High Power 8000 Series User manual

TEL: (203)-634-3900 FAX: (203)-238-2425

EMAIL: HIGHPOWER@HIGHPOWERSECURITY.COM

WEB: WWW.HIGHPOWERSECURITY.COM

If you are having problems using this product, please call Highpower Technical Support

at 203-634-3900. We are here to help and we appreciate your business!

MODEL 8000 DOOR CONTROLLER WITH POWER OVER ETHERNET (POE)

HARDWARE MANUAL

VERSION 1.0.1

DOCUMENT NUMBER: 980-8000-1.0.1

TABLE OF CONTENTS

CONTROLLER DESCRIPTION.................................................................................................2

KEY FEATURES .......................................................................................................................3

8000 CONTROLLER BOARD ...................................................................................................3

BOARD PHOTO AND LAYOUT .............................................................................................3

BOARD CONNECTIONS BLOCK DIAGRAM.........................................................................4

TYPICAL POE CONNECTION DIAGRAM .............................................................................5

NOTICE OF INSTALLER QUALIFICATION...........................................................................6

POWER REQUIREMENTS........................................................................................................6

FLEXIBLE POWER SUPPLY OPTIONS................................................................................6

DETAILS ABOUT POWER OVER ETHERNET FEATURE....................................................6

STAND ALONE OPERATION...................................................................................................7

ADDITIONAL I/O FEATURES ................................................................................................8

DESCRIPTION.......................................................................................................................8

SCHEDULES..........................................................................................................................8

REAL TIME CLOCK ...............................................................................................................9

ADVANCED STAND-ALONE FEATURES................................................................................9

SOFTWARE INTERFACE......................................................................................................9

SCHEDULING PROGRAMMING .........................................................................................10

AUTOMATIC UNLOCKING USING SCHEDULES...............................................................10

HOLIDAYS ...........................................................................................................................12

FIRST-PERSON-IN FEATURE.............................................................................................13

FORCED LOCKDOWNS......................................................................................................13

FORCED DOOR UNLOCK (PASSAGE MODE)...................................................................14

NORMAL DOOR OPERATION.............................................................................................14

HARDWARE FEATURES........................................................................................................15

ON BOARD JUMPER FUNCTIONS.....................................................................................15

REMOTE RELEASE.............................................................................................................15

READER PORTS .................................................................................................................15

ADVANCED READER PORT FEATURES..............................................................................16

PROXIMITY (WIEGAND) FORMATS (BOTH READER PORTS).........................................16

DETAILS ABOUT USING WIEGAND DATA ........................................................................17

Page 2 of 26

READER PORT 1 SPECIAL FEATURES ............................................................................17

BARCODE SYMBOLOGY SUPPORT..............................................................................17

MAGSTRIPE INPUT.........................................................................................................18

DETAILS ABOUT BARCODE INPUT...............................................................................18

PDI MODE........................................................................................................................18

BARCODE NORMALIZATION..........................................................................................18

MASKING INPUT DATA.......................................................................................................18

CUSTOM WIRING DIAGRAMS AND UNIQUE APPLICATIONS ...........................................19

TROUBLESHOOTING ISSUES ..............................................................................................20

WARRANTY INFORMATION..................................................................................................20

APPENDIX A – MEMORY RECORD SIZE CALCULATIONS..............................................20

APPENDIX B – COMPATIBLE POE SWITCHES ................................................................21

APPENDIX C – WIEGAND BIT SIZE TABLE.......................................................................22

APPENDIX D – TESTED COMPATIBLE READERS ...........................................................23

PROXIMITY READERS....................................................................................................23

BAR CODE READERS.....................................................................................................23

MAG-STRIPE READERS.................................................................................................23

APPENDIX E: ELECTRICAL SPECIFICATIONS ...................................................................24

APPENDIX F: CONNECTOR DESCRIPTIONS ......................................................................25

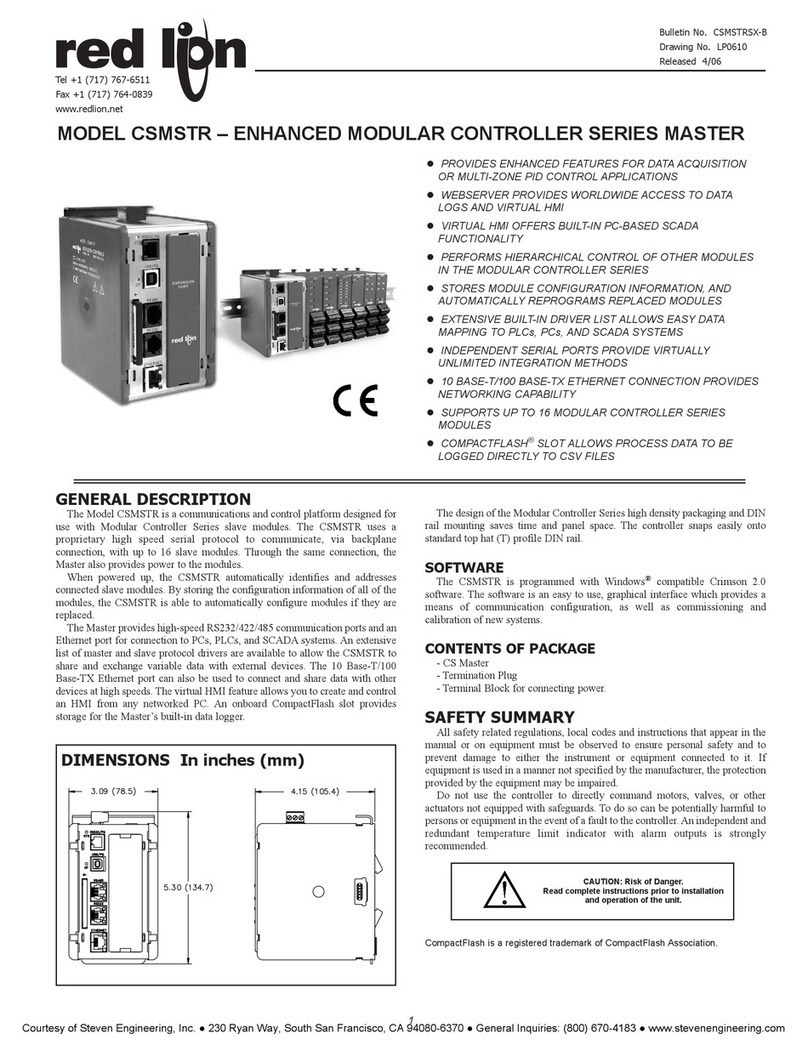

CONTROLLER DESCRIPTION

The 8000 Series is a door controller designed for one or two door operation. It provides the

installer with the latest advancements in Ethernet communications and Power-Over-Ethernet

technology. The 8000 controller has been specifically designed for use with the Highpower

Management System (HMS), which is a SQL based database and control program for the Windows

.NET platform. The 8000 can also run in stand-alone configurations without software. When using the

HMS software the 8000 is networked to provide a rich control environment that allows customers to

manage alphanumeric card IDs, schedules, and holidays and to generate reports based on system

activity.

The 8000 controller is used in conjunction with external card reader(s) to create a secure two-piece

access control solution. The card reader inputs of the 8000 controller support a wide variety of reader

types including:

•Barcode readers (Wiegand Data on Port 1 or Port 2 or Un-encoded Barcode Data on Port 1)

•Proximity Readers (Wiegand Data on Port 1 and Port 2)

•Magnetic Stripe Readers (ABA Data on Port 1 and Port 2)

•Wiegand Card Readers (Wiegand Data on Port 1 and Port 2)

Communications from the controller to the HMS software is accomplished through either RS-232 port

(serial) or more commonly through the built-on Ethernet port, which supports the 802.3af POE

standards.

The Power-Over-Ethernet features of the controller are unique in that the controller allows the installer

to power the controller itself, two card readers and two electric strikes simultaneously when the total

current draw of the connected devices is fewer than 900mA @ 12VDC (around 11 Watts).

This document will describe the features of this controller for simplified installation and setup.

Page 3 of 26

KEY FEATURES

•RS-232 and Ethernet Networking with 802.3af Power-Over-Ethernet built on board.

•Two-Door Operation with Request to Exit and Door Position Switch monitoring.

•One-Door model available.

•Flash-Based Non-volatile memory 512K for each reader.

•25 Schedules with 8 periods (when used with HMS software).

•Automatic door unlocking and relocking cycles.

•Adjustable memory structure – Memory structure is adjusted based on length of longest

user ID in order to maximize memory space for IDs (automatically configured when using

HMS software).

•Reader inputs can be configured to accept different signal types including Wiegand and

ABA. Reader Input 1 can also accept barcode symbologies (including Code 3 of 9, I 2 of 5,

Interleaved I 2 of 5, Codabar, UPC A, EAN13 and Code 128 barcode types).

•Reader inputs can mask data to include or exclude digits from user ID on a hardware level.

8000 CONTROLLER BOARD

BOARD PHOTO AND LAYOUT

Page 4 of 26

BOARD CONNECTIONS BLOCK DIAGRAM

Page 5 of 26

TYPICAL POE CONNECTION DIAGRAM

(Ground)

(+12 VDC)

(Ground)

(+12 VDC)

12 VDC

ELECTRIC

STRIKE

DOOR 1

12 VDC

ELECTRIC

STRIKE

DOOR 2

WIEGAND

READER

DOOR 1

AUXILIARY PLUG

IN WALL

TRANSFOMER

12 VDC

(USE WHEN POE

IS UNAVAIABLE)

NETWORK HUB

(WITH OPTIONAL P.O.E.)

Normally Open—Relay 1

Common—Relay 1

Normally Closed—Relay 1

Ground

+ V dc (note jumper JP6)

Ground

Data 0 / Clock / BCin

Data 1 / Data

Green LED

Red LED

Door Position Switch 1

Ground

Request To Exit 1

Ground

Ground (OPTIONAL)

For future use.

For future use.

For future use.

+12 VDC (OPTIONAL)

Ground (OPTIONAL)

Normally Open—Relay 2

Common—Relay 2

Normally Closed—Relay 2

Ground

(note jumper JP7) + V dc

Ground

Data 0 / Clock

Data 1 / Data

Green LED

Red LED

Door Position Switch 2

Ground

Request To Exit 2

Ground

Spare

Ground

RS-422 TX + (OPTIONAL)

RS-422 TX - (OPTIONAL)

RS-422 RX + (OPTIONAL)

Typical Power-Over-Ethernet

Configuration using Electric Strikes.

BROWN

LED

Data 1

Data 0

Ground

+12 Vdc

WHITE

GREEN

BLACK

RED

WIEGAND

READER

DOOR 2

LED

Data 1

Data 0

Ground

+12 Vdc

BROWN

WHITE

GREEN

BLACK

RED

RS

-

232

RS-422 RX - (OPTIONAL)

Page 6 of 26

NOTICE OF INSTALLER QUALIFICATION

The items listed in this manual may require the services of an individual who is trained in the

application and installation of life safety equipment. All wiring must be in compliance with current NEC

guidelines.

POWER REQUIREMENTS

FLEXIBLE POWER SUPPLY OPTIONS

The controller is powered using either 12VDC connected to one of the terminals on the board (12vdc IN

or ac adapter IN) or through using Power-Over-Ethernet via the Ethernet connector.

There is internal voltage regulation on the controller board, so a 13.8 Volt supply, or an unregulated / or

regulated plug in wall adapter that can provide the required power is acceptable to use.

8000 Controllers equipped with the POE feature can get power directly through the CAT 5 networking

cable through a POE network switch, so a local power supply is typically not required. There are

applications where an external power supply may be required over the POE. Please read the section

below concerning Power Over Ethernet for more information concerning this.

The controller power requirement (for the board only) is:

Without Onboard Ethernet: 150 mA @12 VDC

With Onboard Ethernet: 350 mA @12 VDC

When using a power supply you must make sure that the power supply will support not only the power

requirements of the controller board, but also any readers and locks that you are powering off of the

controller.

Additionally, there are jumpers on the controller board for powering the door strike(s) directly from the

board. When you are powering the strikes from the board, DO NOT connect a power supply to the

common relay contact. The controller sources the power for the strike directly from the power supply

which is supplying power to the controller.

If you decide to power the strikes directly through the board, you must make sure that the total power

usage for both strikes combined is not more than 700ma. This is the limitation for strike power through

the board, whether powering the board from an external plug in adaptor or through POE.

Note that the door strikes can always be powered separately by changing jumpers and using the relay

as a dry contact. In this case, the relay contacts should be limited to a 5 Amp load. To use the relay as

a dry contact remove jumpers 11 and 12 which connect relay 1 and relay 2 contacts to the power

supply on the board. DAMAGE TO THE BOARD WILL OCCUR if you leave these jumpers in and

provide power directly to the relay common line.

DETAILS ABOUT POWER OVER ETHERNET FEATURE

The 8000 is fully IEEE 802.3af compliant. Power can be supplied over the Ethernet data lines, or on

one of the unused pairs. Normally, the power is supplied by an Ethernet switch but it can also be

supplied by a power inserter. A list of tested and recommended power inserters can be found in the

appendices.

The power supplied over the Ethernet cable can also supply the electric strike or maglock connected to

the door. An additional supply typically is not needed for the door lock. Power for the lock mechanism

is taken directly from the controller board, eliminating the need for a separate power supply for the lock

mechanism.

Page 7 of 26

Note that because of POE specification limitations, the maximum combined power that can be supplied

to all connected readers and strikes, is 700mA @12vdc. Do not exceed this power limitation or damage

could occur to the controller board.

When using POE, the typical installation will require installing either a POE switch or a power inserter

near the Ethernet switch. Category 5 cable can be used to connect to the controller board for lengths of

up to 100 meters.

Battery backup can be implemented by using a UPS at the switch or power insertion point instead of

traditionally having a battery backup at each controller box. There is no need when using POE to

provide battery backup at the controller location. It is highly recommended that you install a UPS on

your switch equipment to insure constant uninterrupted controller operation.

Note that an 8000 controller with POE does not have to be powered over the Ethernet. You can still

power it with a standard supply. If you intend to use POE but cannot initially install the POE switch or

power inserter, the 8000 can still be installed using a power supply temporarily. The 8000 should not be

connected to a POE source and a local power supply at the same time. Doing this could damage the

controller.

You can power external devices like electric strikes and maglocks directly from the POE interface by

setting appropriate jumpers. The power insertion jumper(s) must be on for the POE power to pass

through the relay to the lock mechanism. See the jumper configuration section below for setting the

appropriate jumper settings.

STAND ALONE OPERATION

The stand-alone mode operates without the need of a real-time computer connection. This is the

mode that the controller is typically configured to and this mode is used in conjunction with the HMS

software. When a card is read, the controller performs a search for the card number in memory. If

the card number is found and the card’s schedule is valid, access is granted. Cards are normally

entered into the controller by transferring the card data from a PC. You can, however, enroll the

cards locally at a connected reader using control cards. If cards are enrolled locally, there is no

need for a computer connection at all other than for the initial programming.

There is an audit trail feature in the controller while operating in the stand-alone mode. Whenever a

valid card is read, the card number, along with the date and time, is stored in the controller's

memory. This audit trail data can be transferred to a computer at any time and is automatically

retrieved when using the HMS software. Optionally, cards which are read but not granted access

can also be stored in the audit trail to log invalid entry attempts. Audit trail data is stored in non-

volatile flash memory and is not lost if power is lost. A separate audit trail is stored for each of the

two doors (readers).

When a valid card is found, the appropriate output relay is triggered for the pre-programmed time,

allowing the door to be opened. When the door is closed, the controller can automatically re-lock

the door rather than wait until the full time period has elapsed (anti-tailgating feature) when the

controller is used in conjunction with a Door Position Switch (DPS). Anti-tailgating is a

programmable option.

The controller supports scheduling in the stand alone mode. Schedules tell the controller which time

of day a card has access for. A card number can be associated to one or a series of schedule

times, allowing multiple access times during an individual day. When using the HMS software, 25

schedules are provided, each schedule having 8 periods.

Page 8 of 26

ADDITIONAL I/O FEATURES

A "Request to exit" switch can be connected to an input on the controller for remote door unlocking.

When the switch is engaged, the controller will trigger the relay for the pre-programmed time,

allowing the door to open. The Request to exit can operate in both modes, stand-alone and online.

DESCRIPTION

Stand-alone mode is the most commonly used mode in the controller. This mode is used by the HMS

control software. In the stand-alone mode, the controller operates independently from a computer, but

allows a computer to make changes to the controller memory.

All card numbers which have access through the door must be loaded into the controller's memory.

This can be done either by loading in the data from a PC, or by enrolling each card at the reader locally.

The preferred method will depend on the number of cards that you need to enroll and whether you want

to use the scheduling features provided in the controller. Cards which are enrolled locally at a reader

cannot use the scheduling features, so if you need to use schedules then card data must be

downloaded into the controller via software.

The number of cards that can be stored in the controller depends on the size of the cards. Memory in

the controller is pre-allocated and therefore you can adjust the number of allowable cards in the system

based on your card data size. A list of the total number of cards which can be stores is provided in the

Appendices.

SCHEDULES

In the stand-alone mode, schedules are supported in the controller. Schedules allow you to specify the

times of day that an employee has access for. There are 199 unique schedules that can be

programmed into the controller, each schedule representing the allowable times for employee access

for 7 days (Monday thru Sunday). When using the HMS software, these 200 schedules are grouped

into schedules and periods, allowing for 25 schedules each with 8 periods (shifts).

Holiday schedules can also be entered in. The holiday schedule in the system is loaded in as day “8”.

Cards which are enrolled at a reader are enrolled with no schedule, meaning they will have access at

all times. This means that if you enroll cards at the reader you cannot specify a specific schedule.

Currently, you should not use the enrolling feature at the reader if you are also using the HMS software.

Each schedule specifies the start time and end time that access is allowed.

As an example, 0700 thru 1529 represents 7:30 in the morning till 3:29 in the afternoon. At 3:30 in the

afternoon and after, the employee will not have access.

It is possible to associate schedules in the controller. When you associate schedules, you are linking

multiple schedules together.

For example, let us say that you want to allow access between 7 in the morning and noon, and then

again between 1 pm and 4 pm. You would enter in two different schedules in the system, one for the 7

to noon, and another from 1 to 4, and then link them together. The result is a schedule which allows

access from 7 to noon, and then from to 4. From noon until 1259, access is not allowed. When using

the HMS software, the software will link sets of 8 schedules together automatically to form 25

schedules each with 8 intervals (shifts).

Page 9 of 26

There is an audit trail in the controller which will record each transaction that occurs in the reader. The

audit trail can be turned on or off. Whenever a card is read, the date and time, along with the card data

is stored in the audit trail. This data can be retrieved from the controller at any time. This audit trail data

is stored in a circular buffer to prevent the latest audit information from getting lost if the audit memory

space is full. Note that there are separate audit trail logs for each reader connected to the controller.

The HMS software will retrieve this audit trail information for each reader and use the information to

generate reports with the HMS reporting facility.

REAL TIME CLOCK

The time is set in the 8000 using the HMS software or via typed command. Time is accurate to about 1

minute per year. It is suggested that you update the time on a periodic basis. The real time clock is

updated every second. Schedule times, holiday periods, and other real time events are also checked

every second. Audit trail data is accurate to the second.

To set the current time in the system using the HMS software, right click on the controller that you wish

to set the time on. Left click on “Set Clock”.

HMS allows you to set the clock to different times which is important if the Controllers are in different

time zones:

ADVANCED STAND-ALONE FEATURES

SOFTWARE INTERFACE

Adding cards and changing settings in the controller is mainly done using the HMS software. You do

have the option however, to add cards to the controller by using control cards. In doing this, you do not

Page 10 of 26

need software for programming, but you will not be able to easily use the advanced scheduling and

other advanced features of the controller.

SCHEDULING PROGRAMMING

The controller contains memory for the loading of up to 199 schedules. These are identified as

schedule numbers 001 through 199. Each loaded schedule consists of 8 entries total. Seven

schedules for the 7 days of the week and 1 entry which is used for holidays. Each entry contains a

start time and an ending time that access is allowed for. If an entry for a particular day is not entered,

then access is not allowed for that day. The HMS software automatically groups these 200 schedules

into 25 schedules each with 8 intervals (shifts).

Entered schedule times are inclusive, not exclusive. If you want to allow access from 7 in the morning

until noon (don't allow access after noon), then the entered times are 0700 thru 1159. This means that

at 1159 you can still unlock the door, but at 1200 noon you cannot. To refer to midnight, you use 0000.

Schedules cannot cross midnight. To cross midnight you enter in a time period for the first day, and

then a time period for the second day. In order to allow two time periods in the same day, you must

associate two schedules together. This is handled automatically when using the HMS software.

Schedule 0 is a reserved schedule. This schedule is an open schedule, meaning access is allowed at

all times. Any card number entered into the system with schedule 0 is automatically allowed access at

all times, all days, including holidays. Cards which are enrolled locally at the readers are also entered in

with schedule 0. This means they have access at all times.

AUTOMATIC UNLOCKING USING SCHEDULES

Page 11 of 26

The 8000 contains a feature to allow either door to be unlocked during specific times of the day. You

may want, for example, to keep the door open during shift changes, or during lunch periods. The HMS

software can use your scheduling information to lock and unlock the doors automatically.

Schedule number 200 is a special function schedule in that the controller will automatically unlock the

door when the schedule time starts for that particular day. HMS will associate multiple schedules

together (starting with schedule 200) in order to unlock the door for multiple periods of the day.

During the unlock period, card scans are still allowed, but they have no effect on relay operation since

the relay is already actuated. If the audit trail is being used, the card scans will be stored as usual.

The unlock schedules will optionally work on holidays using the "day 8" schedule times. At the

beginning of the holiday period, the relay is automatically locked as usual, and then unlocked when the

schedule 200, day 8 unlock start time is reached.

Adding a schedule with the HMS software is accomplished by right clicking on Schedule in the

configure tree and selecting “Add a Schedule”.

Once you have clicked Add a Schedule, then the schedule screen pops up, which allows you to set up

your schedule times:

Page 12 of 26

Once you have configured your schedule, you must tell HMS to use the schedule as an unlocking

schedule. To do this, right click on the door that you wish to work on an unlock schedule and select

“Properties”:

Once you click on properties, the door properties window will be shown. Pick the schedule that you

have created to use as an unlock schedule:

Once you select “OK” the doors will work on the selected unlock schedule once the system has been

Synced.

Note that Unlock periods are not implemented if the system is in a Forced Lockdown or Forced Open

mode (described in later section).

HOLIDAYS

The controller supports both recurring holidays and non-recurring holiday periods. Recurring holidays

are holiday periods that recur for the same date every year (like New Years Day or Christmas). Non-

recurring holidays do not recur from year to year, or the dates change, and therefore need to be

programmed in every year (Special events, Labor Day, etc).

During a holiday period, the controller automatically turns off the relay, and switches to the day 8

schedule. Day 8 is therefore considered the "holiday schedule". During the holiday schedule, even if

an employee normally has access for that specific day, he will not have access unless access is

permitted under the day 8 schedule or if he has been entered in with schedule 0, which allows access

at all times.

Page 13 of 26

Non-recurring and Recurring holiday periods are specifically handled in the configure tree of the HMS

software. Right-click on either “Event Holidays” or “Recurring Holidays” in order to Add a holiday to the

system:

FIRST-PERSON-IN FEATURE

First-Person-In is a feature which allows a door unlock period to be delayed until at least one valid card

is read. This function is normally enabled to make sure that if the door is to be unlocked, that there is at

least someone around when it does unlock.

If the First Person In option is turned on, then when an unlock period is scheduled to start, the door will

remain locked. When the first valid read occurs, the door is then unlocked and remains open until the

end of the unlock period. A valid read is any card which normally would have been accepted if the

system was not in the unlock period.

The first-person-in features is specifically handled in the configure tree of the HMS software. In HMS,

right click on the appropriate door in the configure tree, select “Unlock Schedule Modes” and then click

on “Don’t unlock this door until a valid swipe occurs, then leave the door unlocked.”

To disable the First-Person-In feature, select “Unlock the door immediately at the start of the unlocking

schedule.

FORCED LOCKDOWNS

Either door connected to the 8000 can be locked down at any time using the HMS software, and also

with the reading of a special lockdown card. During the lockdown period, only cards entered in with a

schedule 0 will have access.

The forced lockdown can be turned off using the HMS software or also by scanning in the "End forced

mode" control card.

In the HMS software, right click on the appropriate door in the configure tree, select “Forced Door

Modes” and click “Keep Door Locked (Lock Down Mode)”.

Page 14 of 26

FORCED DOOR UNLOCK (PASSAGE MODE)

Passage mode (Forced "opens" of the door) can be achieved using the HMS software or by presenting

the "force open" control card to a reader. In the HMS software, you right click on the appropriate door

in the configure tree, select “Forced Door Modes” and click “Keep Door Unlocked”.

The door will remain open until the door is put back into either normal operation or into a forced

lockdown. An "End forced mode" card can also be scanned to enter forced lock open mode.

NORMAL DOOR OPERATION

Normal door operation returns a particular door to normal operation from Forced Lockdown or Passage

Mode. The door will resume operating with schedules and operating with valid cards.

In the HMS software, you right click on the appropriate door in the configure tree, select “Forced Door

Modes” and click “Resume Normal Door Operation”.

Page 15 of 26

HARDWARE FEATURES

ON BOARD JUMPER FUNCTIONS

JUMPERFUNCTION

JP1 When removed and powered up, controller enters “Learn” mode.

JP2 RS-232 or USB active port selection (on models with USB).

JP3 TCP/IP or RS-422 active data port selection (on models with TCP/IP).

JP4 Selects which port data is sent out to in online mode. On selects (TCP/IP/RS-422). Off selects (RS-2

3

JP5

Used to place the RS-232 port into a known state. Forces the controller to start up with the RS-232

port set at 9600 baud, 8 data bits, no parity. Remove this jumper and power up to make the RS-232 t

online port with the above settings. Used when the ports have been changed to some unknown state

JP6

JP7 Both of these jumpers should be on in order to provide 5V power to the readers. JP10 should be OF

F

these jumpers are connected.

JP8 Reserved for future use. THEY MUST BE LEFT OPEN.

JP9 Reserved for future use. THEY MUST BE LEFT OPEN.

JP10 Used to connect 12V power to the reader outputs. JP6 and JP7 must be removed when JP10 is con

n

JP11 Jumper supplies power from the POE supply directly to the common terminal of Relay 1. When open,

1 works as a dry contact set.

JP12 Jumper supplies power from the POE supply directly to the common terminal of Relay 2. When open

,

2 works as a dry contact set.

REMOTE RELEASE

The Remote Release Terminals provide a connection for external switches that are used to trigger Door

1 or Door 2. These switches are normally open switches, that when closed, cause the respective door

to unlock. The doors will remain unlocked for their programmed unlock cycle times.

READER PORTS

The controller has two Ports for reader connection.

NAME FUNCTION

READER PORT 1

(+Vdc) (+5V) or (+12V) Reader Supply Voltage (Selected by Jumpers 6 and 10)

Ground DC Supply Ground

D0/Clock/BC Port 1 Wiegand Data 0 / ABA Clock Input / Barcode Input

D1/Data Port 1 Wiegand Data 1 / ABA Data Input

LED 1 Port 1 Green LED Control Line Output

LED 2 (Optional based on reader) Port 1 Red LED Control Line Output

READER PORT 2

(+Vdc) (+5V) or (+12V) Reader Supply Voltage (Selected by Jumpers 7 and 10)

GND DC Supply Ground

D0 / Clock Port 2 Wiegand Data 0 / ABA Clock Input

D1 / Data Port 2 Wiegand Data 1 / ABA Data Input

LED 1 Port 2 Green LED Control Line Output

LED 2 (Optional based on reader) Port 2 Green LED Control Line Output

Page 16 of 26

ADVANCED READER PORT FEATURES

Both reader inputs of the 8000 support Wiegand and ABA. Reader input 1 additionally supports

barcode symbologies. Readers can use either 12VDC or 5VDC power and can be powered off the

controller in both powered mode and using POE. Power is supplied directly from the controller for

the readers.

The 8000 supports the connection of an undecoded barcode reader directly on the reader #1

connection ONLY. It you have a 2-door controller, and need barcode reading for both doors, a

decoded barcode reader with magstripe emulation or wiegand interface, can be used for the 2nd

reader or for both readers. Contact Highpower for assistance when picking readers with a barcode

input.

Wiegand and Proximity readers should have a standard Wiegand data output (Data 0 and Data 1

signals). Most, but not all, proximity readers have this type of output. Compatible models include

readers from many popular brands including and reader from Farpointe Data, HID Corporation,

Indala and AWID. Barcode readers include readers from International Bar Code (IBC). The inputs

of the 8000 have been tested with the Farpointe Data reader line specifically. Highpower can

provide you with a Farpointe reader for your application.

Magnetic stripe readers should have an undecoded magstripe output, known as "clock and data"

signals. If you need a dual-technology single reader, then any of the Magbar or Smart Prox readers

from International Barcode, with ABA, Wiegand, or wand emulation outputs can also be connected

to the controller. Multiple readers may be connected to the same reader input, as long as the

readers have open collector outputs. If this multiple readers on one port is used, only one reader

can transmit to the controller at a time.

Most 8000’s are in the two-door configuration. The 2-door controller supports the connecting of 2

separate readers. Each reader is treated individually and operates independently of the other. In the

stand-alone mode, each reader uses its own memory space for accessing valid ids, and for the

audit trail. In the online mode, both readers share the same output. Reader styles can be mixed.

You do not have to use the same technology reader on each input. For example, you can have a

barcode reader as reader #1, and a magstripe reader as reader #2, or you could combine

magstripe/proximity readers, etc.

PROXIMITY (WIEGAND) FORMATS (BOTH READER PORTS)

The controller supports all proximity and wiegand data formats up to 64 bits. Each individual field (site

code, id number, and optional issue code) is extracted and converted to a decimalized number,

resulting in a numeric string. This is the string that is used for comparisons in the controller while in the

stand-alone mode. In the online mode, this string is simply transmitted. The controller converts this

information into a string so that masking of the data can be achieved easily should you need to mask

out numbers from the card ID.

A special mode of the controller called open enrollment allows you to accept wiegand data without a

decimalized conversion. In this mode, all wiegand formats up to 64 bits are accepted and stored

directly with no conversion.

Three different formats are programmable, allowing the controller to accept three different card formats

for each reader. Each format is fully configurable by bit, and the extracted data can be modified by the

controller prior to comparison or transmission. Numbers can be added to the data, or deleted from the

data. See the Advanced Concepts section for more information on this topic.

Page 17 of 26

DETAILS ABOUT USING WIEGAND DATA

The controller will accept any size wiegand input up to 64 bits. Please note that most proximity readers

output data in the Wiegand data format.

Because Wiegand data is binary, the data is normally meaningless unless it is decoded into a useful

number in some way. The industry standard for wiegand data is a 26-bit stream, consisting of a site

(facility) code of 8 bits and also a badge (id) number of 16 bits. This is also the default setting for the

controller. The largest site code that can be transmitted with 26 Bit Wiegand is value 255. The largest

ID code that can be transmitted in 26 Bit Wiegand is 65535. The controller therefore decodes 26 bit

wiegand numbers into an 8 digit string, consisting of 3 digits for the site code, and 5 digits for the id

number, by default.

In order to decode a different format, you must program the controller so that it understands the bit

structure that you will be reading. It is necessary to do this so that the controller will end up with the

correct unique id number. You must program in the starting bit position and number of bits for the site

code (if it is being used), as well as the id number. Issue codes are also supported as a separate field

and they can be decoded or ignored.

It is important to note that the controller always processes wiegand bit fields in the order of site, badge

(id), and then issue code (in the rare case where an issue code is being used). The controller will

accept any size wiegand input up to 64 bits.

When decoding numbers are read from the card, the controller will concatenate each of the three fields

in the order of site, badge, and then issue to create the actual card data number that is stored in the

controller.

For example, if you have a proximity card with a facility code of 33 and an ID of 12, and have

programmed the controller to decode the site code to a 3 digit number, the id field to a 6 digit number,

and to ignore the issue code, the resulting number after decoding will be 033000012.

You can program the controller to accept up to 3 different wiegand data formats, and decode them

based on the parameters you have set. It is therefore possible to mix different wiegand or proximity

cards together in the controller. The controller will automatically discriminate them based on their bit

lengths.

It is also possible to mask the wiegand input (omit or add numbers in certain positions from the read

results). Characters can be added to or deleted from the decoded number using one of the input masks

(described later).

Backward bit structures may also be handled by the controller. Some proximity cards contain site codes

and id fields that are encoded backwards with the least significant bit first, rather than last. It is possible

for the controller to read these bit streams and decode the proper number.

READER PORT 1 SPECIAL FEATURES

BARCODE SYMBOLOGY SUPPORT

The 8000 controller supports Wiegand and ABA (also called clock-and-data) on both reader ports.

Additionally, Reader port 1 has some additional unique features in that it can also read unencoded

barcode signals. The controller supports barcode symbologies through reader port 1 only. The

following barcode symbologies are supported:

•Code39

•Interleaved 2 of 5

Page 18 of 26

•Industrial 2 of 5

•Standard 2 of 5

•Codabar

•UPC A

•EAN 13

•Code 128

The maximum number of barcode characters that can be decoded by the controller is 22. This includes

start and stop characters and check digits. The controller can be programmed to auto-discriminate

Kronos barcodes, which are normally 17 or 18 digits long. In this mode, the id is extracted from the

entire Kronos string, and the remaining information is ignored. The controller can also be programmed

to extract the PDI from a military/CAC barcode. This extraction yields a 9 digit number (typically the

SSN). There are a number of programming options that affect the way barcodes are read and

processed. These options can be found under the Advanced Concepts section. Barcode data can also

be masked (omission of digits in barcode) and reformatted (numbers added to the string) on the

hardware level. Note that the controller supports the direct connection of an undecoded barcode

reader ONLY ON READER PORT 1.

MAGSTRIPE INPUT

Both the Track 1 and Track 2 character sets are supported by the controller. Separator character

translation is also supported, as well as B and C start sentinels for the Track 2 character set. Note that

magnetic stripes on tracks normally use the Track 2 character set and is fully supported.

Magnetic stripe data can also be reformatted using the masking commands (see Advanced Concepts).

DETAILS ABOUT BARCODE INPUT

The controller can decode numerous barcode symbologies. For all supported symbologies, it is

possible to prefix and suffix barcode data with up to 5 characters. This prefix and suffix is in addition to

the ability to add and delete characters via the masking commands.

Start and stop characters may also be included, along with check digits and scan direction indicators.

These items are normally only used when in the online mode; however they can be used in the stand-

alone mode as well.

The controller also has advanced barcode decoding options, which are useful when there is writing

before or after the barcode, or there are extraneous bars in the barcode.

PDI MODE

When using the 8000 on Port 1 with an unencoded reader, the 8000 can automatically extract the PDI

from military and Common Access Card (CAC) barcodes. The PDI is extracted to a 9-digit number. This

number, on most cards, is the user's SSN.

BARCODE NORMALIZATION

In rare cases, if you are reading barcodes, you may have information on the card immediately to the left

or right of the barcode, which can interfere in the controller's ability to automatically decode the

barcode. The 8000 has an option for you to "normalize" the barcode, by selecting which part of the data

is to be decoded as a barcode.

MASKING INPUT DATA

The 8000 supports a number of masking parameters, including character insertion, deletion, and

selection. Character insertion allows you to add any sequence of characters to the input data at any

Page 19 of 26

location. Character selection allows you to select only those characters that you want. Unselected

characters are deleted. There are separate masking tables for each type of input.

For example, if you are using 2 different sets of proximity cards, 26 bit and 34 bit, with different site

codes on the 34 bit cards than the 26 bit cards, and want to keep the site codes the same, you can

program the controller to ignore the site codes on the 34 bit card, and then use the masking commands

to add in the appropriate site code so that the site codes are the same as the 26 bit cards.

CUSTOM WIRING DIAGRAMS AND UNIQUE APPLICATIONS

Highpower can provide design services for you application including wiring diagrams, installation

procedures, and system integration. We offer turnkey solutions for your security requirements. Please

feel free to contact Highpower directly for integration services.

Page 20 of 26

TROUBLESHOOTING ISSUES

This section describes troubleshooting information that is discovered through technical support calls

with our customers. Highpower attempts to update this section on a regular basis with solutions to

commonly asked technical support questions. Contact Highpower at 203-634-3900 with technical

questions.

Problem Description Resolution

Nothing currently reported.

WARRANTY INFORMATION

Thank you for choosing a Highpower product! The Highpower Security Products, LLC Door Controller

Model 8000 is manufactured to the highest quality standards to provide years of dependable service.

The Model 8000 is warranted for one year from the date of shipment against defects in parts,

workmanship and materials, when installed in accordance with instructions. Defects that occur within

this warranty period, under normal use of the product, shall be repaired or replaced with a new unit,

solely at our option. Warranty is void when product has been modified, damaged, abused, misused,

subjected to abnormal use or neglect, or subjected to harsh operating environments out of the normal

operating specifications.

No agent, employee or representative of Highpower Security Products, LLC has authority to bind

Highpower Security Products, LLC to any oral affirmation, representation or warranty, other than set

forth above. Highpower Security Products, LLC expressly disclaims all other warranties, expressed or

implied, including but not limited to any implied warranties of merchantability or fitness for a particular

purpose. “Fair-Safe” and “Fail-Secure” are definitions only. Use of these terms is not a performance

warranty, but merely a descriptive term used to characterize a design feature.

APPENDIX A – MEMORY RECORD SIZE CALCULATIONS

This appendix lists the number of available slots in the unsorted memory, sorted memory, and audit trail

log for some of the most widely used record sizes. Please note that the HMS software currently only

uses the Unsorted Memory Area for code storage, although future plans include Sorted Memory Area

support.

Record Size Unsorted Memory Area Sorted Memory Area Audit Log Records

4 10240 32085 16320

5 8777 27501 16320

6 7680 24064 16320

7 6826 21390 16320

8 6144 19251 16320

9 5585 17501 15360

10 5120 16042 14528

11 4726 14808 13760

12 4388 13750 13056

13 4096 12834 12480

14 3840 12032 11904

15 3614 11324 11392

20 2792 8750 9344

25 2275 7130 7936

40 1462 4583 5440

Table of contents

Other High Power Controllers manuals