Highlight MAGNUM 2300 SD-U User manual

OPERATION MANUAL

MAGNUM 2300 SD-U

UNIFORM CASE SEALER

SERIAL NUMBER

Please refer to the serial number in all correspondence with Highlight or any Highlight

Distributor. This identifies your machine and will help in our ability to quickly and

efficiently respond to your needs.

Version 1.2 –March 2008

TABLE OF CONTENTS

1. General System Information

1. System Specifications ……………………………………………………………………... I-1

2. System Overview Prints.…..……………………………………………………………… I-2

3. System Descriptions…..……………………..…………………………….……………….I-3

4. Tape Head and Tape Overview Prints……………………………………………..…….I-4

5. Tape Head Descriptions………………………………………………………………..…. I-5

6. Tape Threading Diagram……………………………………………………………….… I-6

7. Limited Warranty.…………………………………………………………………………. I-7

2. Installation Instructions

1. Safety Precautions…………...…………………………………………………………….. II-1

2. Machine Placement.……………………..………………………………………………… II-2

3. Machine Set-Up……………………………………………………………………………..II-3

3. Operation Instructions

1. Safety Precautions…………...…………………………………………………………….. III-1

2. Pre-Operation Adjustments…………...………………………………………………….. III-2

3. Operator Panel…..……………………………...………………………………………...... III-8

4. Machine Operations……………………………………………………………………… III-9

4. Maintenance

1. Preventive Maintenance…………...……………………………………………………… IV-1

5. Troubleshooting

1. Troubleshooting Guide…………………………………………………………………….V-1

6. Electrical References

1. Electrical Parts List and Prints……………………………………………….……………VI-1

7. Mechanical References

1.Mechanical Parts List and Prints…………………………………………………….…….VII-1

8. Notes

I. Chapter 1

HIGHLIGHT INDUSTRIES, INC.

Magnum®2300 SD-U Uniform Case Sealer Operation Manual

General System

Information

Chapter

1

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-1

SYSTEM SPECIFICATIONS

Highlight’s Magnum® 2300 SD-U is an adjustable side belt drive case sealer designed to

provide accurate, consistent tape application to uniform cases. Highlight’s 200 series

tape head will accept any 2-inch case tape and provide optimum case sealing to the top

and bottom of the case. The system is designed to operate at up to 30 cases per minute.

An optional 3-inch tape head, model 300, is also available and interchangeable with the

model 200. Chromed steel 16-inch long entry and exit conveyors are standard. Height

adjustable legs from 22 inches to 32 inches with locking casters included.

Machine Size

o68” L x 34” W x 55” H (with 16” L Entry Conveyor and 16”L Exit

Conveyor, 36” L without)

oShipping weight –375 lbs on a pallet

oTape Roll Diameter: 3” inside diameter core with up to 16” outside

diameter

oTape Roll Width: 1 ½” and 2” tape standard, 3” Optional

Operation Space

o75” L x 45” W x 70” H

Electrical Data

o120 VAC; Single Phase, 10 Amps, 60 Hz

Production Capacity

oOperating Rate: Up to 30 boxes per minute depending on box length

oCase Belt Speed: 75 feet per minute

oMinimum Load Size: 5” L x 5” W x 5”H (3”H with lowering kit)

oMinimum Load Weight: 4 lbs

oMaximum Load Size: 20” W x 20” H (18”H with lowering kit)

oMaximum Load Weight: 75 lbs

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-2

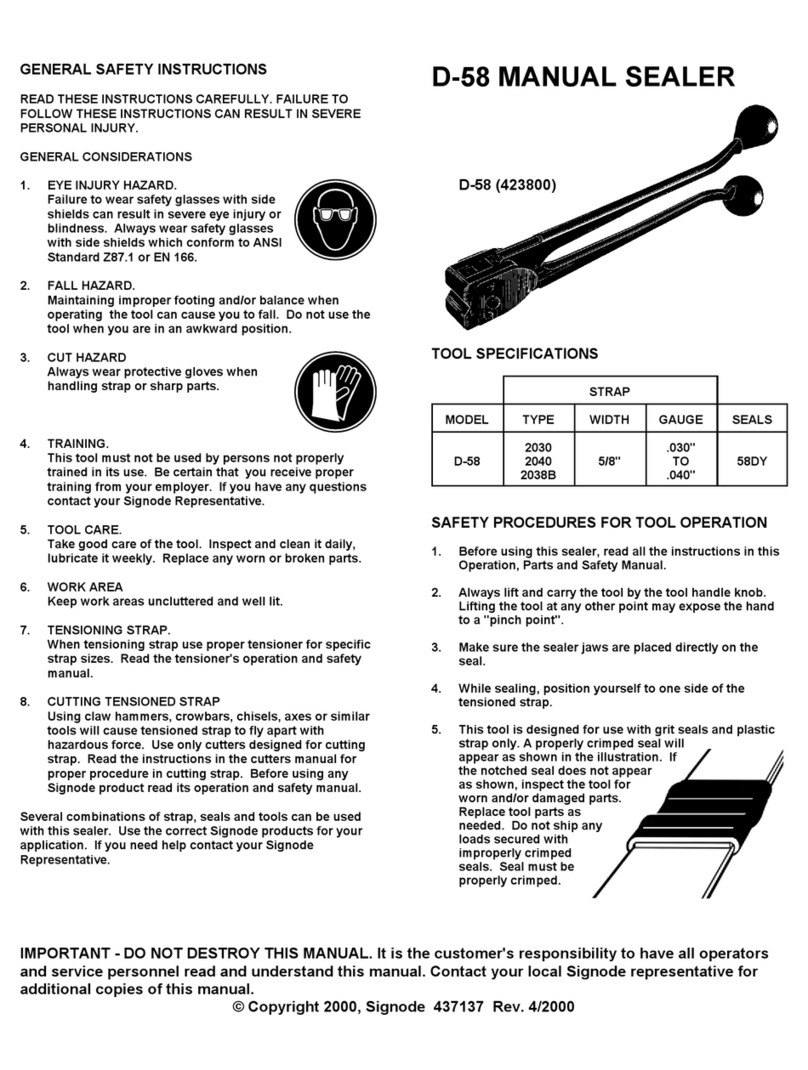

SYSTEM OVERVIEW PRINTS

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-3

SYSTEM DESCRIPTIONS

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-4

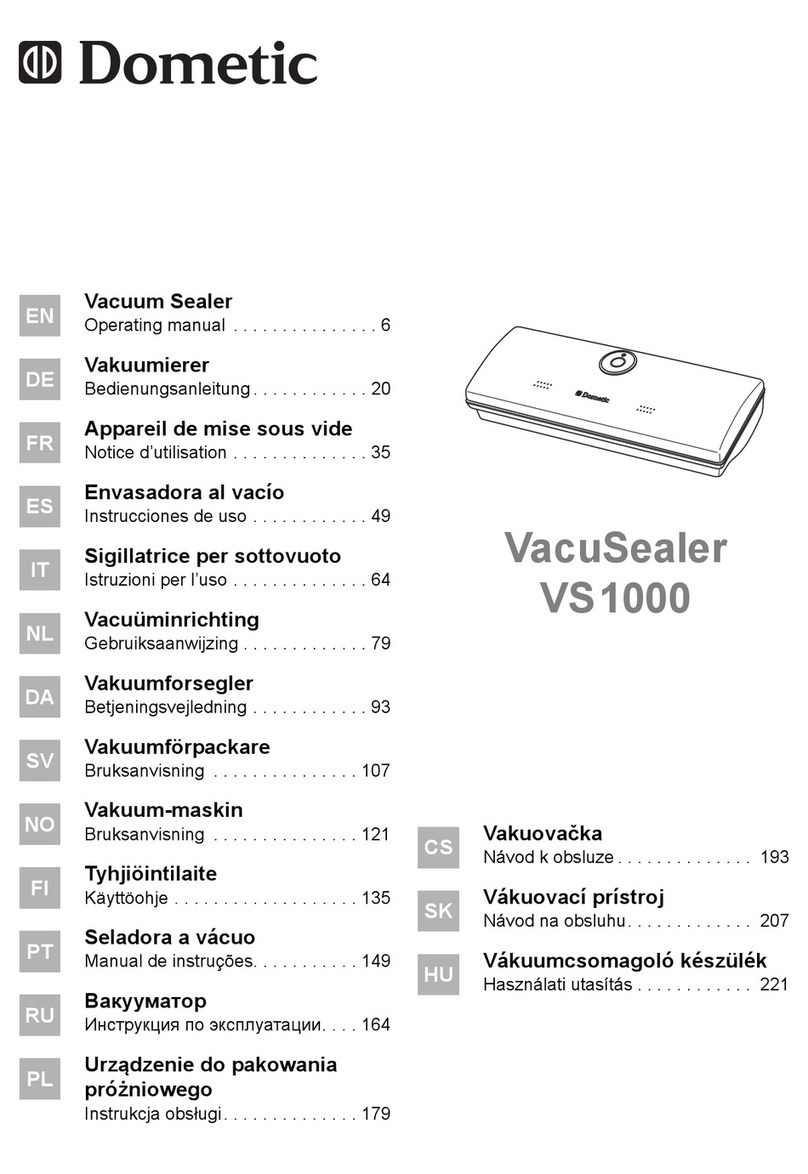

TAPE HEAD & TAPE OVERVIEW PRINTS

2"or 3” Optional

3"diameter

16"max diameter

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-5

TAPE HEAD DESCRIPTIONS

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-6

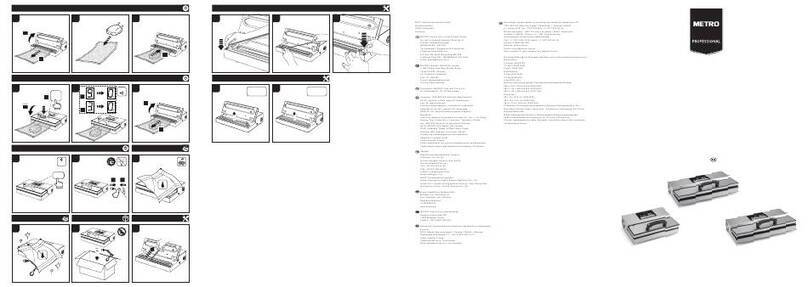

TAPE THREADING DIAGRAM

WARNING: BE SURE EMERGENCY STOP IS PUSHED IN BEFORE THREADING

THE TAPE AND PULLED OUT WHEN TAPE IS THREADED!

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

I-7

LIMITED WARRANTY

Highlight Industries, Inc. warrants that its case sealers will be of merchantable quality, free from

defects in material and workmanship as determined at the date of shipment, by generally

recognized, applicable and accepted practices and procedures in the industry, for a period of:

1. The taping head knife blades, springs and rollers are warranted for ninety (90) days

2. All other taping head parts are warranted for three (3) years

3. All other parts of the Highlight case tapers are warranted for two (2) years

from the Highlight invoice date, under normal use and service.

When the Purchaser gives Highlight written notice of any alleged defect within the applicable

warranty period, Highlight will, at its option, repair or replace the same free of charge F.O.B. its

manufacturing plant, installation not included. Equipment replaced under the warranty shall

have the same warranty as new equipment but does not extend the warranty of the original

equipment.

Satisfaction of this warranty, consistent with other provisions herein, will be limited to the

replacement or repair or modification of, or issuance of a credit for, the equipment involved, at

Highlight’s option.

Highlight neither assumes nor authorizes any person to assume for it any other obligation in

connection with the sale of Highlight’s equipment.

This warranty shall not apply to any equipment which has been repaired or altered by un-

authorized personnel in any way so as to, in the judgment of Highlight, affect serviceability, or

which has been subjected to misuse, negligence, accident, or to equipment made by Highlight

which has been operated in a manner contrary to Highlight’s instructions.

In no event regardless of the cause, shall Highlight be liable for penalties or penalty clauses of

any description or any damages resulting from loss of profits, use of products or for any

incidental indirect or consequential damages, even if advised of the possibility of such damages.

This limitation of Highlight’s liability will apply regardless of the form of action, whether in

contract or tort, including negligence. Any action against Highlight must be brought within

twelve (12) months after cause of action accrues.

“THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESSED,

IMPLIED OR STATUTORY INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY

OF FITNESS AND EXTENDS ONLY TO THE BUYER OR CUSTOMER PURCHASING FROM

HIGHLIGHT OR AN AUTHORIZED HIGHLIGHT DISTRIBUTOR.”

II. Chapter 2

HIGHLIGHT INDUSTRIES, INC.

Magnum®2300 SD-U Uniform Case Sealer Operation Manual

Installation

Instructions

Chapter

2

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

II-1

SAFETY PRECAUTIONS

Read the Operation Manual before operating the machine.

Do NOT attempt to service the machinery unless you are qualified and understand

the Operations Manual.

Do NOT use extension cords to operate the system.

Make sure nothing is on the power cable.

Make sure nothing is on the upper tape head unit.

Loose clothing must NOT be worn while the machine is in operation.

Stay clear of moving parts while the machine is in operation.

Do NOT allow dampness or water to enter the electrical units.

Turn OFF power to the machine when it is not in use.

NEVER try to remove jammed boxes from the machine while it is running.

When feeding boxes manually, push boxes into drive belts using the end of the box,

not with your hands on any corner of the box.

Both tape heads use EXTREMELY SHARP knives! The orange guard is labeled.

Know the knife’s location BEFORE attempting to load and thread tape, or to make

any tape head adjustments.

SEVERE PERSONAL INJURY AND/OR EQUIPMENT DAMAGE could result from

failure to comply with the above.

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

II-2

MACHINE PLACEMENT

Inspections

Before installation, inspect the entire machine for visual damage. If found, please report

this damage to the truck line. Highlight Industries has taken every precaution during the

packaging and loading of this equipment. However, it is YOUR RESPONSIBILITY to

inspect for damage before installation.

Positioning of the Machine

Place your Magnum® Case Sealer close to an area where you will be sealing your loads.

Make sure that there is sufficient room to load/unload the machine and that you do not

stretch the wiring cable. Remember, you will need to provide electrical service to a 120

VAC, 10 Amp-outlet. DO NOT USE EXTENSION CORDS!!

Floor Weight Bearing/Stress Tolerance

The floor must be able to bear the weight of the machine, plus the weight of the

maximum load, which is 75 lbs, plus a safety factor. The floor must also be able to

tolerate the stress of the machine’s operation.

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

II-3

MACHINE SET-UP

It is very important to read all instructions before undertaking any of these steps. The

following steps should help achieving a safe and quick machine set-up.

1. Your Magnum® Case Sealer comes pre-assembled and ready for operation. Set

up the machine where it will not be subject to moisture or damage to its power

cord.

2. Although the Magnum® Case Sealer is pre-assembled, the casters allow for some

height adjustment. To adjust height, loosen “B” screw on all four casters (see

figure below), lift machine to desired height and retighten “B” screw.

NOTE: Nut “A” fixes the caster in place.

3. The rollers are detachable. They are held to the machine by four holding screws

attached to the machine body. To detach the roller tables, loosen (complete

removal is not necessary) all four holding screws, then lift the table straight up

and pull out. The table has four slots fitting over the screws (see figure below).

III. Chapter 3

HIGHLIGHT INDUSTRIES, INC.

Magnum®2300 SD-U Uniform Case Sealer Operation Manual

Operation

Instructions

Chapter

3

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

III-1

SAFETY PRECAUTIONS

Read the Operation Manual before operating the machine.

Do NOT attempt to service the machinery unless you are qualified and understand

the Operations Manual.

Do NOT use extension cords to operate the system.

Make sure nothing is on the power cable.

Make sure nothing is on the upper tape head unit.

Loose clothing must NOT be worn while the machine is in operation.

Stay clear of moving parts while the machine is in operation.

Do NOT allow dampness or water to enter the electrical units.

Turn OFF power to the machine when it is not in use.

NEVER try to remove jammed boxes from the machine while it is running.

When feeding boxes manually, push boxes into drive belts using the end of the box,

not with your hands on any corner of the box.

Both tape heads use EXTREMELY SHARP knives! The orange guard is labeled.

Know the knife’s location BEFORE attempting to load and thread tape, or to make

any tape head adjustments.

SEVERE PERSONAL INJURY AND/OR EQUIPMENT DAMAGE could result from

failure to comply with the above.

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

III-2

PRE-OPERATION ADJUSTMENTS

Belt Adjustment

Belts are tensioned at the factory. When replacement is necessary, follow

the procedure below to re-tension belts.

Turn machine power off. Loosen the screw (A). Use (B) to adjust the belt to a suitable

tension. Tighten screw (A). Grab the belt and pull it forward firmly (towards the front

of the machine) to check if it slips on rear drive pulley. A properly tensioned belt will

cause the motor to be back-driven when manually pulling on the belt. If the belt slips

on the pulley, the belt must be tensioned tighter. See figure below.

MAGNUM 2300 SD-U UNIFORM CASE SEALER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. * 2694 PRAIRIE SW; WYOMING; MI 49509 * 1-800-531-2465

III-3

Tape Head Adjustment

The tape heads are adjusted at the factory for optimum performance. The

procedures below outline the how the factory settings are achieved.

The tape knife in the tape head is EXTREMELY SHARP! The orange guard is labeled

with a warning. KEEP ALL BODY PARTS AWAY FROM THE TAPE KNIFE AT ALL

TIMES! Failure to comply could result in SERIOUS PERSONAL INJURY!

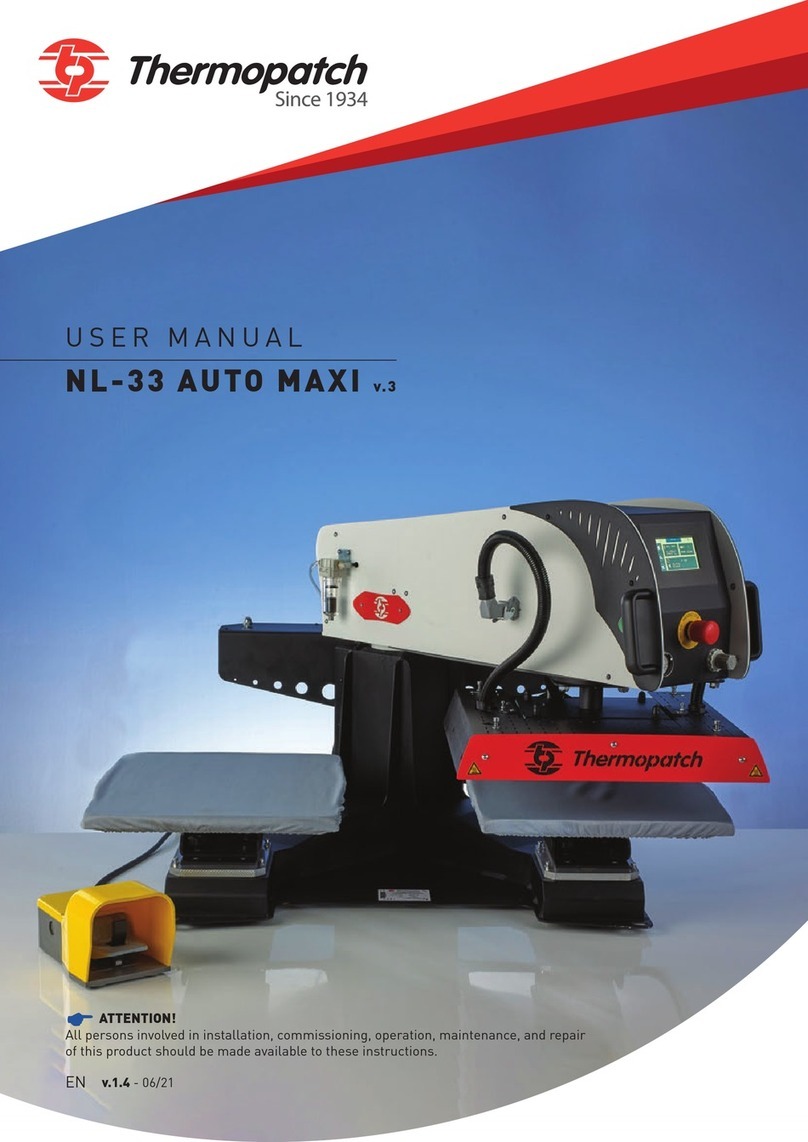

A. Centering the tape on rollers:

1. Make sure the tape is pushed fully against the backstop fingers (see figure

below).

2. Loosen the retaining nut several turns, but do not remove it altogether.

Backstop

Fingers

Retaining

Nut

Support

Plate

Table of contents