High Power 3000 User manual

TEL: (203)-634-3900 FAX: (203)-238-2425

EMAIL: [email protected]

WEB: WWW.HIGHPOWERSECURITY.COM

Dear Customer, if you are having problems using this product, please call Highpower Technical

Support at 800-991-3646. We are here to help and we appreciate your business!

Dear Installer: When using the controller without connection to a fire alarm, place a wire jumper from

terminals #57 and #60 for proper controller operation or use the V+ terminals for power.

MODEL 3000 MULTIFUNCTION DOOR CONTROLLER WITH DELAYED EGRESS

HARDWARE MANUAL

FIRMWARE VERSION 2.1.0

DOCUMENT NUMBER: 980-3000-2.1.0

TABLE OF CONTENTS

CONTROLLER DESCRIPTION.................................................................................................2

KEY FEATURES .......................................................................................................................3

NOTICE OF INSTALLER QUALIFICATION..............................................................................3

ACCESS CONTROL FEATURES .............................................................................................3

CODE TYPES ........................................................................................................................3

SHADOW CARD SYSTEMS ..................................................................................................3

MATRIX AND WIEGAND INTERFACES DESCRIBED..........................................................4

USING THE MATRIX KEYPAD..............................................................................................4

PROGRAMMABLE OUTPUT TIMERS...................................................................................4

REMOTE RELEASE INPUTS.................................................................................................5

DELAYED EGRESS FUNCTIONS ............................................................................................5

DOOR POSITION SWITCH FEATURES................................................................................5

REQUEST TO EXIT OVERRIDE............................................................................................6

FIRE ALARM INTERFACE........................................................................................................6

ADDITIONAL CONTROLLER FEATURES...............................................................................6

VIDEO RECORDER OUTPUT ...............................................................................................6

PANIC SIGNALLING..............................................................................................................6

AUTOMATIC KEY PRESS CLEARING..................................................................................7

WIEGAND LED CONTROL....................................................................................................7

LED INDICATOR OUTPUTS..................................................................................................7

BACKUP BATTERY PASS-THROUGH..................................................................................7

EEPROM MEMORY...............................................................................................................7

SELF-RESETTING DESIGN..................................................................................................7

CODES SPECIFIC TO EACH READER.................................................................................7

HARDWARE CONNECTION.....................................................................................................7

POWER CONNECTION.........................................................................................................7

Page 2 of 30

FIRE ALARM PREPARATION...............................................................................................8

REMOTE RELEASE ..............................................................................................................8

REMOTE RELEASE WIRE CONNECTION DIAGRAM......................................................8

WIEGAND PORTS.................................................................................................................9

WEIGAND PORT WIRE CONNECTION DIAGRAM...........................................................9

TESTED BRANDS OF WIEGAND DEVICES.......................................................................10

PROXIMITY READERS....................................................................................................10

BAR CODE READERS.....................................................................................................10

MAG-STRIPE READERS.................................................................................................10

DELAYED EGRESS PORT..................................................................................................10

DELAYED EGRESS PORT WIRE CONNECTION DIAGRAM.........................................11

LED INDICATOR OUTPUTS................................................................................................12

LED INDICATOR OUTPUTS WIRE CONNECTION DIAGRAM.......................................12

EXTERNAL MATRIX KEYPAD PORT .................................................................................13

MATRIX KEYPAD WIRE CONNECTION DIAGRAM........................................................13

RELAY OUTPUTS 1 AND 2.................................................................................................14

RELAY OUTPUT 1 WIRE CONNECTION DIAGRAM EXAMPLE ....................................15

RELAY OUTPUT 2 WIRE CONNECTION DIAGRAM EXAMPLE ....................................16

CONNECTING A PROXIMITY DETECTOR TO A RELAY OUTPUT ...............................17

TRANSISTOR OUTPUTS 3 AND 4......................................................................................18

TRANSISTOR OUTPUTS 3 AND 4 WIRE CONNECTION DIAGRAM EXAMPLE...........18

FIRE ALARM INTERFACE...................................................................................................18

FIRE ALARM INTERFACE WIRE CONNECTION WITH AUTOMATIC RESET...............20

BATTERY PASS-THROUGH...............................................................................................21

LED INDICATOR FUNCTIONS...............................................................................................21

APPLICATIONS......................................................................................................................22

SAFELY WIRING THE CONTROLLER WITH AN ELECTROMAGNETIC LOCK AND A

PNUEMATIC PUSHBUTTON...............................................................................................22

SAFELY WIRING THE CONTROLLER WITH AN ELECTROMAGNETIC LOCK,

PNUEMATIC PUSHBUTTON AND PIR SENSOR...............................................................23

USING TOGGLE CODES TO LEAVE A DOOR UNLOCKED..............................................24

WIRING DIAGRAM USING TOGGLING OUTPUTS TO LATCH A DOOR IN PASSAGE 24

USING A TRANSISTOR OUTPUT TO CONTROL AN ELECTROMAGNETIC LOCK.........25

TRANSISTOR OUTPUTS WITH FAIL-SAFE DEVICES WIRING DIAGRAM...................25

CONTROLLING FOUR DOORS WITH THE MODEL 3000 .................................................26

MAN-TRAPS (FOR CLEAN ROOMS)..................................................................................26

THIRD-PARTY ADD-ON PERIPHERALS...............................................................................27

CUSTOM WIRING DIAGRAMS AND UNIQUE APPLICATIONS ...........................................28

WARRANTY INFORMATION..................................................................................................28

TROUBLESHOOTING ISSUES ..............................................................................................29

TYPICAL SYSTEM RISER DIAGRAM....................................................................................30

CONTROLLER DESCRIPTION

The Highpower Multifunction Door Controller is a control circuit used to provide delayed egress

for one door and access control functions for two doors. The controller is designed to store access

codes by interfacing with keypads, card readers and biometrics, and can control electromagnetic locks

and electric strikes. Additionally, the controller can be used to interface locks with a fire alarm, can turn

on video recorders during door activity and can provide alarms for unsecured door conditions. This

document will describe the features of this controller for simplified installation and setup.

Page 3 of 30

KEY FEATURES

•Delayed Egress Controller with BOCA and NFPA 101 compatibility modes. Controller provides

both an audible and visual LED response on one door.

•Integrated Access Control with both 26-Bit Wiegand Input and 7-Wire Matrix Keypad Input. Unit

can store 510 users in non-volatile EEPROM memory. Access control module is designed to

work with two doors.

•Wiegand interface has automatic transmission speed adjustment for compatibility with 26-bit

Wiegand readers from many different manufacturers.

•Wiegand port supports multiple Wiegand devices connected simultaneously.

•Integrated Fire Alarm Relay for interfacing the controller to a fire alarm system.

•Four main outputs controlled by five timers. Two outputs are 15 Amp relay outputs and two are

10 Amp FET Transistor outputs.

•Outputs are fused and have surge suppression circuitry.

•Door Monitoring on one door with LED response including Anti-Tailgating and Forced Door

Alarm.

•Active Camera output for turning on video cameras and recorders during door events.

•Fully stand-alone programmable through integrated keypad and led indicators.

NOTICE OF INSTALLER QUALIFICATION

The items listed in this manual may require the services of an individual who is trained in the

application and installation of life safety equipment. All wiring must be in compliance with current NEC

guidelines.

ACCESS CONTROL FEATURES

CODE TYPES

The access control portion of the controller has a memory that is able to hold 510 codes. You may

program codes in memory that can be of six types. Code types include master codes, user codes, one-

time-use codes, “programming add” codes and “programming remove” codes.

Master codes are codes that allow access to programming features. These codes should only be

given to system administrators. They allow an administrator to enter programming mode.

User codes are codes that activate outputs, but do not allow access to programming features.

These codes are given to users for entry.

“One-Time-Use” codes are often called “Service Codes”. These are codes that only allow access

one time. These codes can be given to maintenance people or real-estate salespeople to provide one-

time entry into a door. Since any code can be a one-time-use code, you can have up to 510 one-time-

use codes in memory. You may make a particular one-time-use code work for more than one time. By

adding the code to memory multiple times, the code will work for as many times as it was programmed.

SHADOW CARD SYSTEMS

A new feature added to the controller (with Firmware Version 2.0.0) is support for a “Shadow Card

Systems”. Shadow Card Systems are systems that are designed to simplify the management of user

codes.

In a basic shadow card system, there are two identically coded cards for every user. One of the

cards is issued to the user. The second card is kept with administration. In addition to the sets of user

Page 4 of 30

cards, there are two special cards. These cards are the “Programming Add” and “Programming

Remove” cards.

When Programming Add card is swiped, the controller enters a special programming mode. All

cards swiped after the Programming Add card, are stored in memory as a user card. The Programming

Add card is then swiped at the end of adding all of the user cards, exiting the add mode. All cards

swiped at a particular reader will only work on that reader. If the card is already in memory, the

controller will not allow the addition of the card a second time.

Programming Remove cards allow administration to delete a user code, when a user must be

removed from the system. By swiping the Programming Remove card at a particular reader, the

controller enters another programming mode. Every card swiped after the Programming Remove card

is removed from memory. The second user card that was kept with administration for a particular user

is used in the case where a user card has not been returned or is damaged. This programming mode

deletes all instances of the swiped code in memory for a particular reader. When all the desired codes

have been removed, the same Programming Remove card is again swiped in order to return back to

normal operation. These operations can be performed with no keystrokes on the keypad and is fast

and simple for maintaining a few user codes.

MATRIX AND WIEGAND INTERFACES DESCRIBED

There are two interfaces that can be used to send codes to the controller. The controller has

both a matrix keypad interface and two 26-Bit Wiegand interfaces. The matrix keypad interface allows

the installer to connect a standard matrix keypad to the controller. The matrix keypad can be used for

both access and programming. Multiple matrix keypads can be connected to the matrix keypad port for

this purpose.

In addition to the matrix keypad input, the controller has two Wiegand interfaces can be used to

connect the controller to any standard 26-bit Wiegand device. Since the Wiegand device only sends ID

numbers back to the controller, the matrix keypad must be used for most programming sequences. For

convenience, there is a matrix keypad mounted on the controller’s board, so that users who use just the

Wiegand ports can readily program the unit.

This controller does not use the site code portion of the 26-bit Wiegand data. The controller is

designed to store the lower 16-bits of the data values in order to store codes. Despite this, the

Highpower Wiegand Interface provides full Data Parity Checking over the entire 26-bits to ensure code

integrity. In addition, the Wiegand interface is fully signal de-bounced, in order to filter noisy Wiegand

data, and has automatic detection of data transmission rate, so that 26-bit Wiegand devices from many

brands should work properly. The interface will timeout and recover in the case where the Wiegand

data transmission is incomplete or corrupted.

USING THE MATRIX KEYPAD

The matrix keypad can be used to both program the controller, and send user codes to the

controller. User codes that have been stored in memory as “Reader 1” codes can be activated using

the matrix keypad. For example, if you program the controller to unlock on Port 1 with the code “1234”,

code “1234” will work when the code is entered on the Wiegand Reader 1 or the matrix keypad.

PROGRAMMABLE OUTPUT TIMERS

The controller has 4 programmable outputs. Two of these outputs are 15 Amp relays and the

other two are 10 Amp FET (transistor) outputs. These outputs control up to a 35V control voltage.

Access codes are individually programmed to actuate output timers. There are five output

timers in the controller. The first two output timers activate output 1 (relay) and the additional three

timers are assigned to Outputs 2 through Outputs 4.

Page 5 of 30

When a code is entered, the controller looks up which output timer(s) the code is programmed to

actuate. The duration of each of these timers is programmable. Since each output has a timer

associated to it, the output stays unlocked for the programmed time when actuated. If the timers are

programmed to open for “zero” seconds, the output will toggle instead of time.

Since Relay 1 has two output timers associated with it, you can have two different unlock delays

for Door 1. This feature is commonly used to provide handicapped access. The second timer can be

set for a longer duration, so that Door 1 is left unlocked for a longer time when a handicapped user is

trying to enter.

REMOTE RELEASE INPUTS

In addition to using codes to activate timers, two “remote release” inputs on the controller can be

used. The remote release inputs will activate Timer 1 and Timer 2 with an external signal. This signal

can be a pushbutton or other type of switch that is used to unlock a door from a remote location. Do

not rely on these inputs as a sole form of egress. For most systems, it is required to have (2)

forms of egress, one using the controller, and a second, such as a pneumatic push button

switch, that directly cuts the power to an electromagnetic lock. This port is useful when using

electronic devices for egress like a proximity sensor or remote pushbutton.

DELAYED EGRESS FUNCTIONS

The controller is designed to provide delayed egress functions on Door 1 in addition to access

control functions. The “delayed egress cycle” is a timed unlock of Door 1 that is triggered by a

“Request to Exit” input. This feature is used to allow users to exit out of a locked door after waiting for a

15 or 30 second unlock countdown. There are two standards for this type of operation. These

standards are described in BOCA and NFPA 101 documentation.

In NFPA mode, the controller starts counting down after the Request to Exit input is actuated.

There is a 2 second nuisance delay on the Request to Exit input that prevents false alarms. After a

user holds down the request to exit device for more than two seconds, the delayed egress countdown

begins. The countdown duration is programmable between 15 and 30 seconds. For the next 15 or 30

seconds, the controller “beeps” an audible output and interchanges the led colors between green and

red. At the end of the countdown period, Output 1 unlocks, allowing the user to egress. Once the door

is unlocked, the audible alarm stays on continuously and the Red LED is lit. The unit stays in this state

until a manual reset procedure occurs. An administrator must (1) open the door for more than one

second, (2) close the door and actuate a “manual reset” switch. This switch is usually a key-switch.

After doing the reset, the alarm is halted and the controller returns to run mode.

In BOCA mode, a similar countdown occurs but the reset procedure is different. At the end of

the unlock cycle, a second relock cycle takes place. The relock cycle occurs once the door has been

opened and then re-closed. This relock cycle relocks the door automatically. If the door is re-opened

during this 30 second relock cycle, the relock cycle starts over again. This ensures that there is always

a 30 second window between user passages.

DOOR POSITION SWITCH FEATURES

Because both of the delayed egress modes rely on the opening and closing of the door, a Door

Position Switch (DPS) must be used. Typically, this is a magnetic reed switch that is part of an

electromagnetic lock, or a latch sensor in an electric strike. There is an input in the Delayed Egress

Terminal Block that provides a connection for this switch.

When using a DPS, the controller provides additional features. These features include an anti-

tail-gating feature and a forced door alarm feature on Door #1. The anti-tail-gating feature will relock

Page 6 of 30

Output 1 immediately after a door closure. This prevents another user from “tail-gating”; tail-gating is

passing through the door immediately after another user has entered their code, effectively allowing two

people to pass using the first user’s code.

The Forced Door Alarm is triggered when the locking mechanism of a door is defeated. In this

case, the door is supposed to be locked, but the door position sensor is open. When this occurs, the

audible alarm turns on in order to alert a guard or administrator. The video recorder output is also

activated.

REQUEST TO EXIT OVERRIDE

The delayed egress key switch is used to reset the controller when the controller is in NFPA 101

mode. After counting down, the door unlocks and the controller waits until an administrator performs a

reset using the key switch. Normally, this key switch is a momentary type switch. If you use a two-

position maintained type key switch, instead of the momentary type, the key switch can be used to

override the delay egress countdown. When the countdown is overridden, the request to exit switch will

act as a remote release switch, instead of triggering the delayed egress cycle. This allows an

administrator to use the request to exit device to act as a remote release during special occasions. In

doing this the remote release device will allow immediate passage through door 1. Turning the key

switch back to the run position will cause the controller to perform the delayed egress countdown.

FIRE ALARM INTERFACE

The controller has a relay circuit that is used to interface with a fire alarm system. This relay is

a latching relay circuit that can immediately cut the power to a connected electromagnetic door lock. In

addition to cutting power to a lock, there are relay outputs that can be used for monitoring the status of

the fire alarm.

This fire alarm relay circuit (FAR) can be configured for both manual and automatic reset. In the

manual configuration, the unit will not re-energize an electromagnetic lock unless an external manual

reset is actuated. This manual reset is typically a key-switch. In the automatic configuration, the power

is restored to the locks when the fire alarm is reset. Whenever the fire alarm circuit is used, check

with the Authority Having Jurisdiction for approval of the proposed system connections.

When using the controller without connection to a fire alarm, place a wire jumper from terminals

#57 and #60 for proper controller operation.

ADDITIONAL CONTROLLER FEATURES

VIDEO RECORDER OUTPUT

There is an output on the controller that is specifically designed to trigger an event on a video

recorder. This output is activated when (1) a push on a key on a matrix keypad occurs, (2) a code is

sent to the controller over one of the Wiegand ports, or (3) the Door Position Switch is open due to an

alarm. This output is programmed to stay on for 8 seconds after the event ends. If another event that

occurs during the timing cycle, the second event will cause the cycle to restart.

PANIC SIGNALLING

The controller has a special mode that can be used for panic emergencies or external signaling.

If the matrix keypad is installed as an access device, a user can press both “*” and “#” on the keypad to

activate panic mode. Panic mode will activate programmed output timers. The programmed outputs

can be used to signal a guard or administrator that there is a panic situation. The outputs that the panic

mode activates can be programmed.

Page 7 of 30

AUTOMATIC KEY PRESS CLEARING

The controller will dump any key presses that are entered on the matrix keypad if the code is not

completed in 8 seconds. This feature is disabled when the controller is in programming mode.

WIEGAND LED CONTROL

The Wiegand LED control lines reflect the conditions of Relay 1 and Relay 2. If Relay 1 is

triggered, the LED Control Line on Wiegand Port 1 changes the state of the LED on the Wiegand

Device that is connected to Port 1. If Relay 2 is triggered, the LED Control Line on Wiegand Port 2

changes the state of the LED on the Wiegand Device that is connected to Port 2.

LED INDICATOR OUTPUTS

The controller has outputs for driving external LED indicators. There is an output for the Red,

Amber and Green status LEDs. These outputs allow for external monitoring of the controller status and

provide indications during the Delayed Egress Modes.

BACKUP BATTERY PASS-THROUGH

The controller provides wires that pass the voltage of a back up battery through to an external

power supply.

EEPROM MEMORY

The EEPROM memory on the controller stores all 510 codes and features settings. This data is

retained no matter if there is power to the controller or not. This memory has been tested to perform

over 1,000,000 write cycles, and can provide an infinite number of read cycles. The unit should retain

data for over 90 years without external power. The controller performs internal operations that self-

tests the EEPROM memory, and fully verifies all of the codes that are added to the memory.

SELF-RESETTING DESIGN

The processor of this controller is designed to reset itself if circuit faults should occur.

CODES SPECIFIC TO EACH READER

When a user code is added to the controller, the controller stores which port the code is to be

used on. User codes can be programmed to work on either Reader 1 or Reader 2. In doing this, codes

for a two-door system remain independent to each of the doors.

HARDWARE CONNECTION

POWER CONNECTION

The supply power connections are made at terminals 61 and 60.

The maximum supply voltage is 35 VDC.

TERMINAL # NAME FUNCTION

62 (+V) DC Supply Voltage 35 VDC Maximum

61 GND DC Supply Ground

Page 8 of 30

FIRE ALARM PREPARATION

If the Model 3000 is not being connected to an external fire alarm system, then you must place

a jumper from terminal 60 to terminal 57. If you do not do this, the fire alarm system will not

provide power to the lock outputs (VF). If you are using a fire alarm, be sure to connect the fire

alarm system in the manner described in the Fire Alarm Connection sections.

REMOTE RELEASE

The Remote Release Terminals provide a connection for external switches that are used to

trigger Timer 1 or Timer 2. By activating these timers, the external switches can be used for

the remote release of Door 1 or Door 2.

TERMINAL # NAME FUNCTION

1 Remote Release 1 Opening the Loop from this terminal to ground triggers Timer 1

2 GND DC Supply Ground

3 Remote Release 2 Opening the Loop from this terminal to ground triggers Timer 2

REMOTE RELEASE WIRE CONNECTION DIAGRAM

1 2 3

R

1 R

2

G

N

D

NORMALLY CLOSED

REMOTE RELEASE SWITCH

DOOR 1

NORMALLY CLOSED

REMOTE RELEASE SWITCH

DOOR 2

Remote Release

Terminal Block

TRM0:

NOTE: When using the Remote Release feature, make sure to enable the remote release by setting

the corresponding Remote Release Jumper (JP3 or JP4).

Page 9 of 30

WIEGAND PORTS

The controller has two 26-Bit Wiegand Ports for connection of two Wiegand Devices. Terminals 4

through 9 construct Wiegand Port 1. Terminals 10 through 15 construct Wiegand Port 2.

TERMINAL # NAME FUNCTION

Port 1:

4 (+V) DC Supply Voltage 35 VDC Maximum

5 (+5V) (+5) VDC Regulated

6 GND DC Supply Ground

7 PORT 1:D0 Port 1 Wiegand Data 0 Input

8 PORT 1:D1 Port 1 Wiegand Data 1 Input

9 PORT 1 LED CTRLPort 1 LED Control Line Output

Port 2:

10 (+V) DC Supply Voltage 35 VDC Maximum

11 (+5V) (+5) VDC Regulated

12 GND DC Supply Ground

13 PORT 2:D0 Port 2 Wiegand Data 0 Input

14 PORT 2:D1 Port 2 Wiegand Data 1 Input

15 PORT 2 LED CTRLPort 2 LED Control Line Output

Led Control Lines change the state of the LED on the Wiegand Device. The LED on the first Wiegand

Port indicates the state of Relay Output 1. The LED on the second Wiegand Port indicates the state of

Relay Output 2.

WEIGAND PORT WIRE CONNECTION DIAGRAM

4 5 6

V

+

G

N

D

5

V

Wiegand Port 1

Terminal Bloc

k

TRM1:

7 8

D

0

D

1

9

L

E

D

READER

SUPPLY

POWER

R

E

D

B

L

A

C

K

G

R

E

E

N

W

H

I

T

E

B

R

O

W

N

Page 10 of 30

TESTED BRANDS OF WIEGAND DEVICES

Highpower strives to make the Model 3000 as compatible as possible with Wiegand devices from many

manufacturers. In accordance with this goal, we have created our Wiegand interface to automatically

detect the transmission speed of any Wiegand device connected.

As a result, we are compiling a list of Wiegand devices that have been tested with the Model 3000.

These devices include the following:

PROXIMITY READERS

All 26-Bit Wiegand “Revision D” model readers from AWID (Applied Wireless ID, Inc.)

Note: This brand is highly recommended for use with the Model 3000.

26-Bit Wiegand “Pyramid” Reader Heads from Keri Systems. (Models 300H, 500H).

Note: These are good readers to use if you require HID Card compatibility.

BAR CODE READERS

All 26-bit Wiegand models from IBC (International Bar Code, Inc.)

Note: Use the “Smart” models of IBC products when using extended bar codes.

MAG-STRIPE READERS

All 26-Bit Wiegand models from IBC (International Bar Code, Inc.)

Note: Use the “Smart” models of IBC products when using custom track configurations.

Note to Installers: If you have successfully used another brand of reader with our controller or are

having problems with a particular model of reader, we want to hear from you! Your comments are

appreciated. Please call us direct at 800-991-3646.

Note to Hardware Manufacturers: If you would like us to test your access control product with this

controller, please contact Highpower directly. We would be pleased to add your qualified product to our

list.

DELAYED EGRESS PORT

The Delayed Egress Terminal Block has inputs for the Request to Exit, Door Position Switch, External

Reset key-switch and an Output for the Audible Alarm (Sonalert).

TERMINAL # NAME FUNCTION

16 GND DC Supply Ground

17 REX Request to Exit Loop Input

18 GND DC Supply Ground

19 DPS Door Position Switch Input

20 GND DC Supply Ground

21 RST External Key-Switch Reset Input

22 SON Audible Signal Output (100 mA MAX)

23 GND DC Supply Ground

Page 11 of 30

DELAYED EGRESS PORT WIRE CONNECTION DIAGRAM

16 17 18

REX DPS

Delayed Egress Port

Terminal Block

TRM3:

19 20

RST

21 22

SON

23

NORMALLY CLOSED

REQUEST TO EXIT SWITCH

NORMALLY OPEN

(HELD CLOSED)

DOOR POSITION

MAGNETIC SWITCH

NORMALLY

OPEN

RESET KEY-

SWITCH

AUDIBLE

ALARM

(SONALERT)

+ -

Page 12 of 30

LED INDICATOR OUTPUTS

The LED Indicator outputs are used to monitor the status of the controller externally. These signals are

usually sent to indicators that are mounted externally with the matrix keypad. There is an output in this

terminal block group called “ACT” (active) that is used to trigger a video recorder during events. These

outputs can also be used to power small relays (< 100 mA).

TERMINAL # NAME FUNCTION

24 5V (+5) Volt regulated voltage for external LED power.

25 GREEN Green Status LED Transistor Output

26 AMBER Amber Status LED Transistor Output

27 RED Red Status LED Transistor Output

28 ACT Event Active Output used to trigger a video recorder

29 GND DC Supply Ground

LED INDICATOR OUTPUTS WIRE CONNECTION DIAGRAM

TO VIDEO

RECORDER

TRIGGER

INPUT

G

24 25 26

5

V

A

M

B

E

R

LED Indicator Outputs

Terminal Block

TRM4:

27 28

A

C

T

I

V

E

29

G

R

E

E

N

R

E

D

G

N

D

GREEN

LED

RED LED

AMBER

LED

+ -

+ -

+ -

A

R

Page 13 of 30

EXTERNAL MATRIX KEYPAD PORT

An external matrix keypad can be connected to the controller. This keypad can both be used as an

access device or a programming interface. Using the matrix keypad externally also allows for Panic

Signaling.

TERMINAL # NAME FUNCTION

30 C1 Matrix Keypad Column 1

31 C2 Matrix Keypad Column 2

32 C3 Matrix Keypad Column 3

33 R1 Matrix Keypad Row 1

34 R2 Matrix Keypad Row 2

35 R3 Matrix Keypad Row 3

36 R4 Matrix Keypad Row 4

37 SH Keypad Shield Grounding

MATRIX KEYPAD WIRE CONNECTION DIAGRAM

30 31 32

C

1 C

3

Matrix Keypad

Terminal Block

TRM5:

33 34

R

2

35

C

2 R

1 R

3

37

S

H

R

4

36

1 2 3

4 5 6

7 8 9

* 0 #

Page 14 of 30

RELAY OUTPUTS 1 AND 2

The relay outputs have a common configuration. These outputs are used mainly to run an

electromagnetic lock or electric strike. The maximum current that can be switched by these outputs is

15 Amps.

TERMINAL # NAME FUNCTION

Output 1:

38 VF Supply Voltage from Fire Alarm Relay

39 NC Normally Closed relay contact

40 C Common relay contact

41 NO Normally Open relay contact

42 (+V) DC Supply Voltage 35 VDC Maximum

43 GND DC Supply Ground

Output 2:

44 VF Supply Voltage from Fire Alarm Relay

45 NC Normally Closed relay contact

46 C Common relay contact

47 NO Normally Open relay contact

48 (+V) DC Supply Voltage 35 VDC Maximum

49 GND DC Supply Ground

See connection diagram on next page.

Page 15 of 30

RELAY OUTPUT 1 WIRE CONNECTION DIAGRAM EXAMPLE

V

F

CV

+

N

CN

O

G

N

D

V+ GND

JP7

Relay Output

1

Common

J

JP7:

Note: This jumper is used to connect the common of Relay 1 to either

Ground, V+ or neither.

Thunderbolt Electromagnetic

V+ (1)

GND (2)

Electric Door

+

GND

1N4005

DIODE*

38 39 40

Relay Output

1

Terminal Block

TRM6:

41 42 43

1N4005

DIODE*

* Diode may be required

certain lock models to

surge

Page 16 of 30

RELAY OUTPUT 2 WIRE CONNECTION DIAGRAM EXAMPLE

V

F C V

+

N

C N

O

G

N

D

V+ GND

JP8

Relay Output 2

Common Jumper

JP8:

Note: This jumper is used to connect the common of Relay 2 to either

Ground, V+ or neither.

Thunderbolt Electromagnetic Lock

V+ (1) GND (2)

Electric Door Strike

+

GND

1N4005

DIODE*

44 45 46

Relay Output 2

Terminal Block

TRM7:

47 48 49

1N4005

DIODE*

* Diode may be required on

certain lock models to provide

surge suppression.

Page 17 of 30

CONNECTING A PROXIMITY DETECTOR TO A RELAY OUTPUT

38 39 40

V

F C

Relay Output 1

Terminal Block

TRM6:

41 42

V

+

43

N

C N

O

G

N

D

V+ GND

JP7

Relay Output 1

Common Jumper

JP7:

Note: This jumper is used to connect the common of Relay 1 to either

Ground, V+ or neither. Remove the jumper for this configuration.

Thunderbolt Electromagnetic Lock

V+ (1) GND (2)

NC

C

(V+)

GND

PIR Presence Sensor

1N4005

DIODE* * Diode may be required on

certain lock models to provide

surge suppression.

Page 18 of 30

TRANSISTOR OUTPUTS 3 AND 4

The transistor outputs have a common configuration. These are auxiliary outputs that can run external

indicators, counters or extra access control devices. The maximum current that can be switched by

these outputs is 5 Amps.

TERMINAL # NAME FUNCTION

50 VF Supply Voltage from Fire Alarm Relay

51 3 Transistor Output 3

52 4 Transistor Output 4

53 (+V) DC Supply Voltage 35 VDC Maximum

TRANSISTOR OUTPUTS 3 AND 4 WIRE CONNECTION DIAGRAM EXAMPLE

50 51 52

V

F 4

Transistor Outputs

3 + 4 Terminal Block

TRM8:

53

3 V

+

Electric Door Strike

+

GND

* Lock models without surge suppression require a diode to

suppress voltage kickback.

1N4005

DIODE*

FIRE ALARM INTERFACE

The fire alarm interface is a latching relay that is used to connect the controller to the fire alarm. The

interface controls the “VF” signal in the output terminal blocks. By using the “VF” signal to power an

electromagnetic lock, the power is cut immediately when the fire alarm is triggered. Please contact

your local fire authority as to the configuration of the Fire Alarm Relay Circuit.

TERMINAL # NAME FUNCTION

54 TRIPPED External Monitoring - Tripped Fire Alarm Relay (Supply Voltage)

55 GND DC Supply Ground

56 OK External Monitoring - Fire Alarm Relay OK (Supply Voltage)

57 RST External Reset Switch

58 RST External Reset Switch

59 CON External Fire Alarm Dry Contact

60 CON External Fire Alarm Dry Contact

See connection diagram on next page.

Page 19 of 30

FIRE ALARM INTERFACE WIRE CONNECTION WITH MANUAL EXTERNAL RESET

OK

54 55 56

T

R

I

P

P

E

D O

K

Fire Alarm

Terminal Block

TRM9:

57 58

R

S

T

59

G

N

D

R

S

T

C

O

N

C

O

N

60

NORMALLY

OPEN

MANUAL FIRE

ALARM RELAY

RESET

(KEYSWITCH)

NORMALLY OPEN

EXTERNAL FIRE ALARM RELAY

CONTACT

(HELD CLOSED BY FIRE ALARM

SYSTEM DURING NORMAL

OPERATION)

EXTERNAL LAMP

INDICATES TRIPPED

FIRE ALARM RELAY

CONDITION

T

+ -

+ -

EXTERNAL LAMP

INDICATES OK FIRE

ALARM RELAY

CONDITION

* R2

* R1

* NOTE: Since the output voltage of the “TRIPPED” and “OK” terminals is (V+), a

resistor is required if you are using LEDs as indicators. If using lamps, make

sure that the operating voltage of the lamp is equal to the supply voltage (V+). A

table below provides suggested resistor values for typicalLEDs.

Controller Supply Voltage (V+) Recommended LED Resistor Ranges

12V 360—500 Ohm

24V 760—1K Ohm

Page 20 of 30

FIRE ALARM INTERFACE WIRE CONNECTION WITH AUTOMATIC RESET

OK

54 55 56

T

R

I

P

P

E

D O

K

Fire Alarm

Terminal Block

TRM9:

57 58

R

S

T

59

G

N

D

R

S

T

C

O

N

C

O

N

60

AUTOMATIC

FIRE ALARM

RELAY

RESET JUMPER

NORMALLY OPEN

EXTERNAL FIRE ALARM RELAY

CONTACT

(HELD CLOSED BY FIRE ALARM

SYSTEM DURING NORMAL

OPERATION)

EXTERNAL LAMP

INDICATES TRIPPED

FIRE ALARM RELAY

CONDITION

T

+ -

+ -

EXTERNAL LAMP

INDICATES OK FIRE

ALARM RELAY

CONDITION

* R2

* R1

* NOTE: Since the output voltage of the “TRIPPED” and “OK” terminals is (V+), a

resistor is required if you are using LEDs as indicators. If using lamps, make

sure that the operating voltage of the lamp is equal to the supply voltage (V+). A

table below provides suggested resistor values for typicalLEDs.

Controller Supply Voltage (V+) Recommended LED Resistor Ranges

12V 360—500 Ohm

24V 760—1K Ohm

Other manuals for 3000

1

Table of contents

Other High Power Controllers manuals

Popular Controllers manuals by other brands

Analog Technologies

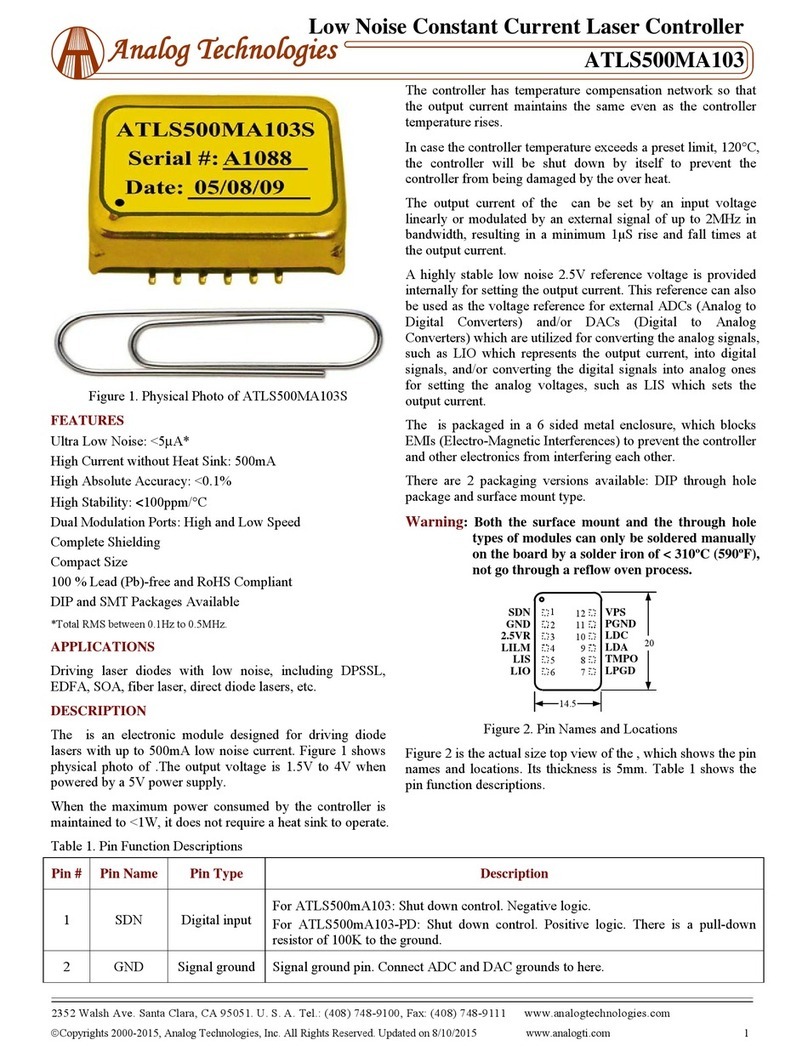

Analog Technologies ATLS500MA103 quick start guide

ICP DAS USA

ICP DAS USA TPD-703 quick start

Lintec

Lintec MC-5000L Series instruction manual

Automationdirect.com

Automationdirect.com GS1-10P2 user manual

HomLiCon

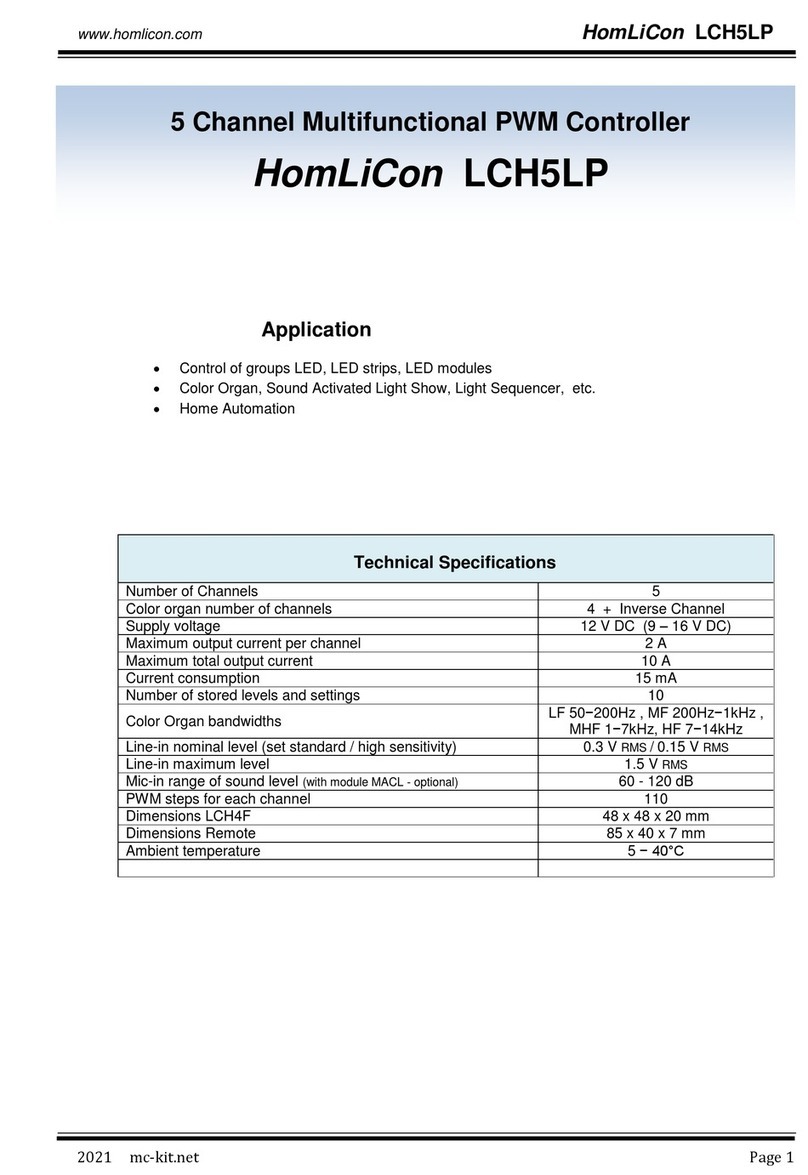

HomLiCon LCH5LP quick start guide

Phytolite

Phytolite Resina Q-Board 120 Series instruction manual