Hillco Technologies, Inc.

3

D-171206CMA01C Sept, 2022

Contents

Model and Serial Number 1

Maximum Header Weights 1

Introduction 2

Safety 3

Signal Words................................................................................................................................... 3

Operation Safety..............................................................................................................................4

Hydraulic Safety...............................................................................................................................4

Service and Maintenance Safety..................................................................................................... 5

Highway Operation and Transport Safety........................................................................................5

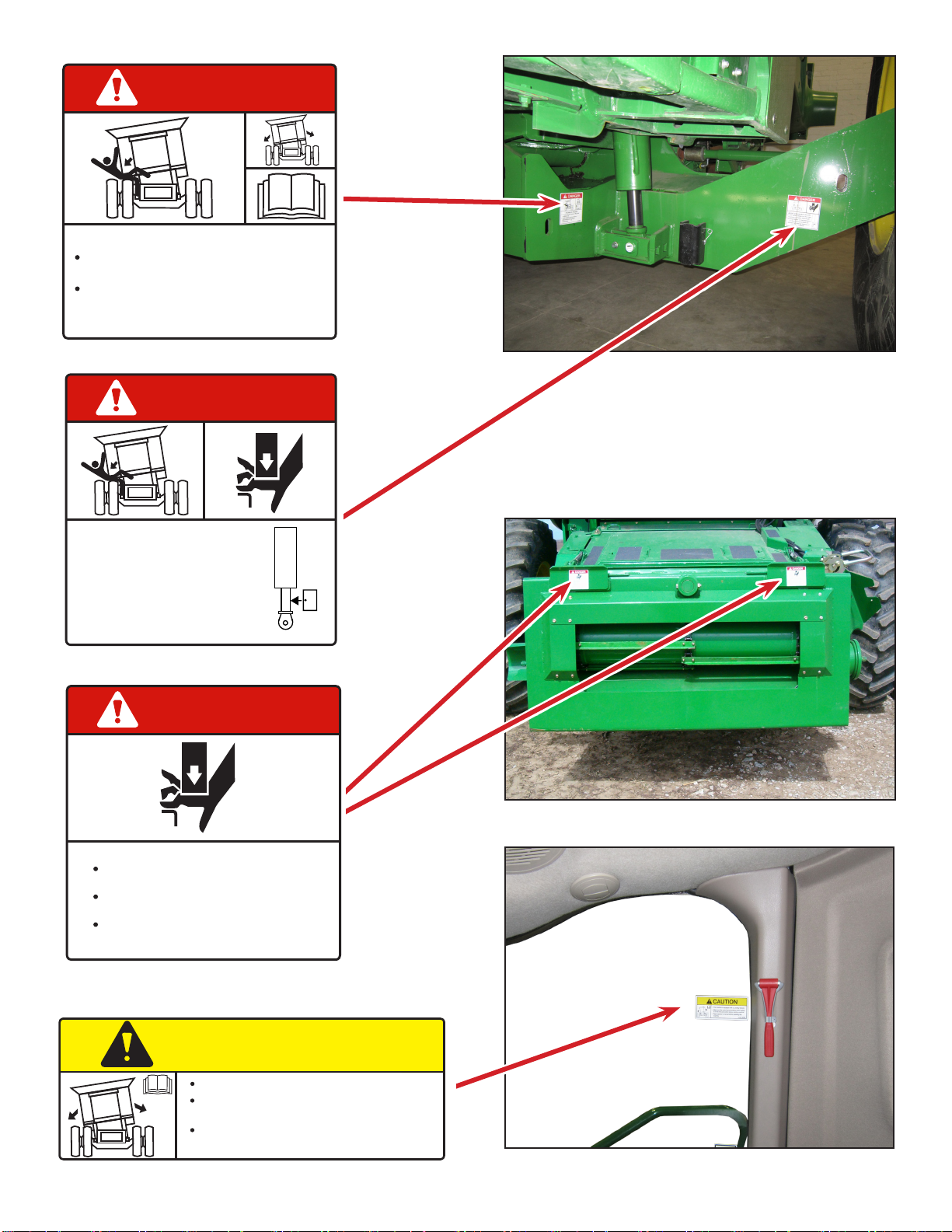

Safety Labels...................................................................................................................................6

Product Description 10

Controls and Components 11

Leveling Control Switches & Monitor............................................................................................. 11

Hydraulic Gear Pump.................................................................................................................... 12

JS9020 Hydraulic Flow..................................................................................................................12

Leveling Control Manifold..............................................................................................................12

Leveling Controller.........................................................................................................................13

Header Tilt Manifold.......................................................................................................................13

Overcarriage Position Indicator..................................................................................................... 14

Slope Sensing Clinometer............................................................................................................. 14

Transition.......................................................................................................................................14

Header Position Sensor.................................................................................................................15

Feeder Chain and Slats.................................................................................................................15

Feeder Drum Arms........................................................................................................................ 15

Retractable Ladder Step................................................................................................................15

Mechanical Leveling Cylinder Stops..............................................................................................16

Carriage.........................................................................................................................................16

Hydraulic Leveling Cylinders and Counter-Balance Valves ..........................................................17

Leveling Cylinder Safety Stops......................................................................................................17

Drop Axle......................................................................................................................................18

Header Tilt Control Switches......................................................................................................... 19

Header Tilt System........................................................................................................................ 19

Header Tilt Controls and Components.......................................................................................... 19

Operation 20

Leveling System Controls............................................................................................................. 21

Lateral Header Tilt / Contour Master............................................................................................. 22

Operator Adjustments....................................................................................................................24

Calibration..................................................................................................................................... 26

Diagnostics....................................................................................................................................33

Storage..........................................................................................................................................38

Transporting Combine on a Trailer................................................................................................ 38

Maintenance 39

Driveline Maintenance...................................................................................................................40

100 Hour - Annual Maintenance....................................................................................................41

Critical Joint Inspection..............................................................................................................42

Adjustments 44

Rear Axle Spacing.........................................................................................................................44

Lateral Tilt Flow Control Adjustment..............................................................................................48

Transition Fore/Aft Adjustment Procedure.....................................................................................48

Header Tilt Setup.......................................................................................................................... 49

Tire Selection 51

Header Tire Compatibility Chart............................................................................................................. 51

Header Compatibility Chart 52

Decal Placement.......................................................................................................................................53

Leveling System Specications 55

Electrical Schematics.............................................................................................................................. 57

JS7020 & JS9020 Leveling Electrical Schematic..........................................................................57

JS9020 Header Trim Schematic (Non Contour Master)................................................................61

JS5010 & JS7010 Header Trim Schematic (Non Contour Master)............................................... 62

Hydraulic Schematics 63

JS9020 Hydraulic (Leveling and Factory Header Trim).................................................................63

JS9020 Hydraulic (Leveling and Hillco Header Trim).................................................................64

JS5010 & JS7020 Hydraulic (Leveling and Header Trim)............................................................. 65

Notes 66