Econo-Wrap EW-1800T User manual

Rel. 06/07/21

Self-loading Bale Wrapper

EW-1800T

Operator’s Manual

Self-loading Bale Wrapper EW-1800T

2

Page left blank intentionally

Self-loading Bale Wrapper EW-1800T

3

CAUTION!

Read this Instrucons Manual prior to using the machine and observe the safety rules described herein.

The Instrucons Manual is an integral part of the machine!

Keep the Instrucons Manual in a safe place, where it should be accessible to the machine operator during

the enre lifespan of the machine.

In the event of its loss or damage, the user must acquire a new copy from the machine dealer or manufacturer.

In the event the machine is sold or made available to another user, the Instrucons Manual must be aached with the dec-

laraon of conformity for the machine.

The manufacturer reserves its copyrights to the Instrucons Manual.

Copying, processing of the Instrucons Manual and its parts without the manufacturer’s permission is strictly prohibited.

Tar River Implements guarantees the ecient operaon of the machine, providing it is being used in accordance with the

technical and operang condions specied in this INSTRUCTIONS MANUAL.

All faults revealed during the warranty period will be repaired by the In-Warranty Repairs Service.

The repair performance date is included in the WARRANTY CERTIFICATE.

Machine parts and components which are subject to wear in normal operang condions are not covered by the warranty,

regardless of the warranty period.

In-Warranty repairs cover only instances such as: mechanical damages not

caused by the user, manufacture defects of parts, etc.

The machine shall not be covered by the warranty condions when damage is caused by:

• mechanical damage caused by the user or a trac accident,

• improper use, adjustment, and maintenance, use of the machine for a purpose other than intended,

operang a damaged machine,

• repairs by unauthorised persons,

• unauthorised changes to the machine structure,

• the use of the machine by persons unfamiliar with this Instrucons Manual.

The user is obliged to immediately report any noced damages of paint coat or spots of corrosion, and order repairs re-

gardless whether or not the damages are covered by the warranty. Warranty condions are specied in detail in the WAR-

RANTY CERTIFICATE aached to the purchased machine.

CAUTION!

It is required to request the dealer to properly ll in the WARRANTY CERTIFICATE. For ex-

ample, if the date of sale or the stamp of a dealer are missing, there is a risk that com-

plaints will not be considered valid.

Self-loading Bale Wrapper EW-1800T

4

Table of contents

1. Introducon ............................................................................................................................................7

2. Machine idencaon............................................................................................................................8

3. Rules of safe operaon ...........................................................................................................................9

3.1. User safety......................................................................................................................................9

3.2. Residual risk assessment ..............................................................................................................12

3.3. Safety decals on the machine.......................................................................................................14

4. Intended use of the machine................................................................................................................19

5. Equipment, design and operang principle..........................................................................................20

5.1. Basic equipment...........................................................................................................................20

5.2. Technical specicaon..................................................................................................................21

5.3. Operang principle.......................................................................................................................23

5.3.1 Film dispenser ......................................................................................................................24

5.3.2 Rotary frame ........................................................................................................................25

5.3.3 Bale pper (unloading) .........................................................................................................26

5.3.4 Cut and hold..........................................................................................................................28

5.3.5 Electrical system...................................................................................................................30

5.3.6 Hydraulic system..................................................................................................................34

6. Machine operaon................................................................................................................................35

6.1. Installing the bale wrapper...........................................................................................................36

6.2. Connecng bale wrapper to a tractor ..........................................................................................36

6.3. Levelling the bale wrapper...........................................................................................................37

6.4. Transport posion ........................................................................................................................38

6.4.1 Principles for driving on public roads...................................................................................39

6.5. Switching between methods for unloading bales ........................................................................41

6.6. Bale li adjustment ......................................................................................................................42

6.6.1 Displacement of the tractor’s drive centerline in relaon to the bale................................43

6.7. Film adjustment............................................................................................................................44

6.7.1 Correct lm tension ..............................................................................................................44

6.7.2 Adjusng lm tension...........................................................................................................46

6.7.3 Adjusng lm dispenser height ............................................................................................47

6.8. Film installaon ............................................................................................................................48

7. Technical servicing................................................................................................................................50

7.1. Adjusng the chain tension of the rotary frame..........................................................................50

7.2. Adjust the tension of the table roller chain..................................................................................52

7.3. Adjusng the bale pper..............................................................................................................53

Self-loading Bale Wrapper EW-1800T

5

7.4. Adjusng the tension of the belts ................................................................................................54

7.5. Changing lm width......................................................................................................................54

7.5.1 Changing the chain transmission rao of the driving table roller .......................................55

7.5.2 Changing the lower holder posion of the lm dispenser post ..........................................56

7.6. Maintaining the running axle .......................................................................................................57

7.6.1 Checking the running axle bearings for play........................................................................57

7.6.2 Removing play in the running axle bearings ........................................................................59

7.6.3 Mounng and dismantling wheel, checking nuts for ghtness ...........................................60

7.6.4 Checking air pressure, assessing the technical condion of res and steel rims. ...............61

8. Control system......................................................................................................................................62

8.1. Control unit...................................................................................................................................62

8.1.1 Descripon of funcons of the control unit ........................................................................63

8.2. Operang modes..........................................................................................................................65

8.3. Control panel operaon ...............................................................................................................66

8.3.1 AUTO mode..........................................................................................................................66

8.3.2 SEMI-AUTO mode.................................................................................................................68

8.3.3 MANUAL Mode ....................................................................................................................68

8.4. Menu ............................................................................................................................................70

8.4.1 Changing the operang mode..............................................................................................70

8.4.2 Changing the bale weight.....................................................................................................70

8.4.3 Stascs ...............................................................................................................................71

8.5. Changing speed in automac and semi-automac modes ..........................................................74

8.6. Contact details..............................................................................................................................75

8.7. Date and me sengs..................................................................................................................75

8.8. Choosing the language .................................................................................................................76

8.9. Applicaon update .......................................................................................................................76

8.10. Last warning..................................................................................................................................77

9. Maintenance.........................................................................................................................................78

9.1. Maintenance aer work...............................................................................................................78

9.2. Machine lubricaon......................................................................................................................79

9.3. Storage..........................................................................................................................................83

9.4. Troubleshoong............................................................................................................................84

10. Disassembly, disposal and environment protecon.........................................................................86

11. Addional equipment.......................................................................................................................87

12. Spare parts catalogue.......................................................................................................................88

Self-loading Bale Wrapper EW-1800T

6

12.1. General design..........................................................................................................................91

12.2. Boom frame, set.....................................................................................................................92

12.3. Drawbar, set………………………………………………………………………………………………………………………..94

12.4. Hitch, set...................................................................................................................................95

12.5. Counter weight, set...................................................................................................................96

12.6. Foot support, set.......................................................................................................................97

12.7. Safety arm, set..........................................................................................................................98

12.8. Manifold xing, set...................................................................................................................99

12.9. Film storage, set.....................................................................................................................100

12.10. Plaorm, set...........................................................................................................................101

12.11. Turntable slide base, set.........................................................................................................102

12.12. Rotary base, set......................................................................................................................103

12.13. Drive assembly........................................................................................................................104

12.15. Chain guard.............................................................................................................................105

12.14. Rotary frame, set....................................................................................................................106

12.16. Film cut and hold, set .............................................................................................................108

12.17. Dispenser post, set.................................................................................................................110

12.18. Film dispenser, set..................................................................................................................112

12.19. Dispenser roller No. 1.............................................................................................................113

12.20. Dispenser roller No. 2.............................................................................................................114

12.21. Table rollers............................................................................................................................115

12.22. Idle table roller, set ................................................................................................................116

12.23. Driving table roller..................................................................................................................117

12.24. Bale li, set.............................................................................................................................118

12.25. Bale pper, set........................................................................................................................119

12.26. Tipper cradle, set....................................................................................................................120

12.27. Adjustable arm, set.................................................................................................................121

12.28. Hydraulic system .................................................................................................. .………………122

12.29. Manifold..................................................................................................................................124

13. Warranty.................................................................................................................................125

Self-loading Bale Wrapper EW-1800T

7

Before the rst use of the machine, you must thoroughly read and understand this Instrucons Manual, and follow all the in-

strucons contained herein.

This Instrucons Manual contains a descripon of hazards that can occur in case of non-compliance with safety rules dur-

ing operaon and maintenance of the machine. The Instrucon Manual species precauonary measures to be taken to

minimise or avoid risks.

This manual also contains principles of correct use of the machine and species the maintenance jobs to be carried out.

If you do not understand any informaon contained herein, please contact the manufacturer directly.

CAUTION!

Read the Instrucon Manual before use.

CAUTION!

This symbol indicates a hazard.

The warning symbol indicates a piece of important hazard informaon

given in the Instrucons Manual. Please read the informaon, follow the

instrucons, and exercise parcular cauon.

INFORMATION!

This symbol indicates addional informaon, descripons of how to op-

erate the machine or references to the secons in this manual.

Self-loading Bale Wrapper EW-1800T

8

2. Machine idencaon

Each bale wrapper has its rang plate, containing the most important idencaon data. The plate is axed on the front

beam of the machine boom frame.

Figure 1 Rang plate

The rang plate includes:

• full name of the manufacturer,

• bale wrapper serial number,

• machine code,

• CE marking,

• weight,

• quality control sign,

• date of manufacture.

Self-loading Bale Wrapper EW-1800T

9

Figure 2 Rang plate of the running axle

The serial number and type of running axle are stamped on the rang plate aached to the running axle beam.

3. Rules of safe operaon

3.1 User safety

The self-loading bale wrapper can only be operated by adults, who have learned how to operate it and have read this In-

strucons Manual, as well as have appropriate qualicaons. The bale wrapper should be operated with all necessary pre-

cauons taken, in parcular:

• Apart from the guidelines contained in this Instrucons Manual, observe also general rules of occupaonal health and

safety.

Self-loading Bale Wrapper EW-1800T

10

• Observe warning symbols placed on the machine.

• It is strictly forbidden, to operate the machine by persons under the inuence of alcohol or other intoxicants.

• Never allow the vehicle towing the bale wrapper to be driven by a person other than the wrapper operator, and under

no circumstances allow any other persons to be on the vehicle, or on the machine, during its operaon.

• The bale wrapper may be operated by a person who holds a proper driving licence for the vehicle equipped with the

bale wrapper, in accordance with the manufacturer's instrucons.

• The operator’s workstaon while working with the bale wrapper is the cab of the vehicle to which the machine is

aached.

• Please note, that there are many elements of the machine that may cause an injury (sharp edges, protruding parts,

etc.). During the use of the equipment, exercise parcular cauon when moving close to the above-menoned crical

spots, and obligatorily use the following personal protecon equipment:

- protecve clothing,

- protecve gloves,

- hearing protecon,

- safety footwear.

• It is forbidden to carry persons or objects on the machine.

• Persons who have not read the Instrucons Manual are not allowed to operate the machine.

• The bale wrapper operator must be provided with the complete rst aid kit with instrucons of use.

• Before starng work, the bale wrapper must be set in the transport posion.

• Take special care when driving on public roads and comply with the applicable road trac regulaons.

• The user is obliged to ensure the visibility of a machine during its transport: use road lightning, the reecve elements,

warning signs and the oponal equipment, the light warning signal.

• Adjust the transport speed to the condion of the road. The speed should not exceed 15 mph.

• Do not leave the vehicle with the machine on a hillside or other sloping surfaces, without securing the vehicle from

automac rolling down. Put wedges under the wheels of the vehicle.

• The bale wrapper must be adjusted to working height, during its aachment to the vehicle.

• Any preparaons, ng, dismantling or adjustment can be performed only aer the drive has been switched o, the

engine stopped, the vehicle immobilised and when all the moving parts of the machine have stopped.

• Aer the rst hour of operaon, check all disjoint connecons like bolt and pin connecons, etc.

• The bale wrapper should be stored on a at, level, paved surface, out of the reach of bystanders and animals. Use the

support foot for stabilising the bale wrapper.

• Exercise cauon during the mounng and dismantling of the bale wrapper and pay parcular aenon to the structur-

al components through which the machine is connected with the vehicle.

Self-loading Bale Wrapper EW-1800T

11

• Before the operaon, check the condion of the machine and of the vehicle it is aached to. Ensure the vehicle and

bale wrapper are in good technical condion. Any worn or damaged parts must be replaced immediately.

• The bale wrapper must be equipped with all the safety guards (provided by the manufacturer), prevenng access to

any moving parts. The guards must be complete and fully operaonal.

• It is not allowed to work with the bale wrapper without safety guards. It is not allowed to work with damaged safety

guards.

• It is not allowed to li the grab arm when the rotary frame drive is engaged.

• Before beginning to work with the machine, learn how to operate it by reading this Instrucon Manual taking into ac-

count occupaonal safety rules and recommendaons for maintenance and adjustment.

• The Instrucons Manual must be kept with the machine. If you loan the machine for use, ensure that it is in good tech-

nical condion and that it is complete with the Instrucons Manual.

• Do not aach addional transport means to the machine.

• During commissioning, check the machine funcons and make the inial adjustments.

• Due to the natural wear and tear the state should be controlled, using the recommendaons described in Secon 9

“Maintenance”.

• When taking over and transporng the machine, inspect its technical condion to check for damage.

• Standing under the raised grab arm is not allowed to prevent being crushed by the components of the machine.

• When adjusng, keep your ngers and limbs away from the structural parts of the machine.

• It is forbidden to leave a tractor’s cabin when the machine is running, and before all the rotang parts have stopped.

• The operator of the vehicle working with the bale wrapper must ensure that no person is approaching the machine

during its operaon, and the distance of at least 160’. from the working bale wrapper is always maintained.

• Before you start wrapping, check that the rotary frame and other structural components will not collide.

• Ensure suitable visibility when u-turning, reversing, or manoeuvring the machine, or ensure assistance from a properly

trained person.

• When connecng the hydraulic hoses, make sure that the hydraulic system is not pressurised.

• Do not stay between the vehicle and the machine when the vehicle engine is running.

• Working on slopes exceeding 5% is not allowed.

• Exercise parcular cauon when working on slopes.

• Never leave the vehicle unaended when the engine is running. Before leaving the driver's seat (the cabin) turn o the

engine of the vehicle, remove the ignion key, and apply the parking brake.

• Avoid wearing unbuoned, hanging parts of work clothes during the operaon, assembly, disassembly or adjustment.

Keep them away from any machine parts which are likely to catch them.

Self-loading Bale Wrapper EW-1800T

12

• Aer work, it is recommended to clean and wash the machine in the wash ed with a sewage treatment plant or a

seling tank to neutralise the resulng wastewater.

• The machine should be kept and stored in places protected from unauthorised access of persons and animals, thus

eliminang the risk of accidental injuries, and on a at, hardened surface, under a protecve canopy.

• In case of failure, immediately turn o the hydraulic system of the vehicle.

• When working with the machine, use hearing protecon headphones to minimise exposure to noise. In addion, it is

recommended to close the doors and windows of the vehicle’s cab.

Failure to observe the above guidelines may be hazardous to the operator and other persons, as well as damage the bale

wrapper. The operator is responsible for any damage caused by failure to adhere to the above rules.

3.2. Residual risk assessment

Tar River Implements has made every eort to ensure that the design of the machine, and its intended use, do not pose

any risk to persons or the environment.

Due to the nature of work being done by the bale wrapper and, for example, the inability to completely cover the ma-

chine’s working unit, certain risk factors may occur.

No. Risk Risk source (cause) Protecon measures against risks

1Overloading the lo-

comotor system

(physical load)

Working in a standing posion,

inclined-forced posion, walking,

moving objects

Read and understand the Instrucons Manual; do

workplace safety training in carrying weights

standards for the manual handling, correct meth-

ods of liing and carrying loads, geng other per-

sons’ help, and the use of handling devices such

as jacks and winches.

2Fall on the same

level (tripping, slip-

ping, etc.)

Uneven terrain, messy environ-

ment - objects lying and standing

around, cables lying on communi-

caon roads, slippery surfaces

Suitable safety footwear, levelled terrain, paying

aenon, maintaining order, reading the Instruc-

ons Manual.

3Bumping into sta-

onary, protruding

parts of the machine

Machine and its surroundings Proper posioning of a machine, safe space to

move around, proper organisaon of work, pay-

ing aenon, reading the Instrucons Manual

4Being hit by moving

objects

Crop bales ejected by the machine,

rolling bales on sloping ground

Maintaining cauon, marking the danger zone,

banning any trac next to the working machine,

banning people standing next to the working ma-

chine, reading the Instrucons Manual.

Self-loading Bale Wrapper EW-1800T

13

5Sharp, dangerous

edges

Protruding parts of the machine

structure, use of hand tools

Personal protecve equipment – safety gloves,

buoned-up work clothes, exercising special

6Gears Rotang components of the rota-

ry frame and table rollers, guards

for moving parts removed

No trac nearby, approaching or making adjust-

ments on the running machine, exercising cau-

on, using guards for moving parts, reading the

7Weight of the

standing machine

Improper mounng, aggregang,

wrong seng of the machine,

improper operaon

Exercising special aenon, use of personal pro-

tecve equipment - safety footwear, safety

gloves, the secure posion of the machine, the

8Microclimate - vari-

able weather con-

Work carried out in varied

weather condions

Suitable work clothes, beverages, creams with

sunscreens, proper rest, reading the Instrucons

9Noise Too high rotaonal speed of the

machine, damaged, loose or vi-

brang parts

Operaon of the machine in good technical con-

dion, inspecons on a regular basis, proper

rotaonal speed, reading the Instrucons Manu-

10 Impact to the head,

trunk, lower limbs

and hand cuts.

Impact by moving

parts of the ma-

Geng in the wrong posion

during grab movements.

Being in close proximity to a

working machine.

Paying special aenon, use of personal protec-

ve equipment: safety footwear, protecve

gloves, secure seng of the machine, use of

appropriate tools, cauous work without haste,

reading the Instrucons Manual. Keep away

when the machine is running.

11 Risk of crushing

and impact

Changing the actuator arm posi-

ons during work when working

parts rotate, working with safety

guards removed

Exercising special cauon, never approach the

machine when it is working, never approach the

rotang machine, prevent actuators from spon-

taneous movements, wear close-ng clothes.

Read the Instrucons Manual. Observe the

Table 1 Residual risk assessment

Self-loading Bale Wrapper EW-1800T

14

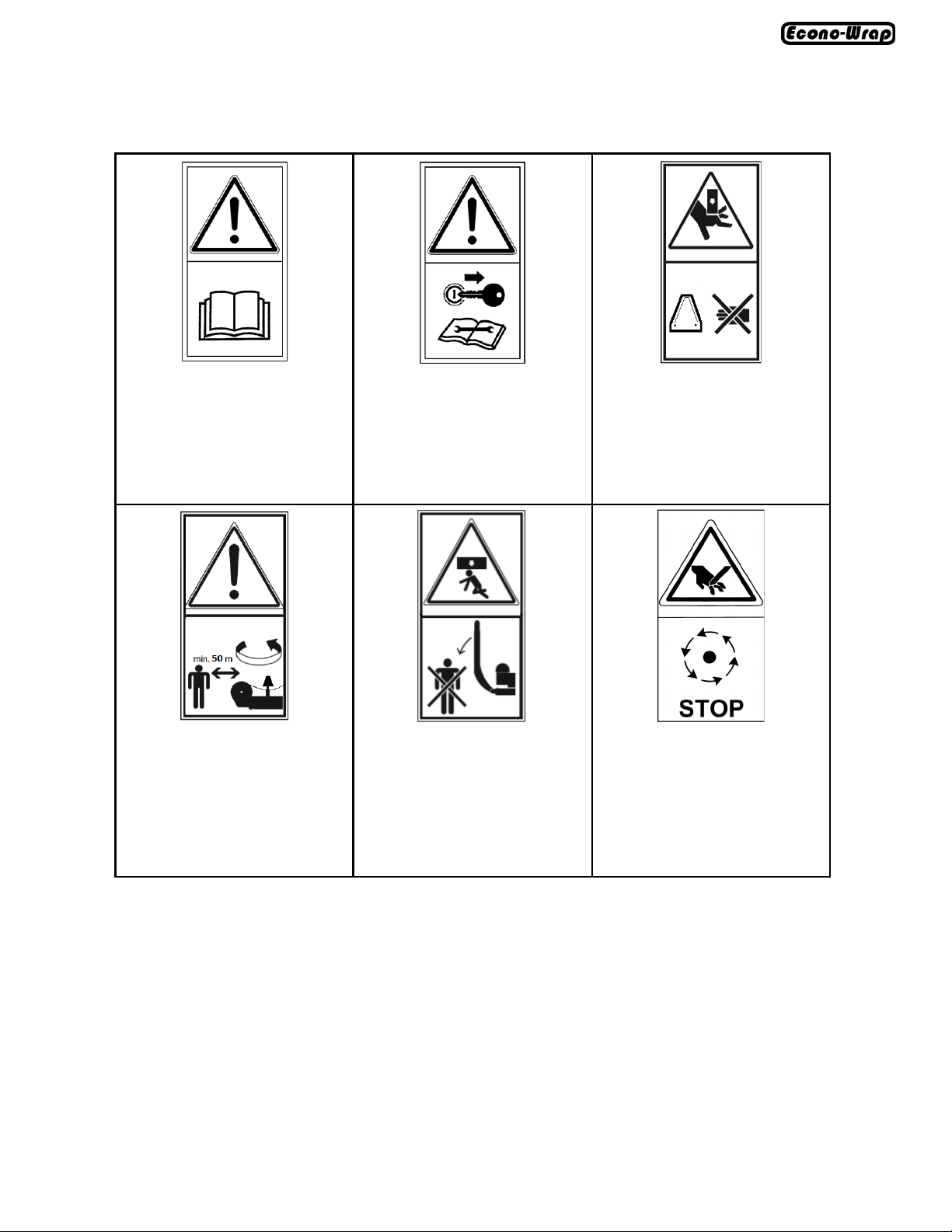

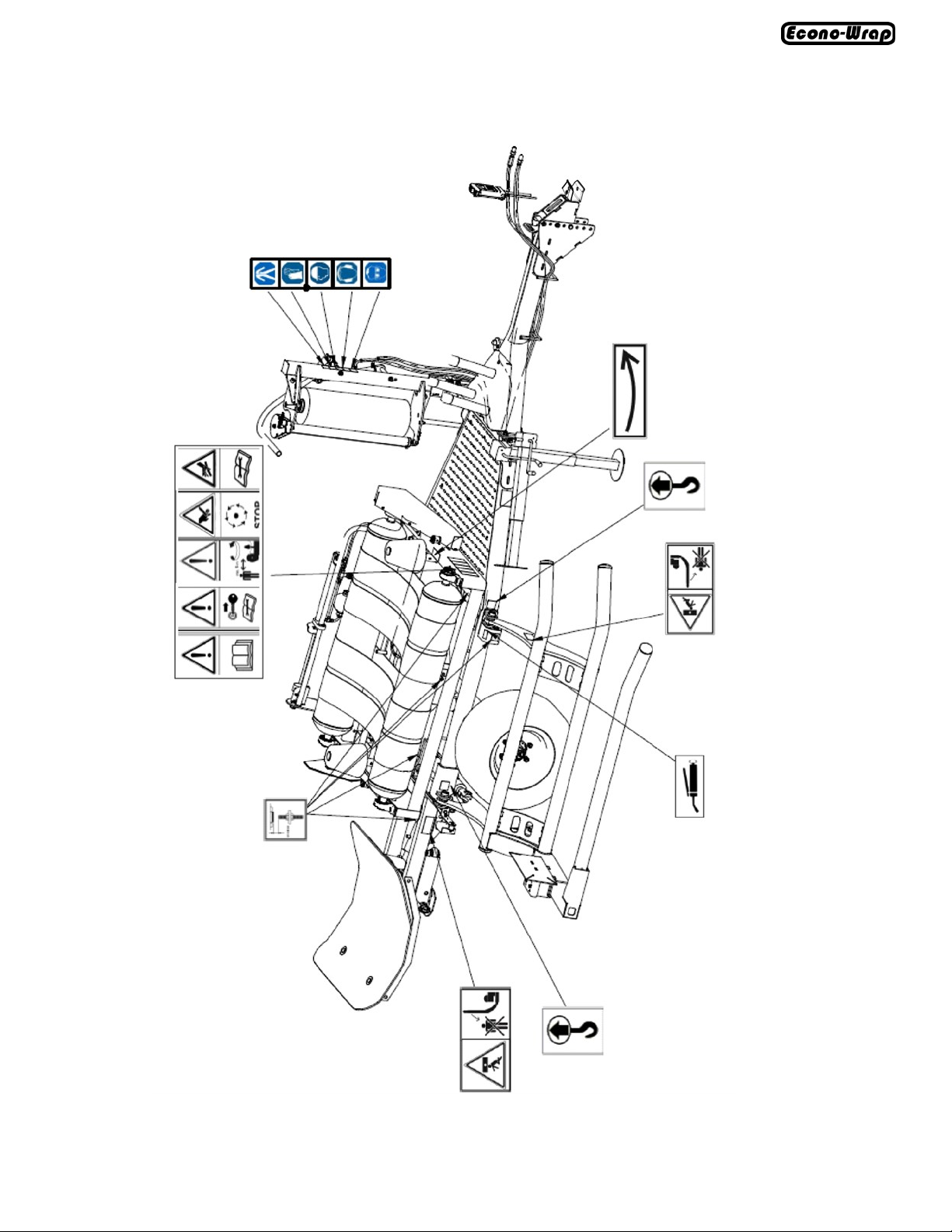

1.1 – Prior to using the machine,

read the Instrucons Manual.

1.2 – Switch o the engine and

remove the ignion key before

any maintenance or repair pro-

cedures.

1.3 – Danger of limb injuries. Do

not reach for the cung blade.

1.4 – Maintain a distance of at

least 50 metres (164 feet) from

the working machine.

1.5 – Danger of crushing. Do not

stand in the area occupied by

the folding bale grab arm.

1.6 – Do not touch the machine

components unl fully stopped

Self-loading Bale Wrapper EW-1800T

15

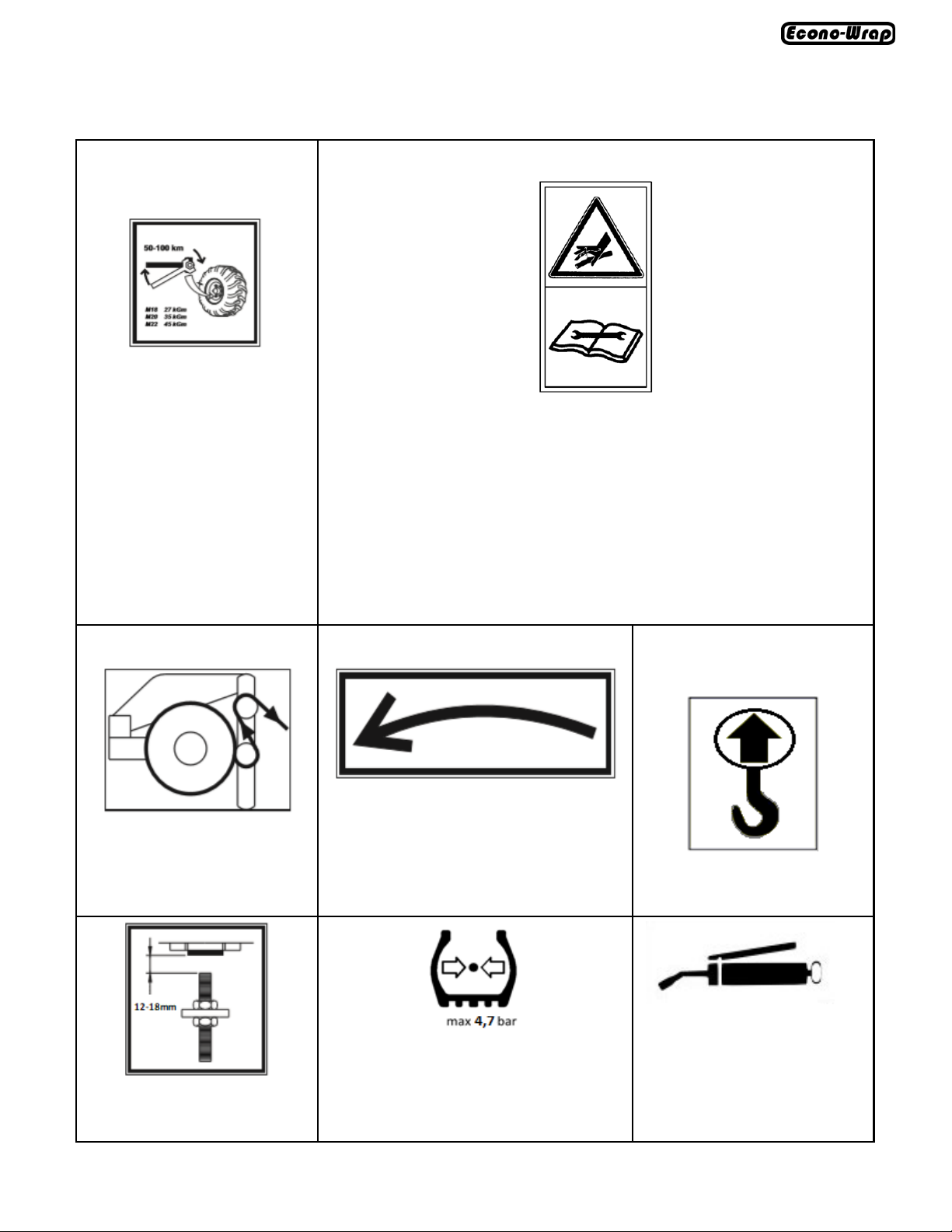

1.7 – Check the torque value of

the running wheel nuts and other

bolt connecons regularly.

1.8 - Avoid exposure to liquids owing under pressure. Read the Instrucons

Manual and learn about the maintenance works

1.9 – Wrapping lm installaon

method.

1.10 – Direcon of table rotaon.

1.11 – Liing hook locaon dur-

1.12 – Informaon on sensor

adjustment.

1.13 – Maximum re pressure symbol.

1.14 – Grease nipple symbol de-

nong the grease lubricaon

point.

Self-loading Bale Wrapper EW-1800T

16

1.15 – Warning about pressure

present in the hydraulic system.

1.16 – Use a protecve coverall.

1.17 – Use safety gloves

1.18 – Use a protecve helmet.

1.19 – Use hearing protectors.

1.20 – Use safety glasses.

Table 2 Safety decals on the machine

Self-loading Bale Wrapper EW-1800T

17

Table 2 (cont.) Safety decals on the machine

Self-loading Bale Wrapper EW-1800T

18

Table 2 (cont.) Safety decals on the machine

Self-loading Bale Wrapper EW-1800T

19

The bale wrapper is designed for wrapping lm around a crop prepared previously in the shape of a bale. The maximum

weight of material to wrap must not exceed 2425 lbs. and 5 . in diameter. Rolled bales can be wrapped with a 20” or 30”

wide stretch lm. Using the machine in other circumstances will be construed as inconsistent with the intended use. Strict

compliance with the requirements for the use of the machine and operaon and maintenance as recommended by the

manufacturer is a prerequisite for use as intended.

The machine should be operated, serviced, and repaired by people familiar with its specic characteriscs and the rules of

conduct in terms of occupaonal safety.

The bale wrapper has been designed in accordance with current safety requirements and machinery standards. The per-

missible speed of the bale wrapper on public roads is 15 mph. During operaon (wrapping), the maximum speed of the

combinaon must not exceed 3 mph, provided that the ride takes place on at, level ground. Accident prevenon regula-

ons and all basic rules of safety and hygiene, as well as trac regulaons, must always be observed.

Intended use involves the observance of the correct and safe operaon and maintenance of the machine. This is why the

user is obliged to:

• Read and follow the contents of the INSTRUCTIONS MANUAL.

• Understand the operang principle of the machine and the safe and correct use of the bale wrapper.

• Observe the general safety regulaons during work.

• Observe the scheduled maintenance and adjustment.

• Comply with road trac regulaons.

• Couple the machine with an agricultural tractor only if such a tractor meets all the requirements set by the Manufac-

turer of the bale wrapper.

Unauthorised changes in design of the machine without permission of the manufacturer waive the manufacturer's liability

arising due to any resulng damage or injury.

It is forbidden to use the bale wrapper for any purpose other than that for which it was intended and to operate the ma-

chine by persons who are not familiar with the Instrucons Manual, the safety regulaons, and the instrucons manual of

the agricultural tractor.

Self-loading Bale Wrapper EW-1800T

20

The bale wrapper comes complete with the basic equipment listed below:

• Instrucons Manual,

• Spare parts catalogue,

• Warranty Cercate.

The bale wrapper is a welded construcon consisng of frames built from steel proles and interconnected with pins or

bolts. The boom frame to which the unbraked running axle is bolted is the base which is coupled using the drawbar with

the tractor. The loading arm hereinaer referred to as a bale li is posioned along the right-hand edge of the machine

and performs the loading movement of the crop. The rotary frame is the base for the table rollers which drive the rotaon

of the bale around its two axes of rotaon. The turntable slide base underneath the rotary frame, pinned to the boom

frame, is to unload bales by a hinged lt to the rear of the machine, where the bale pper captures them and posions

them with precision as required. In the front part of the bale wrapper, there is a lm dispenser on a post, adapted to un-

wind 20.00” or 30.00” wide lm. A lm cut and hold is mounted on the side of the rotary frame to cut o and hold the lm

for subsequent cycles automacally.

The basic version of the machine oers three operang modes:

• Auto mode,

• Semi-auto mode,

• Manual mode.

This is enabled with a control system connected to the hydraulic system driving machine movements. The hydraulic system

is protected by an oil lter mounted on the le-hand side of the drawbar mounng frame. The electrical system is ed

with a 10 A fuse in the top secon of the control unit to protect the controller.

Table of contents

Other Econo-Wrap Farm Equipment manuals

Popular Farm Equipment manuals by other brands

STEIN Automation

STEIN Automation 300 SoftMove operating instructions

Westeel

Westeel Wide-Corr Centurion Side Draw Discharge Installation and Storage Instructions

Norac

Norac UC5 Topcon X30 installation manual

Hupfer

Hupfer CTW/O operating instructions

Woodbay

Woodbay FDS 9200 manual

M K Martin Enterprise

M K Martin Enterprise SCIC250 Owner's/operator's manual