HIRED-HAND 1903-4044 User manual

Light Control Relay Assembly

For EV-1200, EV-3000, & EV-3001 Controls

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 1of 6

WARNING!

Only qualified electrician personnel familiar with the

construction and operation of this equipment and the

hazards involved should install and/or service this

equipment. Read and understand all instructions

and diagrams before proceeding. Failure to observe

this precaution could result in equipment damage,

severe bodily injury, or loss of life.

DESCRIPTION

The assembly described in this manual is used for

converting the EV-1200, EV-3000, or EV-3001

Variable Module connections into On/Off light control

contacts in cases when all other stages are being used

or will be used for other purposes. This assembly

provides a quick and simple relay assembly for

connecting to existing or new EV controllers. The

Light Control Relay Assembly includes the relay, one

prestripped red wire and one prestripped black wire to

connect to the Variable Module terminal block, and two

unterminated crimp terminals for connecting customer

supplied wires to the two normally open relay

terminals.

When the kit is received, check for shipping damage.

Part # Description Qty

1903-4044 HRNS EV1200 Light Contrl Relay 1

Small flat-head screwdriver Crimping Tool

Wire Stripper

Section 1.0 - Light Control Relay Assembly Installation.

Section 2.0 - EV-1200 wiring diagrams.

Section 3.0 - EV-3000/3001 wiring diagrams.

Section 4.0 - EV-1200, EV-3000, or EV-3001

programming requirements.

1.0 Light Control Relay

Assembly Installation

A. Disconnect AC electrical power from all equipment.

B. Remove the 4-position black terminal block (Variable

Module) from the circuit board (EV-1200 PCB186

or EV-3000/3001 PCB169).

C. Connect the red wire to the ‘+’ and the black wire to

the ‘-‘ of either the VAR #1 side or the VAR #2

side. Tighten securely.

D. Place the 4-position terminal block back onto the

PCB Variable Module connection.

E. Remove the adhesive strip backing from the back

side of the Relay and place the relay

approximately midway between the enclosure

cover and PCB to allow access and removal of the

other terminal blocks

F. Ensure that all wires are clear from hole drilling

locations.

G. Refer to Section 2.0 or Section 3.0 for the wire

connections diagram from the Evolution controller

PCB to the Light Control Relay Assembly.

NOTE: All Stage Inputs must be jumpered as shown in

Section 2.0 or Section 3.0 wiring diagram.

H. Refer to Section 4.0 for Program Requirements.

WARNING!

Ensure that ALL Electrical Power Sources are

OFF during installation / wiring.

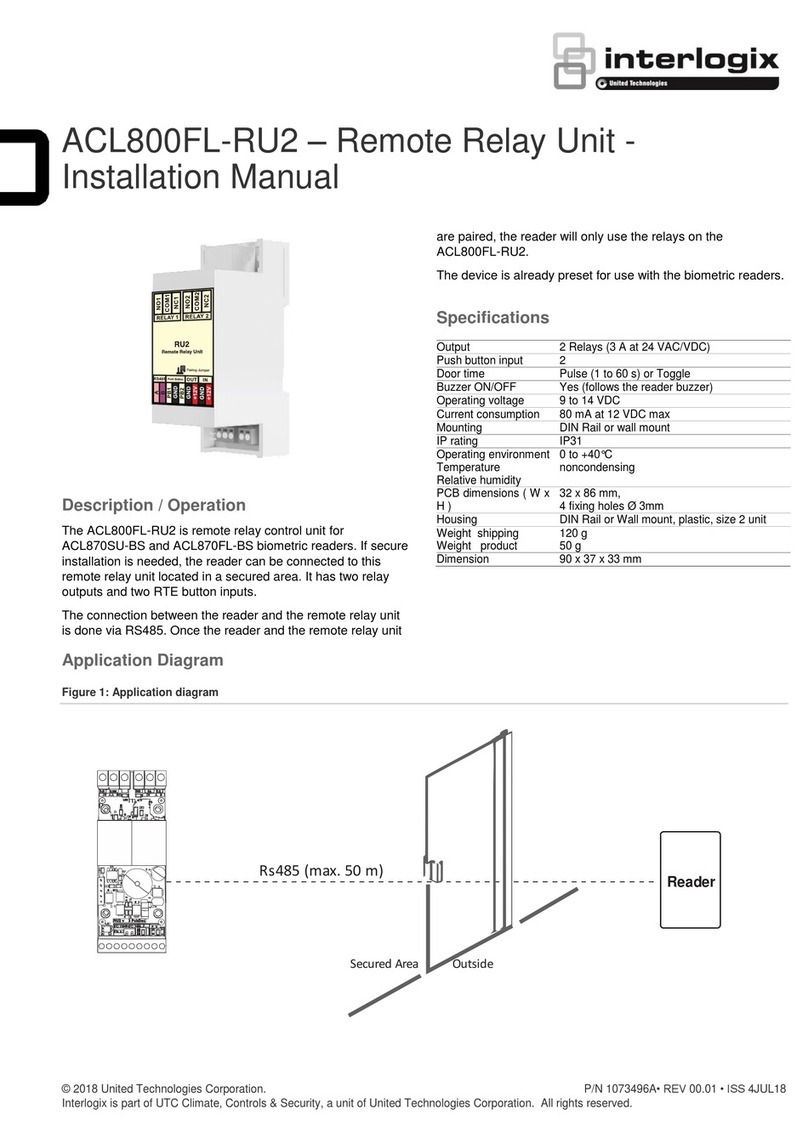

Figure 1: Light Control Relay Installed inside

EV-1200 Controller

Light Control Relay

Variable Module

Contacts

Connector

PCB168

PCB186

Crimp Terminals

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 2of 6

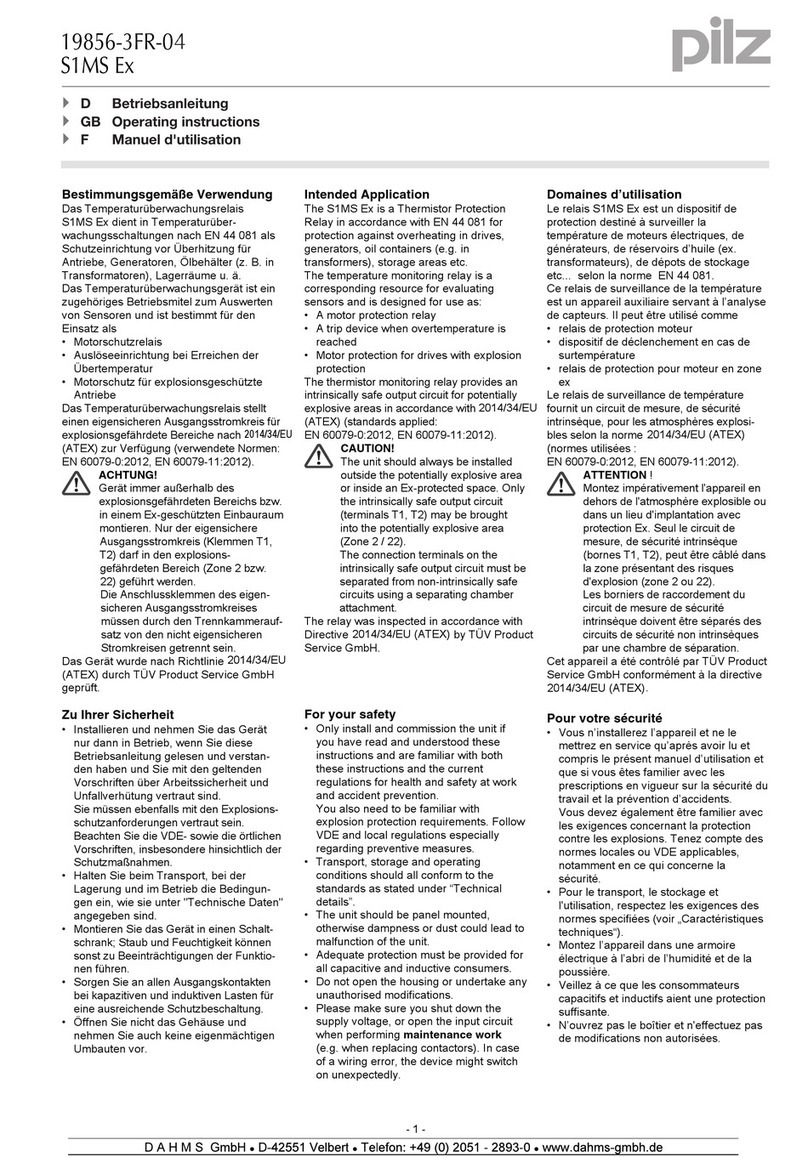

2.0 Setup EV1200 Wiring for use with CCS Panel

EV-1200 Controller

CCS Panel

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 3of 6

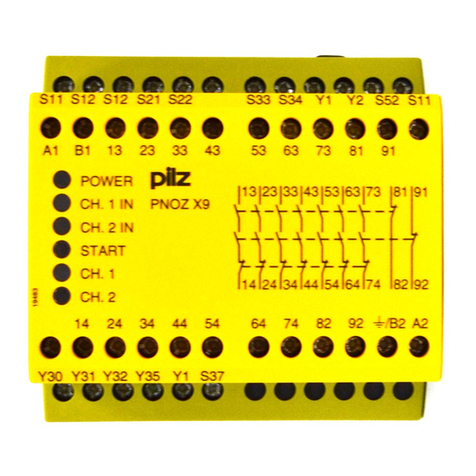

3.0 Setup EV-3000 / EV3001 Wiring for use with CCS Panel

CCS Panel

EV-3000 or 3001 Controller

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 4of 6

Light Schedule: 1

Start Day = 22

Number of On/Off Cycles = 4

CYCLE START RUNTIME INTENSITY RAMP

1 12:00a 2:00 100% 0:00

2 10:00a 2:00 100% 0:00

3 5:00p 2:00 100% 0:00

4 10:00p 2:00 100% 0:00

INTENSITY RAMP

100% 0:00

100% 0:00

100% 0:00

100% 0:00

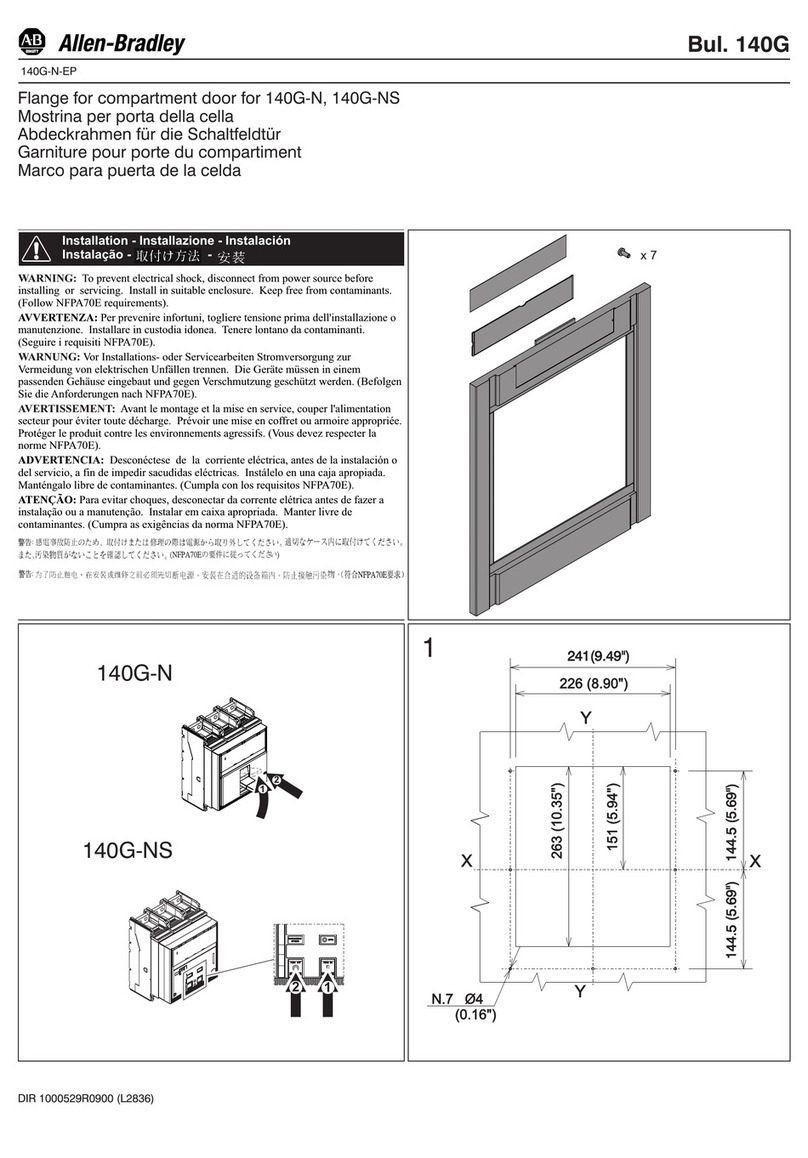

4.0 Setup Evolution Light Clock Programming for use with CCS Panel

The following details provide programming instructions for allowing the Light Control Relay accessory to operate

correctly when connected to the VAR #1 or VAR #2 Variable Output PCB terminal blocks.

Program Setup – For Light Schedule

A. Select the Program Setup screen using the Navigator Select buttons. Highlight Light Clock Setup and press

the ENTER button.

Light Clock Setup

B. Select the individual Schedules in the Light

Clock Setup screen until all of the affected

schedules are correctly updated. Refer to the

EV-1200 controller manual for details on

additional Light Clock Setup screen options.

Light Schedule

C. Each of the Cycles within the Light

Schedules MUST be set to 100%

Intensity and 0:00 Ramp. Refer to the

EV-1200 or EV-3000/3001 controller

manual for details on additional Light

Schedule screen options.

** FREQUENTLY ADJUSTED SETTINGS ** "

GENERAL SETTINGSSTATIC PRESSURE

SENSOR SETUPPROGRAMS & SECURITY

** INITIAL SETUP **

TEMP/TIMER% RAMPTUNNEL SETUP

FEED CLOCK SETUPON/OFF STAGES

LIGHT CLOCK SETUPVARIABLE STAGES

STAGE PROPERTIESNATURAL VENT

DIAGNOSTICSEXPANSION STAGES

FEED LEVEL

Light Clock Setup

**LIGHT CLOCK SETUP**

Feed Cycle Light Override = No

Feed Cycle Light Intensity = 25%

Growout Schedules used by Ramp 1-4

SCHEDULE START DAY

11

217

319

422

525

11

217

319

422

525

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 5of 6

Program Setup – For Variable Stages

D. Select the Program Setup screen using the Navigator Select buttons. Highlight Variable Stages and press

the ENTER button.

Variable Stages

E. Select the specific Variable Stage wired for use with the Light Control Relay.

F. Select “Light” Mode and “Light” Curve.

G. Under Time, determine and select whether “Ramp” or a specific Schedule is required.

H. Refer to the EV-1200 or EV-3000/3001 controller manual for additional details on Variable Stages.

** FREQUENTLY ADJUSTED SETTINGS ** "

GENERAL SETTINGSSTATIC PRESSURE

SENSOR SETUPPROGRAMS & SECURITY

** INITIAL SETUP **

TEMP/TIMER% RAMPTUNNEL SETUP

FEED CLOCK SETUPON/OFF STAGES

LIGHT CLOCK SETUPVARIABLE STAGES

STAGE PROPERTIESNATURAL VENT

DIAGNOSTICSEXPANSION STAGES

FEED LEVEL

V

ARIABLE STAGES

**VARIABLE STAGES**(Target: 77.5°)

# SENSORS MODE MaxON MinON CURVE TIME

1-------1 Light Ramp

2-------1 Cstir 76.2° 74.0° Fan 4 None

Light Light Ramp

HIRED-HAND, INC. •1733 County Road 68 •Bremen, AL 35033 USA •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4802-5109 rev 2-07 Page 6of 6