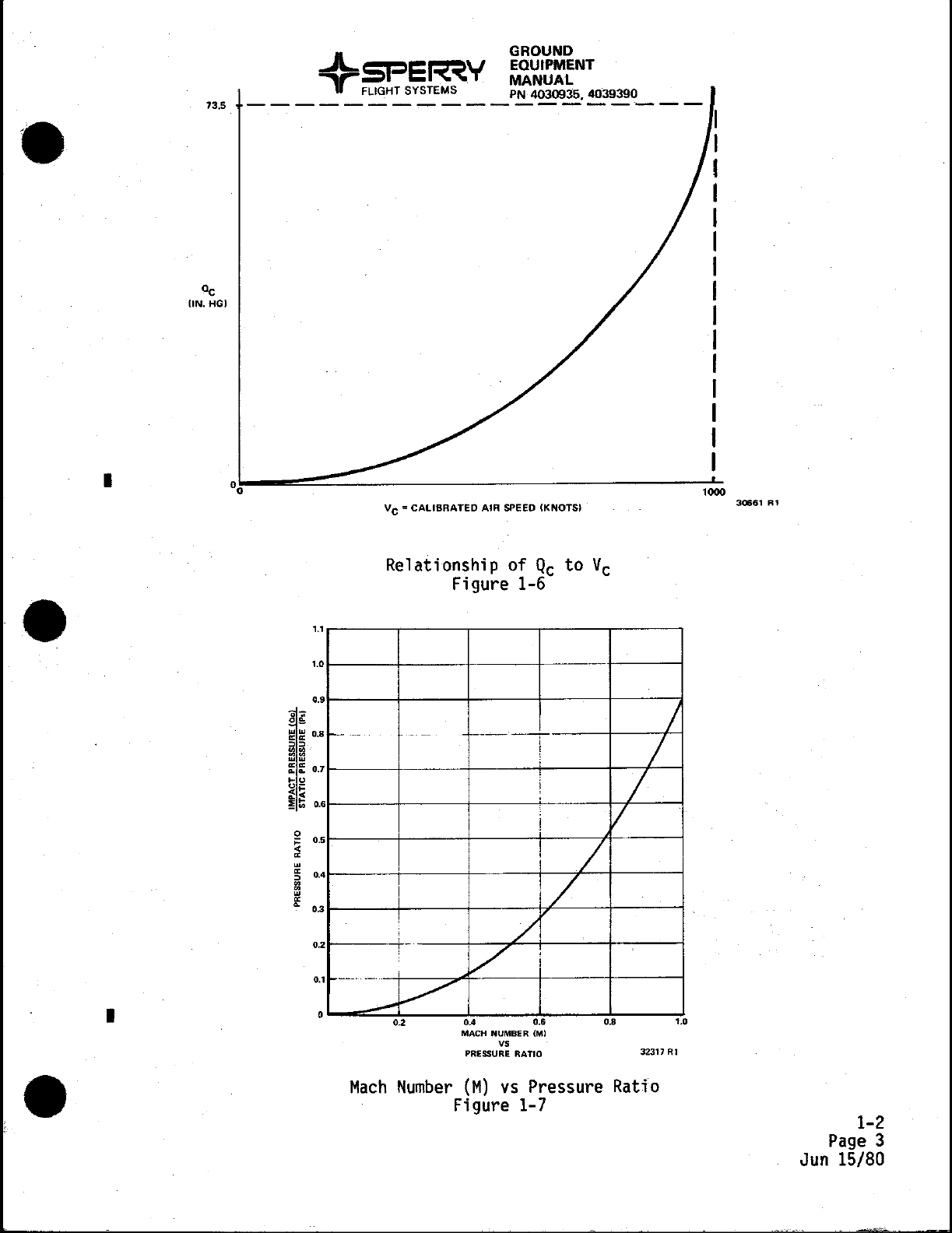

relati~n~p

between

Q

c

and

Vc

follows

the

general curve of

figure

1-6.

Mach

(Ml

~~the

ratio

of

total

pressure

(Ptl

to

static

pressure

(Psl.

Subsonic:

Mach

1

M = 5

1

2

Supersonic:

Mach

1

Pt -1.66 •

92162

p;-

The

relationship

between

Pt

and

Ps follows

the

general curve

of

figure

1-7.

It

should

be

noted, however,

that

this

curve

is

in terms of a

Qc

to

Ps

ratio;

where

Pt

=

Qc

+ Ps•

A

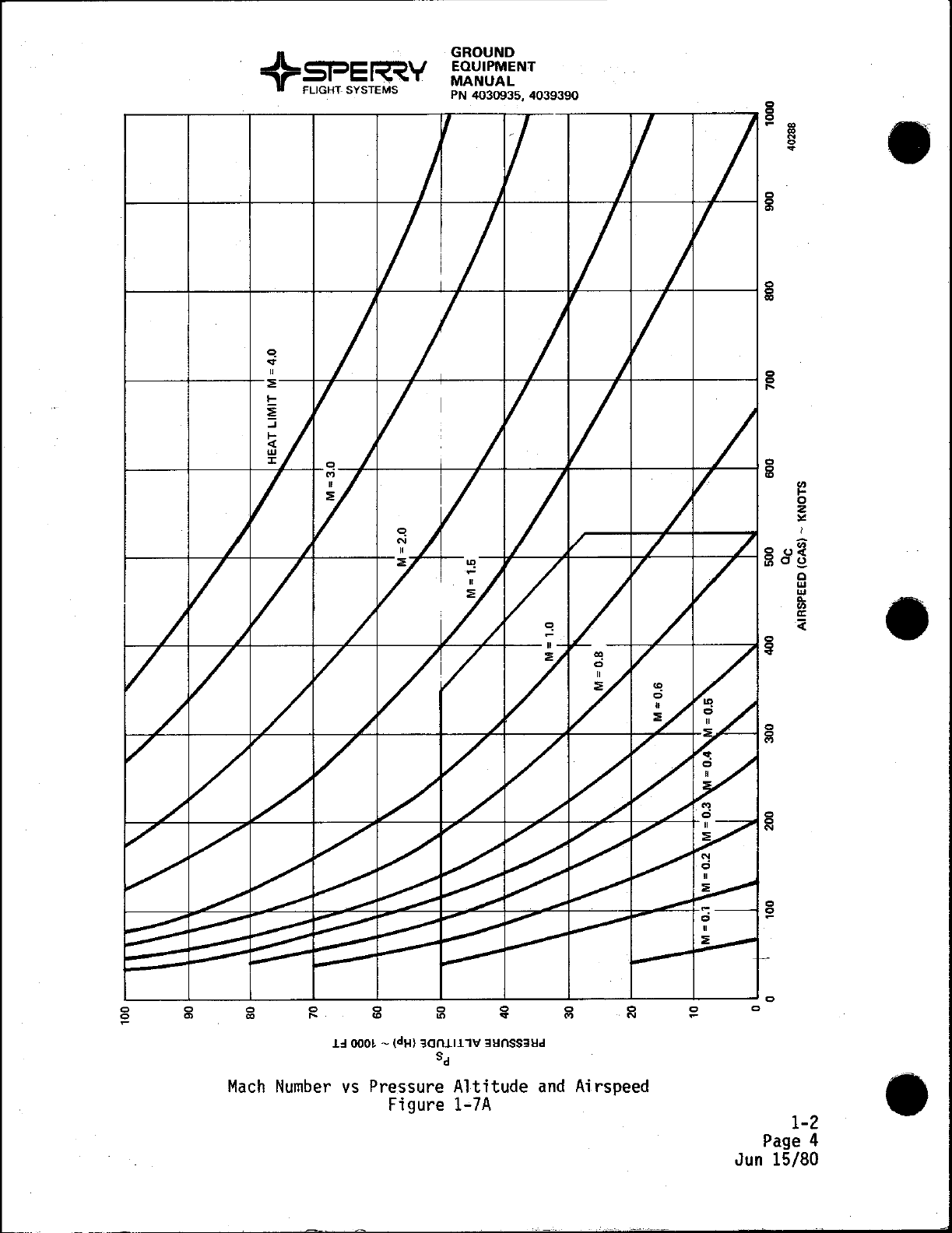

chart

of

Mach

number

versus pressure

altitude

and

airspeed

is

provided

in

figure

1-7A.

Many

air

data instruments are

delicate

devices

and

violent

pressure

variations

can

damage

or cause changes in the

calibration

characteristics

of

the

pressure transducers used in

these

devices. Without

the

protection

limits

imposed

by

the system design, the range

and

response of

the

ADT-222A

could

damage

the

pressure transducer of

the

UUT

if

improperly

commanded

by

the

operator. Built in protection

limits

are

selected

by

the operator

by

use

of

the

DISABLE

Q

c

LIMIT

and

DISABLE

SUBSONIC

LIMIT

switches.

The

switch

combinations

and

the

resultant

protection

limits

are

listed

in

Chapter

I,

section

3.

The

protection

limits

should

be

selected

to

approximate, as

closely

as possible, the allowable

altitude

and

airspeed ranges of

the

UUT.

The

ADT-222A

will then not accept

commands

to

exceed

these

limits.

With

the exception of the

dynamic

input

control,

the

operation of

the

ADT-222A

is

controlled

entirely

by

the

front

panel

controls.

The

front

panel

controls

and

their

functions are

listed

in

table

1-1.

For

reference with

these

instructions,

the

front

panel

is

again

shown

in

figure

1-8.

1-2

Page

2

Jun 15/80

73.5

"c

UN.HGJ

•

•

GROUND

EQUIPMENT

MANUAL

PN4030935.4039390

-------------------

OO~--~~~~::=------------------~l~~~

,.

,

'.0

o.

•

-

.•..

7

•

o

-

o.

~

5

•

< 0,

~

4

f 0.3

0,

2

Vc

= CALIBRATED AIR

SPEED

(KNOTS)

Relationship of Q

c

to

Vc

Figure

1-6

._-

I

_.

----

j

!

!

! /I

I

1/

, A

.-+-

,/'

I

/

/

/

/

1

----"

_.

j...-/'

0,

o 0.2

0.4

0.'

0.8

'.0

MACH NUMBER (M)

V,

PRESSURE

RATIO

32317

R1

Mach

Number

(M)

vs

Pressure Ratio

Figure 1-7

30661

Rl

1-2

Page

3

Jun

15/80

GROUND

EQUIPMENT

MANUAL

PN

4030935, 4039390 8

c

~

.,

.,

N

0

..

c

5l

~----~--~----~----~~---J,f--~----~f----+--~-t-----1~

c c c

S!

'" '"

Mach

--~~~--~--~--~-----b~~--+----J~------~------i~

~

2

"

-

---iI/-------;.4-------f-i!---+--~y

c 0

~

~O~

c c c c

:i!

....

'"

on

..

.L~

OOOL

-(dH)

30n.Ll.L

lit

311nSS311d

Sd

Number

vs

Pressure Altitude

and

Figure

1-7A

o

w

i

;;:

--+-+---b----II~

c

S!

N

Ai

rspeed

-----I

~

c

c

1-2

Page

4

Jun

15/80

"

Table of contents

Other Sperry instrument Test Equipment manuals

Popular Test Equipment manuals by other brands

intrepid

intrepid neoECU AVB/TSN user guide

Baker Hughes

Baker Hughes Druck DPI 620 Genii Safety Instructions and User Guide

Agilent Technologies

Agilent Technologies Agilent 34980A Application note

Jula

Jula Meec Tools 405-056 User instructions

Cascade Microtech

Cascade Microtech IZI Probe Quick reference guide

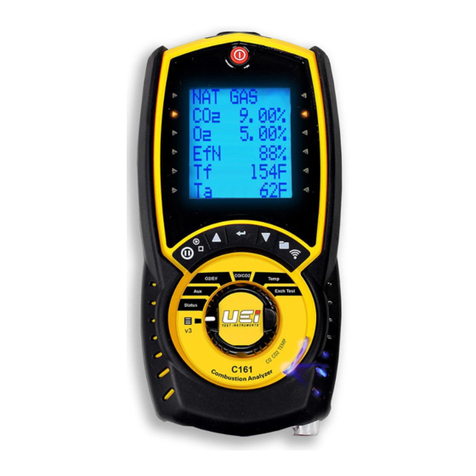

UEi

UEi C161 quick start guide

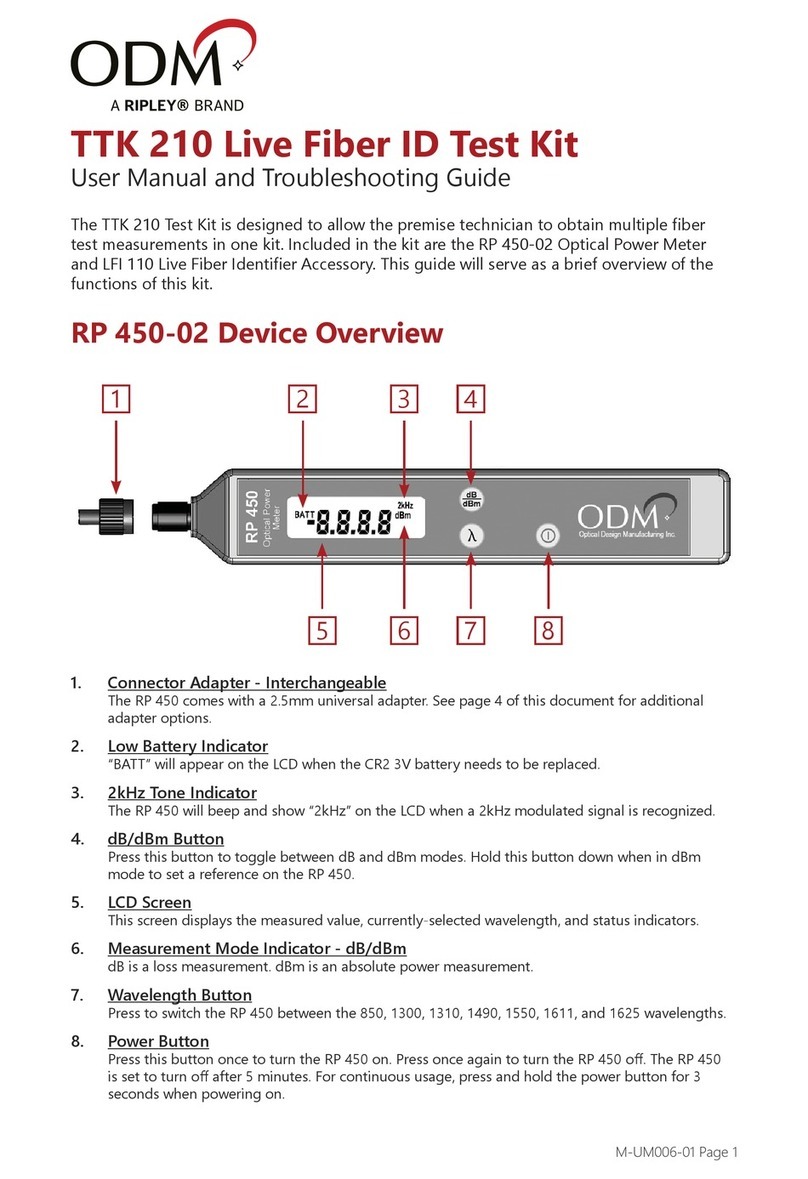

Ripley

Ripley ODM TTK 210 User's manual and troubleshooting guide

Western Digital

Western Digital WD Quick Tester Quick reference guide

Tektronix

Tektronix PM 101 instruction manual

Andatech

Andatech AlcoSense SOBERPOINT 3 user manual

Valhalla Scientific

Valhalla Scientific 2701C CALIBRATION PROCEDURE

Dixon

Dixon Bayco FT450 instructions