High Voltage VLF-CM Series Guide

Safety,Operation,andProcedureInstructionsfortheVLFSeriesof

ACHipots

Danger- Lethal Voltages:

Equipment to be used by trained personnel only

This Operator Manual contains instructions for the operation of a High Voltage power source. The operator of this equipment

must use good judgement and follow all safety precautions noted in this guide to ensure the protection of himself and others in

closeproximitytothetest area. Failure to follow the instructions could result in injury

or death. Proper grounding of the test set must be done prior to

connecting this unit to a powersource.

Mine

VLF-CM

SERIES

Please Refer to

Documentation

Before Operation

Last saved 5/15/2018

T:\DOCUMENTS\Manuals\VLF\MANvlfCM_Rm_2k18.doc

VeryLowFrequency(VLF)ACHighVoltageTesting-OperatorsManualAddendum

Instrument Summary

This instrument is a Very Low Frequency AC high voltage test system – a VLF hipot. It is an AC hipot whose frequency

output is 0.1 Hz or lower, compared to the 50/60 Hz of a conventional AC hipot. The lower the frequency, the lower the

current and power it takes to test a capacitive load like a cable. At 0.1Hz, it takes 600 times less current and power,

compared to 60Hz, to apply an AC voltage to a cable or some other high capacitance load.

At 0.1Hz frequency output, one full cycle of the sine wave takes 10 seconds, 20 seconds at 0.05Hz, and 50 seconds at

0.02Hz. Even though each cycle of the waveform can take 10 seconds or longer, it is still alternating current – AC – and is

sinusoidal.

This is not a DC hipot and it does not operate in the same manner. When the voltage output is raised, the voltage will

climb to its peak and then descend back to zero. The output polarity of the set reverses (a solenoid switch can be heard)

and then climbs again in the opposite polarity. This rise and fall of the voltage is obvious on the voltmeter and is normal.

The current meter will also rise and fall as the cable charges and discharges every half cycle. Unlike DC, there are no

leakage currents to read. This is a go/no-go, or pass/fail, AC stress test. The load under test either withstands the test

voltage and passes, or it breaks down and fails.

Important note: Use the VLF test set properly. Test at the proper test voltage and time duration. Abbreviated tests or

tests at reduced voltage levels should not be performed. An improper test may aggravate cable defects that may cause

cable failure later in service.The proper test voltage and time duration are essential to allow the VLF to do its job.

Helpful Notes to Users

Peak Voltage: The Voltmeter on the VLF test set measures the Peak voltage. It is the peak output voltage that is used

during VLF testing. If your test specification indicates a test voltage in RMS, multiply by 1.414 to obtain the peak value for

the test. The IEEE400.2 chart indicating test voltages for different cable ratings shows both rms and peak. All other AC

hipoting using 50/60 Hz instruments is measured by the rms voltage, not VLF testing, so make sure this issue is

addressed.

Output Frequency: All VLF sets are rated by the uF of load they can test at a given frequency. The lower the frequency,

the higher the capacitance, or the longer the cable, can be tested. Always use the highest frequency possible. Testing

should be performed at 0.1Hz, unless the capacitance of the load is too high for the uF rating of the set at 0.1 Hz. It may

be necessary to reduce the frequency to 0.05, 0.02, or 0.01 Hz depending on the capacitance of the load. The load

capacitance can be measured using the capacitance meter of the VLF or be calculated, if the capacitance per foot or

meter is known. Example: At 0.1Hz, 1 – 2 miles of cable can be tested, depending on size.

Test Duration: The recommended test duration is 30 minutes as a minimum. In the body of this manual are reprints from

the IEEE400.2 standard discussing this issue and additional information on the subject. The longer the test duration the

better, as minor defects that triggered into partial discharge due to the test voltage will have time to grow through to failure

during the test. The duration indicated in the standard is based on using a frequency of 0.1Hz. If lower frequencies are

used, the test time must be extended. Rather than 30+ minutes at 0.1Hz, perhaps 60 minutes should be used at 0.05 and

0.02Hz.

Cable Failure Indication: When the cable fails, the thermal Overload on the front panel will pop up. Also, the Voltage and

Current meters will read erratically as the cable arcs. It may take several cycles of the voltage rising to the arc-over

voltage of the fault to cause the thermal overload to warm up enough to trip.

Use a Sinusoidal AC source (generator, inverter, line power) or your VLF may not reach full output.

Know YourTest Equipment – Read the Operators Manual

Last saved 5/15/2018

T:\DOCUMENTS\Manuals\VLF\MANvlfCM_Rm_2k18.doc

TableofContents

About the Operator Manual 1

SECTION 1

General Information 2

Features and Specifications 2-6

Controls and Indicators 7-10

List of Components 11

SECTION 2

Setting up the Equipment 12,13

Typical VLF Connection Scheme 14

VLF withCable Reel Connection Scheme 15

Operating the Equipment 14-19

VLF Cable Testing Recommendations 20,21

Blank Page for Notes 22

SECTION 3

Performing Special Operations 23

Voltmeter Re-calibration 23,24

Miscellaneous 25

Weekly Maintenance 25

Yearly Maintenance 25

Return Material 26

Warranty 27

OPERATOR MANUAL

- 1 -

AbouttheOperatorManual

Important

This Operator Manual describes the features and safe operation of a High

VoltageACTest Set. The instructions are intended to be clear and simple,

but the operator must be trained and qualified according to the customer’s

established procedures for the use of this type of equipment.

This Operator Manual is organized to provide information on the VLF Series in steps that familiarize the new

operatorwith the entirescope ofoperationof thistestset.

Section 1:SpecificationsandControls.

Section2:SetupandOperation.

Section 3:PerformingSpecialOperations.

TheFunctions,Features,andSpecifications oftheVLFSeriesofACHipotsarealsodiscussedintheVLFBrochure

availablefromHighVoltage,Inc.

OPERATOR MANUAL

- 2 -

GeneralInformation

Thissectionfamiliarizestheoperatorwiththefeaturesandspecificationsof the

VLF Series ofPortable AC Hipots manufacturedbyHIGH VOLTAGE, INC.

FeaturesandSpecifications

The VLF Series of hipot test sets provide true sine wave AC output voltage for the test of high voltage

cablesandothercapacitive loads.

Standard featuresof theVLFSeries ofAC Hipots

•Sinewaveoutput,0.1,0.05 and 0.02Hzfrequenciesstandard.

•Continuouslyadjustable outputvoltage

•Continuous dutyrating

•Fixedthermal circuit breakeroverload

•“ZeroStart”and ExternalInterlock provision

•Single-range voltmeter

•Single-range Current/Capacitance meter

•Two piece portabledesign

•Transitprotectedmeterpreventsdamagebetweentestsites

•Ground stick provided for increased operator safety. Can be used to safely connect the unit and the test load to ground before and

after test

•12ft.input line cord

•10 ft.interconnect cablewith grounds

SECTION

1

OPERATOR MANUAL

-

3 -

•20ft.RG8/Uoutput cable(VLF-4022),20ft.shieldedX-Rayoutput cable(VLF-6022)

•Alligator clip type output connector

•20 ft.2 AWG clear jacketedcable for safety groundingof HVsection.

•RedandBlackMeasuringLeads forCapacitiveLoadMeasurement

WARNING

DO NOT OPERATE THE VLF HIPOT SET IF THE HIGH VOLTAGE TANK IS 5

°

OR MORE FROM

LEVEL.

IF THE UNIT IS OPERATED OUT OF LEVEL, OVERHEATING AND INTERNALARCING MAY OCCUR.

DONOT STORE ORTRANSPORTVLF HIGH VOLTAGE SECTION

ONITS SIDE

OPERATOR MANUAL

-

4 -

Operating Environment

Indoor/Outdoor-fair weather

Altitude: 100% of rating;Sea-level, up to 5000ft.(approx.1500M). The output power is

de-rated 10% above 5000 ft. altitude, 20% above 12,000 ft.( approx. 3600M), and 30%

above 15,000 ft.(approx. 4500M)

Storage Temperature: -20°C to 70°C(-4°F to 158°F)

Operating Temperature: -5°C to 45°C(22°F to 113°F) Output power is de-rated linearly

by 15% from 30 to 45°C ambient.

Maximum Relative Humidity: 80% up to 31°C(88°F), decreasing linearly to 50% at

40°C(104°F)

Mains supply fluctuation: +/-10% of rated voltage

Installation: Category II

Pollution: Degree 2

WARNING

DO NOT OPERATE THE VLF HIPOT SET IF THE HIGH VOLTAGE TANK IS 5

°

OR MORE FROM

LEVEL.

IF THE UNIT ISOPERATEDOUT OF LEVEL,OVERHEATING AND INTERNALARCING MAY OCCUR.

DONOT STORE ORTRANSPORTVLF HIGH VOLTAGE SECTION

ON IT’SSIDE

Safety Symbol Identification

OPERATOR MANUAL

-

5 -

Warning! Please refer to documentation before operation

Protective Earth Terminal

Warning: Hazardous Voltage

OPERATOR MANUAL

-

6 -

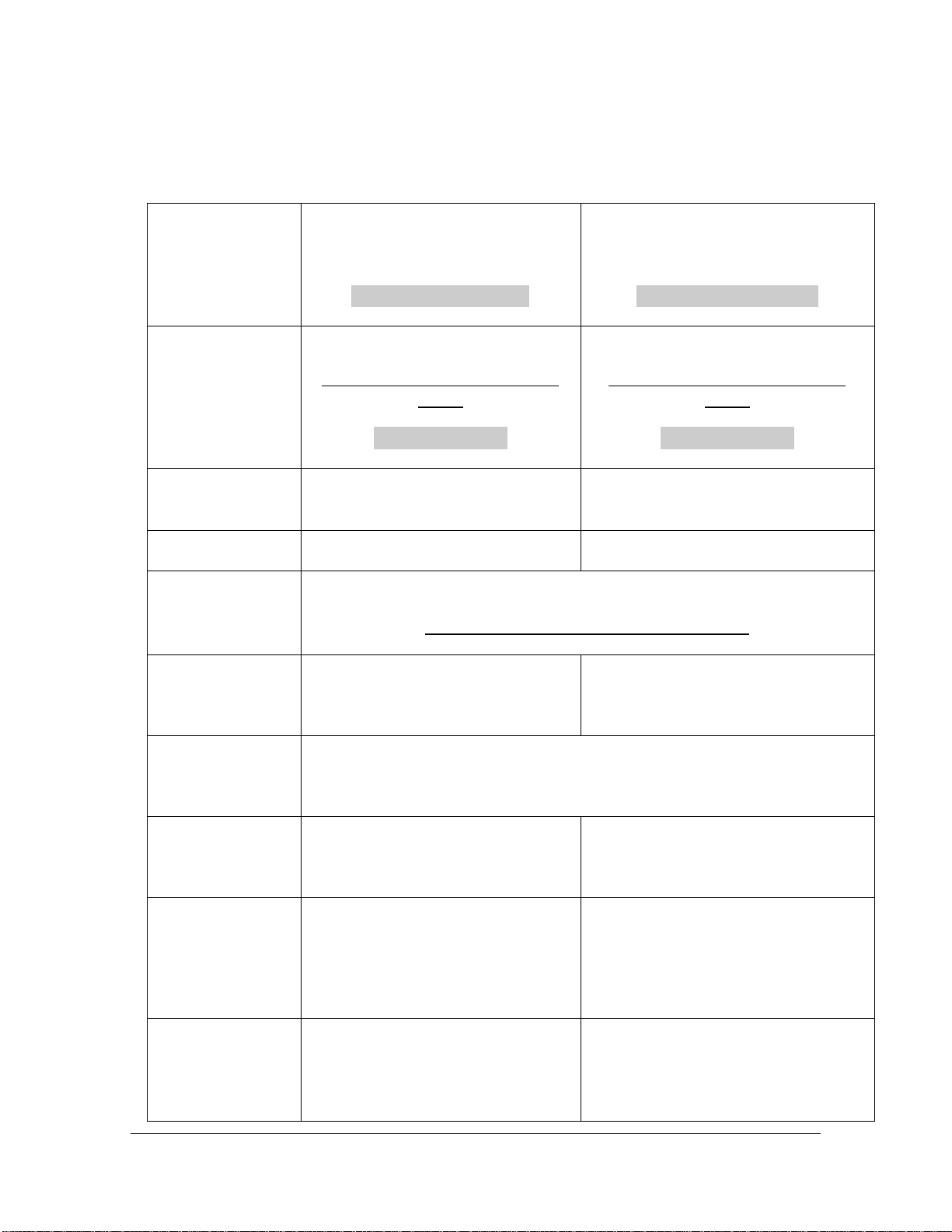

MODEL VLF AC HIPOT SPECIFICATIONS

VLF-4022CM ( 44kV,2.2µF)

Part No. VLF-1450S(120V)

Part No. VLF-1447S(230V)

VLF-6022CM (62Kv,2.2µf)

Part No. VLF-1423S (120V)

Part No. VLF-1439S (230V)

Input

120V,50/60Hz,10 A

Sinusoidal Power Required for full

output

230V,50/60Hz,6 A

120V,50/60Hz,15A

Sinusoidal Power Required for full

output

230V,50/60Hz,8 A

Output

Sinusoidal0-44kVacpeak,0.1,.05,and

.02 Hz frequency

Sinusoidal0-62kVacpeak,0.1,.05,and

.02 Hzfrequency

Duty

Continuous

Continuous

Test Capacitance

(Ins.Res.<10GΩ)

1.1 µF @ .1 Hz,2.2µF@ .05 Hz, 5.5 µf @ .02 Hz

Minimumcapacitancetoachievefulloutput-.01µF

Kilovoltmeter

3.5in., 0-45PEAK KILOVOLTS

2%Full-scale Accuracy

3.5in., 0-65PEAK KILOVOLTS

2%Full-scale Accuracy

Current/uFMeter

CM Models

3.5in.

0-100 PEAKMILLIAMPS,/5-0 uF,5% FS Accuracy

ControlCase Size

HighVoltageTank

22wx11dx15.25 high

14.5w x 10.5dx19high

26wx13d x16 high

15wx11dx21.5high

ControlCase Weight

HighVoltageTank

Weight

50lbs. (23kg)

72lbs. (33kg)

AccessoryBag10lb.(4.5kg)

75lbs. (34kg)

120 lbs. (54kg)

Intercon.cable

length

Outputcable length

10 ft.

RG8/U 20 ft.

10 ft.

ShieldedX-Ray 20ft.

OPERATOR MANUAL

-

7 -

Table 1 VLF SeriesSpecifications.

Figure 1 VLF-40 Series front panel controls

Figure 2 VLF-60 Series front panel controls

OPERATOR MANUAL

-

8 -

INPUT POWER

The INPUT POWER connector (if applicable) accepts most standard line/extension cords. The power

supplied to the input connector must be from a grounded Sinusoidal AC source rated to match the input

power specifications noted in Table 1.If extensions cords are used for the input, use 10 AWG cord for 25

ft, and 8AWG for 50ft cords. The output may not reach full voltage if the input extension is too small and

causesasignificant voltagedrop under power.

PLEASE NOTE- Using Square Wave Power Generators may reduce the maximum output of this

unit.

MAIN POWER

TheMAIN POWER pushbuttonswitchprovidesthepowertothecontrolandpowercircuits.Theneonlamp

in the switch will light when the power is on and voltage is available through input line cord. The INPUT

FUSE locatedelectricallybeforetheMAIN POWER switchprovides inputline protectionfortheunit.

EXT.INTLK (EXTERNAL INTERLOCK)

The Ext. Intlk. connector is provided to allow for a normally open safety interlock switch to control the

energizingofthehigh voltageoutput.

HV OVERLOAD

The HV OVERLOAD circuit breaker protects the variable transformer output control brush. Its thermal

characteristics allow for the short term overload of the variable transformer while still providing proper

protection.

HIGH VOLTAGE ON/OFF

The HIGH VOLTAGE ON (OFF) pushbuttons activate (de-activate) the high voltage power circuits. The

LED indicators provide long life positive indication of thecircuit status.The RED (ON) LED lights when high

voltage isenergized,theGREEN(OFF) LEDlightswhenthehighvoltageisde-energized.

OUTPUT CONTROL

The OUTPUT control variable transformer adjusts the output voltage. The 0-100 markings on the panel

indicate the low to high setting. The control must be at ZERO (0) to energize the high voltage circuits. The

output control must always be returned to zero at the completion of testing, prior to de-energizing

the output , allow the unit tocycle for 60seconds toassure full discharge ofthe load.

VOLTMETER

The KILOVOLT METER allows for accurate output voltage readings. 1-% precision resistors minimize the

need for re-calibration due to aging shift. See Voltmeter Re-calibration in Section 3 for details on

calibration.

OPERATOR MANUAL

-

9 -

SCOPE OUPUT

The SCOPE OUTPUT allows for accurate output voltage monitoring. This connector can be fed into an

oscilloscope for the looking at the actual output wave shape. The peak to peak voltage representing 40

kVacis8voltspeak/peak.(OntheVLF-6022,60kVacis6voltspeak/peak.)

OUTPUT FREQUENCY

The OUTPUT FREQUENCY switch adjusts between calibrated frequencies for testing loads larger than

normal .By allowing slower frequencies the output waveshape is maintained. Output frequency choices are

.1 Hz for 1.1 µF, .05 Hz for2.2 µF,and .02 Hz for5.5µF.

TIMER AND START TIMER PUSHBUTTON

The Timer is provided for tests when dwell time is important. The timer can be set from 1 second

increments up to hour increments. After the test has started, the timer can be started by depressing the

START TIMER pushbutton. The preset time will count down to zero. Upon reaching zero, the timer will

sound an alarm indicating the completion of the timing cycle. The timer will not shut down High Voltage. To

Resetthe timeralarm,withhighvoltageOFF,depresstheSTART TIMER pushbutton.

To set the H5CX Timer

1) Pressand hold ‘mode’ button for 3 seconds to enter program mode

2) Set the time range using the ‘up/down’ push buttons (default30min 00 sec)*

3) Set the timermode using the ‘up/down’ push buttons(default down)*

4) Set the timeroutputmode using the ‘up/down’ push buttons(default F)*

5) Set input signal width using the ‘up/down’ push buttons (default 20mS)*

6) Set keyprotect levelusing the ‘up/down’push buttons(UP-1)*

7) Pressand hold ‘mode’button for 3 seconds to exit programmode

*press ‘mode’ button briefly after adjusting each parameter to move to next step

CURRENT METER

CURRENT/CAPACITANCE METER

ThedualscaleCURRENT/CAPACITANCE meter provides for accurate output current monitoring. The

CURRENT portion of this circuit is for observing the charge and discharge currents in the cable load. 1%

resistors minimize the need forre-calibration due to agingshift. The CAPACITANCE scale is for measuring

the load cable capacitance (0-6uF/0-60uF) prior to test to determine the best operating frequency for that

particularcable run.

Note: The current meter on the VLF Series of AC hipot is for reference readings of current draw. The

current reading is affected by both frequency and cable length and as such is not appropriate for use in

trending orleakagemeasurements.

METER MODE

The METER MODE switch configures the current metering circuit for capacitance measuring or for output

currentmeasurement.

CAPACITANCE (PUSH TO READ X1) PUSHBUTTON

OPERATOR MANUAL

-

10

-

The PUSH TO READ X1 pushbutton changes the scale of the CAPACITANCE metering. The modified

Wheatstone Bridge incorporated in this circuit indicates x10 readings without depressing the PUSH TO

READ X1 pushbutton. When in the x10 scale and the reading is below 6

µ

F(0.6 on x10 scale), the PUSH

TO READ X1 shouldbe depressedtogetanaccurateload capacitance measurement.

CAP ZERO

This potentiometer is for zeroing the capacitance range at full scale prior to measuring the cable

capacitance.

CAPACITANCE MEASUREMENT POSTS

These posts are for connecting the cable to the capacitance measuring circuit. The HOT post is for the

cable center conductor, the COM postis for the cable's grounded shield.Be sure the cable is de-energized

before connectingthis lowvoltage circuit ordamage will result.The resulting capacitance measurement on

the cable will identify the best operating frequency for that particular cable run. A frequency table is

providedinthesectionOPERATING THE EQUIPMENT.

POS/NEG LED DISPLAY

TheseLEDs are toidentifyoutputpolarityasunit cycles.

DATA LOGGER

TheDATA LOGGER connectorisfortheexternalADL-1DataLoggeroption.

Note Regarding use of MCconnectors:

The MC connector requires the operator to push IN before pulling OUT to disconnect.

OPERATOR MANUAL

-

11

-

List of included componentswith the VLFHipot

Groundstick with20ft.ofgroundwire

Ext.Intlk.jumper plug

20ft.longoutputcable RG8/U;VLF-4022,20ft.longX-Raycable;VLF-6022

Alligator clipandhook terminations

10 ft.interconnect cable with grounds

BNC to BNC scopetopanel interconnectcoax cable

20ft.2AWG clearjacketed cable forsafety groundingof theHV section

Redand Black MeasuringLeads forCapacitiveLoadMeasurement

WARNING

DO NOT OPERATE THE VLF HIPOT SET IF THE HIGH VOLTAGE TANK IS 5

°

OR MORE FROM

LEVEL.

IF THE UNIT IS OPERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DONOT STORE ORTRANSPORTVLF HIGH VOLTAGE SECTION

ON IT’SSIDE

OPERATOR MANUAL

-

12

-

SETTINGUPTHEEQUIPMENT

The setup of this equipment has been minimized by careful consideration of the operator during design.

TheVLF Series’ two-piece constructionallows for convenientportabilityfor ACtesting in the field.

Select a locationfor the unit that will allow easy viewing of the controlpanelat a safe distance from the

test object. Place the high voltage tank within 10 ft. of the control on a level area. The cooling and filter

assembly of the VLF series will not operate properly if the high voltage tank is placed on uneven ground. A

maximumangleforcorrectoperationis 5°.Blockingthetank to a levelconditionisacceptable.

1. Be sure that all the controls are off,in their de-energized or fully counterclockwise

position.

2. Secure the interconnect cable to the high voltage tank. Be sure the free-hanging

fan/pump connector is also connected tothe side connector.

3. Secure a ground test lead to the panel. TheGroundpost on the front panel should be

used for that purpose. A lead in the high voltage interconnect has been provided for the ground

connection.

4. Secure a ground test lead to HV TANK. TheGroundstud the top of the tank should be

used for that purpose. A 2 AWG CLEAR JACKETED lead has been provided for the ground

connection. The clampendshouldbeconnectedtoasolidearthground.

5. Connect theground stick to a solid earth ground.

6. Insert the coaxial output cable into the high voltage output connector on

the tank. Tightentheclampingnutsecurely.

7. When using a cable reel assembly with a VLF. Refer to “VLF Connection

Scheme with Cable Reel” in Operating the Equipment Section.

Note Regarding use of MCconnectors:

The MC connector requires the operator to push IN before pulling OUT to disconnect.

SECTION

2

OPERATOR MANUAL

-

13

-

8. Insert the EXT INTLK plug into the socket on the panel. The plug may also be

wiredtoanormallyopen contactofa safety switch for added protection.

The setup of the VLF AC Test Set does notaddress the need for proper safety grounding of the

load (test sample or cable). The grounding requirements vary for different types of tests.

Please consult the local codes where applicable or reference the guidelines for grounding

found under OPERATING THE EQUIPMENT.

WARNING

DO NOT OPERATE THE VLF HIPOT SET IF THE HIGH VOLTAGE TANK IS 5

°

OR MORE FROM

LEVEL.

IF THE UNIT ISOPERATED OUT OF LEVEL,OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DONOT STORE ORTRANSPORTVLF HIGH VOLTAGE SECTION

ONITS SIDE

OPERATOR MANUAL

-

14

-

OperatingtheEquipment

This section provides step-by-step instruction on various test methods. Many facilities have their

own in-house test procedures, and this manual is not to supercede these. The purpose of this

sectionistoexplain thecapabilitiesof thistestsetinreal-worldapplications.

When testing cables, either single or three phase, there are certain extra steps that must be observed to

ensure safeoperation.

It should be noted that the VLF series test sets are not intended to be used

on vacuum bottles or switchgear without cables connected. The VLF requires

a minimum of .01uF load capacitance to achieve full output. If the

capacitance of the load is too low, the kilovolt meter will not read the actual

peak output and damage to theunit (and/or load) may result.

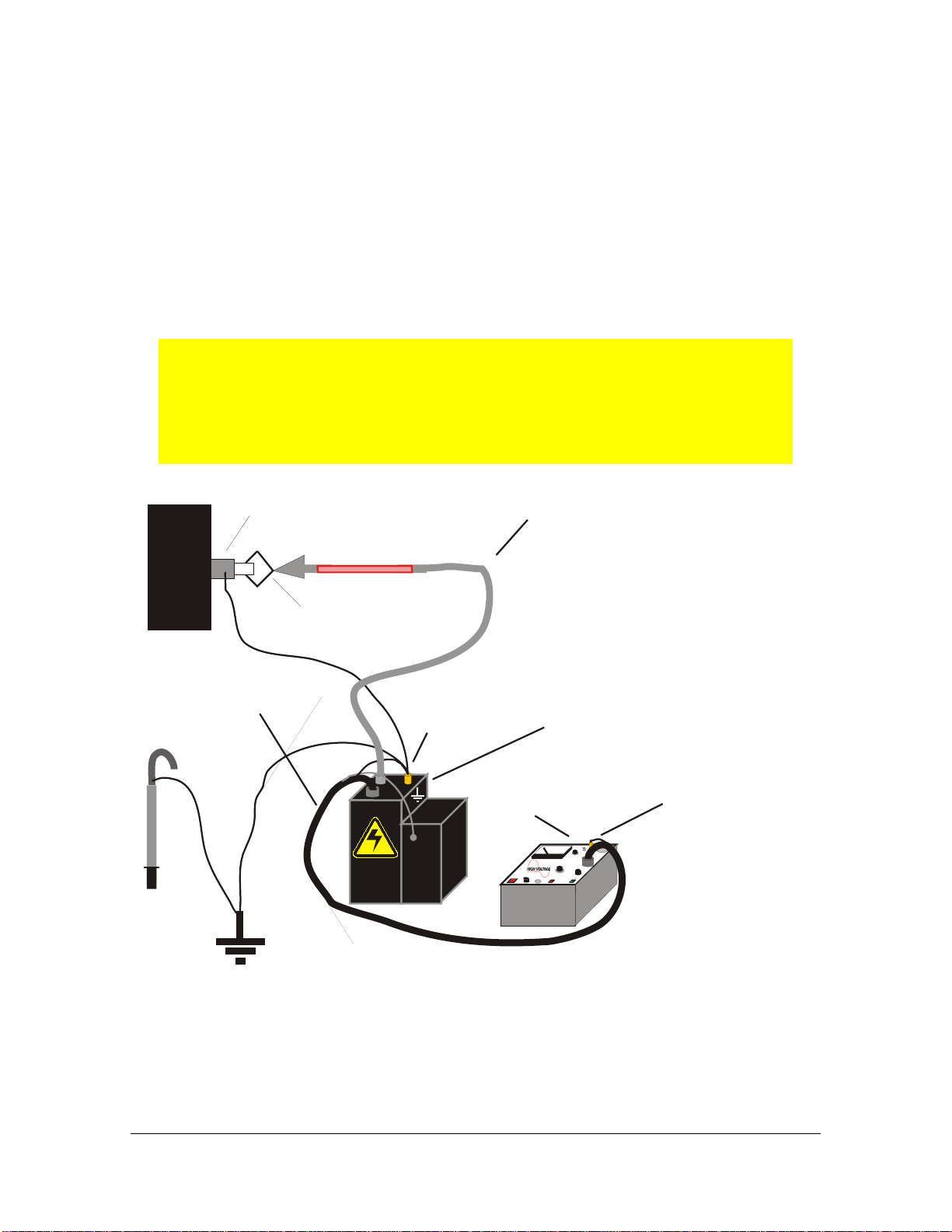

CONTROL

HV TA N K

INTER-CONNECT

CABLE

HV CABLE

(TEST O BJEC T)

O UTPUT C LIP

ORHOOK

HV OUTPUT

CABLE

VLFCONNECTION

SC HEME

TA N K G RO UN D

CONNECTION

CONTROLGROUND

CONNECTION

GROUND

STIC K

OPERATOR MANUAL

-

15

-

CONTROL

HV TANK

INTER-CONNECT

CABLE

VLF WITH C ABLE REEL

CONNECTION

SC HEM E

TANKGROUND

CONNECTION

CONTROLGROUND

CONNECTION

HIGHVOLTAGE

X-RAY C ABLE

GROUND

CABLE

LRO-40

CONNECTIONSTO

TEST O BJEC T

MC

CONNECTOR

ACTesting of High Voltage Cables

1. Ensure that all the steps listed in Setting Up the Equipment have been accomplished. Take

specialnotetogroundthecontrolsectionandthehigh voltagetanktoasolidearthground.

Caution!!

Before making any cable connections,ensure that the cable being

tested has been properly identified,de-energized, and

grounded!

2. Make sure thatall insulators,stresscones, andpot heads are cleanand free of moisture. This

willpreventflashoverandminimizeleakage.

3. Isolate the far end of the conductors under test for the test voltage; that may mean separating

someoftheconductorsinamulti-conductorcablefromeach otherand their shields.

OPERATOR MANUAL

-

16

-

The shields of all cables must be securely tied to ground at

the nearest end of the cable.

4. Anyconductorsorwiresinthecableorthevicinitynotbeingtested mustbegroundedto avoid

abuildupof chargeandpossibleshockhazard.

5. Voltage must be applied according to specifications from the cable manufacturer or any other

applicableteststandards

6. Prior to connecting anything to the test sample, be sure the test sample is identified, de-

energizedandgroundeduntilreadytotest.

7. First, the cable capacitance must be measured to determine the best operating frequency.

Placethecontrolnearthecablebeingtested.

8. Connect the input power terminal block (or cord) to a grounded, 50/60 Hz source as noted in

Table 1 Specifications. A generator is an acceptable power source. If extensions cords are

used for the input, use 10 AWG cord for 25 ft, and 8AWG for 50ft cords. The output may not

reach full voltage if the input extension is too small and causes a significant voltage drop

underpower.

9. Turn on the main circuit breaker. The MAIN POWER light will illuminate at both the power

section andthe control.

10. Operate the METER MODE to

µ

Fposition. Adjust the CAP ZERO for full scale deflection

(ZERO) on the meter.

11. Connect the HOT post to the center conductor of the test cable. Connect the COM post to the

groundedshieldofthetestcable.ReadtheCAPACITANCE scale(x10).

If the reading is below 6.0µF(0.6uF on scale) depress the x1 pushbutton. Then following table

provides operating frequencyversus capacitance.

Capacitance

Frequency

1.1µF orless

.1 Hz

2.2µF orless

.05Hz

5.5µF orless

.02Hz

A minimum load capacitance of 0.01μF is required to achieve full output of the VLF unit.

Other manuals for VLF-CM Series

1

This manual suits for next models

6

Table of contents

Other High Voltage Test Equipment manuals

Popular Test Equipment manuals by other brands

Sykes-Pickavant

Sykes-Pickavant SPe user guide

Berner

Berner 047894 operating manual

Höcherl & Hackl

Höcherl & Hackl PMLA Series user manual

Sensidyne

Sensidyne gilian gilibrator 2 Operation & service manual

JB INDUSTRIES

JB INDUSTRIES F6-BOOST operating manual

Extech Instruments

Extech Instruments 433201 user guide