case open.

5) Take the tlu·eaded bobbin case

by

the latch and place it on the

center

stud

of

the bobbin case holder.

Release latch and press

bobbin

case on to center stud until the latch catches

the

undercut

thereon with a click that

can be heard. Permit about 5

em

of

bobbin

thread

to

hand down freely. Be sure

to

push

the slide plate to the right

before starting to sew.

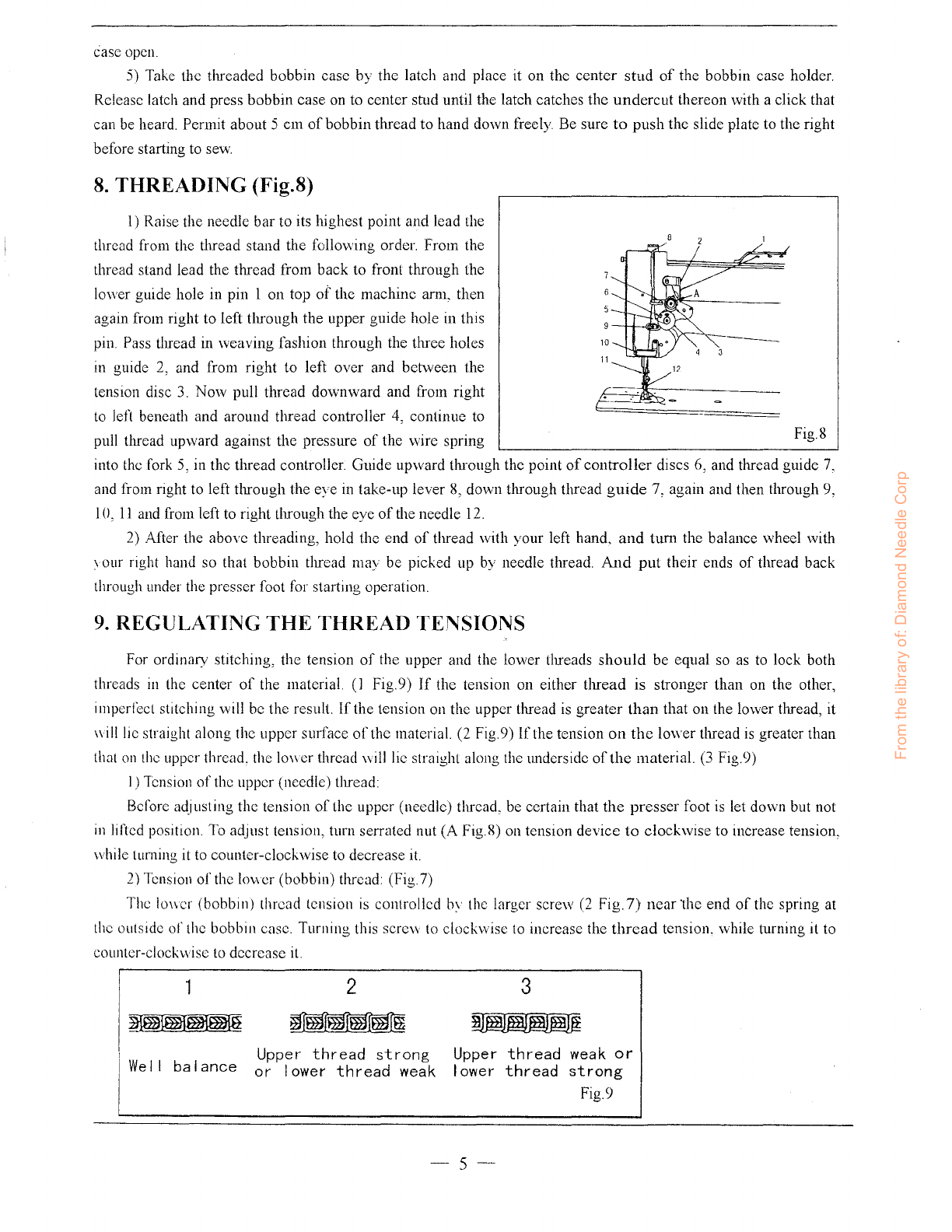

8.

THREADING

(Fig.8)

l)

Raise the needle bar

to

its highest point and lead the

thread from the thread stand the follovving order. From the

thread stand lead the thread from

back

to front through the

lower guide hole in pin 1 on top

of

the machine

am1,

then

again from right to left tlu·ough the upper guide hole in this

pin. Pass thread in weaving fashion through the three holes

in guide 2, and from right

to

left over and

between

the

tension disc

3.

Now

pull thread downward and from right

to left beneath and around thread controller 4, continue to

10

pull thread upward against the pressure

of

the wire spring Fig.8

into the fork 5, in the thread controller. Guide upward through the point

of

controller

discs 6, and thread guide

7,

and from right to left through the eye in take-up lever

8,

down through thread

guide

7, again and then through 9,

I0,

ll

and from left to right through the eye

of

the needle 12.

2)

.ASter

the above threading, hold the end

of

thread with your left hand.

and

tum

the balance wheel with

\our

right hand so that bobbin thread may be picked up by needle thread.

And

put

their ends

of

thread back

through under the presser foot for starting operation.

9.

REGULATING

THE

THREAD

TENSIONS

For ordinary stitching, the tension

of

the upper and the lower threads

should

be equal so as to lock both

threads

in

the center

of

the material. (J Fig.9)

If

the tension on either

thread

is

stronger than on the other,

imperfect stitching will be the result.

If

the tension on the upper thread is

greater

than

that on the lower thread, it

will lie straight along the upper surface

of

the material. (2 Fig.9)

If

the tension

on

the

lower

thread

is

greater than

thot

on

the upper thread_ the lO\\er thread will lie straight along the underside

of

the

material.

(3

Fig.9)

I) Tension

of

the upper (needle) thread:

Before

ad_i

usting the tension

of

the upper (needle) thread, be certain that

the

presser

foot

is

let down but not

in

lifted position. To adjust tension, turn serrated nut

(A

Fig.

S)

on tension

device

to

clockwise

to increase tension,

while tuming it to counter-clockwise to decrease it.

2) Tension

of

the lower (bobbin) threod (Fig 7)

The 10\\er (bobbin) threod tension

is

controlled

hy

the larger screw

(2

Fig.

7)

neor"thc

end

of

the spring at

the outside

or

the bobbin case. Turning this screw to clockwise to increase the

thread

tension. while turning it to

counter-clockwise to decrease it.

2

~

1 Upper

thread

strong

j

We

II

ba I

ance

or

Iower

thread

weak

3

Upper

thread

weak

or

lower

thread

strong

Fig.9

-5-

From the library of: Diamond Needle Corp