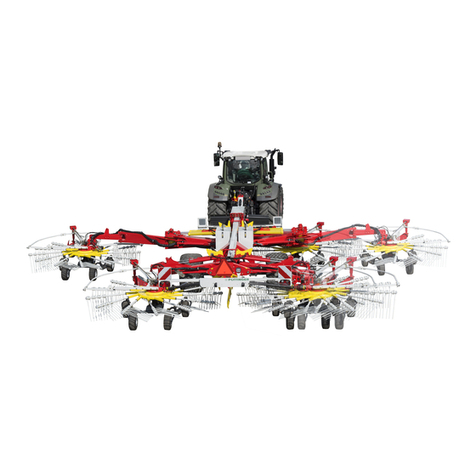

Dear Customer,

"Quality pays for itself." We therefore apply the highest quality standards to our products,

which are permanently monitored by our in-house quality management team and our man-

agement board Because the safety, perfect function, highest quality and absolute reliability of

our machines in operation are the core competencies for which we stand.

These Operating Instructions are intended to allow you to familiarise yourself with the ma-

chine and provide you with clear information on the safe and correct handling, care and

maintenance. Therefore, please take the time to read these instructions.

These Operating Instructions are a part of the machine. They are to be kept in a suitable

place and be accessible to personnel at any time throughout the entire service life of the ma-

chine. Instructions based on existing national regulations on accident prevention, road traffic

regulations and environmental protection are to be supplemented.

Any persons commissioned with the operation, maintenance or transport of the machine

must read and understand these instructions prior to starting work, particularly the safety in-

formation. If these instructions are not observed, the warranty claim will be forfeited.

If there are any questions regarding the contents of these Operating Instructions or further

questions regarding the machine, contact your PÖTTINGER service partner.

Care and maintenance performed in good time and scrupulously according to the mainte-

nance intervals specified ensure operational and traffic safety as well as the reliability of the

implement.

Use only original spare parts or spare parts and accessories that are approved by PÖTTING-

ER Landtechnik GmbH. Only original spare parts that are approved by us have been tested

and accordingly are appropriate for use in your machine. The use of any unapproved parts

forfeits any guarantee or guarantee claim. Even after the guarantee period has expired we

recommend the use of genuine replacement parts in order to ensure the continuous perform-

ance of the machine.

Product liability legislation obliges the manufacturer and the authorised dealer to issue In-

structions when selling implements and to instruct customers in the use with reference to the

safety, operating and maintenance regulations. Confirmation in the form of a declaration of

transfer is required to verify that the implement and Instructions have been transferred cor-

rectly. The Declaration of Transfer was enclosed with the machine on delivery.

For the purposes of the Product Liability Act, every self-employed person and farmer is an

entrepreneur. Entrepreneurial property damage within the meaning of the Product Liability

Act is therefore excluded from liability by PÖTTINGER. Property damage within the meaning

of the Product Liability Act is damage caused by a machine, but not to it.

The operating instructions are part of the machine, therefore pass them on to any new owner

when passing on the machine. Instruct the new owner and make them aware of the regula-

tions mentioned.

Your PÖTTINGER service team wishes you every success.

3880.en-GB.80X.0 Original Operating Instructions NOVACAT V 10000 | 3