Sensia CLIF MOCK TC2000 User manual

Manual No. 9A-70165002, Rev. 02

MEASUREMENT

CLIF MOCK™

True Cut 2000 Sampler

Controller

Installation, Operation & Maintenance Manual

MODEL: TC2000

True Cut 2000 Sampler Controller

2

Page Left Intentionally Blank

3

Important Safety Information

Terms Used in This Manual

Caution

Caution, risk of electric shock

Attention

Attention, risque d'électrocution

WARNING

A warning identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

AVERTISSEMENT

Un avertissement identifie des informations sur des pratiques ou

des circonstances pouvant entraîner des blessures corporelles ou

la mort, des dommages matériels ou des pertes économiques.

Caution

Caution statements Indicate actions or procedures which, if not

performed correctly, may lead to personal injury or incorrect function of

the instrument or connected equipment.

Attention

Indiquez les actions ou les procédures qui, si elles ne sont pas

effectuées correctement, peuvent entraîner des blessures ou un

mauvais fonctionnement de l'instrument ou de l'équipement connecté.

Note

Indicates additional information about specific conditions or

circumstances that may affect instrument operation.

Remarque

Indique des informations supplémentaires sur des conditions ou des

circonstances spécifiques pouvant affecter le fonctionnement de

l'instrument.

REVISION HISTORY

REVISION:

DESCRIPTION OF CHANGE:

ISSUER:

APPROVER:

DATE:

1

Initial Release

AK

TMM

June 2011

2

Update Electronics Package

AK

TMM

September

2020

True Cut 2000 Sampler Controller

4

Table of Contents

Section 1: Introduction.................................................................................................................7

Description......................................................................................................................................................... 7

Section 2: True Cut 2000 Sampler Controller Components and Specifications.......................8

Display............................................................................................................................................................... 8

Power Supply..................................................................................................................................................... 8

Product Identification......................................................................................................................................... 8

Specification ...................................................................................................................................................... 9

Section 3: Installation.................................................................................................................11

General Information......................................................................................................................................... 11

Mounting Options............................................................................................................................................. 11

Hazardous Area Installations........................................................................................................................... 11

Class I, Division 1 (CSA) Installations....................................................................................................... 11

Class I, Division 2 (CSA) Installations....................................................................................................... 12

Field Wiring...................................................................................................................................................... 12

Grounding Procedures .............................................................................................................................. 13

External DC Power Supply........................................................................................................................ 14

Communications........................................................................................................................................ 15

Turbine Input ............................................................................................................................................. 15

Digital Output (Solid State Relay).............................................................................................................. 16

Section 4: Operating the Controller...........................................................................................17

Front Panel ...................................................................................................................................................... 17

Keypad Overview............................................................................................................................................. 17

Common Keypad Functions ............................................................................................................................ 18

Stop a Sampling Period............................................................................................................................. 18

Start a Sampling Period............................................................................................................................. 18

Pause and Resume Sampling Without Starting a New Sampling Period ................................................. 18

Display Status Indicators On Demand ...................................................................................................... 18

Test the Controller..................................................................................................................................... 18

On-Demand Display of Status Indicators and Volumes .................................................................................. 18

Run Time................................................................................................................................................... 19

Percent Done............................................................................................................................................. 19

Flow Rate................................................................................................................................................... 19

Total Volume ............................................................................................................................................. 19

Grand Total Volume .................................................................................................................................. 19

System Voltage ......................................................................................................................................... 19

Sampler Status.......................................................................................................................................... 19

Firmware Version ...................................................................................................................................... 20

Samples Taken.......................................................................................................................................... 20

Section 5: Programming the Controller.....................................................................................21

Time-Based Sampling ..................................................................................................................................... 21

5

Batch/ Time Sampling ............................................................................................................................... 21

Continuous Time Sampling ............................................................................................................................. 22

Volume-Based Sampling................................................................................................................................. 22

Volume Sampling ...................................................................................................................................... 22

Sampler Test ................................................................................................................................................... 23

Keypad Security............................................................................................................................................... 23

Disable Security......................................................................................................................................... 23

Basic Security............................................................................................................................................ 23

Advanced Security..................................................................................................................................... 24

Access Menu ................................................................................................................................................... 24

Communication Port Settings.................................................................................................................... 24

Reset All Totals ......................................................................................................................................... 24

Load Factory Default Settings ......................................................................................................................... 24

Security Bypass............................................................................................................................................... 24

Section 6: True Cut 2000 Sampler Controller Spare Parts.......................................................26

Appendix A: Communications Protocol....................................................................................30

Introduction...................................................................................................................................................... 30

Supported Commands..................................................................................................................................... 30

Data Types ...................................................................................................................................................... 30

Registers.......................................................................................................................................................... 30

Appendix B: Publisher Notes.....................................................................................................34

Support ............................................................................................................................................................ 34

Warranty .......................................................................................................................................................... 34

Disclaimer........................................................................................................................................................ 34

Contact us........................................................................................................................................................ 36

6

GENERAL

WARNING!

To avoid the risk of electric shock and fire, the following safety instructions must be

observed and the guidelines followed.

The specifications must not be exceeded, and the device must only be applied as

described in the following.

Prior to the installation and commissioning of the unit, the installation guide must be

examined carefully.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

GENERAL

AVERTISSEMENT!

Pour éviter tout risque de choc électrique et d'incendie, les consignes de sécurité de ce

manuel doivent être observées, et les instructions suivies.

Les spécifications ne doivent pas être dépassées, et l'unité ne doit être appliquée que

comme décrit dans le texte suivant.

Ce manuel doit être examiné avec soin, avant l'installation et la mise en service de

l'unité.

Si l'équipement est utilisé d'une manière non spécifiée par le fabricant, la protection

assurée par l'équipement peut être altérée.

INSTALLATION

WARNING!

Installation may only be carried out by electrically skilled and instructed personnel in

accordance with national legislation, including the relevant standards.

All technical data on the instrument is to be observed.

Changes to the design and modifications to the equipment are not permitted.

The equipment shall only be operated as intended and only in undamaged and perfect

condition.

Sufficient segregation must exist between different cables and wires carrying different

types of signal or power and all other circuits.

All wires must be terminated, complete with crimping lugs. Unused cores should be

terminated to the earth bus bar.

INSTALLATION

AVERTISSEMENT!

L’installation ne peut être effectuée que par un électricien qualifié, conformément à la

législation nationale, y compris les normes pertinentes.

Toutes les données techniques sur l'instrument doivent être observées.

Modifications de l'équipement ne sont pas autorisés.

L'équipement ne doit être utilisé comme prévu par le fabriquant et uniquement si il est

en parfait état.

Une séparation suffisante doit exister entre les différents câbles et les fils transportant

différents types de signaux ou de puissance et tous les autres circuits.

Tous les fils doivent être terminés, avec pattes de sertissage. Les noyaux non-utilisés

doivent être terminés au jeu de barres de la terre.

Section 1: Introduction

7

Section 1: Introduction

DESCRIPTION

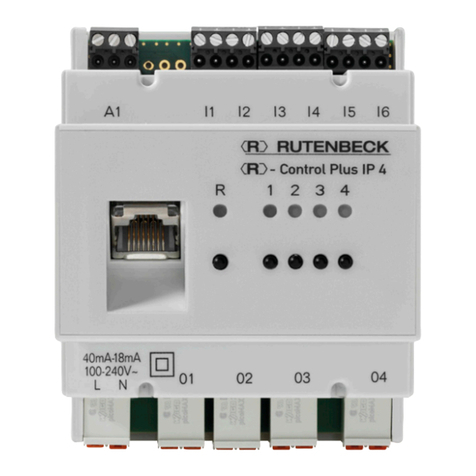

The Clif Mock True Cut 2000 Sampler Controller, see Figure 1, is an electronic controller that can be used to

control any pneumatic device. When paired with a liquid/gas sample pump, the device is ideal for sampling

liquid or gas flow streams.

The controller can be configured to sample as time proportional or flow proportional. This design allows

external pacing devices such as turbines meters to control the sampling frequency.

The controller consists of an explosion proof enclosure with a window for viewing a dual LCD and a six-key

keypad, press control switch and electronic circuitry, see Figure 1.

Figure 1: True Cut 2000 Sampler Controller

True Cut 2000 Sampler Controller

8

Section 2: True Cut 2000 Sampler Controller

Components and Specifications

DISPLAY

Dual readouts in the front panel display provide a real-time sample count during operation and guide users

through configurable settings during device setup. In addition, a user can initiate a scrolling display of

performance status indicators and total volumes on demand during normal operation. Run time, percentage

of sample job completion, flow rate, total volume, grand volume, system voltage, sampler status, firmware

version, and sample count are recorded by the controller and available for display. See Section 4, for details.

Figure 2: True Cut 2000 Sampler Controller, internal view

POWER SUPPLY

The True Cut 2000 Sampler Controller supports external DC power input supply. An external 6 to 30V DC

power supply with a minimum of 65mA can be used to power the controller circuit board.

PRODUCT IDENTIFICATION

A serial tag mounted on top of the enclosure identifies the product by its part number and serial number, see

Figure 3. The current model of serial tag reflects Scanner 2000 microEFM, under Model it will show either

TC2000 (Electronics Controller) or LGS-2000 (Sampling System).

Section 2: True Cut 2000 Sampler Controller Components and Specifications

9

Figure 3: Serial Tag

SPECIFICATION

Table 1: TC2000 Sampler Controller

Enclosure

Explosion Proof, Type 4 enclosure

Keypad

6-Key membrane switch, Password-protected security available

Switch

Explosion Proof external Momentary Control Switch

Power Supply

6-30V DC external power supply

Operating Environment

True Cut 2000 Sampler Controller: -40°C to 70°C (-40°F to 158°F)

0 to 90% non-condensing relative humidity

LCD contrast is reduced below -30°C (-22°F)

Turbine Meter Input

Configurable sensitivity adjustment (20 mV to 200 mV, peak to peak)

Frequency range: 0 to 5000 Hz

Continuous 50/50 duty cycle

Programmable K-factor

Input amplitude: 20 mV to 3000 mV,peak to peak

Turbine

Setting

Input Sensitivity

0 –1000 Hz

1000 –2000

Hz

2000 –3500

Hz

3500 - 5000

Hz

Low (20 mV)

20 mVpp

25 mVpp

50 mVpp

50 mVpp

Med (50 mV)

50 mVpp

70 mVpp

110 mVpp

140 mVpp

High (100

mV)

100 mVpp

150 mVpp

250 mVpp

350 mVpp

Highest (200

mV)

200 mVpp

380 mVpp

620 mVpp

850 mVpp

LCD Display

8-digit top readout of values (7-segment characters)

6-digit bottom readout of scrolling parameters and associated

engineering units (11-segment characters for easy-to-read prompts)

0.3” character height

Configurable scan parameters and duration

8-digit top readout of values (7-segment characters)

Digital Output, Solid State Relay

Rated 30V DC, 60mA max.

True Cut 2000 Sampler Controller

10

Sampling Methods (Time)

Batch Sampling (controller calculates the frequency of samples

required to fill the bottle in a specified time)

Time Sampling (controller collects samples at user-configured

frequency until specified number of samples is collected)

Continuous Time Sampling (controller collects samples at user-

configured frequency until sampling period is manually terminated)

Sampling Methods (Volume)

Turbine Input (controller collects samples to deliver specified volume,

based on turbine input frequency settings)

Volume Units

GAL, BBL, M3, LIT, CF, and NONE

Rate Units

/SEC, /MIN, /HR, and /DAY

Security

Two security levels with password protection

Communications

2 RS-485 communication ports (RTU Modbus®)

Safety Approval

True Cut 2000 Sampler Controller

Approved by CSA for US and Canada

Class I, Division 1, Groups B, C and D (explosion-proof)

Class I, Division 2, Groups A, B, C and D (non-sparking)

Type 4 enclosure

T6 temperature class

Section 3: Installation

11

Section 3: Installation

GENERAL INFORMATION

The True Cut 2000 Sampler Controller is typically installed after the sample probe and flowmeter are

installed in a pipeline.

For sampling liquid or gas, the controller should be installed with a sample pump, a sample probe, a

pressure regulator, a flowmeter, and a receiver. In liquid applications, hazardous gas applications, and low-

pressure gas applications, an external air supply is also required.

Note

This manual describes the installation of the True Cut 2000 Sampler

Controller. For LGS-2000 Sampling System, refer to the LGS-2000

Sampling System User Manual, Part Number 9A-70165003 for

additional details.

MOUNTING OPTIONS

The controller is mounted on the backplate of LGS-2000 system where the system can be direct mounted or

remote mounted. Refer to LGS-2000 Sampling System User Manual for details. True Cut 2000 Sampler

Controller can be mounted remotely using the optional remote mount kit, see Figure 2.1 below.

Figure 4: Remote Mount Option

HAZARDOUS AREA INSTALLATIONS

CLASS I, DIVISION 1 (CSA) INSTALLATIONS

True Cut 2000 is CSA-certified as explosion-proof for Class I, Division 1, Groups B, C and D hazardous

location when sold individually.

Wiring Precautions

True Cut 2000 Sampler Controller

12

Caution

All signal cable from other devices and power must be installed

accordance with local wiring practices for area classification. The cable

used between the True Cut 2000 and other devices must be either

armored MC-HL type cable or standard cable routed through conduit. If

standard cable is used, a conduit seal must be installed within 18 inches

from the True Cut 2000.

Note

All Conduit Seal Compound is to be poured during the field installation

phase.

CLASS I, DIVISION 2 (CSA) INSTALLATIONS

True Cut 2000 is certified for Class I, Division 2, Groups B, C and D hazardous locations.

Wiring Precautions

Caution

All field wiring must conform to the National Electrical Code, NFPA 70,

Article 501-4(b) for installations within the United States or the Canadian

Electric Code for installations within Canada. Local wiring ordinances

may also apply. All field wiring must be rated for temperature of 90 degC

or higher and have wire range of 22 to 14 AWG. Terminal block screws

must be tightened to a minimum torque of 5 to 7 in-lbs. to secure the

wiring within the terminal block. Only personnel who are experienced

with field wiring should perform these procedures.

FIELD WIRING

WARNING

Do not connect/ disconnect equipment unless the area is known to

be non-hazardous. True Cut 2000 poses no hazard when opened in

a safe area.

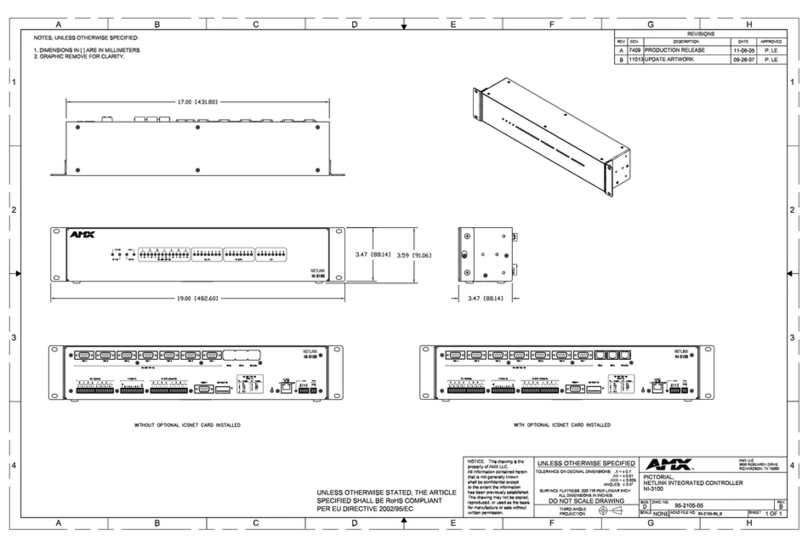

To wire the True Cut 2000 for operation, open the lid of the enclosure to access the circuit board. Complete

the following field connections, referencing Figure 5 for terminal block locations.

Section 3: Installation

13

Figure 5: True Cut 2000 circuit board terminal block layout

1. Unscrew the cover of the enclosure counter-clockwise until it separates from the main body of the

enclosure.

2. Using a small standard blade screwdriver, remove the two #4-40 x 7/8-in. screws located to the right and

left side of the display.

3. Lift the display/ keypad assembly from the enclosure, making sure the circuit assembly does not contact

the enclosure.

4. Connect external power wiring to terminal block TB2, follow the below section of External DC Power

Supply. Refer to Grounding Procedure, for proper grounding practices.

5. Connect Turbine Input wiring to terminal block TB1, follow the below section of Turbine Input.

6. Connect any communication devices wiring to terminal block TB1, follow the below section of

Communication.

7. Place the circuit assembly over the standoffs and fasten with two #4-40 x 7/8-in. screws ensuing that all

connector wiring is inside the enclosure and in no position where it may be damaged when the enclosure

cover is replaced.

8. Replace the enclosure cover by threading it onto the enclosure in a clockwise direction.

GROUNDING PROCEDURES

To power the True Cut 2000 Sampler Controller with an external DC supply, route the ground conductor

through a conduit opening in the top of the True Cut 2000 enclosure with the power conductors and connect

it to the ground screw inside the enclosure (note the round sticker that marks this location).

If national or local electrical codes required the enclosure to be grounded, a protective earth grounding

conductor may be required. To install a protective earth ground, connect an earth ground conductor to the

stainless ground lug near the top of the True Cut 2000 enclosure, or if LGS-2000 system is installed, the

earth ground conductor may be connected to the ground lug at the bottom of the system mounting plate.

Connect the other end of the ground conductor to a ground rod or other suitable system earth ground. The

ground lugs will accept wire sizes from 14 AWG solid conductor to 4 AWG stranded conductor.

True Cut 2000 Sampler Controller

14

Figure 6: Internal ground screw location

EXTERNAL DC POWER SUPPLY

The True Cut 2000 Sampler Controller can be connected to a customer-supplied 6-30V DC power supply by

a two-conductor cable. If the controller is installed in a hazardous area, follow the instruction under the

Hazardous Area Installations Instruction.

The external power supply must be an approved SELV source, insulated from the AC main by double/

reinforced insulation per CSA C22.2 No. 61010-1-04/ UL 61010-1 –2nd Edition.

Note

In all applications using an external power supply, a switch or circuit

breaker must be included in the safe area external power supply

installation within easy reach of the operator. The switch or circuit

breaker must be marked as the “disconnect” for the safe area external

power supply.

Note

If the main circuit board is marked with a revision level of 02 or older

(revision 01, C, B or A), a Zener diode (Part No. 1.5KE33CA) must be

installed for CE approval. The Zener diode is not required for revision 03

and newer circuit board.

Section 3: Installation

15

Figure 7: External DC Power wiring diagram

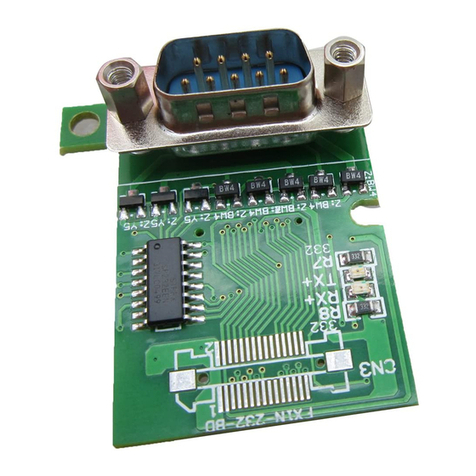

COMMUNICATIONS

Two RS-485 communication ports (COM1 and COM2) are available for use with any device that is capable of

reading Modbus data.

Communications connections are not required for basic operation of the controller.

Figure 8: RS-485 communications wiring diagram

TURBINE INPUT

The flowmeter input can be provided by the magnetic pickup of a turbine flowmeter. This input enables the

True Cut 2000 to calculate and display flow rates and accumulated totals. The controller can detect a

magnetic pickup signal in the range of 20 mV to 3000 mV, peak to peak. Only turbine meters that meet the

required entity parameters may be used with this input.

True Cut 2000 Sampler Controller

16

Figure 9: Turbine flowmeter input wiring diagram

DIGITAL OUTPUT (SOLID STATE RELAY)

Digital Output is used to drive the external low power solenoid based on the True Cut 2000 Sampler

Controller configuration.

The rating of the Digital Output circuit is 30V DC at 60mA max.

Figure 10: Digital Output wiring diagram, Solid State Relay with 30V DC @60mA max. rating

Note

Before operating the controller for the first time, carefully review the

configuration instruction of the controller using the keypad on the

overlay.

Section 4: Operating the Controller

17

Section 4: Operating the Controller

FRONT PANEL

The front panel of the controller contains a Liquid Crystal Display (LCD) with a dual readout and a 6-button

keypad for configuring the controller and retrieving data. During operation, the LCD displays the sample

count for the current sampling period, as shown in Figure 11.

From the front keypad, the operator can change the operating mode, stop a sampling period, start a

sampling period, change the sampling configuration settings, initiate a test of the sampling process, and

display performance and job status indicators on demand.

This section describes each of these functions except for changing configuration settings. See Section 5, for

configuration instructions.

Figure 11: Liquid Crystal display and keypad with the overlay

KEYPAD OVERVIEW

Before programming or operating the sampler for the first time, review this section to familiarize yourself with

the functions of each key.

•MODE—allows the operator to manually control the start and stop of a sampling period.

•RESET—starts a new sampling period using the settings last configured. This function is enabled

only when the controller is in “Stop” mode.

•SAMPLE SETUP—provides access to configurable settings for controlling the sampling process,see

section 5 for step-by-step configuration instructions.

•LEFTARROW/ DISPLAY—during normal operation, initiates the scrolling display of status

parameters and volumes, see Table 1 for details; during configuration, allows user to select a digit to

be changed

•UPARROW/ TEST—during normal operation, initiates a test of the sampling process; during

configuration, increments the value of a selected digit.

•ENTER/SAVE—during configuration, saves each setting entered and advances the display to the

next required configurable parameter.

True Cut 2000 Sampler Controller

18

•External Reset Control Switch—provides 3 different functions based on the hold time.

o0.3 second—scroll through next parameter on display

o5.0 seconds—one button quick RESET and START sampling function if the

Sampler Controller is in Stop or Idle mode

o10 seconds—if the system is running, it will issue a STOP Command; if the system is in

STOP mode, it will resume running

COMMON KEYPAD FUNCTIONS

The following information explains how to perform some common tasks with the controller keypad. For step

by step instructions for configuring a sampling job, see Section 5.

STOP A SAMPLING PERIOD

To terminate a sampling period, press MODE and press UP ARROW/ TEST to navigate to “Stop” mode.

Then press ENTER.

START A SAMPLING PERIOD

To initiate a new sampling period, press MODE and press UP ARROW/ TEST to navigate to “Start” mode.

Then press ENTER.

Alternatively, if the controller is in “Stop” mode, press RESET to start a new sampling period using the

settings last configured. Pressing RESET automatically changes the mode to “Start.” (If the controller is set

to a mode other than “Stop” before pressing RESET, a new sampling period will not be created. In this case,

RESET will have no effect on the sampling job.)

PAUSE AND RESUME SAMPLING WITHOUT STARTING A NEW SAMPLING PERIOD

To resume sampling after putting the controller in “Stop” mode without zeroing the sample count, press

MODE, press UP ARROW/ TEST to select “Continue” and press ENTER. This is ideal for pausing the

sampling process just long enough to change the frequency or volume setting (for example, to expedite

completion of the sampling period).

DISPLAY STATUS INDICATORS ON DEMAND

During normal operation, press UP ARROW/ TEST to initiate a scrolling display of status parameters and

volumes, see Table 1 for details. After several seconds, the display will revert to the normal operating

screen.

TEST THE CONTROLLER

During normal operation, press UP ARROW/TEST to initiate a test of the sampling configuration.

ON-DEMAND DISPLAY OF STATUS INDICATORS AND VOLUMES

During normal operation, the operator can initiate a scrolling display of performance and job status indicators

by pressing LEFT ARROW/ DISPLAY. The parameters displayed can vary, depending on the type of

sampling programmed. Table 1 lists all supported indicators, and indicates which parameters are available

for each sampling configuration. The last two columns of the table show the content of top and bottom

readouts associated with each parameter.

Table 1: Status Indicators

Indicator

Time/

Batch

Volume:

TFM

Continuous

Test

Text Displayed in Readouts

Section 4: Operating the Controller

19

RUN TIME

Yes

Yes

Yes

Yes

TOP

BOTTOM

0.000

RUN TIME -DAYS

PERCENT

DONE

Yes

Yes

No

No

TOP

BOTTOM

0.00 PERCENT

DONE

FLOW RATE

No

Yes

No

No

TOP

BOTTOM

0.00 (GAL)

FLOW RATE (/SEC)

TOTAL

VOLUME

No

Yes

No

No

TOP

BOTTOM

0.000 (GAL)

TOTAL VOLUME

GRAND TOTAL

VOLUME

No

Yes

No

No

TOP

BOTTOM

0.00 (GAL)

GRAND TOTAL

SYSTEM

VOLTAGE

Yes

Yes

Yes

Yes

TOP

BOTTOM

6.656

SYSTEM VOLTAGE

SAMPLER

STATUS

Yes

Yes

Yes

Yes

TOP

BOTTOM

RUNNING

SAMPLER STATUS

FIRMWARE

VERSION

Yes

Yes

Yes

Yes

TOP

BOTTOM

3.00

TRUE CUT2000

SAMPLES

TAKEN

Yes

Yes

Yes

Yes

TOP

BOTTOM

0

SAMPLE TAKEN

RUN TIME

Run Time displays the length of time (number of days) the sampler has been in operation during the existing

sampling period. The run time value is zeroed each time a new sampling period is started.

PERCENT DONE

Percent Done displays the percentage of a sampling job that is completed at any point in time. This indicator

is not available for Continuous Time sampling since the total samples required is not entered or calculated.

FLOW RATE

Flow Rate displays the rate of flow sensed by the input device based on the K-factor entered. The controller

displays the flow rate in terms of flow per second, per minute, per hour or per day.

TOTAL VOLUME

Total Volume is the volume of pipe flow sensed by the input device (TFM frequency input) during a volume-

based sampling period. The controller calculates and displays pipe flow volume totals in gallons, barrels,

cubic meters, litres, or standard cubic feet. If a different unit is required, a “none” option is also available in

the controller. Volume is updated once per second. Both volume per sampling period (total volume) and total

accumulated volume (grand total volume) are stored in the controller.

Total volume is cleared each time a new sampling period is started.

GRAND TOTAL VOLUME

Grand Total Volume is the total accumulated volume of pipe flow. Unlike total volume, which is zeroed each

time a new sampling period begins; the grand total volume is zeroed only when performing a manual reset.

SYSTEM VOLTAGE

System Voltage displays the DC voltage generated by either the battery or an external power supply after

power is regulated internally.

SAMPLER STATUS

Sampler Status indicates the status of sampler operation. When the sampler is in operation (controller is

placed in “Start” or “Continue” mode), the status will display as “Running.” When performing a test of the

sampler (UPARROW/ TEST), status will display as “Test.” When sampling is manually terminated (controller

True Cut 2000 Sampler Controller

20

placed in “Stop” mode), status will display as “Stop.” When a sample period has ended, status will display as

“Done.”

FIRMWARE VERSION

It may be helpful to confirm the firmware version if a question arises about the operation of the device. Over

time, multiple firmware versions may be released with varying functionality.

SAMPLES TAKEN

Samples taken during the current sampling period.

Table of contents

Other Sensia Controllers manuals

Popular Controllers manuals by other brands

Intellian

Intellian Intelligent Mediator Installation and operation user guide

CAL Controls

CAL Controls CALogix installation instructions

Siemens

Siemens ACVATIX SAX319.03 manual

Fisher

Fisher 1078 instruction manual

Verasys

Verasys VEC100 quick start guide

Linear Technology

Linear Technology LTM4613 Demo Manual