3500 VRC Operator’s Manual

2

Revision B

OCT 2005

Part No. : AM-3500VRCV5

U

dated : 19/10/2005

Contents

Step 1...........................................................................................................................................4

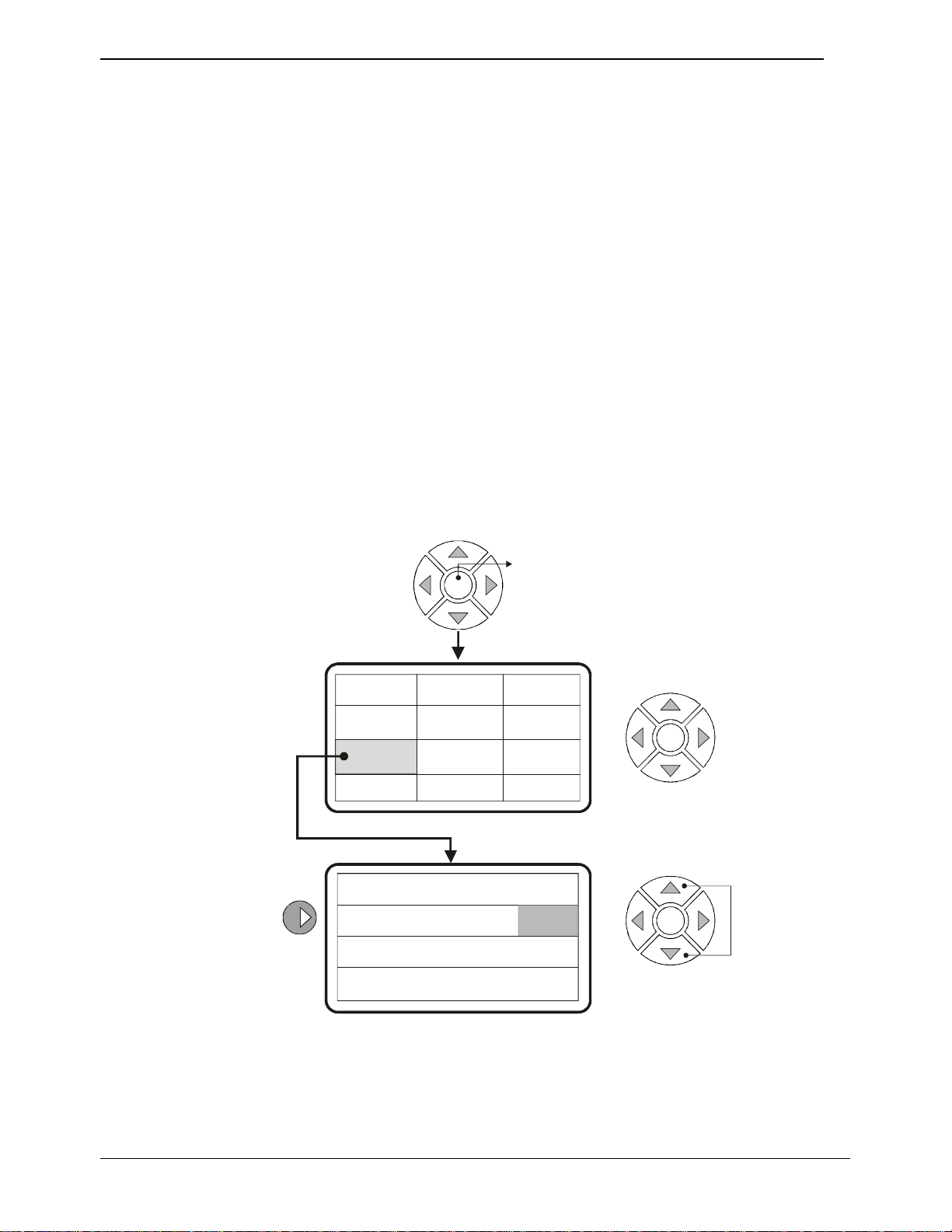

1.1 - Units Selection.............................................................................................................................. 4

1.2 –Pod Selection................................................................................................................................ 5

Step 2...........................................................................................................................................6

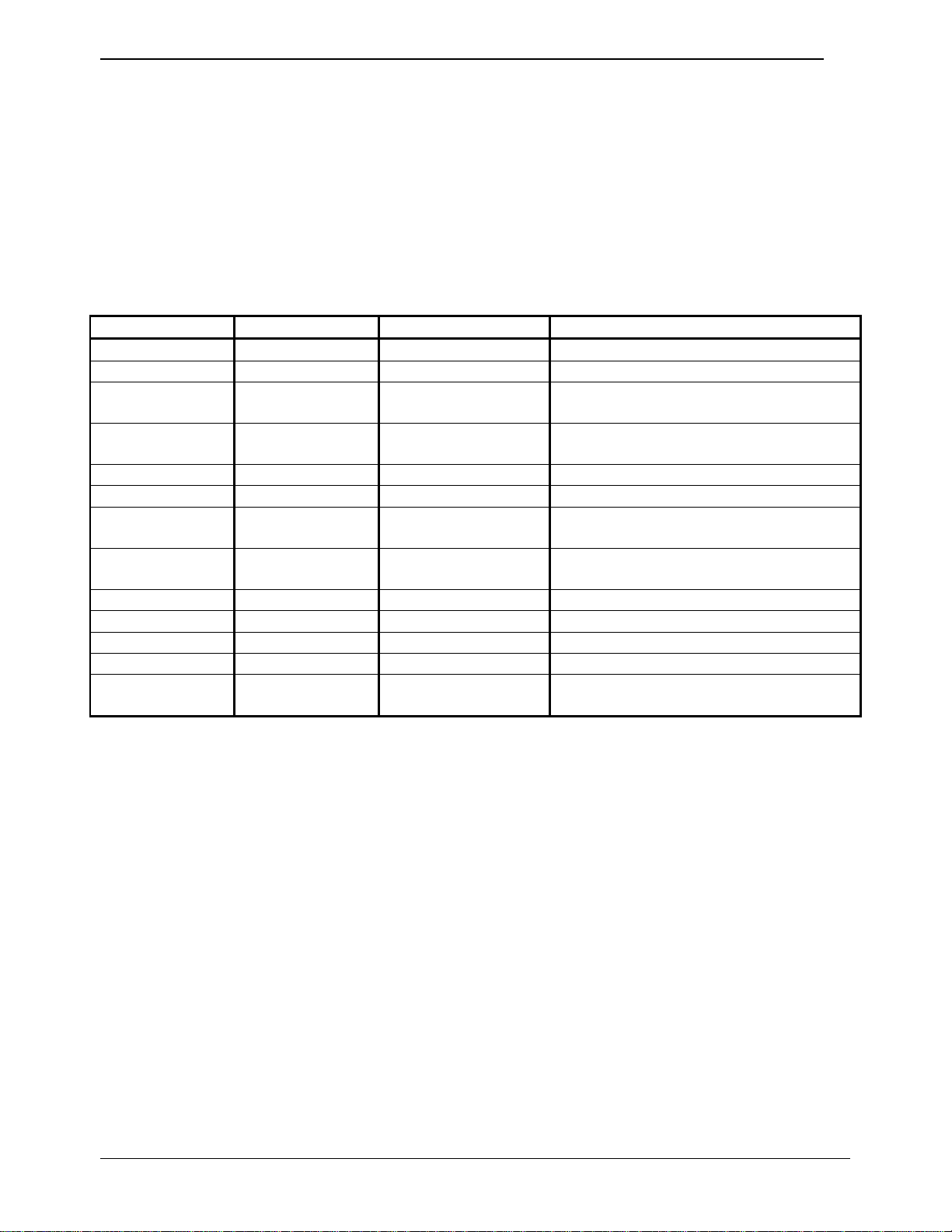

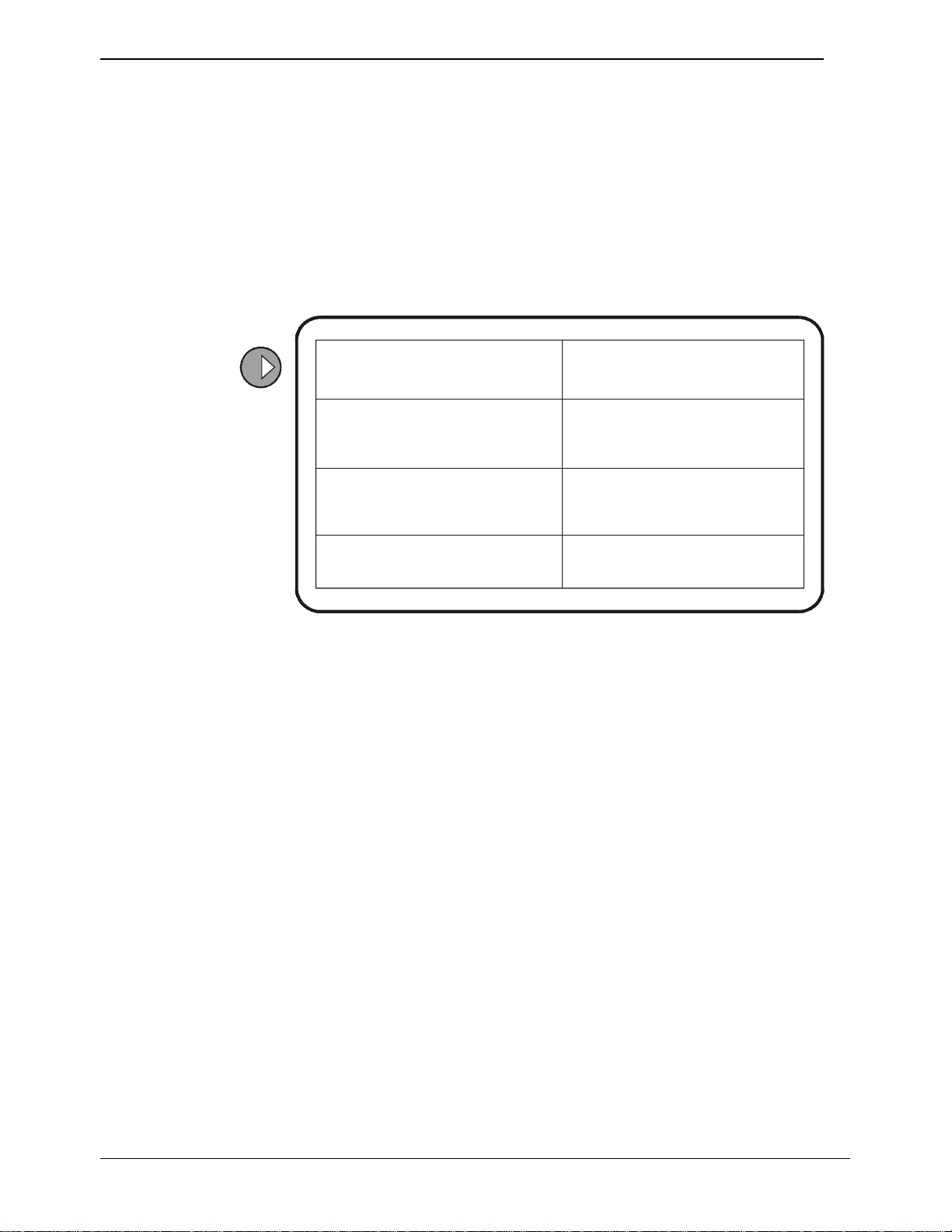

2 - Drive Setup...................................................................................................................................... 6

Step 3.........................................................................................................................................17

3.1 - Product Calibration ..................................................................................................................... 17

3.2 –Target Rate and Step Size ........................................................................................................... 29

3.3 - Fine Tuning Calibration Factors.................................................................................................... 30

3.4 - Reusing Product Calibration Factors............................................................................................. 32

Step 4.........................................................................................................................................33

4.1 - Machine Calibration.................................................................................................................... 33

Step 5.........................................................................................................................................35

5.1 - Alarms Setup.............................................................................................................................. 35

5.3 - Air Pressure Alarm (where fitted) ................................................................................................. 38

5.4 - Drive Ratio/Shaft Alarms (where fitted) ........................................................................................ 39

5.5 - Bin Level Alarm........................................................................................................................... 41

5.6 - Depth Alarm (where fitted).......................................................................................................... 42

5.7 - Aux Alarm (where fitted)............................................................................................................. 43

5.8 –Pump 1 & Pump 2 Speed (where fitted)....................................................................................... 44

5.9 –Bin Liquid Pressure Alarm (where fitted) ...................................................................................... 45

Step 6.........................................................................................................................................46

6.1 - Options Setup............................................................................................................................. 46

6.2 - Pod Selection.............................................................................................................................. 46

6.3 –Run/Hold Input........................................................................................................................... 47

6.4 - Units........................................................................................................................................... 48

6.5 - Prime.......................................................................................................................................... 48

6.6 - Two Tenths of a Hectare ............................................................................................................. 48

6.7 - External Hold 4th Bin.................................................................................................................... 49

Step 7.........................................................................................................................................50

7.1 - Display Setup.............................................................................................................................. 50

7.2 - Contrast ..................................................................................................................................... 50

7.3 - Backlighting................................................................................................................................ 51

7.4 - Display Invert .............................................................................................................................. 51

7.5 - Lightbar Brightness ..................................................................................................................... 51

Step 8.........................................................................................................................................52

8.1 - Time, Date and GPS Setup........................................................................................................... 52

8.2 - Time........................................................................................................................................... 52

8.3 - GPS............................................................................................................................................ 53

Step 9.........................................................................................................................................54

9.1 - Data Card & Logging Interval....................................................................................................... 54

9.2 - Logging Interval.......................................................................................................................... 55

9.3 –Upload Software ........................................................................................................................ 56

9.4 –Application Maps ....................................................................................................................... 57

Step 10.......................................................................................................................................59

10.1 - Guidance Setup ........................................................................................................................ 59

10.2 - Guide Sensitivity........................................................................................................................ 59

10.3 - GPS to Implement..................................................................................................................... 60