Parker P2M Node 24 DO User manual

Other Parker Controllers manuals

Parker

Parker Sporlan PSK Series User manual

Parker

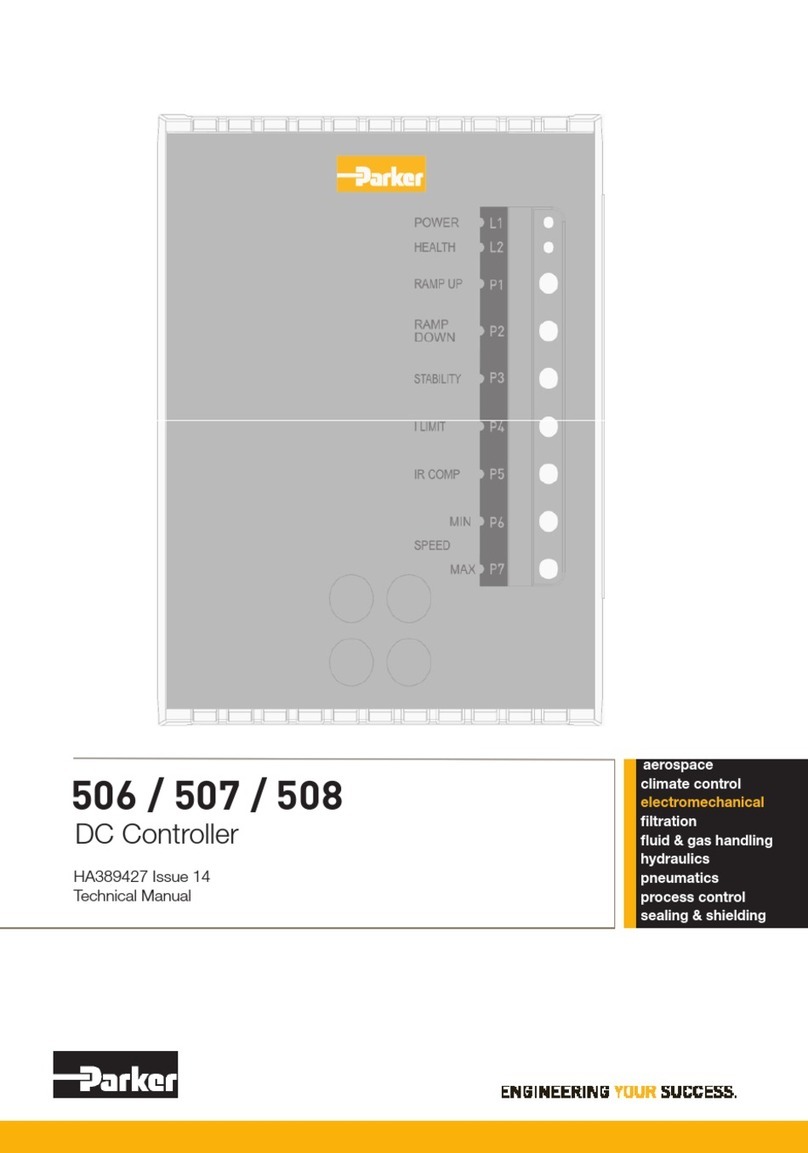

Parker 506 Series User manual

Parker

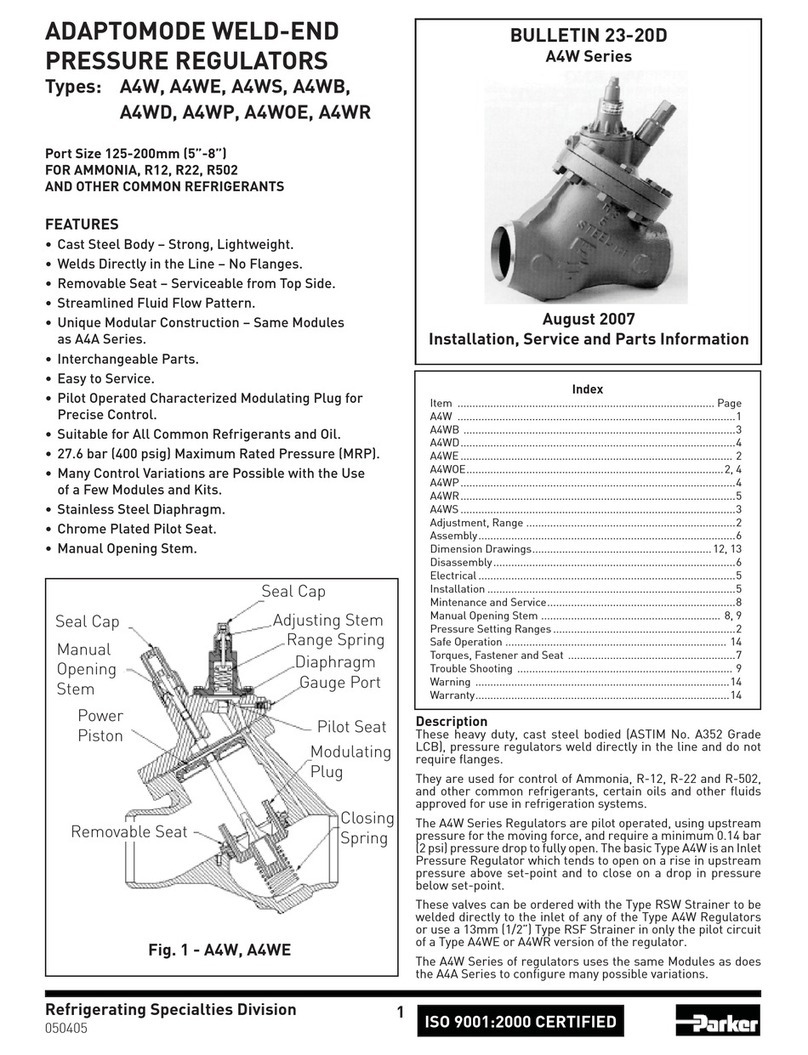

Parker A4W Series Guide

Parker

Parker 650S Series User manual

Parker

Parker GEM6K Series Manual

Parker

Parker TQ10X User manual

Parker

Parker 890 Series Instruction manual

Parker

Parker 8903/DN User manual

Parker

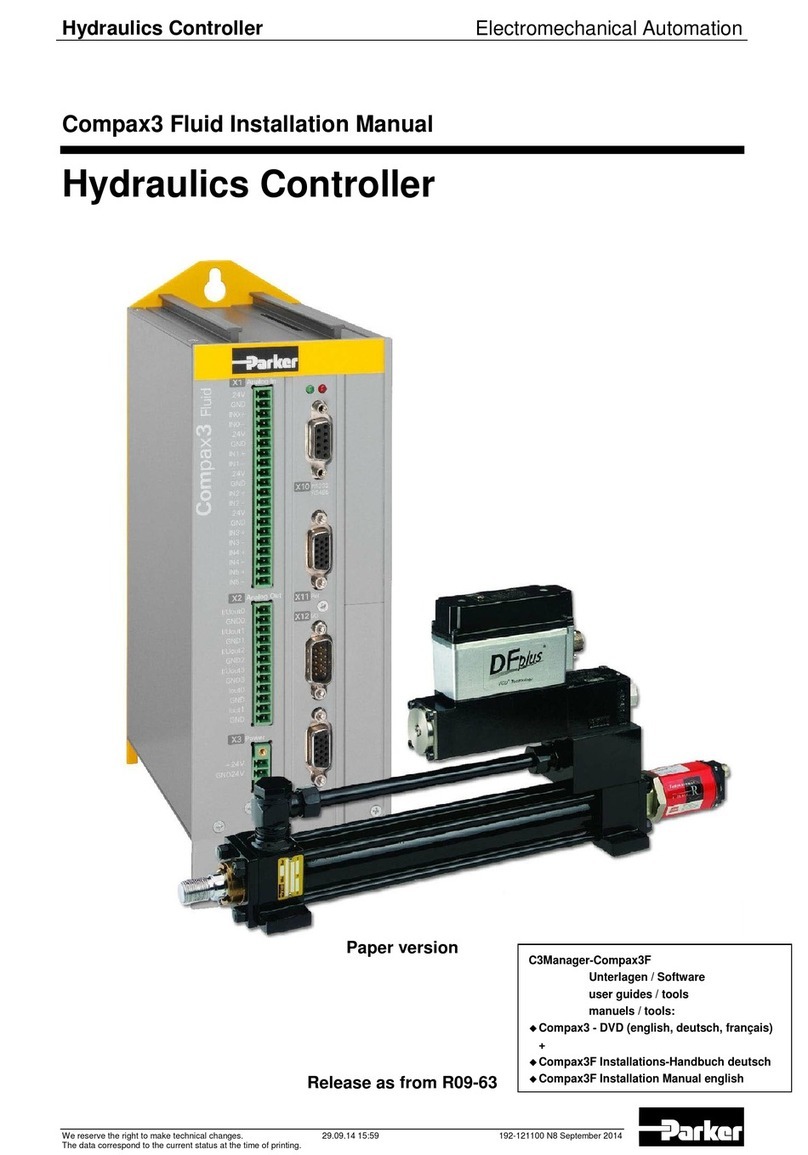

Parker Compax3F Fluid User manual

Parker

Parker ACR9000 User manual

Parker

Parker X-Flow FM-1407 Quick start guide

Parker

Parker SPORLAN SD-378 User manual

Parker

Parker IQAN-LST User manual

Parker

Parker HTR Series User manual

Parker

Parker PAC120 Series User manual

Parker

Parker ACR9000 User manual

Parker

Parker XLR Series Datasheet

Parker

Parker A4AP-DN Manual

Parker

Parker 650G series User manual

Parker

Parker AC30V Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions