Operating instructions for Hillside Blueberry Cultivator

With Hydraulic Width Adjustment

Copy write 2006: Hillside Cultivator Co. LLC 911 Disston View Drive, Lititz, PA 17543 717-626-6194

Parts and description

1. Hydraulic Cylinders 2”X 10” stroke

2. Hydraulic Flow restrictor

3. Hydraulic Hose

4. Main Cultivator Frame 4” tube

5. Sliding Sub Frame

6. Spider Gangs

7. Spiders and Scrapers

8. Pivot Arm

9. Pivot Angle Position Plate

10. Pivot Angle Adjusting Pin

11. Cultivator Mounting Plate

Cultivator Angle Adjusting Plate

12. Angle adjusting bolt.

13. Gauge wheels

Cultivator Setup

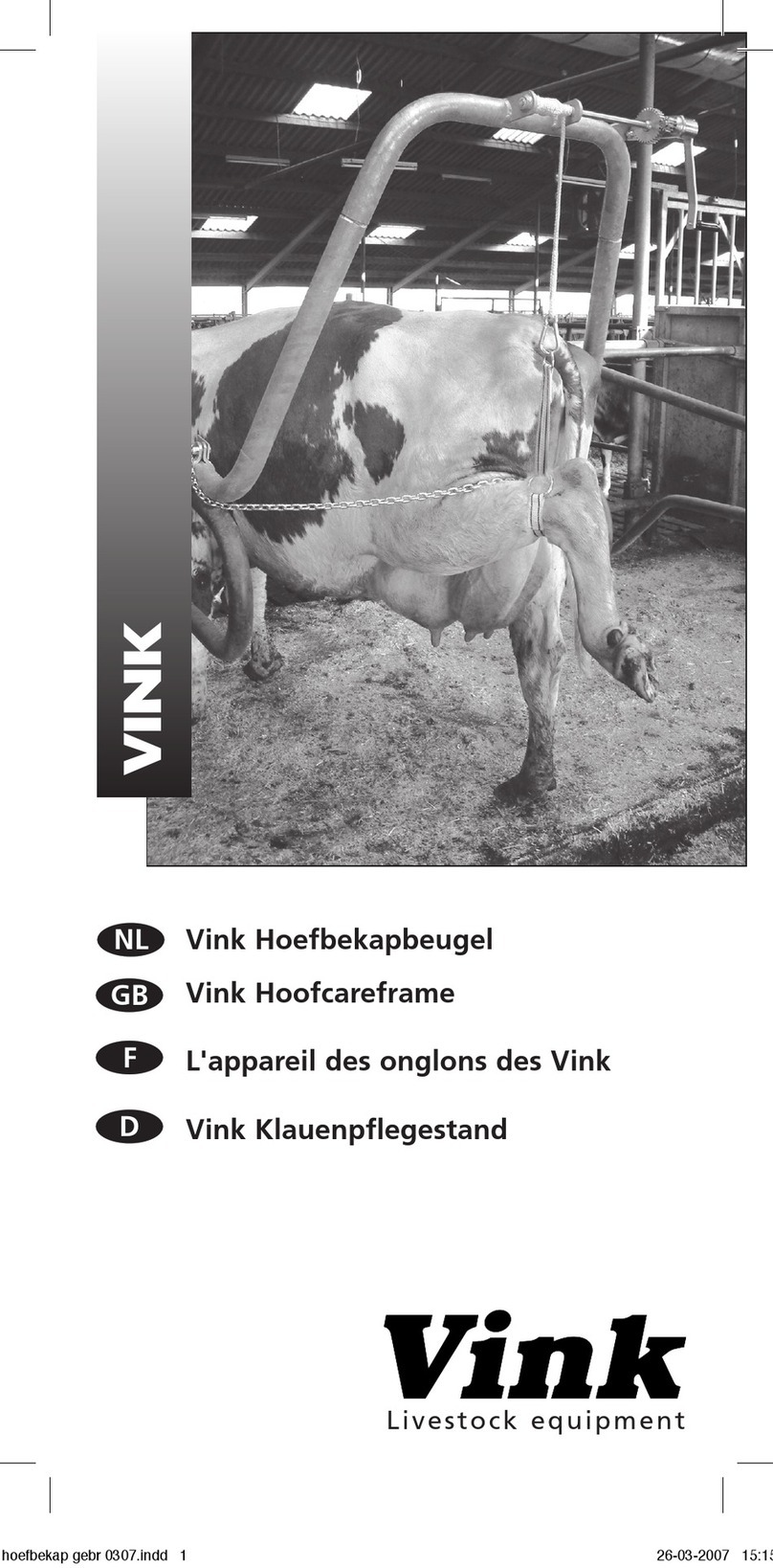

If the cultivator has been shipped by truck, it will arrive with the spider gangs and disk

gangs disconnected from there mounting plates and placed inside of the frame on a pallet

or on a separate pallet. Remove the gangs being careful to keep your fingers out of tight

spots on the gang. The best way to handle the gangs is either by the ends of the axle or to

pick them up by the spider itself. Then the frame itself should be lifted from the pallet by

attaching it to the three point hitch of the tractor. When the cultivator frame is off the

ground, loosen the angle adjusting bolt on the bottom of the cultivator mounting plate.

4 1 2

1

The bolt should be made loose enough to allow the

small plate beneath these bolts to provide enough

clearance to slide the cultivator gang in place. (See

Figure 2) You will notice that the gangs have an

either a No 1 or a No. 2. The spider gangs are

constructed of right or left facing slicer tines. The

cutting edge of the tine is the side which engages

with the soil first and moves the soil laterally. As

you can see in figure 1 the scrapers go toward the

rear of the cultivator. Before tightening the bolts

which hold the gang to the angle adjusting plate, the

cultivator gang may be moved either in or out to give

a preliminary adjustment to the location of the gang.

The angle of aggressiveness can also be adjusted at

this point.

12

11

Figure2