English

User manual

3

CONTENT

INTRODUCTION....................................................................................................................................................4

1. APPLICATION....................................................................................................................................................4

2. SPECIFICATIONS..............................................................................................................................................4

3. EQUIPMENT SET ..............................................................................................................................................5

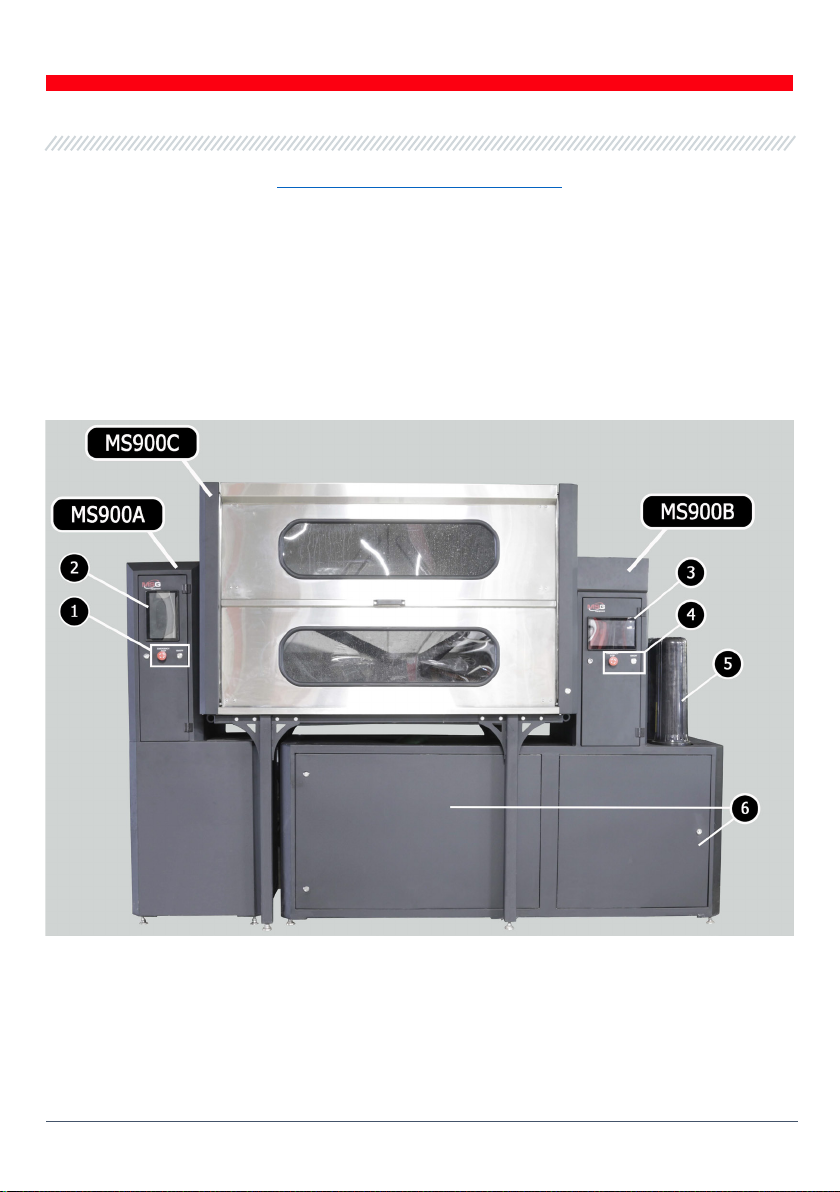

4. STAND DESCRIPTION ....................................................................................................................................6

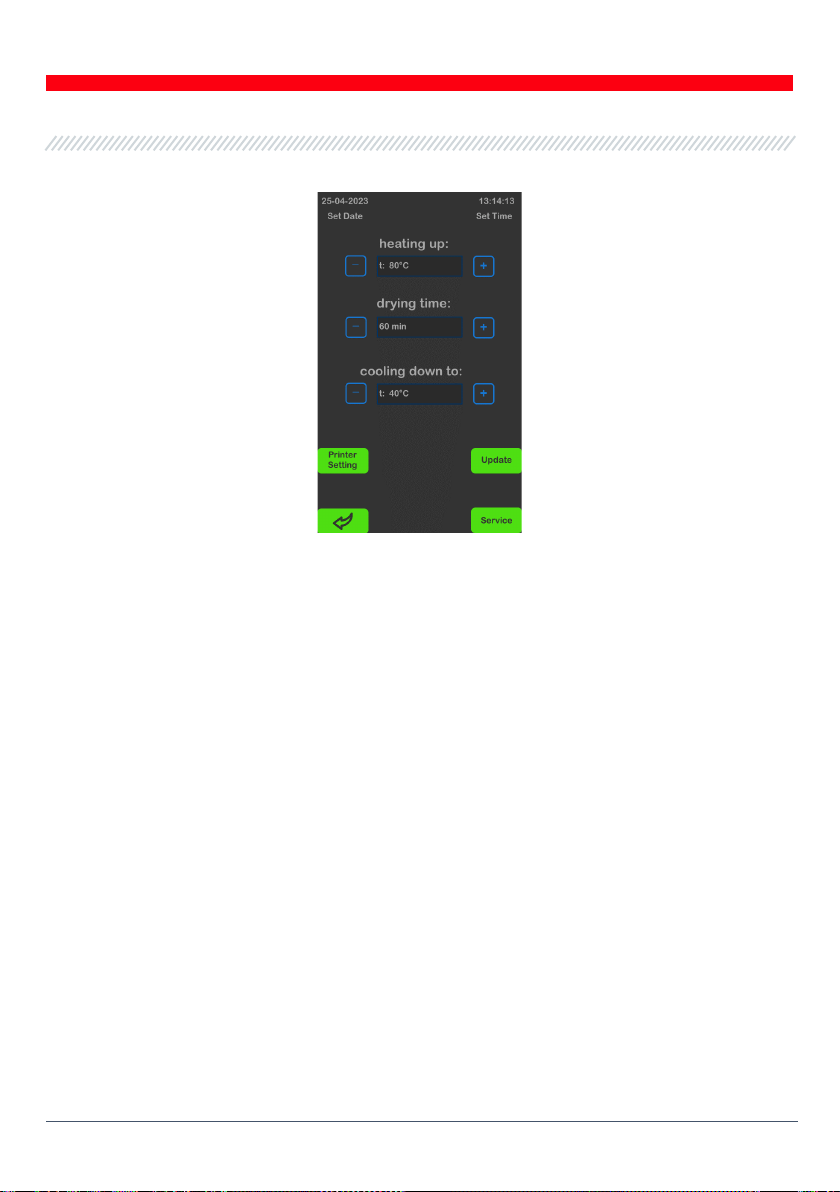

4.1. MS900A module control menu ............................................................................................................7

4.2. MS900B module control menu ......................................................................................................... 11

5. INTENDED USE ..............................................................................................................................................13

5.1. Safety Guidelines...................................................................................................................................14

5.2. Stand installation and preparation for operation .......................................................................14

6. FILTER CLEANING .........................................................................................................................................15

7. STAND MAINTENANCE..................................................................................................................................18

7.1. Replacement of the three polypropylene filters ..........................................................................18

7.2. Cleaning the hydrocyclone..................................................................................................................18

7.3. Checking and cleaning the three-way valve ................................................................................. 20

7.4. Replacement of the blower air filter................................................................................................22

7.5. Water tank replacement......................................................................................................................23

7.5.1. Draining water from the tank without activating the pump ............................................23

7.6. Software update ................................................................................................................................... 24

8. TROUBLESHOOTING GUIDE ........................................................................................................................25

9. RECYCLING.....................................................................................................................................................27

CONTACTS.......................................................................................................................................................... 28