Explanation of symbols and safety instructions

3

Greenstar – 6721852556 (2022/11)

1 Explanation of symbols and safety instructions

1.1 Explanation of symbols

Warnings

In warnings, signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if measures for

minimizing danger are not taken.

The following signal words are defined andcan be used in this document:

DANGER

DANGER indicates that severe or life-threatening personal injury will

occur.

WARNING

WARNING indicates that severe to life-threatening personal injury may

occur.

CAUTION

CAUTION indicates that minor to medium personal injury may occur.

NOTICE

NOTICE indicates that material damage may occur.

Important information

The info symbol indicates important information where there is no risk to

people or property.

Additional symbols

Table 1

1.2 General safety instructions

HNotices for the target group

These installation instructions are intended for heating and electrical

contractors. All instructions must be observed. Failure to comply with

instructions may result in material damage and personal injury, including

danger to life.

▶ Read the installation, service and commissioning instructions (heat

source, heating controller, pumps, etc.) before installation.

▶ Observe the safety instructions and warnings.

▶ Follow national and regional regulations, technical regulations and

guidelines.

▶ Record all work carried out.

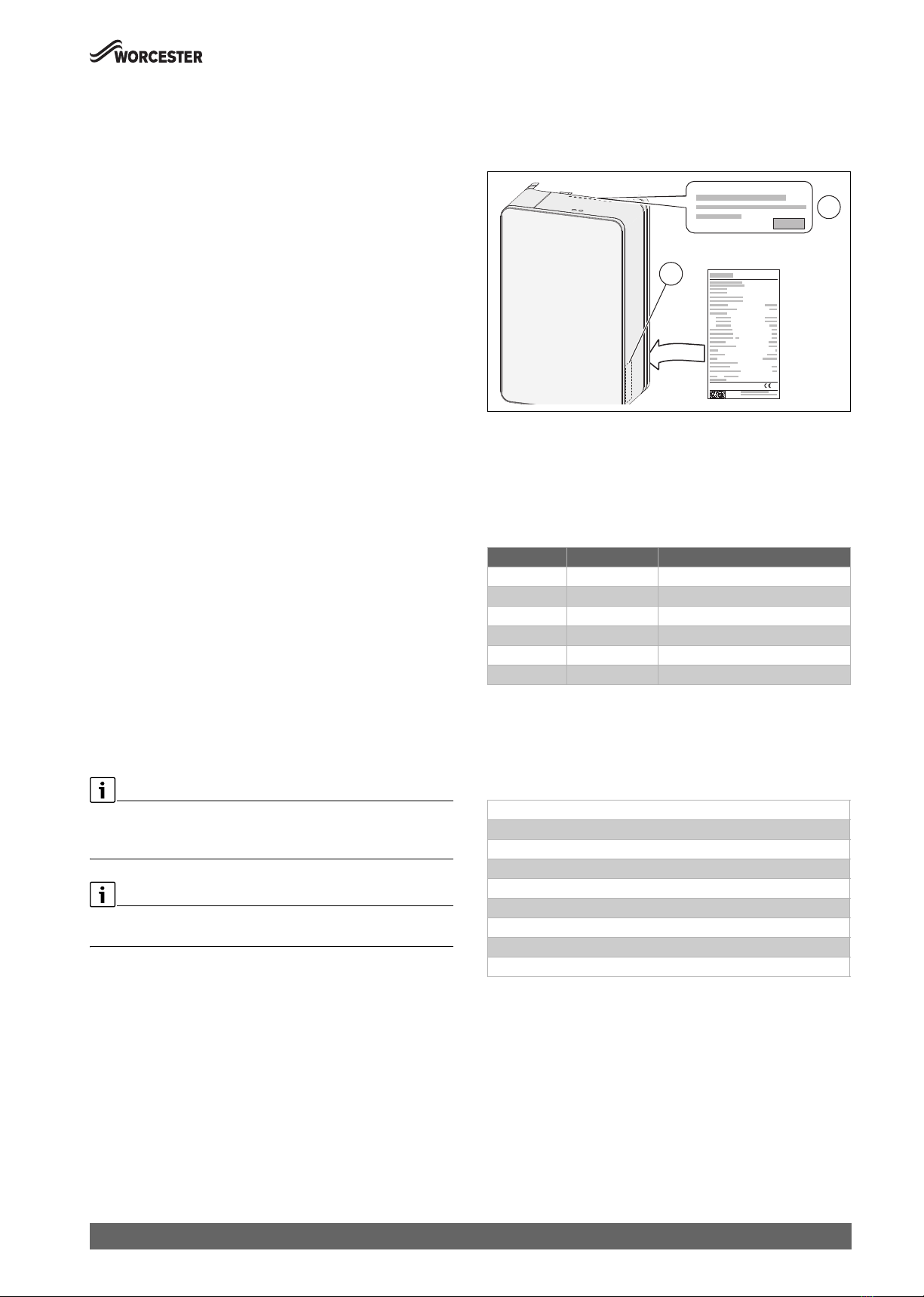

HTransport information

▶ Only remove packaging just before assembly.

▶ Wear protective gloves when transporting the HIU.

▶ Use suitable means of transportation (e.g. sack truck).

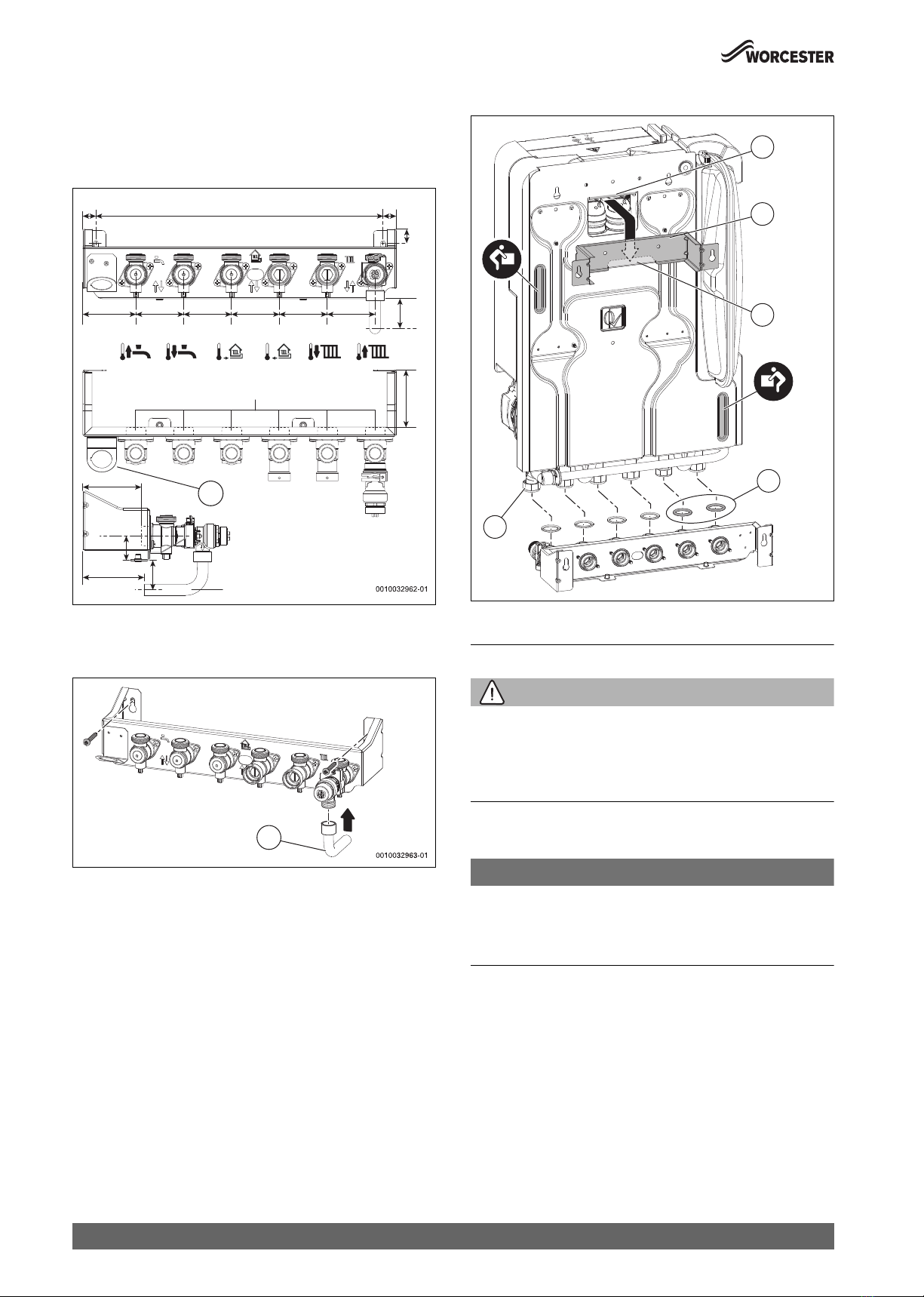

HMounting method

▶ Do not shut off pressure-relief valves.

Risk of fire from soldering and welding!

High pressures and high temperatures may occur on the primary side.

▶ Wear suitable protective equipment.

HPackaging

The following points should be observed during unpacking.

▶ Check the delivery immediately upon receipt for completeness and

possible transport damage.

▶ In the event of transport damage, the delivery should only be

accepted conditionally.

▶ Do not use damaged components for assembly.

▶ Carefully unpack the unit.

▶ Ensure that all packaging material is removed and that the unit is free

from all materials that may prevent the unit from operating correctly.

HHealth and safety

The appliance contains no asbestos and no substances have been used

in the construction process that contravene the COSHH Regulations

(Control of Substances Hazardous to Health Regulations 1988).

HDanger of burns and scalds

▶ Surfaces of individual components, connections and leaking water

can be very hot and cause severe burns and scalds.

▶ Do not touch hot surfaces.

▶ Caution should be taken not to touch any leaking water or drained

system water unless the temperature is known and safe.

HIntended use

The HIU provides DHW and heating energy to buildings that are supplied

indirectly by district heating or heat network systems.

▶ Only use the HIU in sealed systems for central heating and DHW

heating.

▶ To ensurecompliancewiththe intendeduse,observethe information

on the data plate and the specifications.

▶ Only install the HIU in frost-free room or enclosure. Ensure a ambient

temperature range of 2 °C to 30 °C.

▶ Only install the HIU straight and vertically upright, as described in

these instructions.

HDanger of burns and scalds

Individual components and discharging water can be very hot and inflict

burns.

▶ Do not touch hot surfaces.

▶ Unless you know what the temperature of the discharging water is,

you should not touch it.

HInspection and maintenance

Regular inspection and maintenance are prerequisites for safe and

energy efficient operation of the heating system.

We recommend you inspect the HIU at least every three years in line with

BSRIA guidance.

▶ Have work carried out only by an approved installer.

▶ If any faults are discovered, have them remedied immediately.

HHandover to the user

When handing over the heating system, explain the operation and

operating conditions to the operator.

▶ Explain operation – with particular emphasis on all safety-related

actions.

▶ Highlight the following points in particular:

– Point out that modifications or repairs may be carried out only by

an competend contractor.

– To ensure safe and environmentally compatible operation, an

inspection every three years, and also cleaning and maintenance

if required, must be carried out.

▶ Point out the possible consequences (personal injury and possible

danger to life or material damage) of not carrying out inspection,

cleaning and maintenance correctly, or omitting it altogether.

Symbol Meaning

▶ a step in an action sequence

a reference to a related part in the document

• a list entry

–a list entry (second level)