HIRAYAMA Hiclave HVE-50 User manual

No PO1G-OO4-A

27-JUL-2001

.

This manual was created to support smooth service of the HVE-50

autoclave. Use the manual as a reference in addition to the operation manual.

No part of this document may be reproduced without permission.

The contents of this document are subject to change without notice.

This document has been cc3refullycompiled. If you have any questions or require

information not covered in 'the manual, please contact:

Amerex Instruments, Inc.

P.O. Box 787

Lafayette, CA 94549 .U.S,A.

TEL: 925-299-0743

FAX: 925-29~1-0745

E-mail: [email protected]

~~foreUsing ',-

.In this manual the following headwords are applied to items to ...yhichgreat attention should be

given: .~

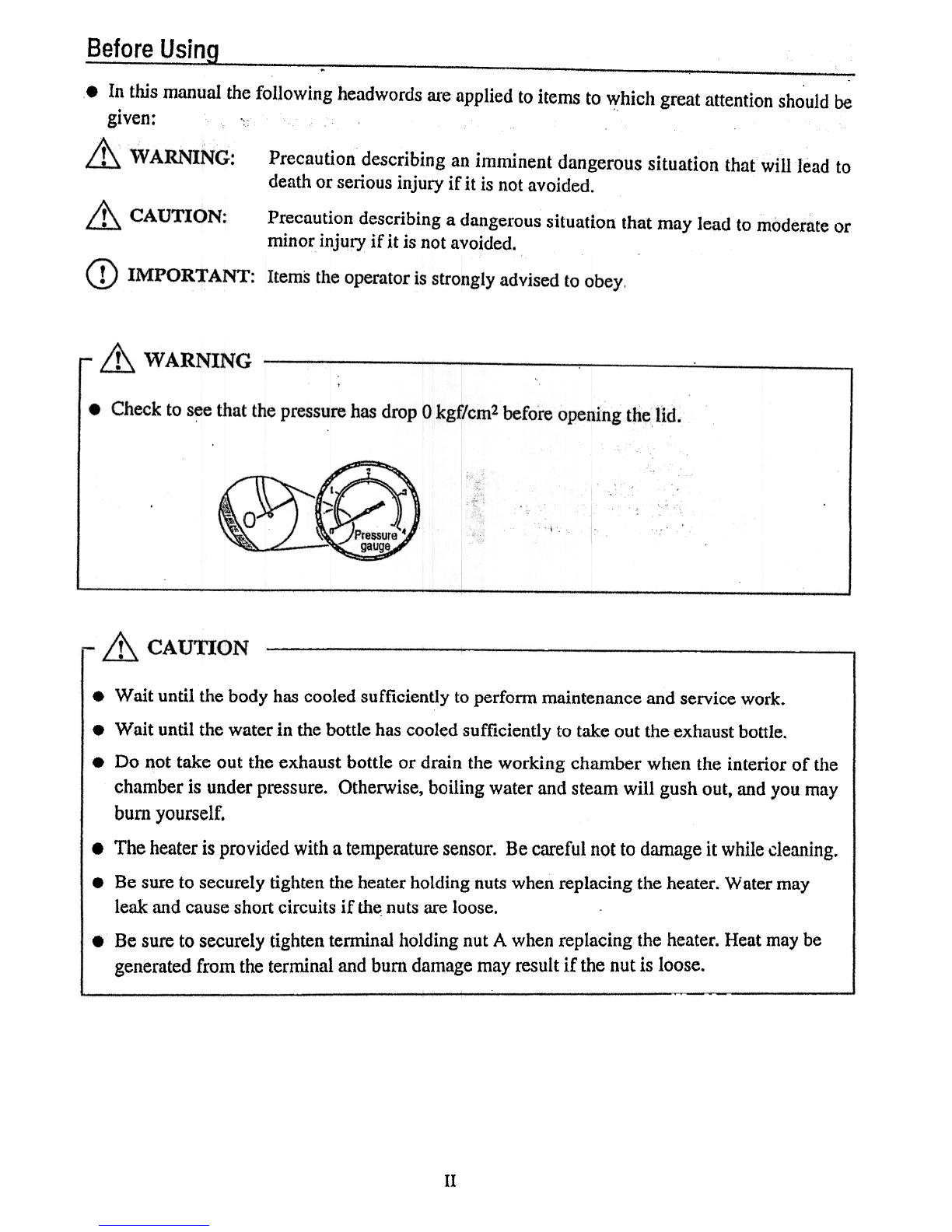

Precautiondescribing an imminent dangeroussituation that will Jeadto

deathorseriousinjury if it is notavoided.

Precaution describing a dangerous situation that may lead to moderate or

minor injury if it is not avoided.

.Wait until the bodyhascooledsufficiently to perfonn maintenanceandservicework.

.Wait until the water in the bottle hascooled sufficiently to take out the exhaustbottle.

.Do not take out the exhaust bottle or drain the working chamber when the interior of the

chamber is under pressure. Otherwise, boiling water and steam will gush out, and you may

bumyourself.

.The heaterisprovided with atemperaturesensor.Be carefulnotto damageit while cleaning..

.Be sure to securely tighten the heaterholding nuts when replacing the heater. Water may

leakandcauseshortcircuits if the.nutsareloose.

.Be sureto securelytightentenninal holding nutA whenreplacingthe heater.Heatmaybe

generatedfrom theterminalandbumdamagemayresultif the nutis loose.

II

Howto ReadThis Manual

.This manual consists of the following sections covering the information required for proper

operation of the autoclave HVE-25/50:

This section describes the maintenance procedures for the unit as we:ll as the methods for

replacing and adjusting the main parts.

Chapter2. Troubleshooting Chart

This sectiondescribestheitemsto checkandmeasur~sto takewhena problemoccurs.

Chapter3. Product Description

This section describesthe operations and internal structural parts of the product.

Chapter4. OperationCheckProcedure

This sectiondescribesthemethodfor checkingtheoperationof electricalpartsusingthecheck

program.

Chapter5. MainPartsList

The code numbers of the main parts arelisted in the table here.

III

.Contents

II

1/1

IV

Introduction """""""""""""""""""!"!"""""'"TableofContentsBefore Using ~How to Read Th1s ManualContents , ,.

1

1

2

3,3

4

5

5

6

7.

8

Chapter 1. Maintenance and Adjustment1. Draining Water from the Exhaust Bottle2. Draining the Working Chamber3. Cleaning the Working Chamber :4. Body Repairs ; , ~ ;;;5. Lid Gasket6. Solid State Relay (SSR) Replacement ~ ; : ; ;7. Replacement of Temperature Sensor for Control8. ROM Replacement , :...,9. Heater Replacement10. Display Board Replacement ! , ,

11

11

13

15

Chapter 2. Troubleshooting Chart1. Error Detection (Alarms) ~ ",.., ;;.;;.., ,...;;.~.~..;:..~2. Early Troubleshooting3. Troubleshooting ::~ ,' ;,

17

17

1'8

20

22

23

27

27

28

28

29

30

31

Chapter 3. Product Description.Operation sequence/proce(jure flow chart , ~.., ..,

.Timing Charts '

.Error Monitoring Charts ; ,.External Appearance.Assembly Diagram.Detailed Display and Operation Switch Diagram.Diagram of Over-pressurization Prevention Switch Area :.Atmospheric Pressure Switch Diagram.Switchboard Diagram.Piping Diagram.Wiring Diagram.Connector Table ;

32

32

32

32

35

Chapter4. OperationCheckProcedure1. CheckProgramOutline2. CheckProgramStartup ,..

3. CheckPrograms ~.Referent~eTableforTemperatureSensorUsedforControl

37

Chapter5. MainPartsList...

IV

Chapter1. Maintenanceand Adjustment

& WARNING ---

.Wait until the body hascooled sufficiently to perform maintenance and servic~ work.

.Turn off the eal1h-leakage circuit breakerbefore replacing any parts.

1. Draining Water from the Exhaust Bottle

.Since the water level in the exhaust bottle increases with continued operation, water must be

drained using the procedure below when water reachesthe HIGH level.

.Wait until the water in the bottle hascooled sufficiently to take out the exhaustbottle.

G) Remove the exhaustbottle from the body.

.Pull the bottle out until the handle canbe grasped then hold and

remove.

@ Place the drain/supply port face down in a level sink.

.Excess water will drain out until the LOW level is reached.

@ Cnfinn thatthewateris atthe LOW level

.Since stearncools in the exhaustbottle, be sureto leave the water

atthe LOW level.

@ Replace the exhaustbottle in the housing area.

.If the bottle is not pushed completely into the housing, an error

( ) will occur when operation starts.

2. Draining the Working Chamber

.Drain water using the following procedure after confirming that the inside of the working

chamberhascooledsufficiently.

.Do not unload the exhaust bottle or drain the working chamber wh~~ t.h~chaIn:~r is under

pressure. Boiling water or steammay gust out causing burns. ;, "

<D Openthelid.

@ Connect one end of the accessory

drainhoseto the tapof thedrainvalve

located at the lower part of the right

sideof thebody.

@ Put the other end of the hose in a

container.

(4) Remove the exhaust bottle from the

body.

@ Turn the drain valve knob, located at

the bottom of the exhaust bottle

housing area, counterclockw~se to

open.

@ Check that draining of the working

chamberis complete.

(Z) Turn the knob clockwise to closethe

drainvalve.

Be surethe exhaustvalve is closed.

2

Cleaning the Working Chamber

3.

.The heateris provide,dwith atemperaturesensor.Becareful notto damagethis sensorwhen

cleaning.

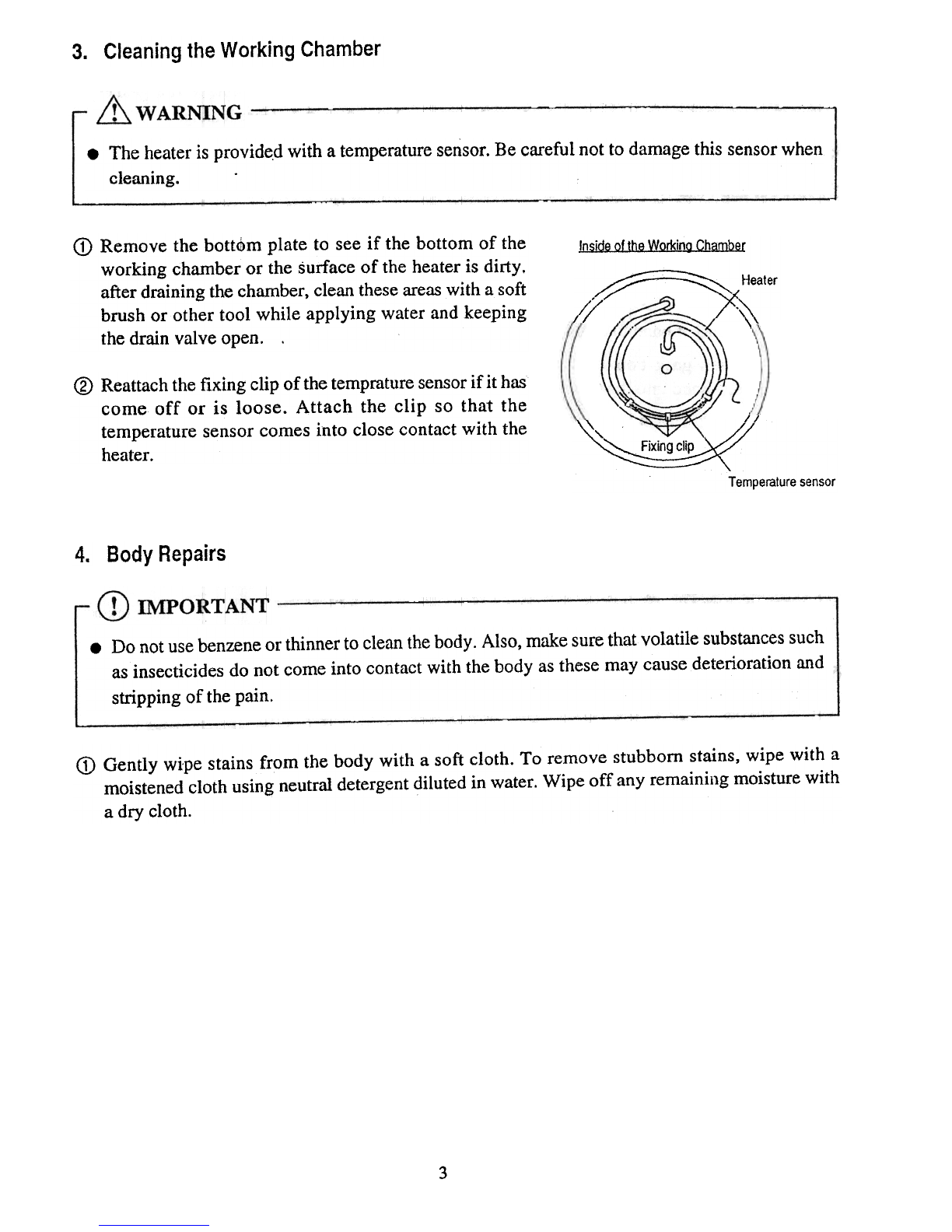

CDRemove the bott<1>mplate to see if the bottom of the

working chamber or the surface of the heater is dirty.

after draining the chamber, clean theseareaswith a soft

brush or other tool while applying water and keeping

the drain valve open. .

InsideoftheWorkinaChamber

Y=~ Heater

// .~

\

//

\'

@ Reattachthefixing clip of thetempraturesensorif it has

come off or is loose. Attach the clip so that the

temperaturesensorcomesinto closecontactwith the

heater.

//

~, ":.,:_~AI:A, d

~..~::~~~~:::~ '

Tempemluresensor

Body Repairs

4.

.Do notusebenzeneor thinner to cleanthebody. Also, make sure that.volatile substancessuch

asinsecticides do not come into contact with the body asthese may cause deterioration and

stripping of the pain.

CD Gently wipe stains from the body with a soft cloth. To remove stubborn stains, wipe with a

moistened cloth using neutral detergentdiluted in water. Wipe off any remaining moisture with

a dry cloth.

3

5. Lid Gasket

.When the end of the lid gasket becomesdiscolored and whitened, replace the gasket in

accordancewith the following procedure.A worn gasketmaycausesteamleakage.

CDOpenthelid.

@ Lift outandremovetheold gasketinsulation.

@ Using awastecloth, wipe dirt off theareaof the

working chamberwherethe gasketwas..

(1) Remove the gasket band from the old gasket,

andwipe dirt off thebandusingawastecloth.

@ Attachthe gasketbandto a newgasket

.Lay the new gasketonthe chamberandpress

thegasketbandinto thegroove. , 1--- Gasketband

Workingchambercross-section

@ Attachthe newgaskectto theworking chamber.

.Attach while making sure the gasketband

remainsproperlypositioned.

If the gasketband comesout of the groove,

press in the band using a flat-blade

screwdriveror similar tool.

0 Pushthe new gasket down with the fingers to

eliminate anyunevenness.

.,&,$

~~~~~~~~~-- Lidgasket

:.1.$

,.

1~...1!: :1,

, 'I

, '..',

I~ '--.Workingdlamber

.Unevenness in the gasketcancauseleaks.

@ Start normal operationsand confirm thatthere

areno leaksfrom thelid gasket.

Ii

6.

Solid State Relay(SSR) Replacement

CD Pullout the connector from the solid state relay (SSR).

C?)Turn the SSR holding screws and remove the SSR

form the switchboard.

@ Wipe off the heat dissipating grease, dust, and other

matter adhering to the switchboard in the vicinity of

the SSR attachment screw hole.

@ Clean the attachment surface of the new SSR, then

evenly apply heatdissipating greasetQthe surface.

@ Attach the SSR to the switchboard and plug in the

connector.

.Since the IN side of the SSR has +/- polarity, be

sure to attach this side in the original connection

direction.

7. Replacement of Temperature Sensor for Control

<D Hold the sensorand loosen.

@ Pull the temperature sensorfor control from the sensorhr;lding hole.

@ Insert the new sensorthrough the sensorholding ho]e, adjust so the internal working chamber

surface and the end of the temperature sensorare at the sameposition, and firmly tighten the

sensorholder using the fingers and riot a monkey wrench or other tool.

Sensorholder

/

Internalworkingchambersurface

~

"'"

"'--

Temperaturesensorfor control

End ofthe temperaturesensorforcontrol

5

8. ROMReplacement

CD IMPORTANT -

.When replacing the ROM, usea specialtool

to avoid damagingthecontrolPCBorthenew

ROM. .

.The PCB or ROM canbedamagedif touched

or brought into contact with people or

clothing having a static electricity charge.

Touch a metal object or take othermeasures

to discharge static electricity before

performingtheseoperations.

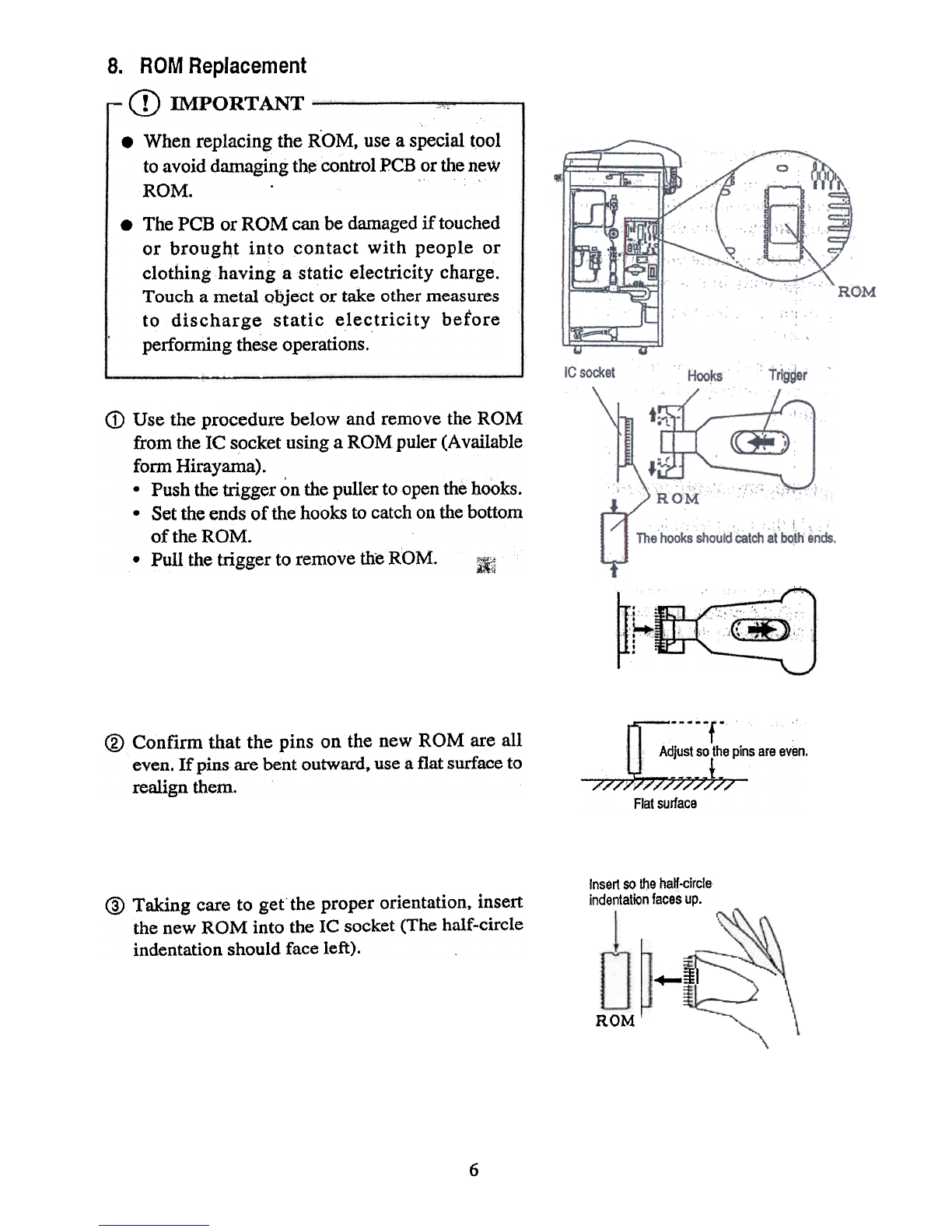

CDUse the procedure below and removethe ROM

from theIC s~cketusinga ROM puler(Available

fomI Hirayama).

.Push thetrigger onthepullerto openthehooks.

.Set theendsof thehooksto catchonthebottom

of theROM.

.Pull the trigger to removetheROM. :if~

@ Confirm that the pins on the new ROM are all

even.If pinsarebentoutward.usea flatsurfaceto

realignthem.

f-

Adjustsothepinsareeven.

~ t-

//////////////

Flatsurface

Insert $0 lIJehalf-circle

indentationfacesup.

@ Taking careto get the proper orientation, insert

the new ROM into the IC socket (The half-circle

indentation should face left).

-+-~I

ROM

6

9.

Heater Replacement

& CAUTION

.Be sureto securely tighten the heaterholding nuts whenreplacing the heater. Water may leak

andcauseshortcircuits if thenutsareloose.

Be sure to securely tighten terminal holding nut A when replacing the heater. Heat may be

generated from the terminal and bum damage may result if the nut is loose.

.Required tools

.Monkey wrench (with maximum opening

width of 23 mm or more)

.Spanners, etc. .

(for 7 mmnut)

G) Drain the water from the working chamber.

@ Turn off the earth-leakage circuit breaker

located on the right side of the body.

@ Remove the plate from the rear of the body.

@ Pull the temperature sensor out from the sensor

fixing tube on the heater.

@ Loosen terminal holding nut A and remove the

round terminal.

Healer"

@ Remove the neaterholding nuts.

.If the nut cannot be removed using a monkey

wrench, lay the body down, and insert a box

spanner into the hole on the underside to

removethenut.

Gasket Workingchamber

FI

Rou Fixingclip

Terminalholdingnut8

-Terminal holdingnutA

<V Remove the heaterfrom the working chamber.

@ Remove anybilge or other matter from the area

around the heaterattachment holes.

@ Remove the heaterholding nuts and flat washers

attachedto the new heater. ..~'.'."""".".""""'.""""'-. \, ., ,

.I ..

, , .,

"., .. \"":0-' .:.;,

:':':"

"1¥::::~~~""::: Heater

, , .

..,. .

;:' t:i

.,' iJ Gasket

,"7 Heaterattachmentholes

~ ..-

~

@ Bring the heater screw sections through the

attachment holes on the bottom of the working

chamber. Be careful that the gaskets do not

come out and fall into the chamber during this

operation.

-M

::~::~~

1:1:::tJ ~ Flatwashers

"""""""~ Heaterholdingnuts

@ Attach the flat washers, then tighten the heater

holding nuts.

@ Remove teffilinal holding nut A from the newly

attachedheater.

7

@ Attach the round terminaland tighten terminal holding nutA. At thi~ point, securet~~inal

holding nutB with a wrenchand stronglytightennutA.

@ I~s~rtthetemperaturesensQrintothefixing tubes. ..,

@ Placewaterin theworking chamberandcheckfor leaksfrom the heaterattnchment(areas. :,.

@ Turn onthee~h-leakage circuit breaker,andbeginoperationin accord;1ucewith theordinary

operationprocedure. Checkto seethutth~reisno.1~akagefrom~e he~~er.inst~.lation@(~awhile

pressureis increasing. Install theplate ontherearof thebody.

10. Display Board Replacement

.Required tools

.Plus driver (for M5 screws)

.Plus driver (for M3 screws)

.Adhesive tape

<D Disconnect connector CNI on the control PCB. Wrap th~ connectof and bracket cable in

adhesive '.tapeto make them pass through the duct easily. ., .-' .' .' ':. ". !

,

Adhesivetape

Connector

@ Openthelid andremovethe holdingscrewsfor the.lidbottom cover..

@ Removethelid coverholding screws.

8

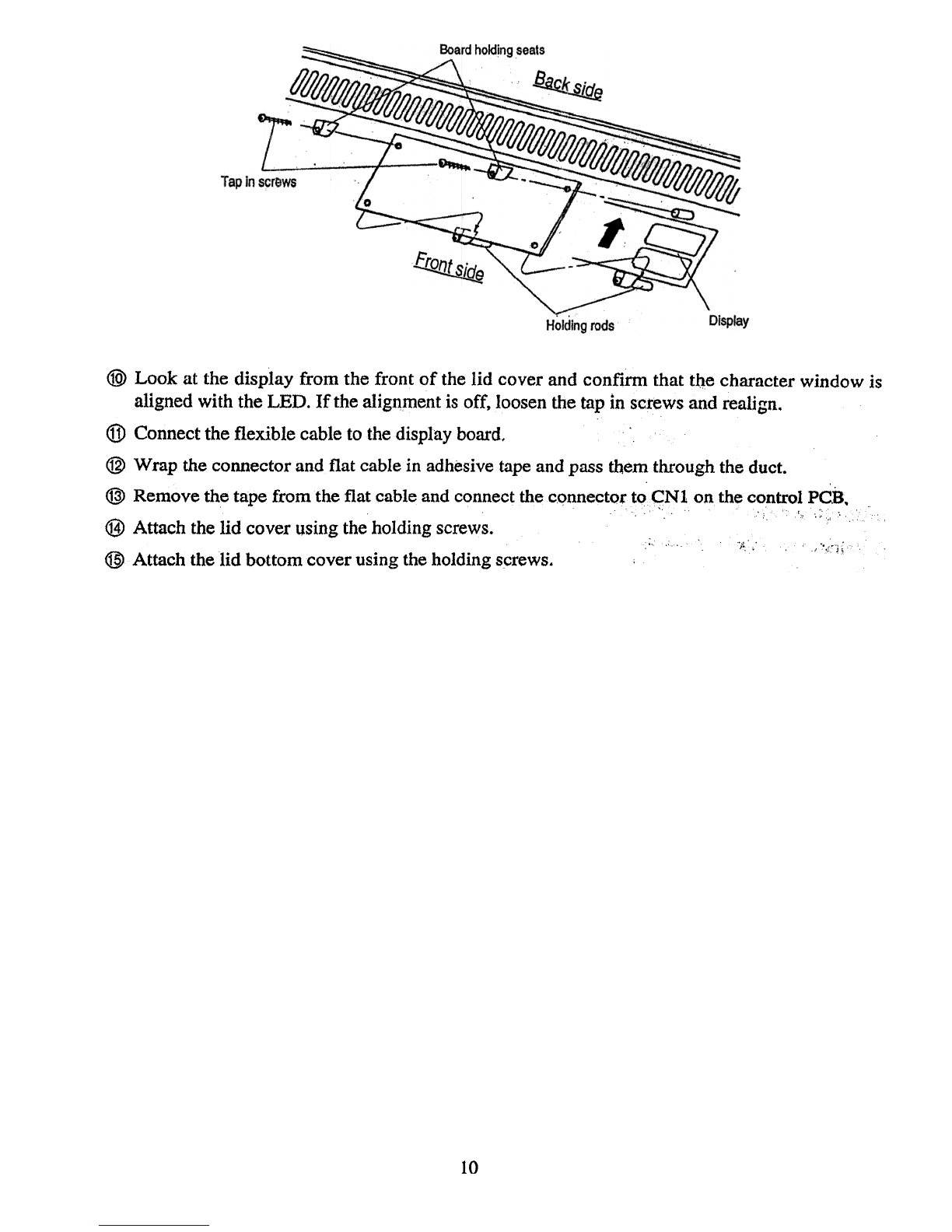

@ Removethe2 tapin screwsonthebackandremovethedisplay.board.

CDLoosenthe2 tapin screwsonthe frontby 1 or2turns.

@ Pressthedisplayto thefrontandbringthenewdisplayboardinto contactwith theholdingrods.

PassthetapinscrewSthroughtheboardholdingseatsanddisplayboardholdingholesandattach

to thelid cover.

9

@>Look at the display from the front of the lid coverand confirm thatt~e characterwindow is

aligned with theLED. If the alignmentis off, loosenthetapin screwsandrealign.

@ Connecttheflexible cableto the displayboard,

@ Wrapthe connectorandflat cablein adhesivetapeandpassthemthroughtheduct.

@)Removethetapefrom the flat cableandconnectthe cQnnectorto~Nl onthecontrolPC.B.

!, .:: c.

@ Attach thelid coverusingtheholding screws. ..f'.. , ~..,':l{

@Attach thelid bottom coverusingtheholding screws.

10

C~aEt~~~. !roubleshooting C~art

1. ErrorDetection (Alar~5)

Disolav Cause Items to check Remed~:

Userjnstruction

I

User check

'Er1I

(Lack-oi-water

alarm)

:

User check Userinstruction

Checkcontact/open

iactivation distance

I

Lack-of-water

preventiondeviceII

replacement

Control PCB

!replacement

~- ~ --~--!

I) Water was not placed in the

.I

working chamber

2) Water was not replenishedI

durin~ continuous ~peration

3) Defectlve contact pOInt

! operation of the lack-or-waterI

prevention device

4) Defective input circuit for theI

lack-or-water prevention

device on the control PCB

5) Wiring contact problem

i between the lack-of-waterI

prevention device and the

control PCB

:

Check using the checkI

program ..c4"

;

Check wiring Wiringrepair

I

R~place sensor

1) Defectivetemperaturesensor

IEr2I

(Broken wiring

for temperature

sensorforI

control)

iReplace

control

IPCB

12) Defective input circuit for the

temperature control sensoronI

the control PCB

Measure temperature I

sensor resistance value (at

normal temperature: ,

resistance between wrute I

and yellow wires is 79 -

156 K.Q) I

Check using the check

program ..c6" (display of

47 -91 is nonnal at

normal temperatures)

Check using the check

program ., c7" (display of

175 isnonna1 a_t121°C)

[Replace

control

IPCB

Checkusingthe check

Iprogram "c3"

I

1) Defective solid state relay

(SSR) output circuit on the

I control PCB

12) Defective SSR

!Er3

I(Excessive

temperature

ialarm)

I

Replace SSRICheck contact/open

Iactivation distance

~ ---

1) Defective heateroperation

'Er4-

I(Excessive

Icoolingalarm)

I

Replace the

sensor

12) Defective temperature sensori

for control

:

Refer to trouble shooting

measures to take when the

Itemperature in theworking!

Ichamber will not rise

!Measure temperature

,sensor resistance value (at

100°C: resistance between

white and yellow wires is

Iabout 63 Kg)

11

:

,Reroed~

!;, ",,' '" crReplacetheI

control PCB

Itemsto 6tle'ck

Cause

Display Checkusingthecheck

program ..c7" (a display

valueof.92i~ ~orrnal at

100°C)

~3) Defective input qircuit for the

II temperatureconttol sensor on

the control PCB

i~r5 1) Defective solenoid-controlled

valveoperation

(Excessive

oressurealarm)

Referto troubl~ shooting

measuresto takewhenthe

,

air inth~ wor~.ng champ~r

will not purge

Checkwhetherthe contact

make/breakisdisabled,

2) Defective over-pressurization

preventionswitch

ICheck using the check

,

program..c11" (~display

I ., , .:

valueof 1or }snorm~l

iat.lQQO~)_~; ..':' "!~

Replaceover-

pressurization

prevention

switch.

'IReplace the

control PCB

3) Defective input circuit for the

over-pressurization

..prevention switchon the

contr91 PCB

ITighten

the[screws

1) Lock plateattachrilentisloose

.Er6

(Lid abnormality

alarm)

I

'I'Tighten the

screws

2) Limit switchLSWI attachment

is loose

3) befective limit switchLSWI

iCheckthe loosenessof the

lock plate attachment

screws

Checkthe loosenes

limit switchLSWl

attachmentsCrews:

Checkcontact/open

activationdistance

Check using the check

program ".c4"

Replacethe limit

switch

Replacethe

control PCB

4) Defective input circuit for

limit switchLSWI on the

control PCB

Same as ..Er4."

IEr9

(Sterilization

1eaterabnormal-

ity alarm)

"~rL 1) Limit switchLSW2attachment

is loose ITighten screW$

(Open!closelever

lock abnormality

alarm) 2) Defective limit switchLSW2

Checkthe loosenessof theI

limit switchLSWl)

iattachment

Check contact/open

activation distance

Checkusing the check

,program "c4)"

!Replace

iswitch

i

IReplaceiPa;J

Checkthe loosenessof the

solenoid !Tighten screws

3) Defective input circuit for

limit switchLSW2) on the

control PCB14)

'Sole~oid attachment loose

12

limit

control

Disolav Cause Items to check Remedy

15) Defective solenoid of 4X

r~lay

IReplace

defective

parts,

!

Check using the check

Iprogram ..c3"

User check

I

User instruction

IErEI

(Exhaust bottle

abnormalityI

alarm)I

:Tighten screwsI

1) Exhaust bottle was

removed during

operation or while thei

pressure in the working

, chamber wasO.5kgf/cm2I

or more

2) Limit switch LSW3I

attachment is loosei

3) Defective limit switch

LSW3

4) Defective input circuit for

II limit switch LSW3 on the

control PCB

i

Check looseness of limit

switchLSW3)I

Check contact/open activation

distanceII

Check using the check

program "c4"

Replacei

switch,ReplaceI

PCB

2. EarlyTroubleshooting

I

Condition

,I

Displays do not

light whentheI

power switch

j(breaker) is

turnedon.

Cause Itemsto check Remedy

I

Repajr or replace'i

defective parts

1) Poor connection or

contact atterminalsand

connectors

iC~;ctili~---

Iproblem with the

facilities

:Replace the

I power cord

Replace the

'breaker

iReplace the

I transformer

L12) No power

jPower cord connection IBreaker (power switch)

connection ,

Tab tenninal connection I

Connection of CN2connector

on the control PCB

Connecl:ion of CNl)

connector on the control PCB

Power socket (rated voltage)

3) Powercord brokenI

iPower

sideof breaker(rated

voltage)I

Breaker load (rated voltage)

14) Breaker broken

I5) Transformerbroken

ICheck, repair, ori

replace the shoft

Replace theI

control PCB

jCorrect theI

reason for the

blown fuse and

replace the fuse

Between terminals 1 and 2 onl

Iconnector CN1 on the control IiPCB

(AC14V)

Between terminals 12V and I

IOV (DC+12V)

[Between terminals 5V and OV

(DC+5V)I.

Check visually

'6)

Defective parts in the

i control PCB

i7) Defective parts in the

control PCBI

8) Blown fuse in the control

I PCB .

13

limit

control

itemstocheck

Condition

L..

One digit on the

LED displaydoes

not light

Pressurein

working chamber

will not rise

1) Defective circuit i: LED s~ldering points

2) Defective LED LED broken ",

Leak from safe~y valve,: ~.

1) I?efect:ive safety valve

Pressuregaugeneedle

2) Brokenpressuregauge

Steamleaksfrom piping

3) Piping loose or damaged

;RemedY.

Rep~r 'soldering

poin;ts

Replace;LED

",' '.,

Rep~ror replace

safetyvalve':"':

Replacepressure'

gauge

, Rep,~r leaking

.

,.--~ 1s!cj1~~4) Refer to trouble shooting section

, ~ "

1) Refer to trouble shooting section

Air not purged

from working

chamber

Steamleakfrom

the lid gasket

iE;

.'

I) Old or damaged lid gasket Visually check the Replac~ the lid

deterioration and damage to gasket : ;,c"

the gasket ,

Visually check the , "

attachment evenly:,

i

Visually check for foreigtt Remove,

matter adhering to the lid or colltamina~t~: " ,

lid gasket ".,",'~,'"

2) Improper lid gasket

attachment

3) Adhering foreign matter

'!:".;;i:

:;,..,

.;: !

Waterleak form

thebottomof the

body

1) Leak from heater

attachmentnut section

Ti$hten .i ' c',,:'

attachmentnuts";'

Rep1acegasket

Tighten

a~t.achmentnuts

2) Leak from lack-or-water

preventiondevice

attachmentnut section

3) Leak from piping

4) Leakfrom exhaustbottle

Loosenessof heater

attachmentnuts

Gasketdeterioration

Loosenessof lack-or-water

prevention device attacp~ent

tnu s !.

Piping looseness

Damageto exhaustbottle

Cracksin exhausthose

5) Leak from exhausthose

Stateof the exhaustvalve

Tightenpiping

Replaceexhaust

bottle

tReplaceexhaust

hose

Closeexhaust

valve

6) Leak from exhaustport

dueto openexhaustvalve,

if:- Referto the trouble shooting section

Open/closelever

will not move

Lid will not raise 1) Open/closeleveris not Check lever position (right Slide lever

or lower completely to one side end) completely to the

--right end

14

Cause ,

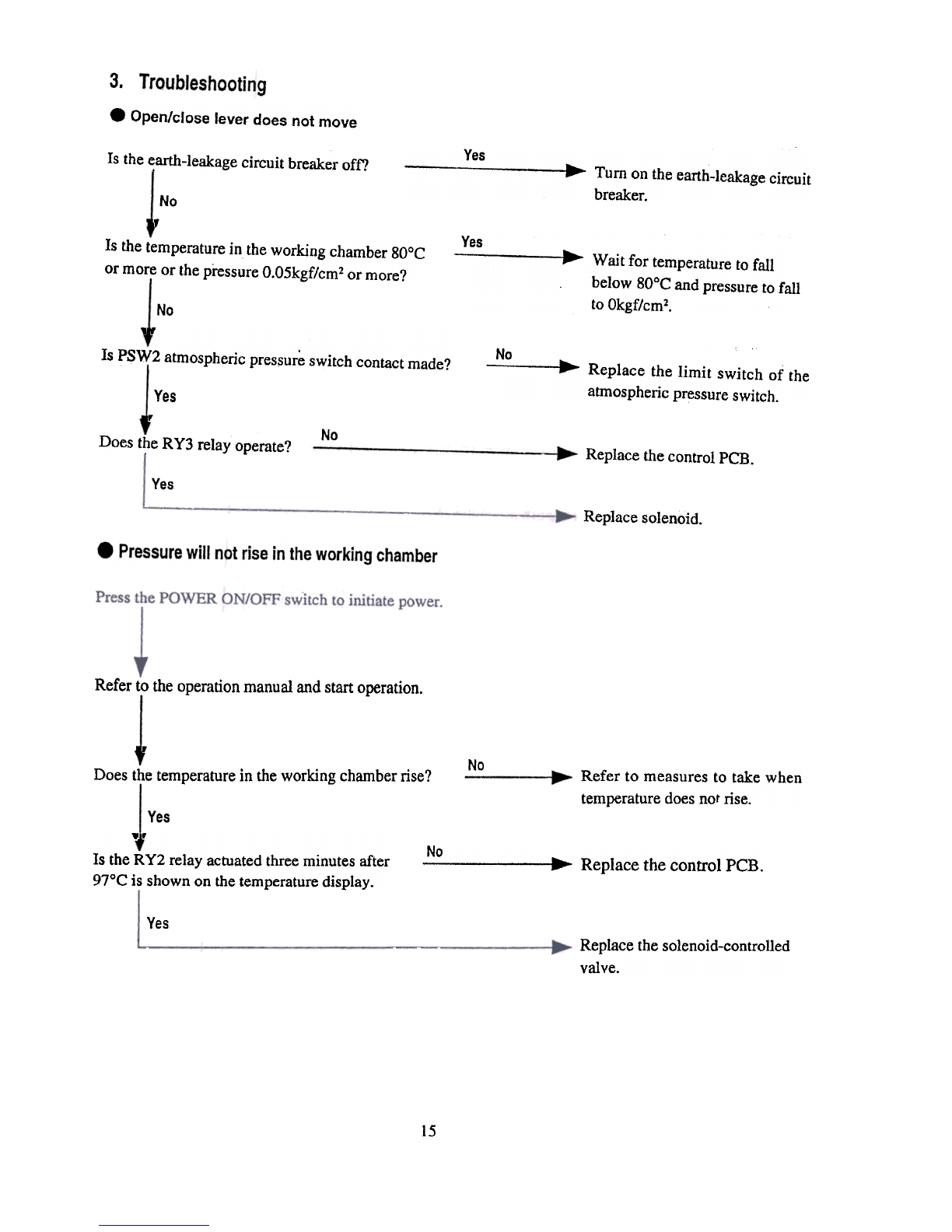

3.

.Open/close lever does not move

Is thee;arth-leakagecircuit breakeroff? Yes

~ ...Turn on the earth-leakage circuit

breaker.

No

,

Is thetemperaturein theworking chamber80°C

ormore or thepressureO.O5kgf/cm2or more?

I

Yes Wait for temperaturetofall

below80°Candpressureto fall

toOkgf/cm2.

No

1,

Is PSW2atmosphericpres.sur~switchcontactmade? No ...Replace the limit switch of the

atmosphericpressureswitch.

Yes

,

No

DoestheRY3 relayoperate? ReplacethecontrolPCB.

Yes

Replacesolenoid.

Refert.otheoperationmanualandstartoperation.

.

No

Doesthetemperaturein theworkingchamberrise? Refer to measuresto take when

temperaturedoesnotrise.

Yes

..

Is theRY2 relayactuatedthreeminutesafter

97°Cis shownonthetemperaturedisplay.

No ..Replace thecontrolPCB.

Yes Replacethesolenoid-controlled

valve.

15

Table of contents

Other HIRAYAMA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

MELAG

MELAG MELAquick 12+ p user manual

Barnstead International

Barnstead International DIamond 1265 Series Operating manual and parts list

Buchi

Buchi B-811 Operation manual

REPLIGEN

REPLIGEN TangenX PRO PD LHV user guide

Helmer Scientific

Helmer Scientific i.Series Service and maintenance manual

Civco

Civco GUS G32-S Operator's manual

Chopin

Chopin Alveo PC graph Quick installation and first test

Thermo Scientific

Thermo Scientific TSQ Endura Hardware manual

Storz

Storz 8403 XSB Instructions for use

Gilson

Gilson MyPIPETMAN Select manual

IKA

IKA ULTRA-TURRAX T 18 basic operating instructions

Shimadzu

Shimadzu LC-40D X3 CL instruction manual