Hilman Deluxe Toe Jack User manual

Deluxe Toe Jack

Instruction Manual

Models 6-ton, 10-ton and 25-ton

12 Timber Lane • Marlboro NJ 07746

tel:732.462.6277 • fax:732.462.6355

09/06/2019

CONTENTS

3 INTRODUCTION

4 OPERATING INSTRUCTIONS

6 SAFETY WARNINGS

7 MAINTENANCE AND STORAGE

7 TROUBLESHOOTING

9-10 SPARE PARTS LIST

11 LIMITED WARRANTY

2

Thank you

For choosing a Deluxe Hilman Toe Jack

The Deluxe Hilman Toe

Jack enables you to lift

heavy loads, machines and

other items safely.

Please read and comply with this user manual and the safety

warnings prior to the use of these toe jacks to protect you and

others.

This equipment must not be used to carry or lift personnel.

WARNING

IMPROPER USE OF HILMAN DELUXE TOE JACKS CAN RESULT IN

SERIOUS INJURY

TO AVOID INJURY:

Always make sure that the load is fully supported by the claw or top plate

Jack to rest on solid ground in VERTICAL position

Jack only with the pivoting feet facing towards the load

Never exceed maximum lifting capacity

No side load permissible

Keep body parts from beneath the load and all moving parts at all times -

Bystanders should keep clear of the load (to a min. of 1.5 times the highest point of the

load)

Support the load with suitable supports

Lift on fixed parts of the load

Do not use the jack if it is damaged or without a valid inspection certificate

Always use recommended lubricants

Always use genuine replacement parts

Periodically check lubricant level

Read the user manual provided with the jack and follow all instructions before

operation

The user is responsible for condition of all warning labels

These instructions are guide- lines and you should always refer to the operating

manual if in doubt.

In all circumstances consider “S A F E T Y F I R S T “

3

!

Deluxe Hilman Toe Jack User Manual

991004002

4

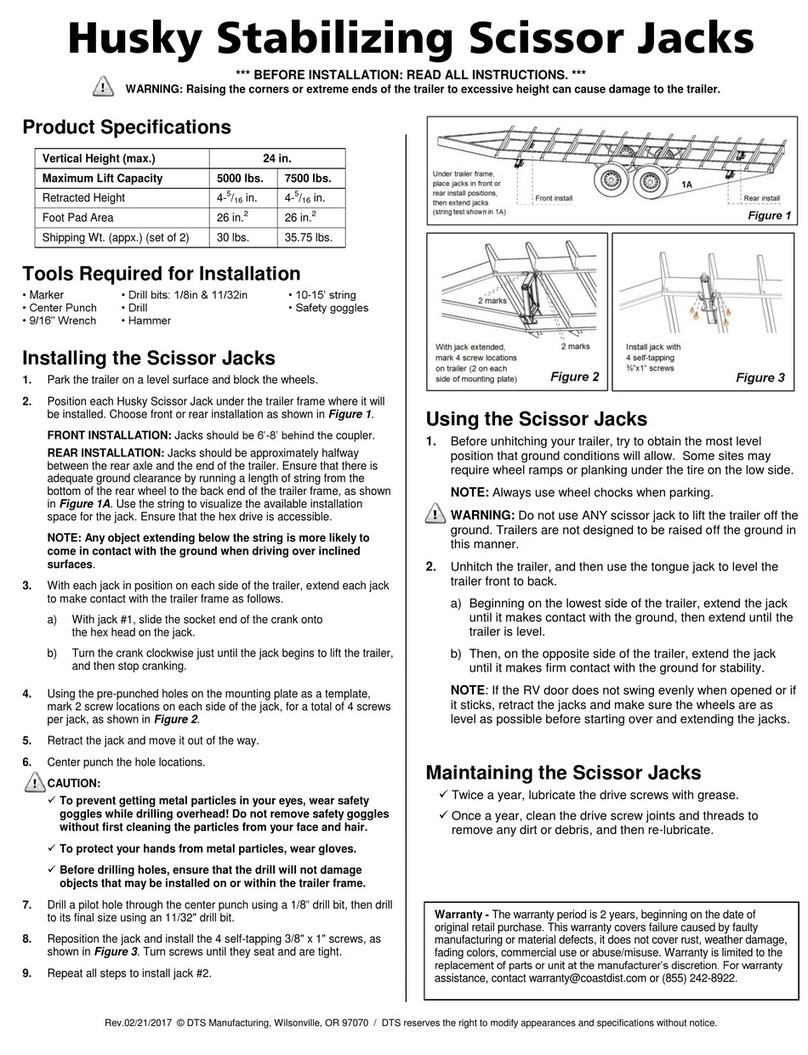

Before you start using your new Hilman

Deluxe Toe Jack, please check the following:

- The weight you have to lift (A)?

- Center of gravity?

- Which toe height fits best (B)?

- The area where the jack is positioned should

be even for the whole base area including the

support legs

When using the Jack you should always:

Put the swiveling legs to the front of the jack (A)

Then locate the lifting toe in the correct position (B).

To do this you have to lift up the toe assembly, pull it

out and push it back into the desired position and

lower the toe until it cannot go down any further.

Fast stroke SH (only 25 ton) with 3-times the speed of the

regular stroke NH.

This lifts the toe very fast into the required position under the

load without actually contacting the load itself. Do not lift the

load using fast stroke SH (A).

Use the regular stroke to lift the load as described in 3 (B).

Move the lever as described before (C).

To lower the lifted load:

Turn the valve carefully and slowly counter-

clockwise to open the valve (A). By opening

the valve slowly you are effectively metering

the rate of descent of the load. Store the

pump lever away where it will not get lost (B).

To avoid damage to the guides and extend

the lifetime of the jack, please make sure

that the lowering speed is slow.

Determine the position you want your Hilman Deluxe

Toe Jack at the base of the load.

The load must not be positioned on the welding or cast

radius of the toe

Position the handle in the slot of the pump head (A),

Close the valve clockwise (B) then pump the lever up

and down for regular stroke NH and fast stroke SH (C).

991004002

5

Lifting and lowering using an external pump:

Use only an external pump that can be pressure-

regulated to a maximum pressure of 7540 psi (520 bar)

-Connect the pump (hand or power) to the jack with a high

pressure hose with the correct fittings (A).

-Close the valve on the toe jack as shown in step 3 (B).

-Make sure the external pump has adequate oil supply,

then lift the toe jack from the external pump.

-Lower the load by opening the valve slowly (using the

valve as a means of metering the rate of descent).

In cases where the swiveling legs have no

space you should consider the following:

Spread the legs to the outside (never to the

back) and lift the load above the height of the

legs

Place a piece of wood underneath the load (A).

and lower the load onto the wooden blocks.

Then swing the legs to the front and continue

the lifting process (B).

If you lift one side of a top-heavy object the load

could top over (A). Watch the angle of the load

carefully - if you see problems lower the load and

use more than one toe jack and/or re-think the lifting

plan.

The load must never be placed on the front area of

the toe (B).

Always place the jack in a position that maximizes

toe contact area, but never on the welded or cast

radius of the toe.

Never lower a load from a crane or fork lift

onto the jack. This could cause overload and

seriously damage the jack (A).

Lift up the load only in well-supported areas

of the object, never on sheet metal covers

because they could get damaged (B).

Where there is sufficient height under the load you can

also use the top plate (head) of the jack to lift (A).

Use the jack only on even floors (never on inclined

floors), otherwise the jack, including the load, could tip

(B).

Never use the jack on uneven or rough surfaces. This

could cause damage to the jack and the surface of the

floor (C).

991004002

6

Always make sure that bystanders and

children are away from the work area. Cordon

off a NO-GO area with cones and tape, etc.

The NO-GO area must be the area of the load

plus a radius around the load of at least 1.5

times the highest dimension of the load. This

is the operators’ responsibility (A).

Make sure the load is supported during the

lifting and lowering process, and that the load

will not shift during lifting/lowering (B). Under

load, the jack should never be left unattended

and should stay in the same position for only a

short period of time.

The jack will not lift loads above the rated

capacity due to the built in safety valve (A).

If you use more than one jack you should support

the load gradually step by step (see diagram) to

prevent an unbalanced load with different loads

on each jack. Failure to do so could cause an

overload on one jack and the load might tip (B).

If the load is lifted and you need to work on

the load, always lower the load onto wooden

supports first. Do not work on the object

while the load is on the toe jack.

Never put arms, legs, head etc. under a lifted

load (A).

Wear protective footwear (B).

Wear a helmet if necessary (C).

Wear safety glasses if needed (D)

Wear gloves if necessary (E)

Wear a hair net if you have long hair and fix

loose clothing (i.e. ties)

! Comply with all other safety warnings and

other safety signs in the working area.

The ground support should be equal to the

force which is distributed through the base area

of the jack. Overloading could damage the

surface of the ground which could result in a tip

of the load. (A).

Never put your arms or hands into or under

moving parts of the jack if loaded or unloaded

(B).

Attention - Be aware of the dangers of

moving parts and the risk of injury to

hands.

Maintenance

and

Storage

Grease all assigned areas at least once per year depending on the use of the jack.

We recommend an annual oil change. This should be carried out as part of the

yearly safety inspection.

Procedure for oil change:

Lift up the jack a little and release the retaining screw (B). Open the valve and push

the lifting unit back to the lowest position. Take out the lifting unit.

Release the four screws on the bottom of the jack (C) which loosens the cylinder

and pump in order to fully extract.

Open C-clip (D) and remove the legs (not necessary of you have grease nipples on

legs). Open the oilscrew (E) incl. valve and if necessary take out valve (F). Recycle

the old oil according to local environmental laws. Fill oil into the tank but not more

than a maximum of 1 inch (20-30 mm) between the top and the oil level.

Storage: always store in the upright position and in a dry area.

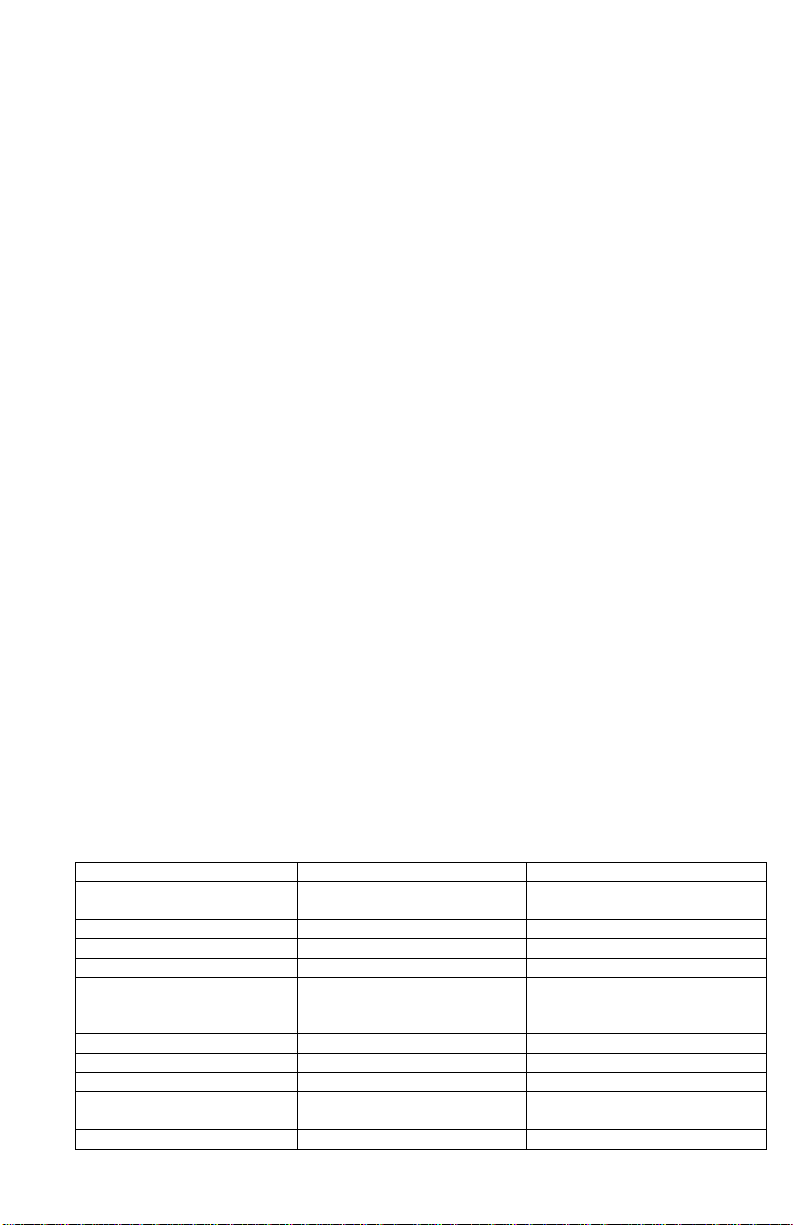

Troubleshooting

What if

Reason

How to solve

Load can be only partly

lifted

Too little oil in the Tank

Refill oil (see above)

Load cannot be lifted at all Valve open Close

Capacity not sufficient

Use additional or stronger jack

Safety valve loose

Tighten Pumpscrew

Ball on valve does not seal Press ball into bottom, close

valve very tightly if necessary

by using pliers

Safety valve dirty

Take out and clean or replace

Safety valve damaged Take out and replace

Head seal pump damaged

Take out and replace

Load lowers with valve

closed

Safety valve dirty or

damaged

Take out and clean or replace

Seal damaged

Take out and replace

7

Before you start working you should fully understand that lifting and shifting heavy loads

brings different risks and is dangerous. Therefore please follow this manual, ensuring that

everyone who is using this equipment has fully read and understood this manual and the

safety warnings. Nobody should use this equipment without first reading this manual.

Always create a lifting plan so you know how you want to do the job prior to starting – and

so that everybody involved knows what is going on.

Do not operate this equipment if you are ill, feeling sick or tired, or under the influence of

alcohol or drugs. When you work under such condition you might harm yourself and

others or even cause life threatening injuries.

An annual safety inspection of the jack should be carried out.

8

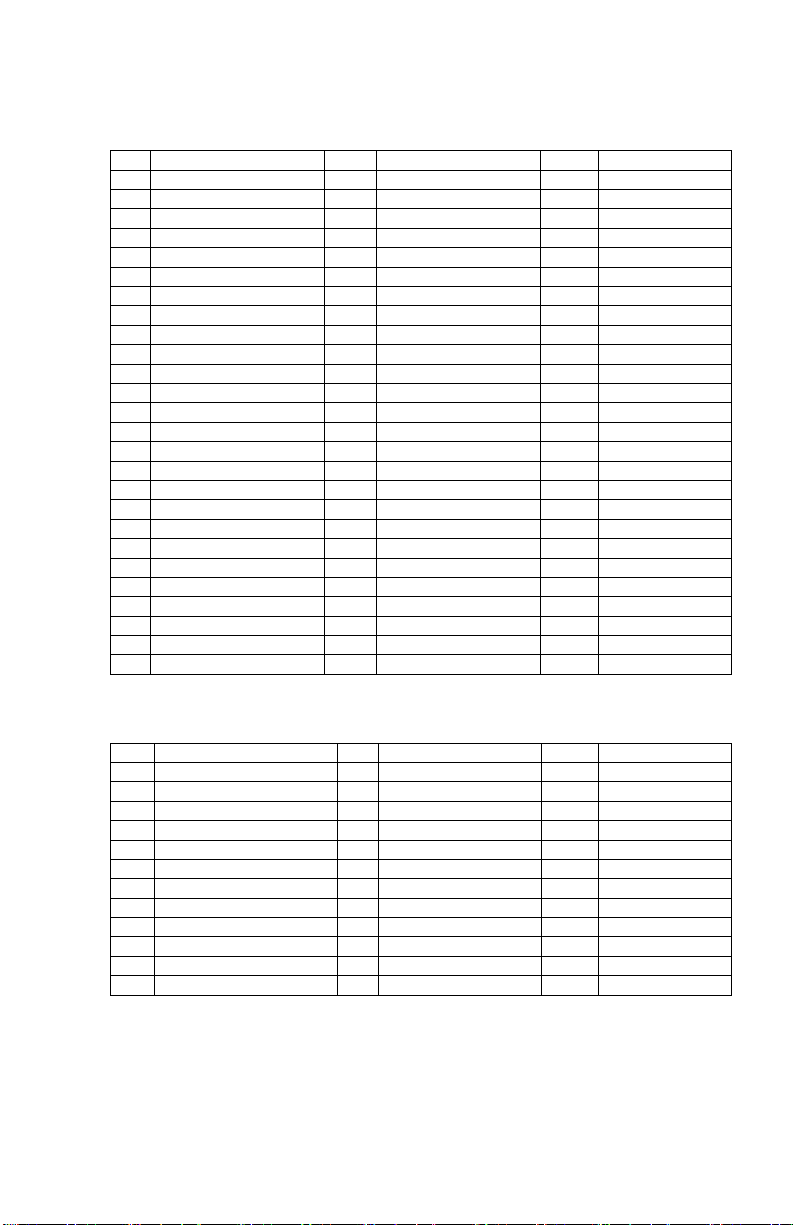

Please supply with your order the correct part number, quantity required and

description as well as the type of the jack and serial number. If a repair has to be

carried out, please send only the defective parts. Thank you.

9

Spare parts, universal

Pos. Description

Qty

HTJ-6D / HTJ-10D

Qty

HTJ-25D

Diagram 1:

1

Pump joint 1

1

951057100

1

951057100

2

Pump joint 2

1

951057200

1

951057200

3

Spring pressure ball

1

990061501

2

990061501

4 Nut for 3 1 990193010 2 990193010

5

Joint screw

2

990193009

4

990193009

6

Joint nut

2

990198001

4

990198001

7 Distance washer 1 990112001 2 990112001

8

Nut M18x1

1

951059200

2

951059200

9

Jointbox

1

951057300

2

951057300

10 Pin 1 990114001 2 990114001

11

Pump Ram NH

1

951059300

1

951059300

12

Ram seal

1

991005000

1

991005000

13

Screwed socket ram

1

991059100

2

991059100

14

O-Ring pump

1

991004002

2

991004002

15

Cylinder pump NH

1

951059400

1

951059400

16

Copper Seal

2

990176001

4

990176001

17 Safety-valve 1 991200520 2 991200520

21

SH-pump ram

1

952559300

22

SH-piston

1

952559500

23 SH-piston guide 1 991001251

24

SH-U-seal

1

991003251

25

SH-C-clip

1

990147008

26

SH-Cylinder pump

1

952559400

27

SH-Cylinder adapter

1

951058000

1

951058000

Diagram 2:

30

Valve

1

951058000

1

951058000

31

Stargrip

1

990063100

1

990063100

32 O-ring valve 1 991004001 1 991004001

33

Oil screw

1

990055001

1

990055001

34

wheel

2

110521101

35 Wheel washer 4 990112001

36

Wheel screw

2

990193011

37

Stud coupling S/G-FL

1

991102007

1

991102007

Stud coupling XR

1

991102006

1

991102006

38

Male hose coupler

1

080270001

1

080270001

Diagram 3:

48

Lever pump

1

951057400

1

951057400

10

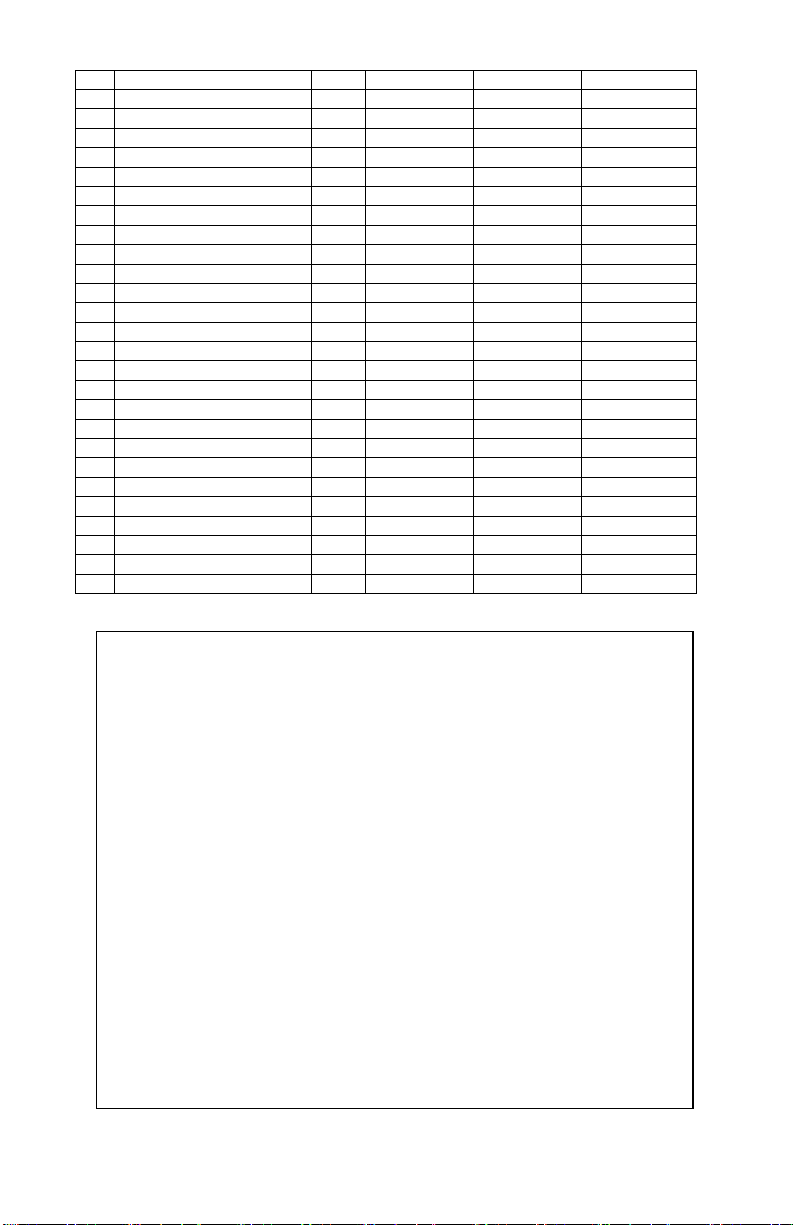

Spare parts specific

Pos. Description

Qty

HTJ-6D

HTJ-10D

HTJ-25D

Diagram 3:

40

Pump /cylinder S/G-FLT

1

950620000

950620000

950620000

Cylinder XR

1

991103045

991103100

991103250

41

Screw cylinder S/G-FLT

4

990191019

990179007

990179007

Cylinder XR

1

990191022

990191023

990191025

42

Frame S/G-FLT

1

950610101

950610101

950610101

Frame XR 1 950610101 950610101 950610101

43

Swiveling leg

2

950610201

950610201

950610201

44

C-Clip/Nut+washer leg

2

990147007

990147007

990147007

45 Lifting unit S/G-FLT 1 950630000 950630000 950630000

Lifting unit XR

1

950630000

951130000

951130000

46

Screw lifing unit

1

990179008

990179006

990179001

47

Toe

1

950640000

951040000

952540000

48

Lever

1

991057400

991057400

991057400

Diagram 4:

50

Piston rod

1

950650300

951050300

952550300

51

Piston

1

950650200

951050200

952550200

52

Piston guide

1

991001050

991001100

991001250

53

U-Seal piston

1

991003050

991003100

991003250

54 C-Clip piston 1 990147002 990147005 990147010

55

Piston head

1

950650100

991050100

952550100

56

Piston head guide

1

991002050

991002100

57

C-Clip securing plate

1

990147006

990147002

Screw securing plate

1

990179005

58

Securing plate S/GFLT1

1

950550400

951050400

952550400

11

LIMITED WARRANTY

We warrant each new Hilman Toe Jack sold by us to be free from

manufacturing defects in normal service for a period of one (1) year

commencing with delivery of the Toe Jack to the original user. Our

obligation under this warranty is expressly limited at our option, to

the replacement or repair at Hilman, Incorporated, Marlboro, New

Jersey 07746 USA, or at a service facility designated by us, of such

part or parts as inspection shall disclose to have been defective. This

warranty does not apply to defects caused by damage or unreasonable

use, including failure to provide reasonable and necessary

maintenance while in the possession of the consumer.

WE SHALL NOT BE LIABLE FOR CONSEQUENTIAL

DAMAGES OF ANY KIND, including, but not lim

ited to,

consequential labor costs or transportation charges in connection with

the replacement or repair of defective parts. We make no warranty

with respect to trade accessories. They are subject to the warranties

of their manufacturers.

ANY IMPLIED OR STATUTORY WARRANTIES, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, ARE EXPRESSLY LIMITED TO

THE DURATION OF THIS WRITTEN WARRANTY. We make no

other express warranty, nor is anyone authorized to make any on our

behalf.

*In compliance with 1975 Consumer Product Warranties Law

HILMAN, INCORPORATED, 12 Timber Lane, Marlboro, New

Jersey 07746

Deluxe Toe Jack

Warnings & Inspection

Approval Stamp:

! WARNING

IMPROPER USE OF HILMAN DELUXE TOE JACKS CAN RESULT IN SERIOUS INJURY

TO AVOID INJURY:

Always make sure that the load is fully supported by the toe or top plate

Jack to rest on solid ground in VERTICAL position

Jack only with the pivoting feet facing towards the load

Never exceed maximum lifting capacity

No side load permissible

Keep body parts from beneath the load and all moving parts at all times -

Bystanders should keep clear of the load (to a min. of 1.5 times the highest point of the

load)

Support the load with suitable supports

Lift on fixed parts of the load

Do not use the jack if it is damaged or without a valid inspection certificate

Always use recommended lubricants

Always use genuine replacement parts

Periodically check lubricant level

Read the user manual provided with the jack and follow all instructions before

operation

The user is responsible for condition of all warning labels

These instructions are guide- lines and you should always refer to the operating

manual if in doubt.

In all circumstances consider “S A F E T Y F I R S T “

Models 6-ton, 10-ton and 25-ton

12 Timber Lane • Marlboro NJ 07746

tel: 732.462.6277 • fax:732.462.6355

email: sales@hilmanrollers.com

Capacity / Model Number: Serial Number: Manuf. Date:

____________________ ___________ _________

Inspected by: ___________________________________

Inspection Date: Inspector’s Signature:

____________ ______________________

This manual suits for next models

3

Table of contents

Other Hilman Jack manuals