Hissmekano Viksam 3.0 User manual

Viksam 3.0

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 1

Table of Content

Table of Content...................................................................................................................................... 1

1 Data ................................................................................................................................................. 2

2 Installation....................................................................................................................................... 3

3 Connections..................................................................................................................................... 5

3.1 Voltage supply......................................................................................................................... 5

3.2 Motor and encoder connection .............................................................................................. 5

3.3 Interface and settings.............................................................................................................. 6

3.4 Pinch/crushing protection....................................................................................................... 6

3.5 Relay contacts.......................................................................................................................... 7

3.6 Blocking ................................................................................................................................... 7

3.7 Door hanging........................................................................................................................... 7

4 Commissioning ................................................................................................................................ 8

4.1 Learning trip ............................................................................................................................ 8

4.2 Manual mode .......................................................................................................................... 8

5 Troubleshooting .............................................................................................................................. 9

6 Spare parts..................................................................................................................................... 10

7 Maintainance................................................................................................................................. 10

7.1 Lubrication of tension roller.................................................................................................. 10

7.2 Adjustment of belt................................................................................................................. 10

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 2

1Data

Values

Supply voltage: 230 VAC

Internal voltage: 36/24 VDC (+/- 5 %)

Nominal current: 3A

Max internal current: 10A

Allowed temperature: 0 till +50 °C

Max voltage/current for relays: 230 VAC / 10A

Fuse

6,3A slow, 5x20mm

Inputs

Open Signal

Close signal

Connections

12 x screw terminals for motor/encoder/signals

Supply cable: IEC C14

Relay contacts

Obstruction

Closed door position

Open door position

Buttons

Normal operation/learning trip

2-Threads [COM to open or close] / 1-Thread [COM to open/close]

Dimensions

410x160x70mm

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 3

2Installation

1. Mount the motor and idler pulley with corresponding brackets as close as possible to the

pilaster. The motor should be placed on the hinge side.

The picture shows left opening door installation

2. Mount the brackets at the backside of the hanger rail. Each angle needs 4x square nuts and 4x

hexagonal screws. Adjust the angles to approx. 10mm from each pilaster. Mount the idler pulley

furthest into the track of the bracket to be able to tension it outwards when the belt has been

attached.

Angles mounted on the rail with distance to each pilaster

3. Mount the belt around the idler pulley and gearwheel from the motor. Connect the belt ends

with the belt coupling. Cut the length of the belt if necessary.

Belt with belt coupling

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 4

4. Attach the belt coupling with the belt slider on the double plate.

Belt coupling when assembled

5. Adjust the tension of the belt by pushing the angles or idler pulley further against the edge of

the pilaster. One way to tension it is by using a chisel with a 3mm thick blade and bending the

tool carefully against the angle and against the idler pulley, so that the idler pulley is pressed

against the frame. See the figure below. This requires that the angle is correctly mounted on the

rail and that the idler pulley has some space left in the track.

Belt tension adjustment with hand tools.

6. Mount the mechanical stop in the groove at the motor angle. As belt coupler takes towards the

mechanical stop, the folding door has a clear limit in the open position. Adjusted accordingly

based on needs, but we recommend approx. 10mm before it stops when you open the door

manually.

7. Attach the control to the basket/car roof using the appropriate screw in the 6mm wide slotted

holes for vertical or horizontal mounting.

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 5

3Connections

ALL ELECTRICAL CONNECTIONS MUST BE DONE WITH NO POWER.

3.1 Voltage supply

The door control is supplied with a quick-connect IEC C14 cable for the power supply.

This is connected to 230 VAC and earth. A fuse (2.5A slow) is located in the connection housing.

3.2 Motor and encoder connection

The motor is delivered including an encoder with cabling that is connected as shown below.

NOTE. The encoder is connected differently depending on whether it is a right- or left-hanging

door.

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 6

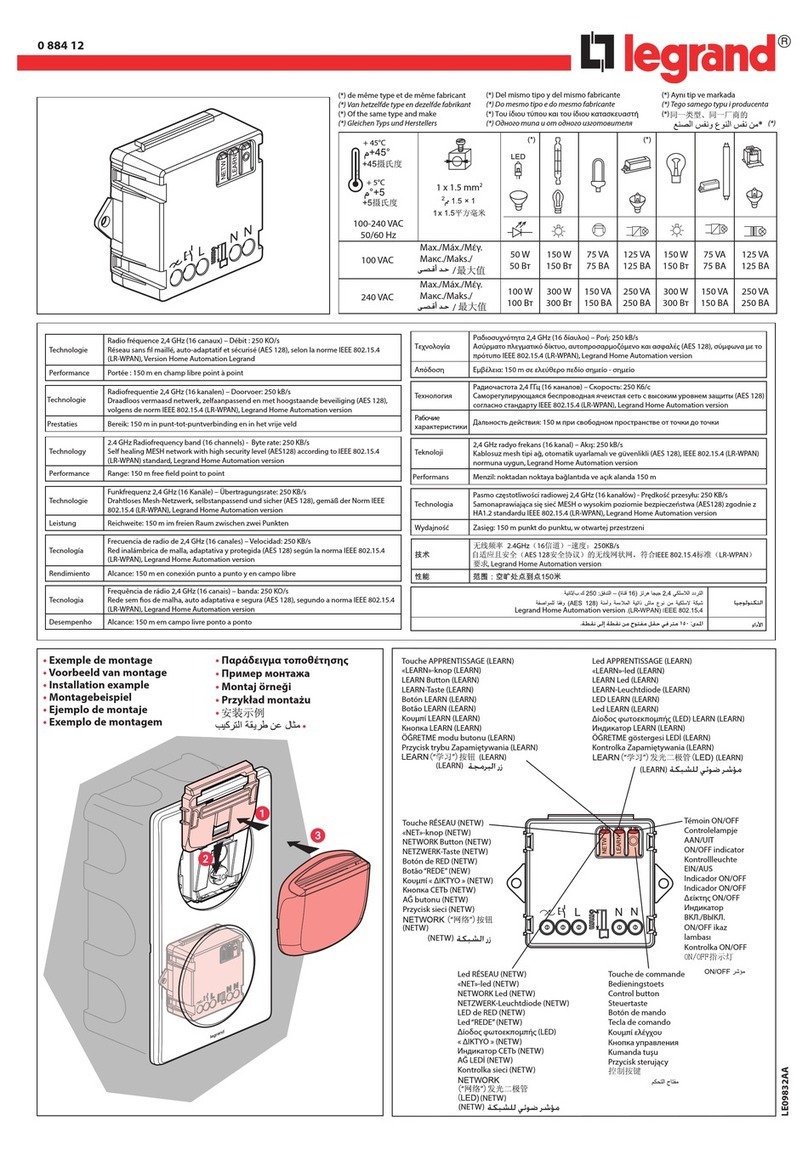

3.3 Interface and settings

The connection of open and close signals takes place through two different options: 1-wire or 2-wire.

2-wire is recommended when these signals are available in the control system.

The desired option is set on the push button, see below.

Control of the door is done via the digital inputs on the screw terminal inputs "9–12". If the door

control is connected with a separate opening and closing signal, i.e. 2-wire communication, the

pushbutton on the left of the image above must be set to "2-wire". The door will then open when

closed between "9" and "11" and close when closed between "9" and "12". If there is no signal or if

both signals are active, the door will stay in its current position.

If the door control is connected to a common opening and closing signal, 1-wire communication, the

push button must be set to "1-wire" as above. The door will then close in the event of a short circuit

between "9" and "10" and open when the connection is broken.

The folding door closes when "12" is activated

and opens when "11" is activated.

The folding door closes when "10" is activated

and opens when it is deactivated

3.4 Pinch/crushing protection

Pinch protection in both opening and closing cycles and managed internally.

In case of blocking, the door will reverse and then make another opening attempt where the door

slows down to the position where the door was previously blocked. After a complete open/close

cycle, the door returns to normal operation again.

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 7

3.5 Relay contacts

If you need to use the relay contacts, you need to remove the cover on the control and connect the

relays according to the picture below. NOTE: We only use relays 1-3.

Obstruction: This contact switches/triggers when the torque limit is reached in the close/open cycle.

Closed position: This contact switches/triggers when the door is fully closed.

Open position: This contact switches/triggers when the door is fully open.

3.6 Blocking

When the door is blocked, the door must reverse.

In case of blocking in the opening/closing phase, the door will always reverse, but the signal can be

taken from the relay contacts on the inside of the control. After 3 attempts, the control will wait for a

new signal.

3.7 Door hanging

For the opening and closing signals to steer the door in the right direction, the encoder cables must

be correctly connected, see below. If it is connected correctly, the door will stop in the closed

position after the learning trip. If the engine is on the right side seen from a floor plan, it is a right-

hanging door.

NOTE. When changing direction, it is important to switch off the power and start up the steering

learning journey mode. Otherwise, there is a risk that the door runs at full speed toward the limit

positions when it thinks that the position is outside the doorway.

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 8

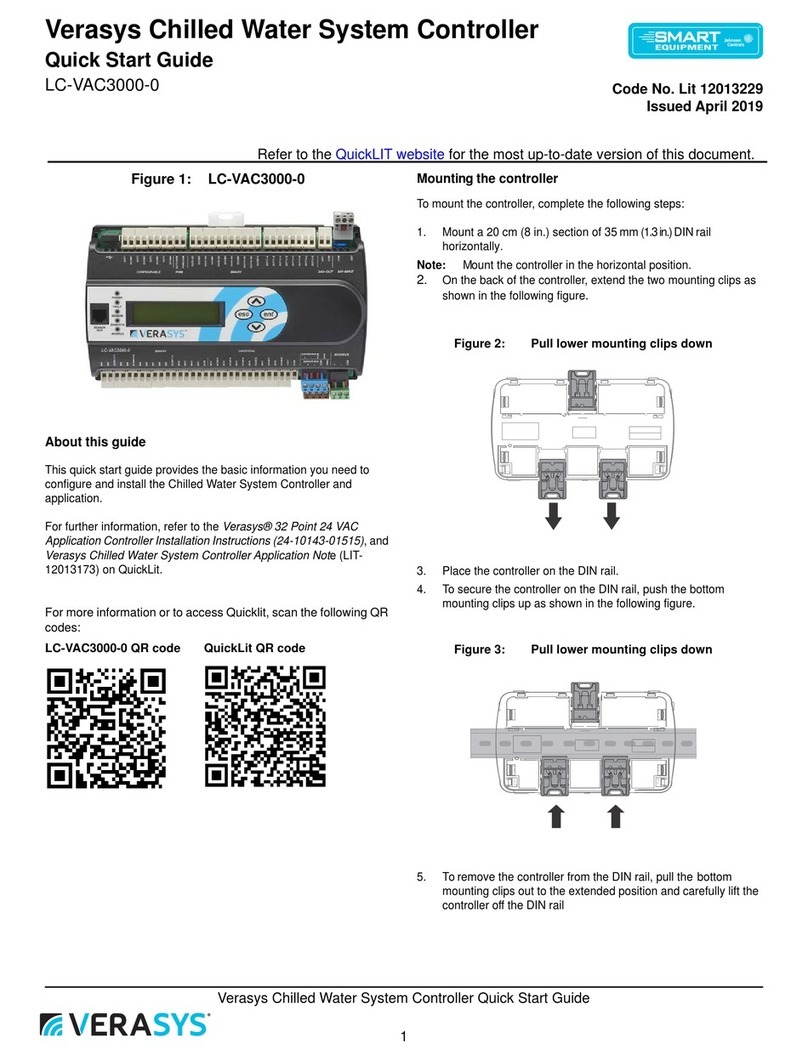

4Commissioning

4.1 Learning trip

For the door control to know the door's opening width, a learning trip is required. Set the power

switch to “Normal” and turn on the power. Then press the button as below to "learning trip". The

door will now at low speed open fully and then close and after a few cycles it will stay in the closed

position. NOTE. If it stays in the open position, the encoder may be incorrectly connected, see section

3.2. When the learning journey is finished, the push button must be set to the "normal" position and

then the door can be put into operation.

4.2 Manual mode

It is not a manual mode, but if you want to see if the door opens and closes as it should, you can set

the push buttons to the "2-wire" and "Normal" positions and jumper between screw terminals "9"

and "11" (open) / " 12” (close).

NOTE. Be sure to disconnect the cables that go to the elevator control before the jumper.

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 9

5Troubleshooting

www.hissmekano.se

Manual Viksam 3.0 version 2 –October 2022 10

6Spare parts

Door controller 3710333

Drive belt (per meter) 3700007

Tension roller incl. shoulder 3700006

Fuse 7070239

Motor 3710331

Motor/tension roller angle 3710298

Power supply unit 3710332

7Maintainance

7.1 Lubrication of tension roller

Push the roller down so that a small gap appears and spray some spray grease into the gap that

appears. Recommended to be performed at the time of service.

7.2 Adjustment of belt

If adjustment of the belt is required, see the instructions in chapter 3.5.

Table of contents

Popular Controllers manuals by other brands

Unites

Unites KERBEROS POWER 6000.B installation manual

B&K

B&K Reference 20 Plus A/V System Controller owner's manual

KI0BK

KI0BK SBCC Operation manual

Worcester

Worcester Greenstar HIU Installation and maintenance instructions

Condair

Condair Links Series Installation and operation

Eaton

Eaton ATC-800 Instructions for installation, operation and maintenance

Parker

Parker R35 Series Installation and service instructions

GESTRA

GESTRA TA 7 Installation and service instructions

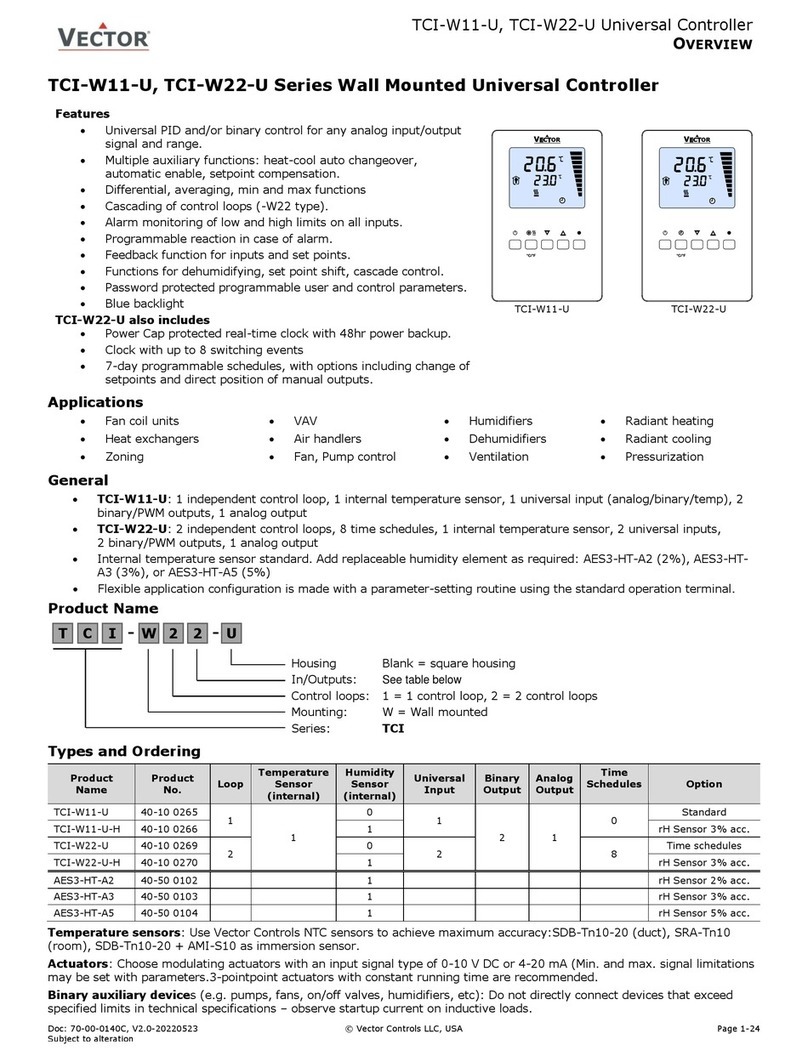

Vector

Vector TCI-W11-U Series manual

Cosytoes

Cosytoes Mirage Timerstat instruction manual

steute

steute Ex BF 80 Mounting and wiring instructions

Kessler

Kessler Second Shooter Pro user guide