HIPEQ ROPEFLEX RX2500 DUAL Installation guide

PLEASE REGISTER YOUR NEW PRODUCT

To register your product online please go to:

www.hipeq.com/product-registration

Product serial number is located on equipment or is shown in the box below

SERIAL NUMBER

If serial number is not sown

please check equipment

ORYX –RX2500 DUAL

Assembly Instructions & Manual

DOC: 32-1019

Configuration subject to change

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U A L 32- 0 0 1 9 R E V . A

1

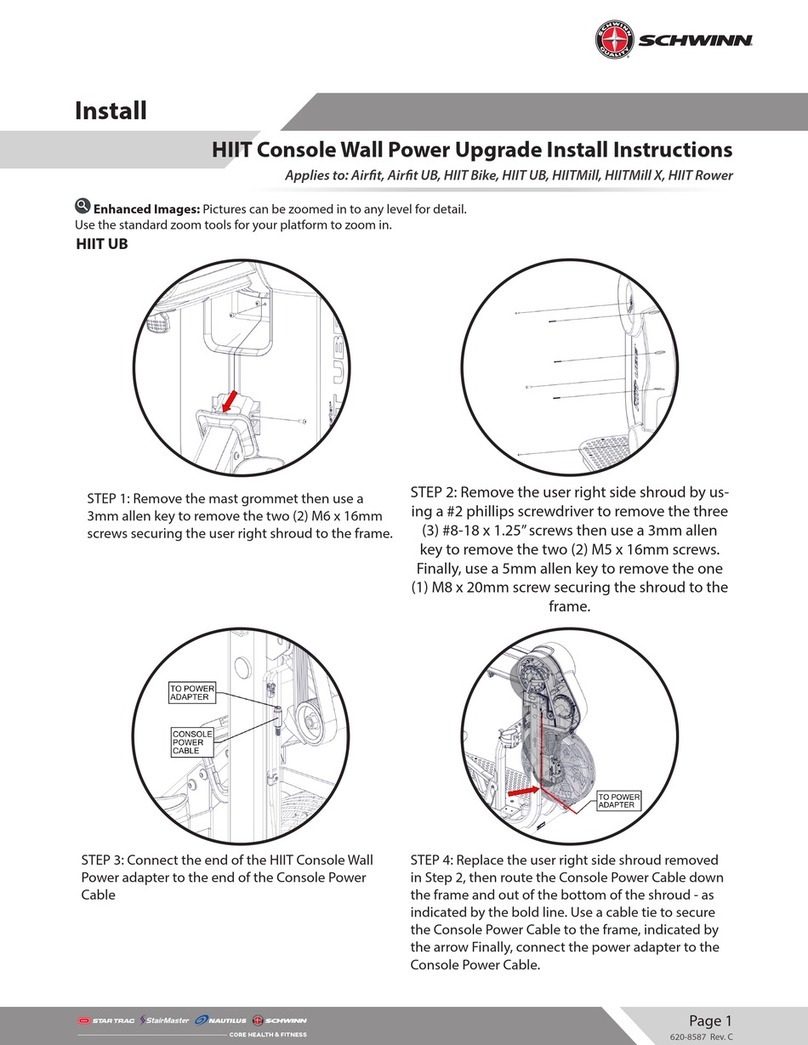

WARNING DECAL PLACEMENT

The decals shown here have been placed on

the equipment in indicated locations. If any of

the decals are missing or illegible, call us toll-

free at 650.549.5888, Monday through Friday,

9 a.m. until 5 p.m. Pacific Time, to order

replacement decals. Apply replacement decals

in the locations shown.

Adjustable Pulley

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U A L 32- 0 0 1 9 R E V . A

2

IMPORTANT PRECAUTIONS

WARNING: To reduce the risk of serious injury, read the following important precautions

before using this equipment.

1. Read all instructions in this manual and

assemble as described before using this

equipment.

2. It is the responsibility of the owner to ensure

that all users of this equipment are

adequately informed of all precautions.

3. Use this equipment only on a level surface.

Cover the floor beneath to protect the

surface.

4. Keep children under 12 and pets away from

the equipment at all times.

5. Make sure all parts are properly tightened

each time you use this machine. Replace

any worn parts immediately.

6. Make sure the adjustment knobs are fully

engaged / disengaged before using the

equipment.

7. Always wear athletic shoes for foot

protection while exercising.

8. This equipment is designed to support a

maximum user weight of 300 pounds.

9. Pull on one the rope only and never grab a

rope in a way that prevents the drum from

rotating. Never attempt to hang on the rope.

Pull rope with hands only.

10. If you feel pain or dizziness at any time

while exercising, stop immediately and

begin cooling down.

WARNING: Before beginning this or any exercise program, consult your physician. This is

especially important for persons over the age of 35 or persons with pre-

existing health problems. Read all instructions before using. HIPEQ assumes

no responsibility for personal injury or property damage sustained by or

through the use of this product.

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U A L 32- 0 0 1 9 R E V . A

3

Contents / Parts List

ITEM

QUANTITY

DESCRIPTION

1

2

RX2500 Rope Drum

2

2

RX2500D (Dual) Main Vertical Post

3

2

RX2500D (Dual) Base

4

2

RX2500 Cushioned Seat

5

2

RX2500 Seat Stand

6

2

Rope Pulley Assembly

7

36

Socket Screw 5/16”-18 x 1”

8

18

Socket Screw 5/16”-18 x 1.5”

9

54

Washer 5/16”

10

4

Socket Screw 3/8”-16 x ¾”

11

1

Smart Device Bracket with Hipervision Module

12

2

Stiffening Bracket

13

1

Base Binding Plate

14

1

Base Back T-Support

15

1

Security Bar

(installed on Smart Device Bracket with Hipervision Module

16

2

Security Bar Screws #6-32 x 3/8”

17

2

Washer 3/8”

(installed on Pulley Bracket Assembly)

18

2

Lock Nut 3/8”-16

(installed on Pulley Bracket Assembly)

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

4

Tools Required for Assembly

•3/8 Hex Key for 7/6” Socket Screw

•3/16 or 1/4 Hex Key for 5/16” Socket Screw

•5/16 Hex Key for 3/8” Socket Screw

Philips #2 Screw Driver

Torx T15 Drive

9/16”Hex Open Wrench

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

5

Product Assembly

STEP 1 (Standard RX2500 Configuration)

Parts:

•RX2500 Seat Stand –2x

•RX2500 Cushioned Seat –2x

Hardware:

•Socket Screw 5/16”-18 x 1” –8x

•Washer 5/16” –8x

Tools:

•3/16 or 1/4 Hex Key for 5/16” Socket Screw

1-1 Attach RX2500 Seat support plate to RX2500 Seat stand.

1-2 Install and completely tighten hardware (use screw only).

1-3 Attach item from step 1-2 to ORYX Seat

1-4 Install and completely tighten hardware (use screw & washer).

Cushioned Seat

Seat Stand

Hardware (washer)

Qty.4

Hardware (screw)

Qty.8

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

6

Product Assembly

STEP 2

Parts:

•RX2500D Main Vertical Post –2x

•RX2500D Base –2x

•RX2500D Base Binding Plate –1x

•RX2500D Base Back T-Support –1x

•RX2500 Seat Assembly –2x

•RX2500D Stiffening Bracket –1x

Hardware:

•Socket Screw 5/16”-18 x 1.5”–18x

•Socket Screw 5/16”-18 x 1” – 12x

•Washer 5/16” –30x

Tools:

•3/16 or 1/4 Hex Key for 5/16” Socket Screw

2-1 Place 2 Base assemblies and Base Binding Plate on the floor as shown

below. Binding Plate is installed on top of the Base assemblies and joins

them together in the next step.

2-2 Attach both RX2500D Main Vertical Posts to Base as shown by placing

them on top of the Binding Plate using 5/16”-18 x 1.5” Socket Screws with

Washers. Do not tighten hardware completely.

2-2.1 Attach speed sensor cable (3.5mm mono plug) as shown

2-2.2 If applicable attach USB power cable as shown

2-3 Install Stiffening Bracket as shown using 5/16”-18 x 1” Socket Screws with

Washers. Do not tighten hardware completely.

2-4 Attach RX2500 Seat Assembly to RX2500D Bases as shown and

completely tighten hardware (use screws and washers).

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

7

Product Assembly

STEP 2 –Illustration -01

RX2500D Main Mast

RX2500D Base

Seat Assembly

RX2500D Base Back T-Support

RX2500D Binding Plate

RX2500D Stiffening Bracket

Smart Device Bracket with

Hipervision Module

STEP 3

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

8

Product Assembly

STEP 2 –Illustration -02

RX2500D Main Mast

Sensor Cable

USB Power Cable

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

9

Product Assembly

STEP 3

Parts:

•Assembly from STEP 2

•Smart Device Bracket with

Hipervision Module

•Security Bar

Hardware:

•Socket Screw 5/16”-18 x 1” –4x

•Washer 5/16” –4x

•Torx Screw #6-32 x 3/8 –2x

Tools:

•3/16 or 1/4 Hex Key for 5/16” Socket Screw

•Torx T15 Driver

3-1 Refer to illustration. Install Smart Device Bracket with Hipervision Module as

shown using screws and washers.

3-1.1 Route sensor cables coming from the mid-section of the

Main Mast Assemblies and connect them as shown

3-1.2 Route Power Cable as shown

Note: Do no close opening at the bottom of the

Hipervision module until all connections are tested

3-2 Fully tighten all screws from STEP 2 and STEP 3

RX2500D Base

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

10

Product Assembly –Rope Drum installation

STEP 4

Parts:

•Assembly from STEP 3

•RX2500 Rope Drum –2x

Hardware:

•Socket Screw 5/16”-18 x 1” – 12x

•Washer 5/16”–16x

Tools:

•3/16 or 1/4 Hex Key for 5/16” Socket Screw

4-1 Tilt assembly from STEP 3 and lay it down as shown.

4-2 Attach RX2500 Rope Drum to assembly from STEP 3 and completely

tighten hardware on both sides (use screws and washers).

4-3 Attach sensor cable from the Drum to the connector on the RX2500 Main

Vertical Post. Ensure full insertion, most of the time a “click” will be heard

and felt.

4-4 Tilt machine back up to a standing position.

Screw & Washers 5/16”

Connect sensor cables

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

11

Hipervision –iOS Version

Hipervision Application for iOS can be download directly from the Apple App Store.

Hipervision is available on iPhone, Apple Watch and AppleTV.

Hipervision virtual training technology unlocks the following features when

combined with the Ropeflex Training Equipment:

•Multiuser real-time interactive training environment

•Set goals for time or distance

•Keep track of, and accurately measure your progress

•Interval training mode for rest-and-go training

•Share results with friends and training partners

•Programmable goal presets

•Kiosk mode and many more additional features

For a hassle-free experience QR Code labels are attached to equipment. Scan

using native camera app on the phone or pad and follow the link.

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

12

Product Assembly –Pulley Assembly

STEP 5

Parts:

•Assembly from STEP 4

•RX2500 Pulley Assembly –2x

Hardware:

•Socket Screw 3/8”-16 x ¾” –2x

•3/8”-16 Nut –2x

Tools:

•5/16 Hex Key for 3/8” Socket Head Screws

•9/16”Hex Open Wrench

5-1 Attach Pulley Assembly to assembly from STEP 4 by sliding it from

top of the rail as shown below. Use pull pin to fix pulley in different positions.

5-2 Install “stop screw” as shown and tighten it with an appropriate hex key.

5-3 If installed, remove 2 nuts holding Pulley Bracket handle, remove the handle

and position rope inside the pulley track as shown. Reinstall the bracket

handle and tighten nuts (use washers).

Adjustable Pulley

Bracket Assembly

Pull Pin

Stop Screw 3/8”-16 x ¾”

Pulley Bracket Handle

3/8”-16 Nuts

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

13

Product Assembly –LCD Display (not applicable on Hipervision models)

STEP 6

Parts:

•Assembly from STEP 4

•Display Bracket

•LCD Display

Hardware:

•Button Head Screw 5/16” x 1”

•Washer 5/16”

•Thread Forming #4-20 Screw

Tools:

•3/16 or 1/4 Hex Key for 5/16” Button Head Screws

•Philips #2 Screw Driver

6-1 Attach Display Bracket as shown and tighten hardware

(use screws and washers).

6-2 Remove bottom screw from LCD display, mount display on bracket and

install Thread Forming #4-20 Screw.

Do not over-tighten screw to avoid stripping newly formed plastic threads

6-3 Attach sensor connector from RX2500 Mast to newly installed LCD Display.

LCD Display

Display Bracket

Screw & Washer 5/16”

Screw #4-20

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

14

Equipment Maintenance

WARNING: Routine inspection and maintenance is of critical importance to ensure

maximum safety and performance. We use the highest quality materials available, but

wear is inevitable. Be advised that dangerous conditions can arise even during a

warranty period. A warranty does not negate the owner’s responsibility to thoroughly,

carefully and daily inspect the machine. Consult your physician before starting your

exercise program. For your own safety, do not begin any exercise program without

proper instruction.

1. Check Rope

While the machine is not in use carefully inspect the rope for damage and tears.

Carefully inspect connection of rope ends and make sure that stitching (threads) are

not torn or damaged. Do not use equipment until damaged rope has been replaced.

2. Upholstery

Wipe down after every workout.

Periodically take the time to use a mild soap or mild vinyl upholstery cleaner. Avoid

using any abrasive cleaner not intended for use on vinyl.

Keep sharp or pointed objects out of your pockets and clear of all upholstery.

3. Nuts/Bolts/Fasteners

Periodically inspect all nuts and bolts. Tighten if needed. If bolts seem to loosen

periodically, use Loctite 242 for a long-term cure.

Go through a re-tightening sequence periodically to ensure that all hardware is

properly tensioned.

4. Adjustments / Locking Pins / Tightening Knobs

Check all pieces for signs of visible wear or damage.

Check springs in Snap Links and Pop Pins for proper tension and alignment.

If the spring sticks or has lost its rigidity, replace it immediately.

5. Anti-Skid Surfaces

Replace if they appear worn or become slippery.

7. Warning Instruction Labels

Inspect and familiarize yourself with all safety warnings and other user information on

decals. Replace decals if damaged, illegible, or removed.

R X 2 5 0 0 D U A L A S S E M B L Y I N S T R U C T I O N S & M A N U AL 3 2 - 0 0 1 9 R E V . A

15

WARRANTY

We strive to offer the simplest and fastest resolution to all product related concerns. Our

warranty service program gives its customers the option to return the product for repair,

exchange or refund if the product is determined to be defective.

•All products are warranted to the original purchaser and must be

registered to receive coverage.

•Warranties apply and cover all defects in material and workmanship.

WARRANTY

Frame (not coatings)

10 years

Structural parts

10 years

Pulleys

5 years

Bearings

5 years

Labor

1 year

Electronics

1 year

Rope / Upholstery

6 months

Accessories

6 months

•Customer is responsible for the cost of shipment to HIPEQ. Company

“ship to” address for product returns and service will be provided once the

RMA has been issued. It will be at HIPEQ’s discretion to determine the

party responsible for cost of shipment back to customer.

Out-of-Warranty Products are repaired only with the customer’s prior approval. If you

have any questions regarding HIPEQ equipment or any instruction found in this

document, please call 650.549.5888 for assistance.

16

If you have any questions regarding ROPEFLEX

equipment or any instruction found in this document,

please call 650.549.5888 for assistance.

Table of contents