HIRAYAMA HV-25 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction

We would like to express our gratitude for your purchase of our autoclave. This brochure covers

the operation method and a simple maintenance method for the Autoclave

HV-25/50/85/110

you

now own. We hope that owing to your proper handling the autoclave can demonstrate its full

performance and that you

will

make regular use of it for a long time.

For

optional equipment

(0

printer,

O

floating sensor,

0

cooling fan, automatic water supply

equipment),

if

any, read the attached operation manuals for the equipment.

Please check whether or not the product conforms to your order and confirm that it was not

damaged during transportation, Should it be damaged or out of order, please contact the sales

outlet from which you purchased it.

Be

sure to send the enclosed warranty registration card to us.

+\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\K

2

Q

(1)

No

part

of this document may be reproduced without permission.

+

Q

(2)

The contents of this document are subject to change without notice.

Q

2

(3)

This document has been carefully compiled. If you have

any

questions or necessary

t

$

information uncovered

in

the

document, please contact us

or

the sales outlet from which

?

$

you purchased the product.

k\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\~:

Table

of

Contents

Date Descriptionof Revision

Jun.

11, 1996

Additions and revisions to

WARNING,

CAUTION and NOTE.

Instructions under "Replacing Lid Packing" in Chapter

4:

Maintenance and Service revised.

Instructions for "Operation with

a

WaSte Disposal Bag" added.

Instructions for "Successive Operations with the Product" added.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Before

Using

In this manual the following headwords are applied to items to which great attention should

be

given:

WARNING:

Precaution indicating an imminent dangerous situation which if not avoided

may lead to death or serious injury.

a

CAUTION:

Precaution indicating a dangerous situation which if not avoided may lead to

moderate or slight injury.

IMPORTANT:

Indicates items you are strongly advised to obey.

NOTE:

Items you should pay attention to during operation.

r

/(\

WARNING

Never use the autoclave to sterilize the following dangerous objects or substances containing

alkali content. Sterilization of such objects may cause explosion, corrosion of the working

chamber or piping, and deterioration in packing.

/

List

of Dangerous Objects:

(1)

Explosive substances

Nitroglycol, nitroglycerin, nitrocellulose, and other explosive nitric esters.

*Trinitrobenzene,trinitrotoluene, picric acid, and other explosive nitro compounds.

*Peraceticacid, methyl ethyl ketone peroxide, benzoyl peroxide, and otherorganicperoxides.

(2)

Ignitable substances

*Metallic lithium, potassium, sodium, yellow phosphorous, phosphorus sulfide, and red

phosphorus

Celluloids, calcium carbide (carbide), lime phosphide, and magnesium powder

Aluminumpowder, magnesium powder, and metallic powders otherthan aluminum powder

*Sodium.dithionite(or sodium hydrosulfite)

(3)

Oxidizer

*Potassiumchlorate, sodium chlorate, ammonium chlorate, and other chlorates

Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other perchlorates.

*Potassiumperoxide, sodium peroxide, barium peroxide, and other inorganic peroxides

*Potassiumnitrate, sodium nitrate, ammonium nitrate, and other nitrates

Sodium chlorite and other chlorites

Calcium hypochlorite and other hypochlorites

(4)

Inflammable substances

Ethylether, gasoline, acetaldehyde, propylene oxide, carbon disulfide, and other substances

whose flash points range from

-30°C

to

0°C

exclusive.

*Methanol,ethanol, xylene, benzyl acetate (or amyl acetate), and other substances whose

flash points range from

0°C

to

30°C

exclusive.

Kerosene, gas oil,turpenineoil, isopentyl alcohol (orisoamyl alcohol), acetic

acid,

and other

substances whose flash points range from

30°C

to

65°C

exclusive.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

(5)

Harnmable gas (hydrogen, acetylene, ethylene, methane, ethane,propane, butane, and other

substances that are

gas

at

a

temperature of 15°C at 1atmospheric pressure.)

Before opening the lid,

be

sure to check that the pressure gauge reads

"0

kgf/cm2".

I

0

Never modify the product.

-

A

CAUTION

Foreign matter (metals, liquid) may enter through the vent hole. Operating the equipment

with such foreign matter inside may cause trouble with the equipment, fire and electric

shock.

Do not forcibly bend, twist, tie or extend the power cord. Do not place heavy objects on the

cord.

A

damaged cord or exposed wire may cause fire orelectric shock.

Never connect the power cord to a power supply other than the voltage that is rated.

Connection to such a power supply may cause fire or electric shock.

If

not plugging the sterilizerinto a grounded socket, ground the equipment separately before

connecting it to a power source.

Never ground to a gas pipe or vinyl chloride water servicepipe.

Before closing the lid, check to see that there are no foreign matters in the portion of the lid

which is in contact with the lid packing. Foreign matters may cause steam leakage.

Whenever

a

bag, such

as

a

waste disposal bag, isused for sterilization,put it in the wire mesh

basket and place the

basket

in

the working chamber. If the bag is placed directly in the

working chamber, the piping may become cloggedby itand overheating, overpressurization,

and/orlack of water

may

result.

,

Be careful not to pinch hands when closing the Iid.

Do not put your face or hands close to the working chamber when lifting the lid after

operations are complete; steam will gush out of the opening of the chamber.

The lid, working chamber, packing and panel are extremely hot immediately after the

completion of operation. Do not touch the equipment or you may

get

burned.

Put on heat insulation gloves before removing a substance from the working chamber. Do

not put your hands into the chamber until the steam has been vented.

@

It takes

a

lot of timefor the liquid to cool. Be sureto check that the temperature has dropped

sufficiently before unloading the liquid from the working chamber, or you may get burned.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Do not unload the exhaust bottle or drain the working chamber when the chamber is under

pressure. Boiling water or steam may gush out, and

you

may get burned.

a

Do not unload the exhaust bottle before water in the bottle has been sufficiently cooled.

0

Do not dispose of used batteries in fire; they may explode.

a

If you encounter any anomaly

(e.g.

abnormal sound

and

smell, smoking), immediately shut

off power. After checking to see that the abnormal condition is not continuing, call us or our

authorized sales outlet from shich

you

purchased

it.

0

If the display differsbetween the steps, turn off the

POWER

switch, and then turn the power

on again.

If

the condition still remains, turn off the power and call us or our authorized sales

outlet from which

you

purchased it.

a

If

the equipment is installed in a place which is

800

m

or higher than sea level (i.e. under low

pressure

in

mountain areas), the over pressure preventive device and the air vent device

require changes to their setting.

In

this case, be sureto contact us. Do not use theequipment

before changing the setting.

a

In transporting the equipment, put the lid on and slide the open/close lever

to

the end of the

close side to prevent the lid from opening.

When moving the

lid,

do not hold it

by

the handle, otherwise the lid may become difficult to

close.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

How

to

Read

This

Manual

a

This operation manual consists of the following sections covering the information required for

proper operation ofthe autoclave

HV-25/50/85/110:

Chapter

1.

What IsAutoclave

HV-25/50185/11O?"

This section describes the uses and features of the product and the names

and

functions of its

parts.

Chapter

2.

Installation

This

sectionexplains where the equipment should be installed and how to install it.

The

product

incorporates precision parts. Be sure to follow the instructions covered in this document.

Chapter

3.

Operation Method

This section illustrates how to change various set values,

and

describes operation before starting

the equipment and after automatic operation. This section also covers the display and action of

the equipment during automatic operation.

Chapter

4.

Maintenanceand Servicing

This section explains the methods for draining water from the exhaust bottle or working charn-

ber, servicing the body, and parts replacement.

Chapter

5.

Specifications

his

section includes dimensions, power consumption, working range, piping and wiring dia-

grams of the product. Refer to this section as is required.

Chapter

6.

Inthe Event

of

Suspected Failure

This section covers troubleshooting procedures for the product. If you encounter anything sus-

pected to be due to failure, read this section first of

all.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Contents

Introduction

...................

..

............................................................................................

Table of Contents

.........................................................

....................................

BeforeUsing

...............................................................................................................

How to ReadThis Manual

...................

....

.................................................................

Contents

....................

...

..............................................................................................

...........................................................

Chapter

1

.

What Is Autoclave

HV-25/50/8511lo?

.................................................................................................................................

1

.

Product Uses

2

.

Product Features

..........................................................................................................................

3

.

Name and Functions of Each Part

.............................................................................................

Chapter

2

.

Installation

...................

...

.......................................................................

1

.

InstallationInstructions

...........................

....................................................................................

2

.

InstallationProcedure

................................................................................................................

Chapter

3

.

Operation Method

...................

......

.........................................................

Basic Operation Method

...........................................................................................................................

Turning

"ON"

POWER Switch

....................................................................................................

PouringWater

...............................................................................................................................

Loading Substance

.......................................................................................................................

Selecting Mode (Process)

............................................................................................................

Changing Set Values (RegisteringValues

by

Customer)

.............................................................

Checking andCorrectingthe ClockTime

...................................

....

...............................................

Checking and Setting of Turn-onTimer

......................................................................................

StartingOperation

........................................................................................................................

Unloading

......................................................................................................................................

10

.

After Completionof Operations

..................................................................................................

11

.

To Interrupt Operation

................................................................................................................

12

.

If Power Supply Is Cut Off during Operation

...................

..

.......................................................

13

.

Operatjonof Cycles

...................

..

.......................................................................................

Chapter

4

.

Maintenance

and

Service

.............................................................................

1

.

DrainingExhaust Bottle

...................

A

....................................................................................

2

.

DrainingWorking Chamber

...........................

............

....................................................................

3

.

Cleaning Working Chamber

.......................................................................................................

4

.

Body Service

................................................................................................................................

5

.

ReplacingLid Packing

...................................................................................................................

6

.

Replacing Backup Battery

........................................................................................................

Chapter

5

.

Specification

...................

..

.....................................................................

Chapter

6

.

Inthe Event

of

SuspectedFailure

.................................................................

1

.

Error Detection (Alarming)Operation

...................

..

......

..

......................................................

2

.

EarlyTrouble Shooting

....................................

....

..........................................................................

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Cha~ter

1.

What

Is

Autoclave

HV-25/50/85111O?

1.

Product

Uses

This product is designed for research use only (Modes

1

-

3).

It is not labeled or marketed

for

use in medical

or

clinical applications.

This product is also used to liquefy media (Mode

4).

Mode 4 can also be used to prewarm the

chamber for a faster start.

2.

Product Features

This product is equipped with

a

cover for the lid that may be heated at hlgh temperature during

use.

Theproduct incorporates an automatic timer which permits you to begin operation at any desired

time within a period of one week.

The product is provided with a variety of modes of operation. The modes are divided into two

broad categories: Sterilization-warming mode and liquefaction mode.

If

you do not take out the

sterilized medium immediately, then select the sterilization-warming mode, and coagulation is

prevented. To liquefy a coagulated medium, use the liquefaction mode.

This autoclavecan be set to automatically exhaust

%

inside the chamberat a desired rate (exhaust

valve aperture) after sterilization is over.

Optional equipment (printer, floating sensor, cooling fan, automatic water supply equipment)

can be installed onto the product at a later date.

3.

Name and Functions

of

Each Part

Outer View of Body

When the lid is open

Lid

nT

Magnetcatch

!I:er switch

-

%

Pressure gauge

Front View

Port

for

attaching

printer

Exhaustbottle

-,..-

El-

Drain port,

Water receiver Panel

Lid

gasket Workingchamber

\

Comer plate

I

Vent hole

arrying handle

Side

View

11

(2

pieces

for

HV-85

Exhaust

port'

lo)

Rear

View

fa

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

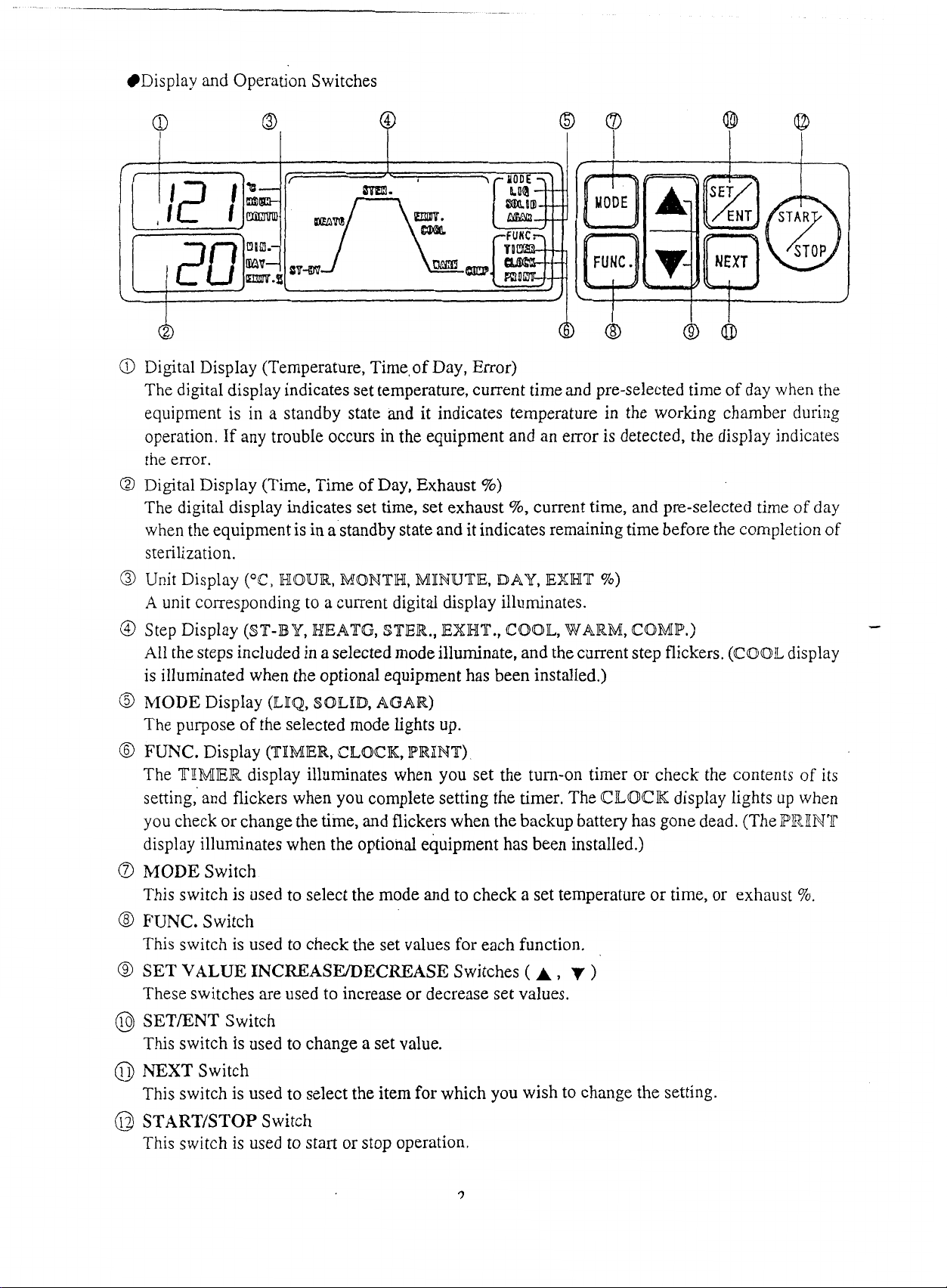

Display and Operation Switches

@

Digital Display (Temperature, Time,ofDay, Error)

The digital display indicates set temperature, current time and pre-selected time of day when the

equipment is in a standby state and it indicates temperature in the working chamber during

operation.

If

any troubIe occurs in the equipment and an error is detected, the display indicates

the error.

@

Digital Display (Time, Time of Day, Exhaust

%)

The digital display indicates set time, set exhaust

%,

current time, and pre-selected time

of

day

when the equipmentisin a'standbystate and itindicatesremaining time before the completion of

sterilization.

@

Unit Display

("C,

HOUR, MONTH, MINUTE,

DAY,

EWHT

%)

A

unit corresponding to a current digital display illuminates.

@

Step Display (ST-BY, HIEATG, $TIER., EXWT., COOL,WARM,

COMP.)

-

All the steps included in a selected modeilluminate,and the current step flickers. (COOLdisplay

is illuminated when the optional equipment has been installed.)

6)

MODE

Display

(ILIQ,

SOILID,

AGAR)

The purpose of the selected mode Lights up.

@

FUNC.

Display (TIMIER,CLOCK, PRINT)

The

TIIMIER

display illuminates when you set the turn-on timer or check the contents of its

setting, and flickers when you complete setting the timer. The

CLOCK

display lights up when

you check or changethetime, and flickers when the backup battery has gone dead. (The

PRIINT

display illuminates when the optional equipment has been instalIed.)

a

MODE

Switch

This switch is used to select the mode and to check

a

set temperature or time, or exhaust

5%.

8

FUNC.

Switch

This switch is used to check the set values for each function.

@

SET

VALUE

INCREASEDECREASE

Switches

(

A,

)

These switches are used to increase or decrease set values.

@

SETENTSwitch

This switch is used to change a set value.

0

NEXT

Switch

This switch is used to select the item for which you wish to change the setting.

@

START/STOP

Switch

This switch is used to start or stop operation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter

2.

Installation

-

A

CAUTION

If

the equipment

is

installed in

a

place which is

800

m

or higher than sea level

(i.e.

under

low

pressure in mountain areas), its specifications require to be changed. In this case,

be

sure to

contact

us.

Do

not

use

the

equipment

before

changing.

In

transporting the equipment, put the lid on

and

slide the opedclose lever to the end of the

close side

to

prevent the lid from opening.

When moving the lid, do

not

hold

it

by

the handle, otherwise the lid may become

difficult

to

close.

1.

InstallationInstructions

O

Avoid installing the equipment in a place where

its body may be exposed to water or chemicals, or

where corrosive and explosive gases may

be

produced nearby.

Q

Avoid installing the equipment in a place which is

exposed to high humidity, direct sunlight or much

dust.

O

Avoid placing the equipment directly under a fire

detector. If you open the lid immediately after

completion of operation, steam comes out of the

working chamber, and may activate the detector.

@

Arrange the equipment with a clearance of 10 cm or

wider on the right side and

12

cm or wider on the rear

sideto prevent the vent hole fiom being blocked.

I

2

cm

or

over

1

10

cm

or

over

O

Avoid installing the equipment with its rear side

located near outlets or electrical appliances as steam

comes out of the exhaustport on the rear.

@

Avoid

an

installation place which is subject to impact

orvibration.

6

Place the unit in a level,

fm

place.

@

Avoid installing in

a

place which is subjected

to

a

room temperature of

5°C

or below or

35OC

or above.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

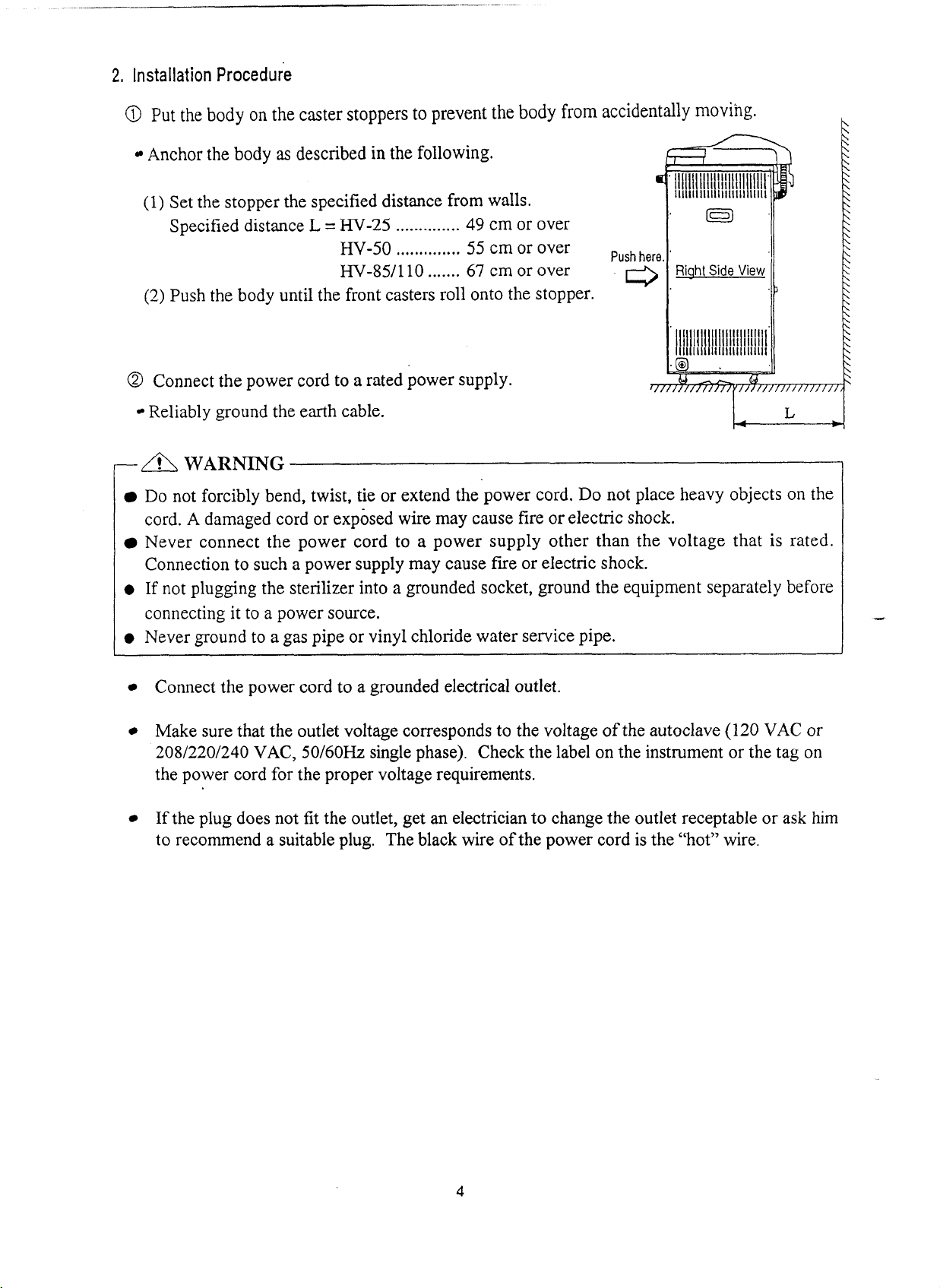

2,

Installation

Procedure

@

Put the body on the caster stoppers to prevent the body from ac

Anchor the body

as

described in the following.

(1) Set the stopper the specified distance from walls.

Specified distance

L

=

HV-25

..............

49

cm or over

HV-50

..............

55

cmor over

Push

,,

HV-85/110

.......

67

cm or over

(2)

Push the body until the front casters roll onto the stopper.

@

Connect the power cord to a rated power supply.

Reliably ground the earth cable.

w

a

WARNING

Do not forcibly bend, twist, tie or extend the power cord. Do not place heavy objects on the

cord.

A

damaged cord or exposed wire may cause fire or electric shock.

Never connect the power cord to a power supply other than the voltage that is rated.

Connection to such a power supply may cause f~eor electric shock.

0

If

not plugging the sterilizer into a grounded socket, ground the equipment separately before

connecting it to a power source.

0

Never ground to a gas pipe or vinyl chloride water service pipe.

Connect the power cord to a grounded electrical outlet.

Make sure that the outlet voltage corresponds to the voltage ofthe autoclave (120 VAC or

20812201240 VAC, 50160Hz single phase). Check the label on the instrument or the tag on

the power cord for the proper voltage requirements.

If

the plug does not fit the outlet, get an electricianto change the outlet receptable or ask him

to recommend a suitableplug. The black wire ofthe power cord is the "hot" wire.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

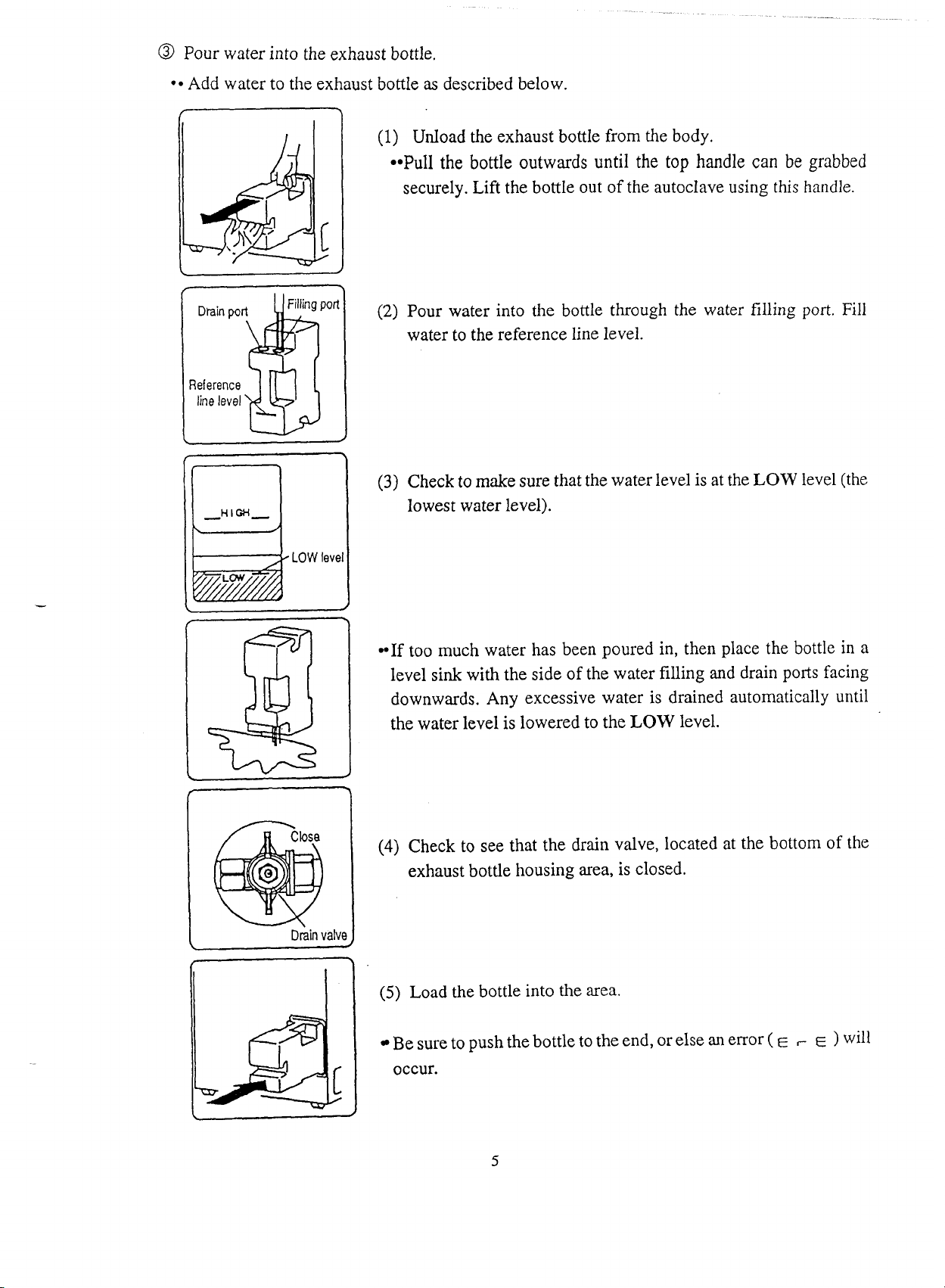

@

Pour water into the exhaust bottle.

Add water to the exhaust bottle

as

described below.

Drainpo

Pol

Reference

line

level

(1)

UnIoad the exhaust bottle from the body.

Pull

the bottle outwards until

the

top

handle

can

be

grabbed

securely.

Lift

the bottle out of the autoclave using

this

handle.

(2)

Pour water into the bottle through the water

filling

port.

Fill

water to the reference line level.

LOW

level

1

Drain

valve

(3)

Checkto make sure that thewater level is at the

LOW

level (the

lowest water level).

If

too much water has been poured in, then place the bottle in a

level sink with the side of the water filling and drain ports facing

downwards. Any excessive water is drained automatically until

the water level is lowered to the

LOW

level.

(4)

Check to see that the drain valve, located at the bottom of the

exhaust bottle housing

area,

is closed.

(5)

Load

the

bottle into the area.

Besureto pushthebottle to the end,orelse

an

error

(

E

,

E

)

will

occur.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

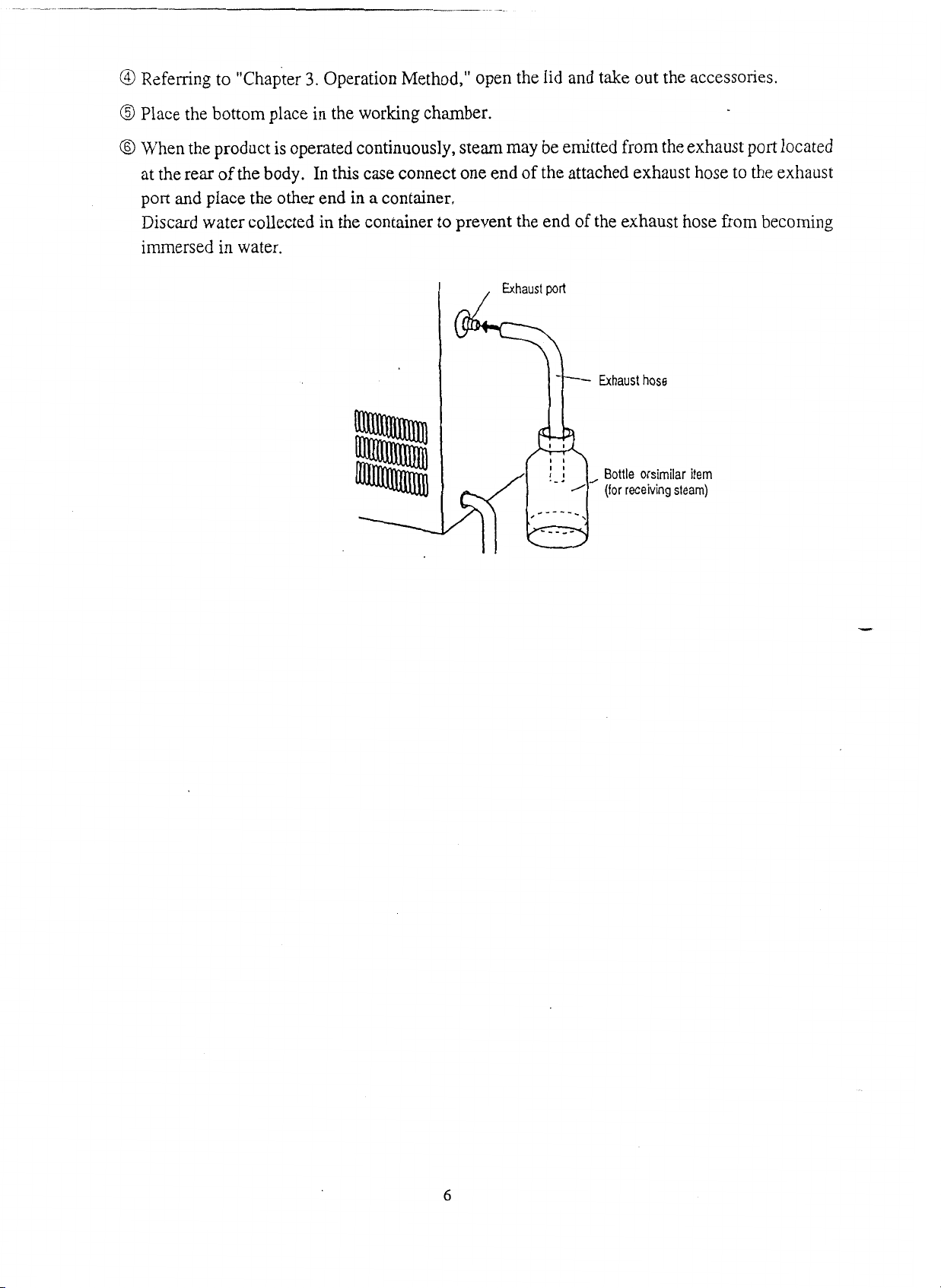

@

Referring to "chapter

3.

Operation Method," open the lid and take out the accessories.

@

Place the bottom place in the working chamber.

@

When the product is operated continuously, steammay be emitted from

the

exhaust

pon

located

at the rear of the body. In this case connect one end of the attached exhaust hose to the exhaust

port

and

place the other end in a container.

Discard water collected in the container to prevent the end of the exhaust hose from becoming

immersed in water.

Bottle orsimilar item

(for receivingsteam)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

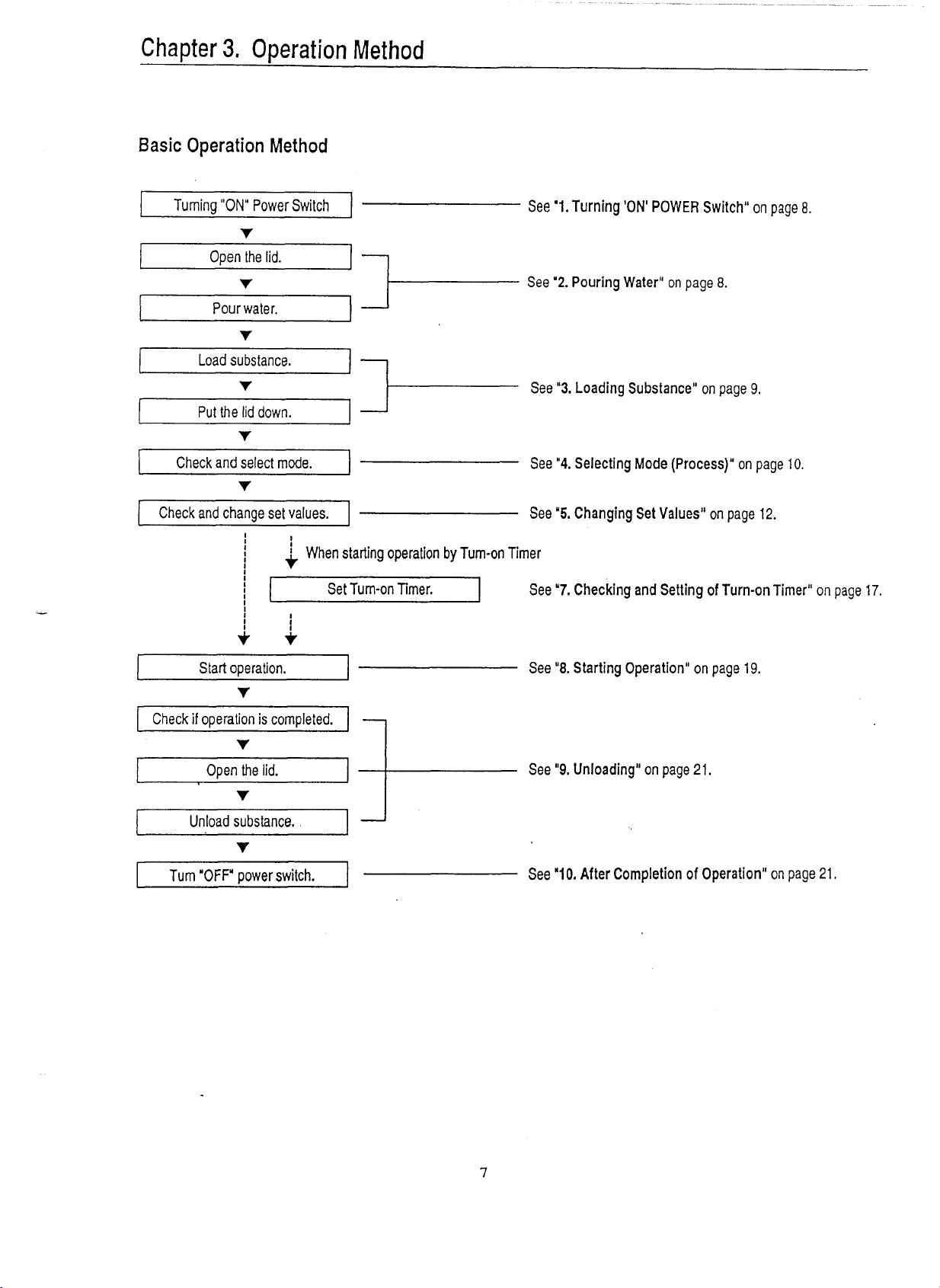

Chapter

3.

Operation

Method

Basic

Operation Method

Turning

"ON'

PowerSwitch

1

See

'1.

Turning 'ON' POWER Switch"

on

page

8.

v

Open the lid.

I1

v

See

'2.

Pouring

Water"

on

page

8.

Pourwater.

v

i

Loadsubstance.

11

v

A-

See

'3.

LoadingSubstance" on page

9.

1

Put the lid down.

i

Check andselect mode.

-

See

"4.

Selecting Mode (Process)" on page

10.

I

Check and change set values.

1

---------

See

'5.

Changing Set Values" on page

12.

I

I

i

i

Whenstarting operation

by

Turn-onTimer

I

Start operation.

1

See

"8.

StartingOperation" on page

19.

1

I

Set Tum-on Timer.

Check

if

operation is completed.

I

v

1

Openthe lid.

I

See

"9.

Unloading"on page

21.

v

Unloadsubstance.

v

See

"7.

Checking and Setting of Turn-onTimer" on page

17.

Turn

'OFF'

powerswitch.

I

---------

See

"10.

After Completion of Operation'' on page

21.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1.

Turning

"ON" POWER

Switch

O

Turn

ON

the

POWER

switch at the front of the body.

When the openiclose lever is set to

"LOCK"

(left side), settings light up on the display. The

autoclave is ready in this state.When the open/close leveris setto

"UNLOCK"

(anywhere other

than

on the left side),

"

L

is shown on the display.

Ready

state

2.

Pouring

Water

,

<r>.

IMPORTANT

0

In operation of

UNLOCKLOCK

lever, never fail

to

put

POWR

switch

ON.

a

Slide the open/close lever to the

UNLOCK

side (the right end).

@

Grab the handle, and lift the lid

as

shown in the figurebelow.

@

Pour water through the opening of the working chamber until you can see water through the

hole at the center of the bottom plate.

The HV-25 requires

1.5

liters ormore of water; the HV-50,2liters ormore; theHV-85,4liters or

more; and the HV-110.5 liters or more. It is also required to pour water forMode

4

(AGAR).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

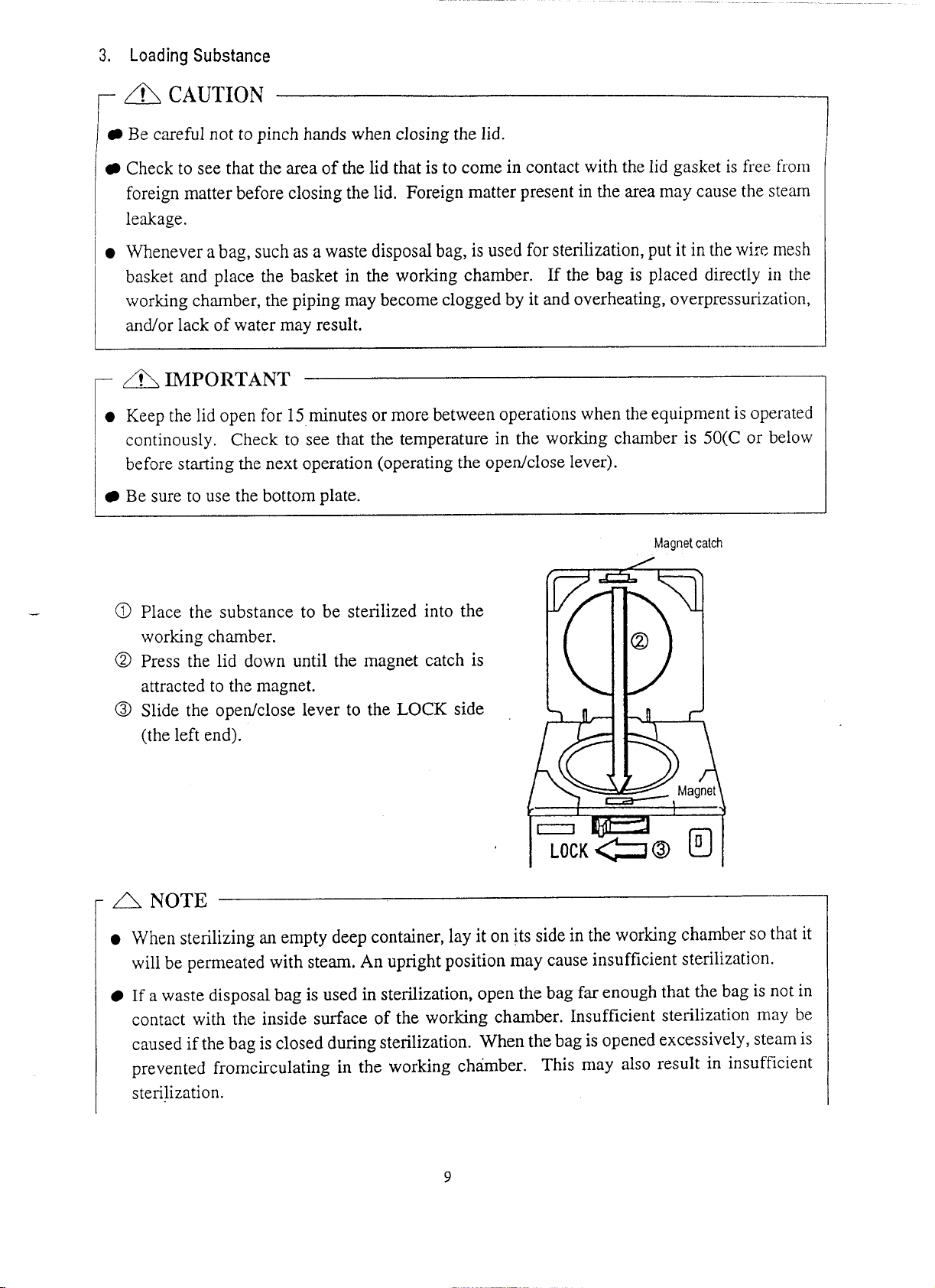

3.

Loading Substance

I

Be careful not to pinch hands when closing the lid.

Check to see that the area of the lid that is to come in contact with the lid gasket

is

free

from

foreign matter before closing the lid. Foreign matter present in the area may cause the steam

leakage.

a

Whenever abag, such as a waste disposal bag, is used for sterilization,put it in the

wire

mesh

basket and place the basket in the working chamber. If the bag is placed directly in the

working chamber, the piping may become clogged by it and overheating, overpressurization,

andorlack of water may result.

A

IMPORTANT

0

Keep the lid open for

15

minutes or more between operations when the equipment is operated

continously. Check to see that the temperature in the working chamber is

50(C

or below

before starting the next operation (operating the opedclose lever).

Be sure to use the bottom plate.

-

@

Place the substance to be sterilized into the

working chamber.

@

Press the lid down until the magnet catch is

attracted to the magnet.

@

Slide the opedclose lever to the

LOCK

side

(the left end).

Magnet

catch

3

y

A

NOTE

a

When sterilizing

an

empty deep container, lay

it

on its sidein the working chamber sothat it

will be permeated with steam. An upright position may cause insufficient sterilization.

If

a waste disposalbag is used in sterilization, open the bag far enough that the bag is not in

contact with the inside surface of the working chamber. Insufficient sterilization

may

be

caused if the bag is closed during sterilization. When thebag is opened excessively,steam is

prevented fromcirculating

in

the working chamber. This may also result in insufficient

sterilization.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Do not pile specimens on top of one another. When the chamber is overly packed, steam fails

to penetrate

to

all points, resulting in incomplete sterilization.

0

In sterilizing liquids such as chemical and medium, pay attention to the quantity

of

the liquid

in relation

to

its container. For

an

Erlenmeyer

flask,

the amount of chemical should

be

approx.

314

of the capacity of the container; for

a

test tube, the appropriate quantity of chemical is

approx. half of the capacity of the container. Toomuch chemical may result in overflow from

the container during the temperature rising or coolingprocess.

When using a container, loosen the cap or use

a

breathable cap. An unbreathable cap

may

cause the container to burst.

In

the caseof liquefaction of agar medium, its quantity should be 2 liters or less per container.

Two liters

or

more of agar medium ,maynot be completely liquefied.

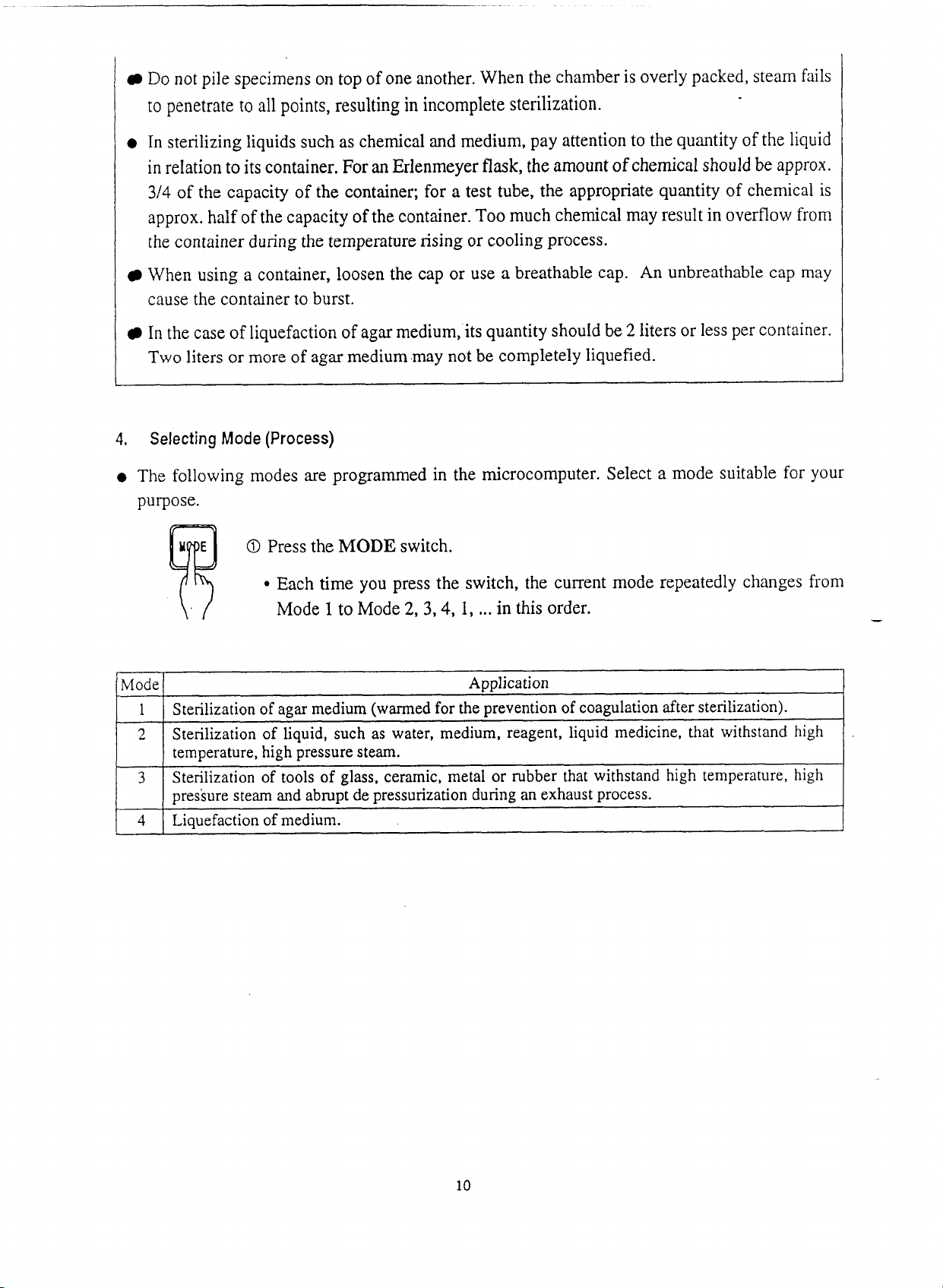

4.

Selecting

Mode

(Process)

The following modes are programmed in the microcomputer. Select a mode suitable for your

purpose.

O

Press the

MODE

switch.

Each time you press the switch, the current mode repeatedly changes from

\.

/

Mode

1

to Mode 2,

3,4,

1,

...

in this order.

Mode

1

2

Application

Sterilizationof

agar

medium (warmed for the prevention of coagulation after sterilization).

Sterilization of liquid, such as water, medium, reagent, liquid medicine, that withstand

high

3

temperature,high pressure steam.

Sterilization of tools of glass, ceramic, metal or rubber

that

withstand high temperature,

high

4

pressure steam and abrupt de pressurization during an exhaust process.

Liquefaction of medium.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Mode

1

Mode

2

Mode

3

Mode

4

Initial Set

Value

XI-J-

Step Display

WEATG

-+

STER.

-+

EXHT.

(Varied)

-+WARM

Step Display

BEATG

-+

STEW.

-+

EXHT.

(Varied)

Alternate display

IVIUUC

Display

ILJQ

Sterilization

Temperature

12

1

OC

I

NOTE:

Lid can only

be

opened at approximately

3O

below

boiling

point.

Mode

~i~~l~~

L~Q

Initial

Set

Value

Mode

~i~~la~

XDLD

Step Display

HEATG

-+

STER.

-+

EXHT.

(Fixed)

Sterilization

Time

20 minutes

Mode

Display

AGAR

Step Display

WEATG

WARM

Exhaust

%

10%

Initial Set Value

Warming

Temperature

50

"C

Warming

Temperature

/

Sterilization

Temperatul~

121OC

Sterilization

Temperature

121OC

Initial Set Value

Exhaust

%

10%

Sterilization

Time

20 minutes

Sterilization

Time

20 minutes

W~rming

Exhaust

%

Temperature

50 OC

Sterilization

Temperature

100

OC

Sterilization

Time

10minutes

Warming

Temperature

/

Exhaust

%

/

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5.

Changing SetValues (Registering Values

by

Customer)

To change setvalues (sterilization temperature, sterilization time, warming temperature, opening

of

exhaust valve, liquefaction temperature, liquefaction time), follow the steps below: Settings

cannot

be changed while the

chamber

is running except if wanting

to

change

the

exhaust

rate

while exhausting the chamber. For details on changing exhaust rate while exhausting the

chamber, see

"Exhaust

%

during the Valve Opening Variable Exhaust Cycle"

on

pagel

8.

O

Press the

SETIENT

switch.

The display of a set sterilization (liquefaction) temperature starts

flickering. This indicates that the set value is now changeable.

O

Press the

NEXT

switch

to

select an item the setting of which you desire

to change.

*

Each time you press the switches, the changeable set items change

repeatedly as follows:

[mi

W]

Switch

Operation

NEXT

O

Change the displayed value using the setting increaseldecrease switches

(A,

v)-

Each time you press the switches, the displayed value increases or

decreases as follows:

Sterilization temperature:

In increments of

1°C

within

a

range of:

HV-25

105

-

126°C

HV-50

105

-

135°C

EN-85

105

-

135OC (105

-

128OC)*

HV-110

105

-

135OC (105

-

123OC)*

*

Specification

for

particular area

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Other manuals for HV-25

1

This manual suits for next models

3

Table of contents

Other HIRAYAMA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

TSE

TSE PhenoMaster Hardware operating instructions

Live Photonic

Live Photonic Sequencer LPS-200H user manual

Diesse

Diesse cube 30 touch quick start guide

Agilent Technologies

Agilent Technologies 6475 user guide

Fluke Biomedical

Fluke Biomedical INCU Operator's manual

Hettich

Hettich ROTOFIX 32 A operating instructions

Thermo Scientific

Thermo Scientific Dionex ICS-5000 Operator's manual

Biotage

Biotage Isolera Prime user manual

caron

caron CRSY102 quick start guide

Research Instruments

Research Instruments WITNESS Installation and service manual

Oase

Oase Vitronic 11 W operating instructions

natus

natus Olympic Warmette 48 instruction manual