SHOP ONLINE @ WWW.AGSPRAY.COM 3

1. Read and understand the Operators Manual and all

safety signs before using.

2. Place all controls in neutral, stop tractor engine, turn

monitor off, set park brake, remove ignition key, wait

for nozzles to stop spraying before servicing,

adjusting, or repairing.

3. Before using it in a field, be familiar with all potential

hazards: trees, rocks, ditches, gullies, etc. Plan the

spraying route to avoid hazards. Remember you are

driving a wide machine. USE CAUTION WHEN

CORNERING.

4. Keep hands, feet, hair and clothing away from all

moving and/or rotating parts.

5. Do not allow riders on the applicator or tractor during

operation or transporting.

6. Clear the area of all bystanders, especially children,

before starting or filling with water or chemical.

7. Stay away from wing pinch points when folding or

extending wings. Keep others away.

8. Stay away from power lines when extending or

folding wings. Electrocution can occur without

direct contact.

13. In case of poisoning, get immediate medical attention.

15. Do not eat in the field when side dressing.

16. Before applying pressure to the hydraulic system,

make sure all components are tight and that steel

lines, hoses and couplings are in good condition.

17. Before applying pressure to fertilizer system make

sure that all connections are tight and that all hoses

and fittings are in good condition.

18. Review safety instructions annually.

INTRODUCTION

Before operating the Applicator and each time thereafter, the

following areas should be checked off:

1. Lubricate the machine per the schedule outlined in

the “Maintenance Section”.

2. Use only a tractor of adequate power and weight to

operate the Applicator.

3. Ensure that the machine is properly attached to the

tractor. Be sure that a mechanical retainer is installed

through the drawbar pin and the safety chain is

attached to the drawbar cage. Jack is in full up

position.

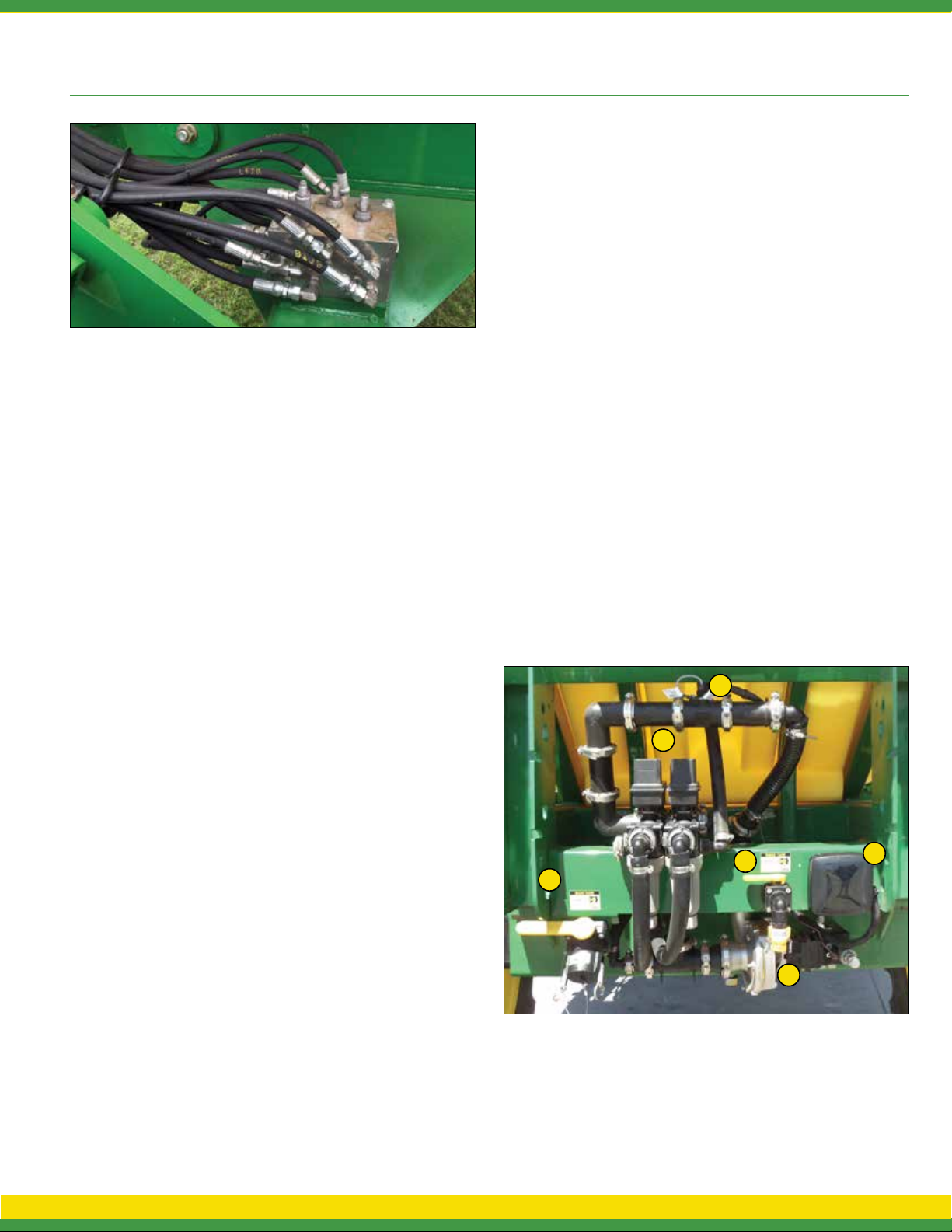

4. Check the hydraulic system. Ensure that the

hydraulic reservoir in the tractor is filled to the

required specifications.

5. Inspect all hydraulic lines, hoses, fittings and couplers

for tightness. Use a clean cloth to wipe any

accumulated dirt from the couplers before

connecting to the hydraulic system of the tractor.

6. Check the tires and ensure that they are inflated to

the specified pressure.

7. Calibrate the Applicator if it is the start of the season

or a new chemical is being used. Calibrate as

specified in rate control manual.

8. Check the condition and routing of all chemical hoses

and lines. Replace any that are damaged. Re-route

those that are rubbing pinched or crimped.

9. Check the spray pattern of each nozzle. Remove and

clean or replace any that have an unusual pattern.

10. Remove the steel mesh line filters and wash with

clean water. Reinstall.

11. Check that all connections in the electrical system are

connected and tight.

13. Before unfolding boom remove transport wing lock

pins (Figure 7) and tower cylinder Transport stop

(Figure 6) Reinstall lock pins and tower stop

before parking sprayer.

PRE-OPERATION CHECKLIST