High Voltage DTS-60A User manual

DTS-60A

Dielectric Oil Test Set

Operator’s Manual

Version 1.20

HighVoltage

INC

.

DTS-60A OPERATORS MANUAL

All rights reserved. Total or partial reproduction of this manual, whether by printed or

electronic means, is forbidden. Information regarding any errors found in it or suggestions

concerning improvement are appreciated. Since products are subject to continuous check

and improvement, High Voltage inc. reserves the right to make changes in information

contained in this manual without prior notification.

Manual Revision 07/03/2008 Version 1.20

Copyright 2005 High Voltage inc. – USA

HIGH VOLTAGE, INC.

31 County Route 7A

Copake, N.Y. 12516

Phone : 518/329-3275

Fax : 518/329-3271

Web :

http://www.hvinc.com

e-mail: [email protected]

DTS-60A OPERATORS MANUAL

DTS-60A OPERATORS MANUAL

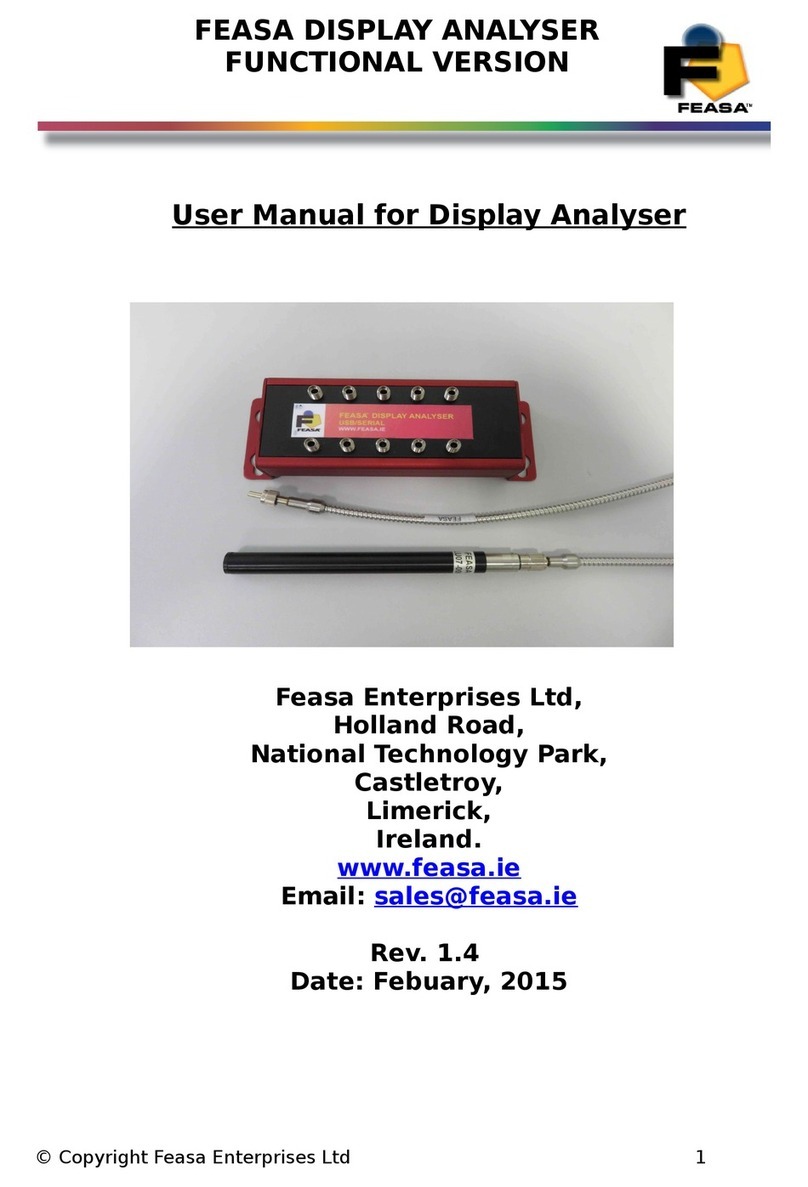

Icons & Notation

This icon indicates danger conditions!

Danger!

This icon indicates warnings!

Warning!

This icon indicates a hint or a tip!

Note!

DTS-60A OPERATORS MANUAL

DTS-60A OPERATORS MANUAL

This Operator manual contains instructions

for the operation of a High Voltage power

source. The operator of this equipment must

use good judgement and follow all safety

precautions noted in this guide to ensure the

protection of himself and others in close

proximity to the test area. Failure to follow

the instruction could result in injury or

death.

Proper grounding of the test set must be

done prior to connecting this unit to a power

source.

DTS-60A OPERATORS MANUAL

DTS-60A OPERATORS MANUAL

Table of Contents

1. Specifications and Controls

1. Features and Specifications

2. ControlPanel

3. User Interface

1. MenuOverview

2. KeyboardOperations

3. Warning Messages

4. QuestionMessages

5. ErrorMessages

6. Indicators

4. Setup the Equipment

5. Using the Shielded Output Cables

6. Startup the Equipment

2. Menu/ Submenus and Settings

1.

Main Menu Overview

2. MainMenu

3. ProgramsSubmenu

4. SettingsSubmenu

1. Time/DateSetup

2. OperatorSetup

3. LCDContrastSetup

4. LanguageSetup

5. RegionSetup

3. SimpleTest

1. SimpleTestOperations

2. Simple Test Initialization

3. Simple Test Execution

4. SimpleTestTermination

5. SimpleTestExample

4. StandardTests

1. StandardTestDescription

2. SelectaStandardTest

3. StandardTestExecution

4. StandardTestExample

DTS-60A OPERATORS MANUAL

5. UserDefinedTests

1. TestDescription

1. TestStructure

2. TestOperations

2. TestMenu

1. SelectTest

2. CreateTest

3. EditTest

4. DeleteTest

3. Script Files for Tests

1. Script File Commands and Arguments

2. ScriptFileTestExample

6. History and Results

1. +++

2. +++

7. PrinterandPrintouts

1. PrinterDescription

2. ChangingthePaperRoll

3. PrintoutDescription

8. RemoteOperation

1. Enable the Remote Operation

2. VerCommand

3. clsCommand

4. timeCommand

5. dateCommand

6. operatorCommand

7. contrastCommand

8. program Command

1. program list Command

2. program read Command

3. program delete Command

4. program download Command

9. historyCommand

CareandMaintenance

Appendix I Standard Test Script Files

Appendix II Firmware Upgrade Procedure

Acronyms&Abbreviations

Index

DTS-60A OPERATORS MANUAL

1

1

Specifications and Controls

This section familiarizes the operator with the features and the

specifications of the DTS-60A AC Dielectric Oil Test Set manufactured

by High Voltage, inc. Moreover, a brief introduction about the

equipment’s set-up and start-up is presented.

1. Features and Specifications 1-2

2. Control Panel

1-4

3. User Interface

1-5

1. Menu Overview 1-5

2. Keyboard Operations 1-6

3. Warning Messages 1-8

4. Question Messages 1-10

5. Error Messages 1-12

6. Indicators 1-13

4. Setup the Equipment

1-14

5. Using the Shielded Output Cables 1-15

6. Startup the Equipment

1-16

DTS-60A OPERATORS MANUAL

2

1.1 Features and Specifications

The DTS-60A AC Dielectric Oil Test Set provides automatic,

programmable and accurate measurement of breakdown voltage for

insulating oils used in high-voltage electrical equipment.

Main features of the DTS-60A Series of AC Dielectric Oil Test Set

User Interface

Dot Matrix Liquid Crystal Display (128x64)

Compact 5-key keyboard for operation

User friendly, menu driven functionalities

Large Output Voltage Digits (3.1 digits)

Functionalities

Test-Result report

Real-Time clock

Ambient Temperature measurement

International Standard Tests

User defined Tests

Test-Results storage

Language selection

Measurements and Control

High accuracy of High Voltage measurement (0.5%)

Digitally selected Voltage rate of rise (0.1kV/s step)

Arc detection with less than 5 milliseconds shutdown

Digital Closed-Loop for voltage control

Equipment Case

Rugged aluminum case

Window for observation of oil test

DTS-60A OPERATORS MANUAL

3

Table 1.1 - Specifications

DTS – 60A

Input 120V, 50/60 Hz, 5 amps, single phase

230V, 50/60 Hz, 3 amps, single phase

Output 0 – 60kVac, 800VA resistive load, between bushings

Output Termination Dual Capacitively Graded Bushings

Display Dot-Matrix 128x64

Keyboard 5 keys for equipment’s functionalities

Printer Optional 40 columns dot-matrix

Remote Management RS-232 Serial Interface

Breakdown Shutdown Less than 5 ms

Accuracy 0.5%

Operating

Temperature -14 F to 104 F (-10 C to 40 C)

Case Size 14.75w x 14d x 11.5h in (36.88w x 35d x 28.75h mm)

H.V. Tank High Voltage Tank Included

Weight 60 lbs.

DTS-60A OPERATORS MANUAL

4

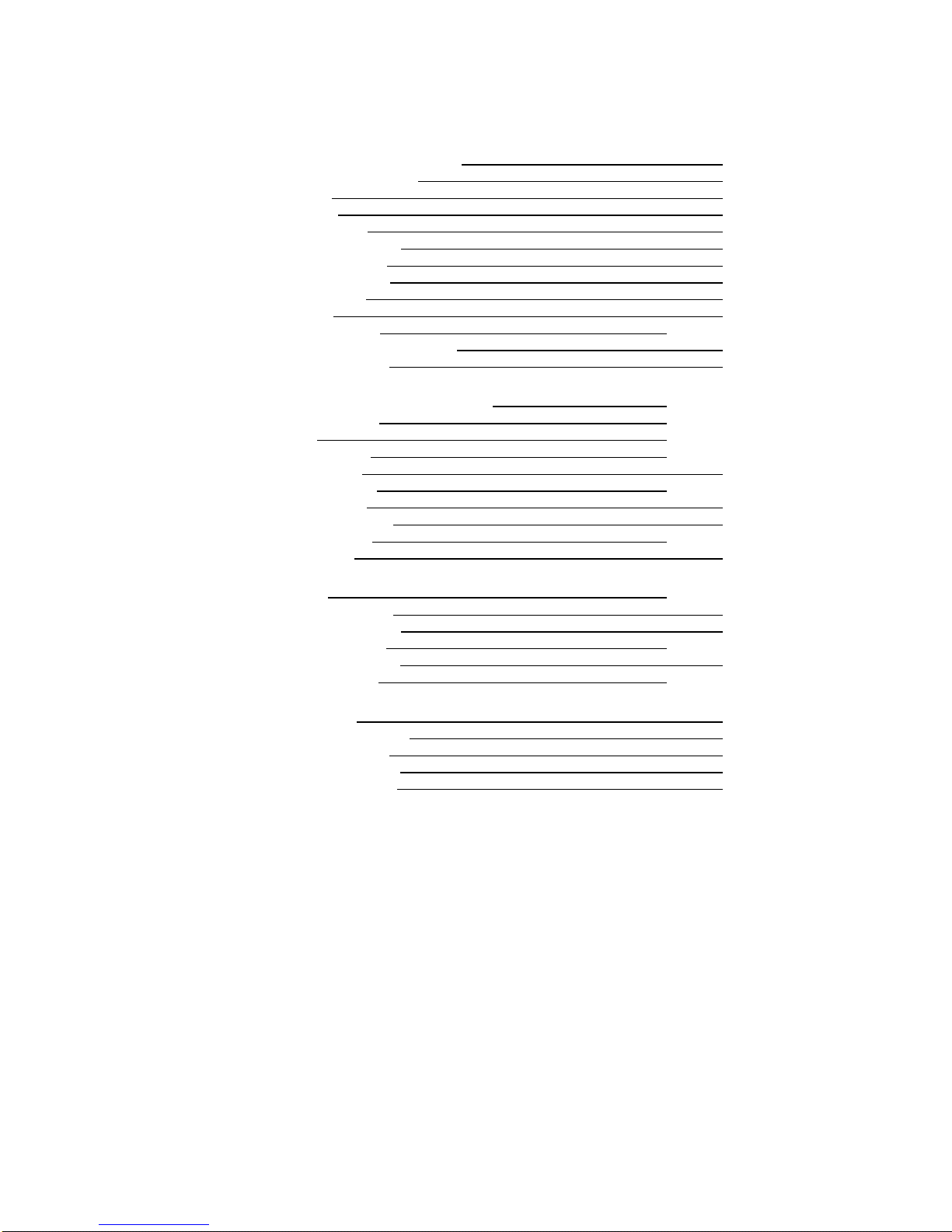

1.2 Control Panel

The equipment’s Control Panel is depicted in Figure 1.1. It

consists of the following:

Input Power

The Input Power connector accepts most standard

electrical equipment type cords. The power supplied to

the input connector must be from a grounded source

rated to match the input power specifications noted in

Table 1.1.

Main Power

The Main Power switch provides the power to the

control and power circuits. The neon lamp will light

when the power is on and the voltage is available

through the input line cord. The Input Power Fuse

located electrically before the Main Power switch

provides line fault protection for the unit.

Fuse Socket

LCD display

The Liquid Crystal Display guides the user to the

system’s functionalities.

Keyboard

Compact 5-key keyboard for equipment operation.

Figure 1.1 – DTS-60A Control Panel

DTS-60A OPERATORS MANUAL

5

1.3 User Interface

The equipment User Interface is based on a dot-matrix Liquid

Crystal display (LCD) and a compact 5-key keyboard, Figure 1.2. The

user-friendly graphical interface makes the equipment's operation

simple and attractive.

Figure 1.2 – Equipments User Interface

1.3.1 Menu Overview

The equipment operation is based on a user friendly structure of

menu/ submenu driven functions. An overview of the menu/

submenu selections is summarized in Figure 1.3.

Figure 1.3 – Equipment's User Interface

MENU

TESTS

SETTINGS

TEST HISTORY

REMOTE OPERATION

TESTS

SELECT

CREATE

EDIT

DELETE

SETTINGS

TIME/DATE

OPERATOR

LCD CONTRAST

LANGUAGE

TEST HISTORY APP

REMOTE OPERATION APP

SELECT TEST APP

CREATE TEST APP

EDIT TEST APP

DELETE TEST APP

SETUP TIME/DATE APP

SETUP OPERATOR APP

SETUP LCD CONT. APP

SETUP LANGUAGE APP

REGION SETUP REGION APP

DTS-60A OPERATORS MANUAL

6

1.3.2 Keyboard Operations

Although most of the keyboard operations are based on similar

methods, there are some cases where an optional key functionality is

enabled. These exceptions are described analytically in the

respective manual paragraphs.

The most common keyboard operations are the following:

Menu and Submenu Operations

MENU Enter to the Menu or Selected Submenu

BACK Exit from Menu or Current Submenu

UP Go to the previous selection

DOWN Go to the next selection

ENTER Enter to the selection

Simple Test Operations

MENU Enter to the Menu or Selected Submenu

BACK Enable/ Disable Stirrer

UP Increase Voltage Rate of Rise

DOWN Decrease Voltage Rate of Rise

ENTER Execute Test

ANY After Starting the Test ANY key interrupts the

process

Number Edit Operations

MENU -

BACK Discard changes and return

UP Increase the current value

DOWN Decrease the current value

ENTER Enter the value

String Edit Operations

MENU Select Capitals, Smalls, Numbers, Symbols

BACK Delete Character

UP Select previous character

DOWN Select next character

ENTER Enter the string

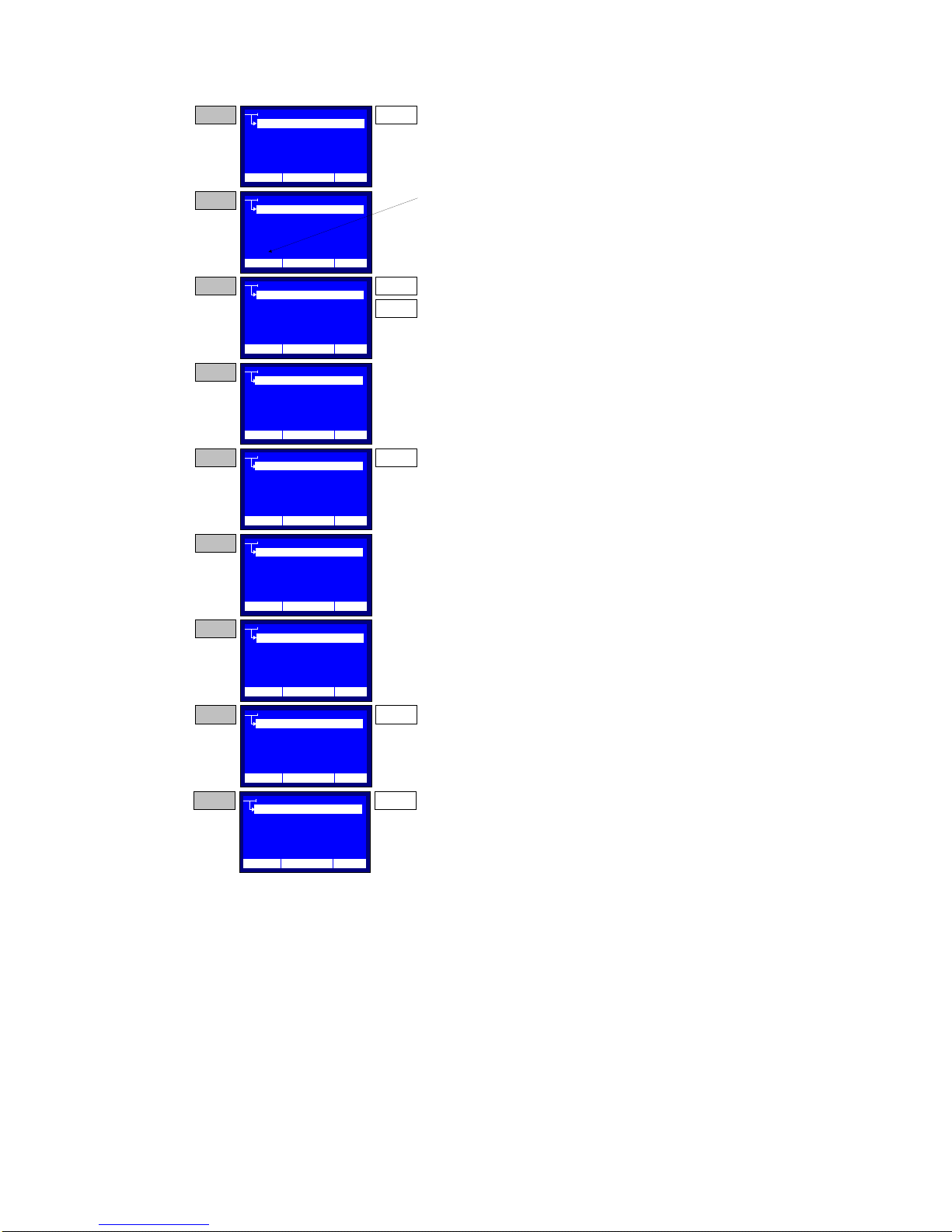

A detailed example follows, Figure 1.4, in order to clarify the

String Edit keyboard operation. The example refers to a string entry

for the Name of the Operator Setup menu (see paragraph 2.3.2).

DTS-60A OPERATORS MANUAL

7

Figure 1.4 – String Entry Keyboard Operation

OPERATOR

12:10 01/08/04 25 C

NAME

COMPANY

CONTACT INFO

OTHER INFO

Press the ENTER key in order to enable the String

Entry keyboard operation for the Name

OPERATOR

CONTACT INFO

OTHER INFO

_

STEP 1

The String Entry Cursor is displayed. This

indicates the current possition of the editable

character.

OPERATOR

CONTACT INFO

OTHER INFO

O

Use the UP and DOWN keys to select the desired

character. Dont leave more than 2 seconds

between key pressings. After every UP key

pressing the next character of the alphabet will be

displayed. In contrast, after every DOWN key

pressing the previous character of the alphabet will

be displayed. The character sequency is circular.

OPERATOR

CONTACT INFO

OTHER INFO

O_

Stop pressing the UP and DOWN keys for more

than 2 seconds. The character will be entered and

the cursor will be displayed in the next possition.

STEP 2

STEP 3

STEP 4

ENTER

UP

DOWN

OPERATOR

CONTACT INFO

OTHER INFO

_

A mistake occured! Press the BACK Key in order

to delete the last entried character.

OPERATOR

CONTACT INFO

OTHER INFO

P_

Select the correct character according STEP 3

instructions. Then wait 2 seconds, until the cursor

is displayed at the next possition.

OPERATOR

CONTACT INFO

OTHER INFO

PETER_

Repeat the character entry operation for the whole

string.

OPERATOR

CONTACT INFO

OTHER INFO

PETER_0

Press the MENU key twice, in order to enter

numbers in the string.

STEP 5

STEP 6

STEP 7

STEP 8

BACK

MENU

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

NAME

NAME

NAME

NAME

NAME

NAME

NAME

12:10 01/08/04 25 C

12:10 01/08/04 25 C

12:10 01/08/04 25 C

12:10 01/08/04 25 C

12:10 01/08/04 25 C

12:10 01/08/04 25 C

12:10 01/08/04 25 C

OPERATOR

CONTACT INFO

OTHER INFO

PETER_007

Press the ENTER key in order to enter the edited

sting and return.

STEP 9 ENTER

COMPANY

NAME

12:10 01/08/04 25 C

DTS-60A OPERATORS MANUAL

8

1.3.3 Warning Messages

Display shows Warning Messages in the following cases.

1. Lid is Open, Figure 1.5.

This warning message is displayed when the Lid of the

equipment is open and a test procedure is enabled. The

current operation (i.e. test execution) will be restarted when

the lid will close.

Warning Message

PROGRAM : ASTM-D1816

12:10 01/08/05 65 °F

Lid is Open

DURATION: 00:00:00

SYSTEM HALTED...

Figure 1.5 – ‘Lid is open' Warning Message

If the Warning Message “Lid is Open” is

depicted when the Lid is closed, contact

the distributor or the manufacturer.

DTS-60A OPERATORS MANUAL

9

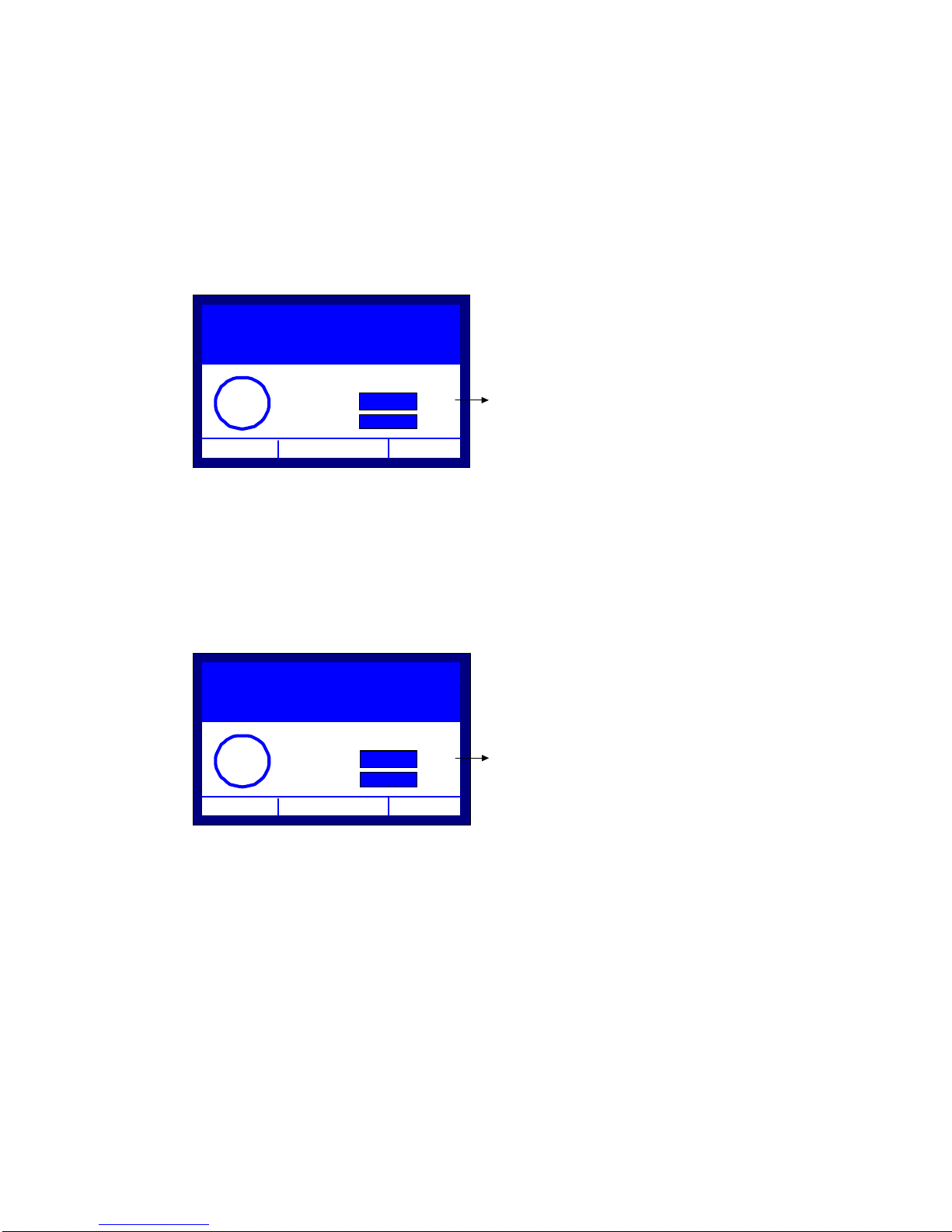

2. Verify Electrode/Gap Spacing, Figure 1.6a/b.

This warning message is displayed at the startup of every

test procedure, in order to remind the user to check the

electrodes type and spacing, according to the selected test.

If the selected test is a standard one (where the spacing

and the type of the electrodes is specific) the message will

inform the user for the appropriate settings (type, spacing),

Figure 1.6a. The user may release the system by pressing

the ‘ENTER’ key.

Warning Message

PROGRAM : ASTM-D1816

12:10 01/08/05 65 °F

Electrodes:

Space: 0.04±0.0010in

DURATION: 00:00:00

SYSTEM HALTED...

Figure 1.6a – ’Electrodes/ Space’ Warning Message

If the selected test is the Simple Test (where the

spacing and the type of the electrodes is not specific) the

message will prompt the user for verification of the desired

electrode type and spacing, Figure 1.6b. The user may

proceed by pressing the ‘ENTER’ key.

Warning Message

PROGRAM: SIMPLE TEST

12:10 01/08/05 65 °F

Verify Electrodes &

Gap Spacing

VOLTAGE: 0.5 kV/s

DURATION: 00:00:00

Figure 1.6b – Verify Electrode/Gap Spacing’ Warning Message

DTS-60A OPERATORS MANUAL

10

1.3.4 Question Messages

The unit may display the following Question Messages.

1. Continue Test?, Figure 1.7.

This question message is displayed after a breakdown

detection in the Simple Test procedure. The system

prompts the user for continuing the current test with a new

stage, or terminating the test. User may press the ‘ENTER’

key for continuing the test, or the ‘BACK’ key for

terminating the test. All other keys are disabled.

Question Message

PROGRAM: SIMPLE TEST

12:10 01/08/05 65 °F

Continue Test?

Yes:

No:

VOLTAGE: 0.5 kV/s

DURATION: 00:00:30

?

ENTER

BACK

Figure 1.7 – ‘Continue Test?’ Question Message

2. Print Results?, Figure 1.8.

This question message is displayed only if the equipment

has a printer. The message prompts the user for printing

the test report after a test is finished. User may press the

‘ENTER’ key for printing the test report, or the ‘BACK’ key

for discarding the printing. All other keys are disabled.

Question Message

PROGRAM: SIMPLE TEST

12:10 01/08/05 65 °F

Print Results?

Yes:

No:

VOLTAGE: 0.5 kV/s

DURATION: 00:00:30

?

ENTER

BACK

Figure 1.8 – ‘Print Results?’ Question Message

Other manuals for DTS-60A

1

Table of contents

Other High Voltage Test Equipment manuals

Popular Test Equipment manuals by other brands

Bosch

Bosch MTS 6513 user manual

Fluke

Fluke 5522A Operators Operator's manual

IDEAL

IDEAL LinkMaster PRO XL instructions

Static Solutions

Static Solutions OHM-STAT CT-8900 Owners manual and operation guide

Leslie's

Leslie's AccuBlue Home quick start

Sartorius Stedim Biotech

Sartorius Stedim Biotech 16756 operating instructions