High Voltage DTS-60A User manual

DTS-60A

DTS-100A

Dielectric Oil Test Set

Operator’s Manual

Manual Version 2.01

High Voltage

I C

.

DTS-60A / DTS-100A OPERATORS MANUAL

All rights reserved. Total or artial re roduction of this manual, whether by rinted or electronic means, is

forbidden. Information regarding any errors found in it or suggestions concerning im rovement are a reciated.

Since roducts are subject to continuous check and im rovement, High Voltage inc. reserves the right to make

changes in information contained in this manual without rior notification.

Manual Revision 4/6/2017 Version 2.01

Copyright 2016 High Voltage, Inc. – USA

HIGH VOLTAGE, INC.

31 County Route 7A

Copake, N.Y. 12516

Phone : (518) 329-3275

ax : (518) 329-3271

Web : http://www.hvinc.com

e-mail: [email protected]

DTS-60A / DTS-100A OPERATORS MANUAL

Icons & otation

This icon indicates danger conditions!

Danger!

This icon indicates warnings!

Warning!

This icon indicates a hint or a tip!

ote!

DTS-60A / DTS-100A OPERATORS MANUAL

This Operator manual contains instructions for the operation

of a High Voltage power source. The operator of this

equipment must use good judgement and follow all safety

precautions noted in this guide to ensure the protection of

themselves and others in close proximity to the test area.

Failure to follow the instruction could result in injury or

death.

Proper grounding of the test set must be done prior to

connecting this unit to a power source.

DTS-60A / DTS-100A OPERATORS MANUAL

Table of Contents

1. Specifications and Controls

1.1 Features and S ecifications

1.2 Control Panel

1.3 User Interface

1.3.1 Menu Overview

1.3.2 Key ad O erations

1.3.3 Warning Messages

1.3.4 Question Messages

1.3.5 Error Messages

1.3.6 Indicators

1.4 Setu the Equi ment

1.5 Startu the Equi ment

2. Menu/Submenus and Settings

2.1 Main O eration Overview

2.2 Main Menu

2.3 Settings Submenu

2.3.1 Time/Date Dialog

2.3.2 O erator Dialog

2.3.3 LCD Contrast Dialog

2.3.4 Language Dialog

2.3.5 Region Dialog

2.3.5 U date Firmware Dialog

3. Simple Test

3.1. Sim le Test O erations

3.2. Sim le Test Initialization

3.3. Sim le Test Controls

3.4. Sim le Test Execution

3.5. Sim le Test Termination

3.6. Sim le Test Exam le

4. Standard Tests

4.1. Standard Test Descri tion

4.2. Select a Standard Test

4.3. Standard Test Execution

4.4. Standard Test Exam le

DTS-60A / DTS-100A OPERATORS MANUAL

5. User Defined Tests

5.1. Test Descri tion

5.1.1 Test Structure

5.1.2 Test O erations

5.2. Select Test Menu

5.3. Scri t Files for User Defined Tests

5.3.1. Scri t File Commands and Arguments

5.3.2. Scri t File Test Exam les

6. History and Results

6.1. History Results

6.2. Exam le Using History Results

7. Printer and Printouts

7.1. Printer Descri tion

7.2. Changing the Pa er Roll

7.3. Printout Descri tion

8. Remote Operation

8.1. Remote O eration Descri tion and O eration

8.2. System Commands and Parameters

8.2.1 ver

8.2.2 cls

8.2.3 time

8.2.4 date

8.2.5 o erator

8.2.6 contrast

8.3 Test Commands

8.3.1. test list

8.3.2. test read

8.3.3. test delete

8.3.4. test erase

8.3.5 test download

8.4 Test Results Download Commands

8.4.1 history list

8.4.2 history read

8.4.3 history erase

Appendix I - Care and Maintenance

Appendix II - Example Test Program Script Files

Appendix III - Firmware Upgrade Procedure

Appendix IV - DTS Remote Operation Program

DTS-60A / DTS-100A OPERATORS MANUAL

1

Specifications and Controls

This section describes the s ecifications, controls, and features of the DTS-60A & DTS-100A

AC Dielectric Oil Test Sets.

Included in this section is a brief introduction about the equi ment’s set u and start u .

Features and S ecifications 1.1

Control Panel 1.2

User Interface 1.3

Menu Overview 1.3.1

Key ad O erations 1.3.2

Warning Messages 1.3.3

Question Messages 1.3.4

Error Messages 1.3.5

Indicators 1.3.6

Setu the Equi ment 1.4

Startu the Equi ment 1.5

1

DTS-60A / DTS-100A OPERATORS MANUAL

1.1 Features and Specifications

The DTS-60A & DTS-100A AC Dielectric Oil Test Sets rovide automatic, rogrammable, and

accurate measurement of breakdown voltage for insulating oils used in high-voltage electrical

equi ment.

Main features of the DTS-60A & DTS-100A Series of AC Dielectric Oil Test Sets

User Interface

Dot Matrix Liquid Crystal Dis lay (128x64)

Com act 5-key key ad for o eration

User friendly, menu driven functionalities

Large out ut voltage dis lay

Functionalities

Test Result storage and re orting

Real Time Clock

Ambient Tem erature measurement

International Standard Tests

User Defined Tests

Language selection

Measurements and Control

High accuracy of High Voltage measurement (0.5%)

Digitally selected Voltage rate of rise (0.1kV/s ste )

Arc detection with less than 5 milliseconds shutdown

Digital Closed-Loo for voltage control

Equipment Case

Rugged aluminum case

Window for observation of oil test

2

DTS-60A / DTS-100A OPERATORS MANUAL

Table 1.1 - S ecifications

DTS-60A & DTS-100A unless otherwise indicated

Input 120V, 50/60 Hz, 5 am s, single hase

230V, 50/60 Hz, 3 am s, single hase

Output DTS-60A: 0 – 60kVac, 800VA resistive load, between bushings

DTS-100A: 0 – 100kVac, 800VA resistive load, between bushings

Output Termination Dual Ca acitively Graded Bushings

Display Dot-Matrix 128x64

Keypad 5 keys for equi ment’s functionalities

Printer 40 column dot-matrix

Remote Operation RS-232 Serial Interface or USB HID Serial Interface

Breakdown Shutdown Less than 5 ms

Accuracy 0.5%

Operating Temperature -14F to 104F (-10C to 40C)

Case Size 14.75w x 14d x 11.5h in (36.88w x 35d x 28.75h mm)

H.V. Tank High Voltage Tank Included

Weight 60 lbs.

3

DTS-60A / DTS-100A OPERATORS MANUAL

1.2 Control Panel

The equi ment’s Control Panel is de icted in Figure 1.1. It consists of the following:

Input Power Connector

The In ut Power connector acce ts most standard electrical equi ment ty e

cords. The ower su lied to the in ut connector must be from a grounded

source rated to match the in ut ower s ecifications noted in Table 1.1.

Main Power Switch

The Main Power switch rovides the ower to the control and ower circuits. The

neon lam will light when ower is on and voltage is available through the in ut

line cord. The In ut Power Fuse, located electrically before the Main Power

switch, rovides line fault rotection for the unit.

Fuse Socket

LCD Display

The Liquid Crystal Dis lay guides the user to the system’s functionalities.

Keypad

Com act 5-key key ad for equi ment o eration.

Printer

Dot Matrix rinter for o tionally out utting results from the current test, or from

the stored history of the last fifty tests erformed.

Figure 1.1 – DTS-60A / DTS100A Control Panel

4

DTS-60A / DTS-100A OPERATORS MANUAL

1.3 User Interface

The Equi ment User Interface is based on a dot-matrix Liquid Crystal Dis lay (LCD) and a

com act 5-key key ad, shown in Figure 1.2. The user-friendly gra hical interface makes the

equi ment's o eration sim le and attractive.

Figure 1.2 – Equi ment User Interface

1.3.1 Menu Overview

The equi ment o eration is based on a user friendly structure of menu/submenu driven

functions. An overview of the menu/submenu selections is summarized in Figure 1.3.

Figure 1.3 – DTS-60A & DTS-100A User Interface

5

MENU

SELECT TEST

SETTINGS

TEST HISTORY

REMOTE OPERATION

SETTINGS

TIME/DATE

OPERATOR

LCD CONTRAST

LANGUAGE

TEST HISTORY APP

REMOTE OPERATION APP

SELECT TEST APP

SETUP TIME/DATE APP

SETUP OPERATOR APP

SETUP LCD CONT. APP

SETUP LANGUAGE APP

REGION SETUP REGION APP

UPDATE FIRMWARE UPDATE FIRMWARE APP

DTS-60A / DTS-100A OPERATORS MANUAL

1.3.2 Keypad Operations

The DTS-60A and DTS-100A use a ty ical lcd/key ad interface in which the actions of the keys

are defined by the ty e of menu or a lication dialog that is active. The most common ty es

are listed below. Any s ecial key functionality for a given dialog are detailed later in the

manual.

Simple Test Operations

ME U Proceed to the Main Menu before/after test

BACK Enable/Disable Stirrer (before stage begins)

Select "No" for rom t

UP Increase Voltage Rate of Rise

Pick "Yes" rom t

DOW Decrease Voltage Rate of Rise

Pick "No" rom t

E TER On Entry, Execute Sim le Test

Begin Test Stage with chosen voltage rate

Select "Yes/No" rom t

A Y After Starting the Test ANY key interru ts the rocess

Standard and User Defined Test Operations

ME U Proceed to the Main Menu before/after test

BACK Select "No" for rom t

UP Pick "Yes" rom t

DOW Pick "No" rom t

E TER Execute Standard or User Defined Test Test

Select "Yes/No" rom t

A Y After Starting the Test ANY key interru ts the rocess

Main Menu and Submenu Operations

BACK Exit from Main Menu to Test O erations

Exit from Submenu to Main Menu

UP Move U to the revious selection

DOW Move Down to the next selection

E TER Proceed to the selection

umber Edit Operations

BACK Discard changes and return

UP Increase the current value

DOW Decrease the current value

E TER Enter the value

Operator String Edit Operations

ME U Choose Character Set: u er case; lower case; numbers; symbols

BACK Delete Character

UP Select revious character, wait 3 seconds to enter individual character

DOW Select next character, wait 3 seconds to enter individual character

E TER Enter the com leted string

6

DTS-60A / DTS-100A OPERATORS MANUAL

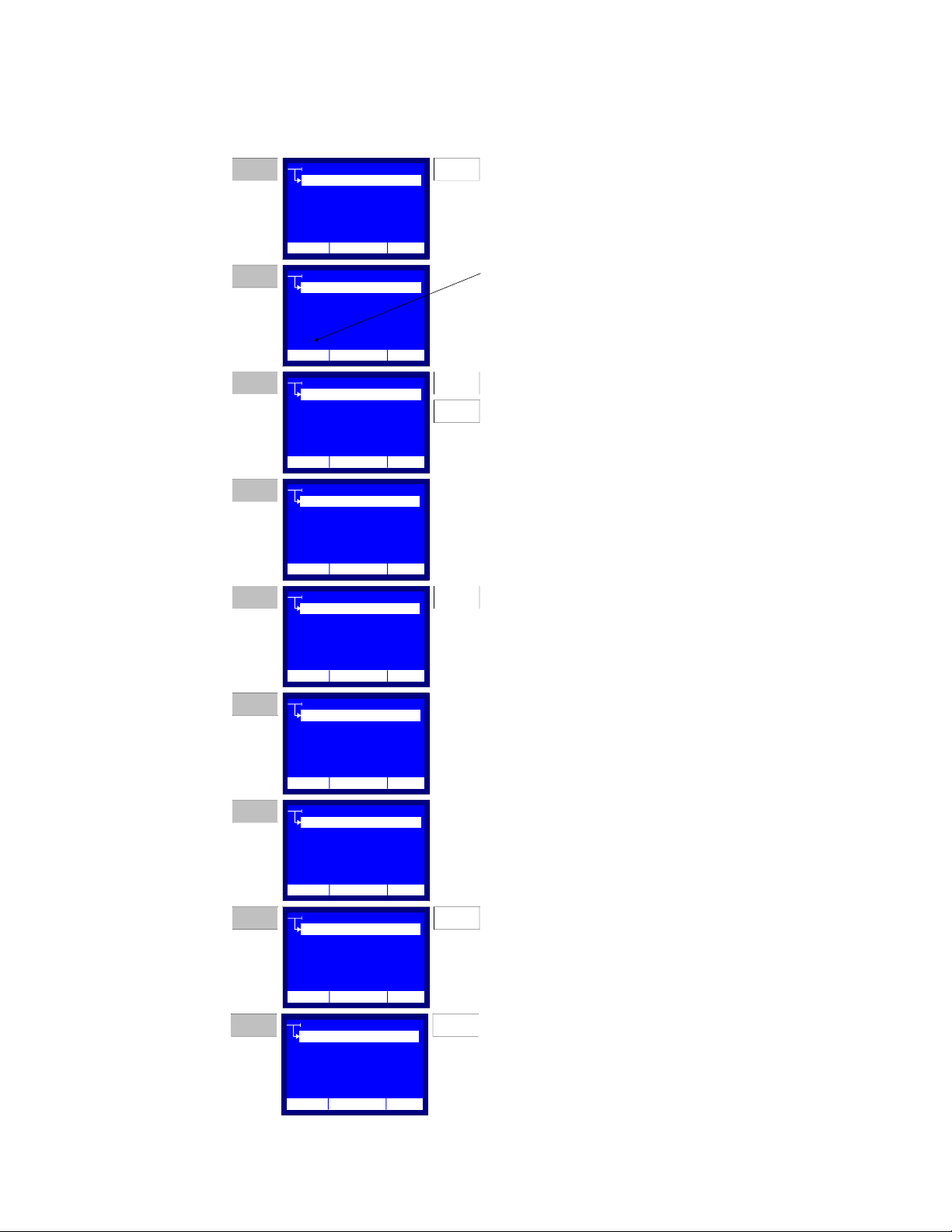

Figure 1.4 illustrates the O erator String Edit O eration. The exam le refers to a string entry

for the O erator Name (see section 2.3.2).

Figure 1.4 – String Entry Key ad O eration

7

OPERATOR

12:10 01/08/16 25 C

NAME

COMPANY

CONTACT INFO

OTHER INFO

Press the ENTER key in rder t enable the String

Entry keyb ard perati n f r the Name

OPERATOR

CONTACT INFO

OTHER INFO

_

STEP 1

The String Entry Curs r is displayed. This

indicates the current p siti n f the editable

character.

OPERATOR

CONTACT INFO

OTHER INFO

O

Use the UP and DOWN keys t select the desired

character. D nt leave m re than 3 sec nds

between key pressings. After every UP key

pressing the next character f the alphabet will be

displayed. In c ntrast, after every DOWN key

pressing the previ us character f the alphabet will

be displayed. The character sequence is circular.

OPERATOR

CONTACT INFO

OTHER INFO

O_

St p pressing the UP and DOWN keys f r m re

than 3 sec nds. The character will be entered and

the curs r will be displayed in the next p ssiti n.

STEP 2

STEP 3

STEP 4

ENTER

UP

DOWN

OPERATOR

CONTACT INFO

OTHER INFO

_

A mistake ccured! Press the BACK Key in rder

t delete the last entried character.

OPERATOR

CONTACT INFO

OTHER INFO

P_

Select the c rrect character acc rding STEP 3

instructi ns. Then wait 3 sec nds, until the curs r

is displayed at the next p siti n.

OPERATOR

CONTACT INFO

OTHER INFO

PETER_

Repeat the character entry perati n f r the wh le

string.

OPERATOR

CONTACT INFO

OTHER INFO

PETER_0

Press the MENU key twice, in rder t ch se the

numeric character set.

The character sets r tate in rder:

upper case

l wer case

numbers

symb ls

STEP 5

STEP 6

STEP 7

STEP 8

BACK

MENU

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

COMPANY

NAME

NAME

NAME

NAME

NAME

NAME

NAME

12:10 01/08/16 25 C

12:10 01/08/16 25 C

12:10 01/08/16 25 C

12:10 01/08/16 25 C

12:10 01/08/16 25 C

12:10 01/08/16 25 C

12:10 01/08/16 25 C

OPERATOR

CONTACT INFO

OTHER INFO

PETER_007

Press the ENTER key in rder t enter the edited

sting and return.

STEP 9 ENTER

COMPANY

NAME

12:10 01/08/16 25 C

DTS-60A / DTS-100A OPERATORS MANUAL

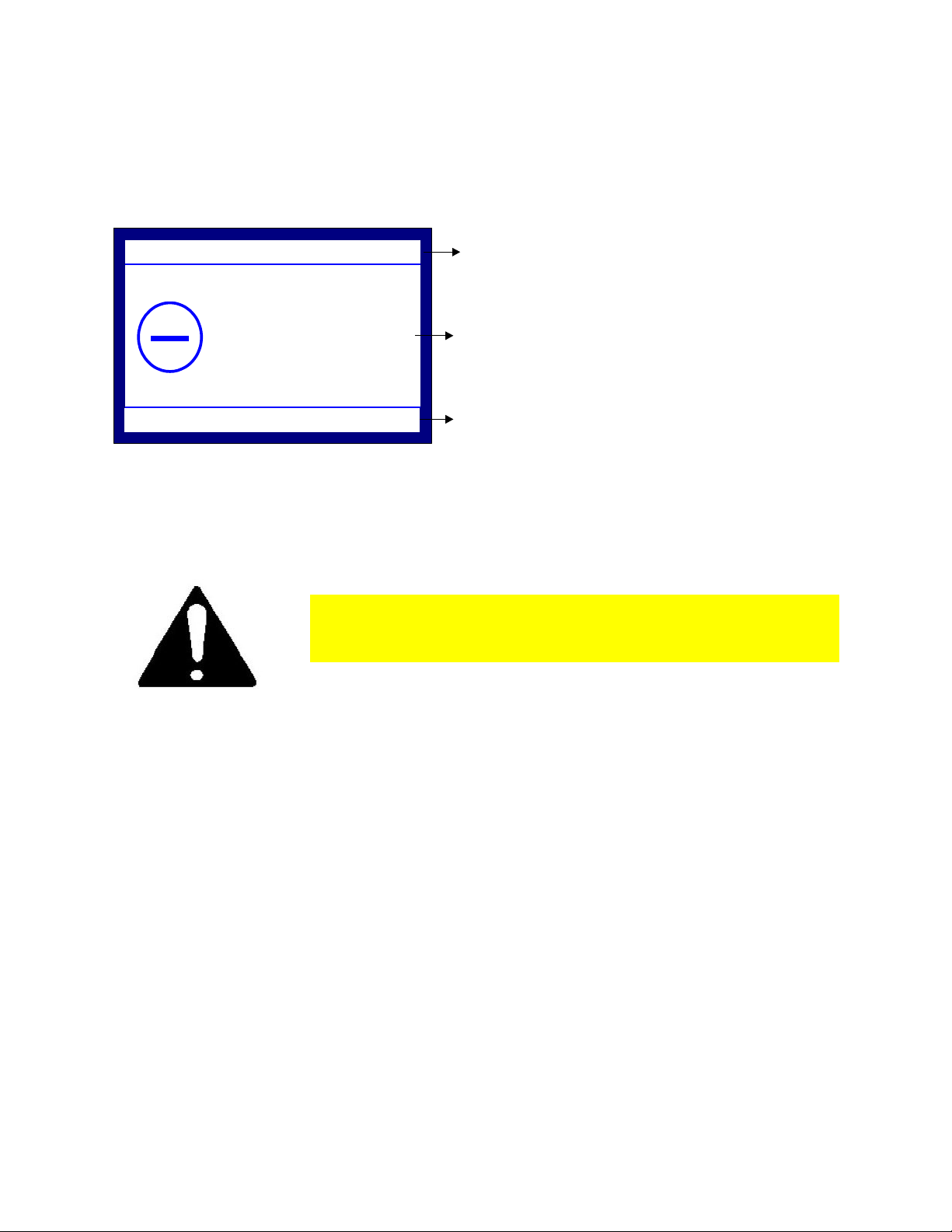

1.3.3 Warning Messages

The LCD dis lay will show a warning message in the following cases:

1. Lid is Open, Figure 1.5.

This warning message is dis layed when the Lid of the equi ment is o en while a

test is running. The current o eration (i.e. test execution) will be restarted when the

lid is closed.

Warning Message

Lid is Ope

SYSTEM HALTED...

TEST:ASTM D1816/84

12:10 01/08/16 65°F

TIMER:00:00:00

Figure 1.5 – ‘Lid is o en' Warning Message for Standard Test ASTM-D1816/84

If the Warning Message “Lid is Open” is depicted when

the Lid is closed, contact the distributor or the

manufacturer.

8

DTS-60A / DTS-100A OPERATORS MANUAL

2. Verify Electrode/Gap Spacing, Figure 1.6a/b.

This warning message is dis layed at the startu of every test rocedure, in order to

remind the user to check the electrodes ty e and s acing, according to the selected

test. If the selected test is a Standard Test or User Defined Test one (where the

s acing and the ty e of the electrodes is s ecific) the message will inform the user

for the a ro riate settings (ty e, s acing), Figure 1.6a. The user may roceed by

ressing the ‘E TER’ key.

Warning Message

TEST READY...

TIMER:00:00:00

TEST:ASTM D1816/84

Electrodes:

Spacing:0.04in

ENTER > PROCEED TEST

Figure 1.6a – ’Electrodes/ S ace’ Warning Message

If the selected test is the Sim le Test (where the s acing and the ty e of the

electrodes is not s ecified) the message will remind the user to verify the desired

electrode ty e and s acing, Figure 1.6b. The user may roceed by ressing the

‘E TER’ key.

Warning Message

MENU > GO TO MENU

TEST:SIMPLE TEST

VOLTAGE: 0.5 kV/s

TIMER:00:00:00

Verify Electrodes

Figure 1.6b – Verify Electrode/Ga S acing’ Warning Message

9

DTS-60A / DTS-100A OPERATORS MANUAL

1.3.4 Question Messages

The unit may dis lay the following Question Messages.

1. Continue Test?, Figure 1.7.

This question message is dis layed during the Sim le Test after a breakdown has

been detected. The o erator is rom ted with a "Yes/No" rom t. Use the 'UP' key

to select the "Yes" icon or use the 'DOW ' key to select the "No" icon.

In this dialog, choosing the "Yes" icon will set u a new test stage and choosing the

"No" icon will sto the Sim le Test and roceed to the Print Results Question

Message.

Press the 'E TER' key to make your choice.

?

Questi n Message Sh wing "Yes" Ic n Selected

TEST:SIMPLE TEST

VOLTAGE: 0.5 kV/s

TIMER:00:00:00

12:10 01/08/16 65°F

Continue

Test?

YES

Figure 1.7 – ‘Continue Test?’ Question Message

2. Print Results?, Figure 1.8.

This question message rom ts the user for rinting the test results after a test is

finished. Similar to the "Continue Test" message, use the 'UP' and 'DOW ' keys to

choose the "Yes" icon or the "No" icon.

Press the 'E TER' key to make your choice.

?

Questi n Message Sh wing "N " Ic n Selected

TEST:SIMPLE TEST

TEST RESULTS

NUM. BD: 5

12:10 01/08/16 65°F

Print

Results?

NO

X

Figure 1.8 – ‘Print Results?’ Question Message

10

DTS-60A / DTS-100A OPERATORS MANUAL

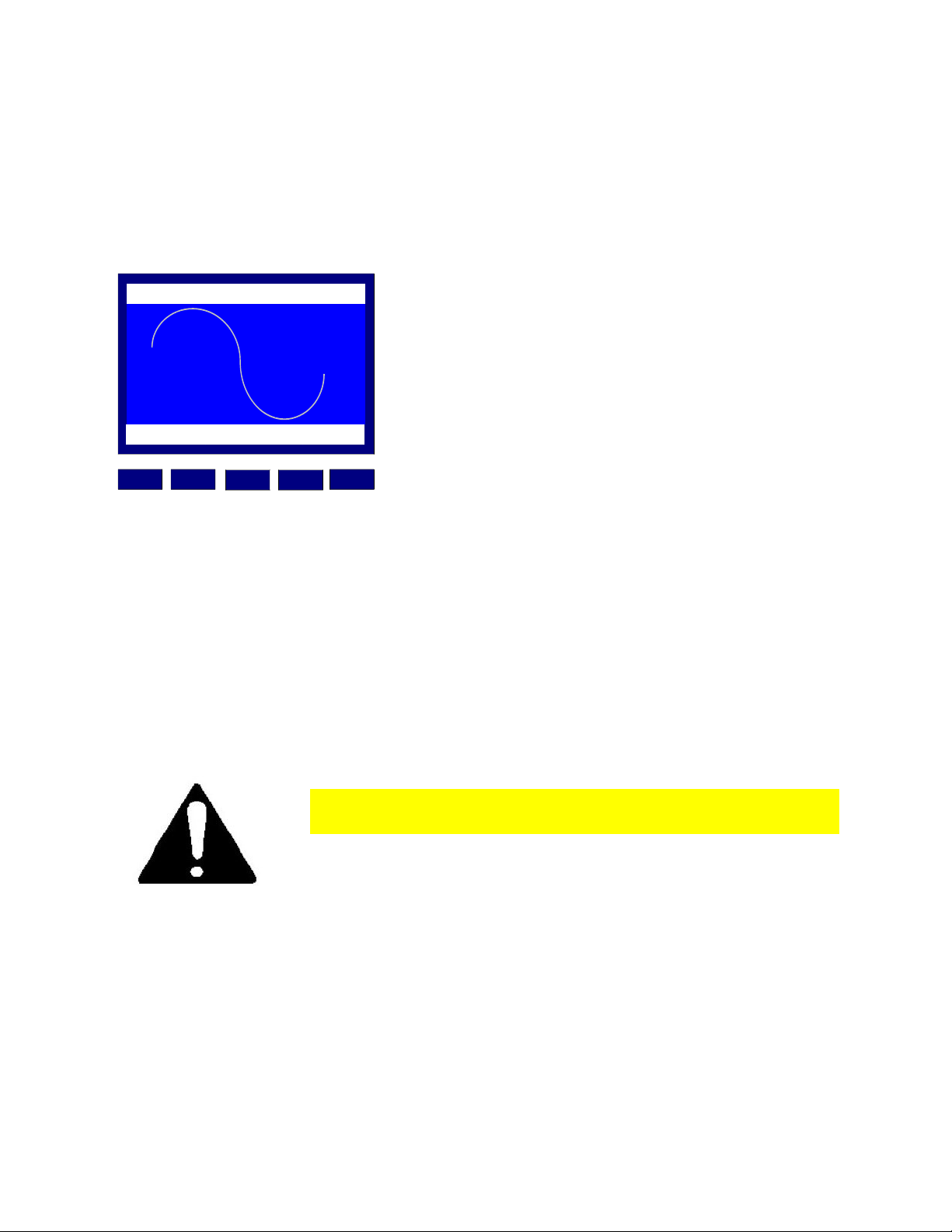

1.3.5 Error Messages

Error messages indicate serious equi ment malfunction. The system can dis lay the following

Error Code/Messages, Figure 1.9:

Error 100, Error 101, Error 102, Error 110, Error 111

Error 112, Error 113, Error 120, Error 121, Error 122

Err r C de

Err r Message

User Interface Help Message

ERROR: 102

C ntact

High V ltage Inc.

f r m re inf rmati n...

+1 518-329-3275

12:10 01/08/16 65°F

Figure 1.9 – Error Message

Whenever you see an ERROR message, contact the

distributor or High Voltage, Inc.

11

DTS-60A / DTS-100A OPERATORS MANUAL

1.3.6 Indicators

Dis lay shows the following Indicators, in the following cases, Figure 1.12a/b.

1. Current Stage Indicator

This indicator notifies the user for the current stage of a test rocedure.

2. High Voltage On/Off Indicator

This indicator notifies the user for the status of the high voltage tank.

If the indicator is dis layed, the high voltage is ON.

3. Stirrer Indicator

This indicator notifies the user for the status of the stirrer.

If the indicator is dis layed the stirrer is ON.

4. Breakdown Blinking Indicator

After a test stage, this blinking indicator notifies the user that a breakdown was

detected.

TEST:ASTM D1816/84

TIMER:

00:00:02

kV

STIR

HV ON

Stirrer n/ ff indicat rHigh V ltage On/Off Indicat r

Current Stage Indicat r

STAGE

3

0.5kV/s > BREAKDOWN

01.0

12:10 01/08/16 65°F

Figure 1.12 – Indicators during a test stage: high voltage ON; stirrer ON; test stage 3

TEST:ASTM D1816/84

TIMER:

00:00:05

kV

STIR

Stirrer n/ ff indicat r

Current Stage Indicat r

STAGE

7

AFTER BD WAIT TIMER...

35.2

12:10 01/08/16 65°F

BD

BreakD wn Blinking Indicat r

Figure 1.12 – Indicators after breakdown detected: high voltage OFF, stirrer ON; BreakDown detected; test stage

7; After BreakDown Timer counting down.

12

DTS-60A / DTS-100A OPERATORS MANUAL

1.4 Setup the Equipment

The setu of this equi ment has been minimized by careful consideration of the o erator

during design. The DTS-60A and DTS-100A one- iece construction ermits convenient

ortability. The test set requires that the unit is o erated with the control anel in the

horizontal osition, in order to kee oil level over high voltage transformer in the high voltage

tank.

1. Select a location for the unit that will allow easy viewing of the LCD dis lay

2. Be sure that all the controls are off, in their de-energized state.

3. Remove all components and oil vessels from the test chamber

4. Install the input line cord into the Input Power rece tacle

5. Connect the line cord to a suitable (120V or 230V, see Specifications

Table) grounded power source.

6. Select the desired Test cell. Fill in with sufficient oil for the testing to be

erformed.

7. Clean the Test Cell and Electrodes thoroughly and adjust the electrodes to

conform with the ro er ASTM S ecification. Be sure the electrodes are securely

tightened on the adjustment osts inside the oil vessel.

Use Isolation transformer (1/1) if the electrical

installation has neutral earthing.

All the oil vessels designed and made by High Voltage Inc. have

interchangeable posts and electrodes. These oil vessels were designed to

conform to the ASTM test specifications requiring simple disassembly for

cleaning. This design greatly reduces the time and effort required keeping

your oil vessels in top operating condition.

The operator of this equipment must use good

judgement and follow all safety precautions noted in

this guide to ensure the protection of himself and others

in close proximity to the test area. Failure to follow the

instructions could result in injury or death.

13

DTS-60A / DTS-100A OPERATORS MANUAL

1.5 Startup the Equipment

1. Ensure that setu has been com leted as described in section 1.4, Setu the

Equi ment.

2. Turn on Main Power.

3. The equi ment initiates a self-test, Figure 1.13. The Firmware Version is shown, then

the Self Tests begin executing. In case of malfunction, an error message is dis layed

and the system will be halted (see section 1.3.5).

...SELF TEST 1

MEN U B AC K D OW NU P ENTER

INC

TM

HIGH VOLTAGE

12:10 01/08/16 65°F

Figure 1.13 – Startu and Self Test

4. After the self-tests are com leted, the last selected test is resented: Sim le Test;

Standard Test; or User-Defined Test.

5. The unit will dis lay the Electrode Warning message and will wait for ‘E TER’ to be

ressed to start the test(see section 1.3.3).

6. Before starting a test the user may o en the lid, check the electrodes (ty e and

s acing) and finally fill the a ro riate test vessel with insulating oil. After closing the

lid, the user should ress the ‘E TER’ key to start the test.

Whenever you see an ERROR message contact the

distributor or High Voltage Inc. directly.

14

Other manuals for DTS-60A

1

This manual suits for next models

1

Table of contents

Other High Voltage Test Equipment manuals