Hissmekano AB Reprovägen 7 SE-183 77 Täby Tel: +46-(0)8-586 272 00 Fax: +46-(0)8-732 51 26 E-post: info@hissmekano.se

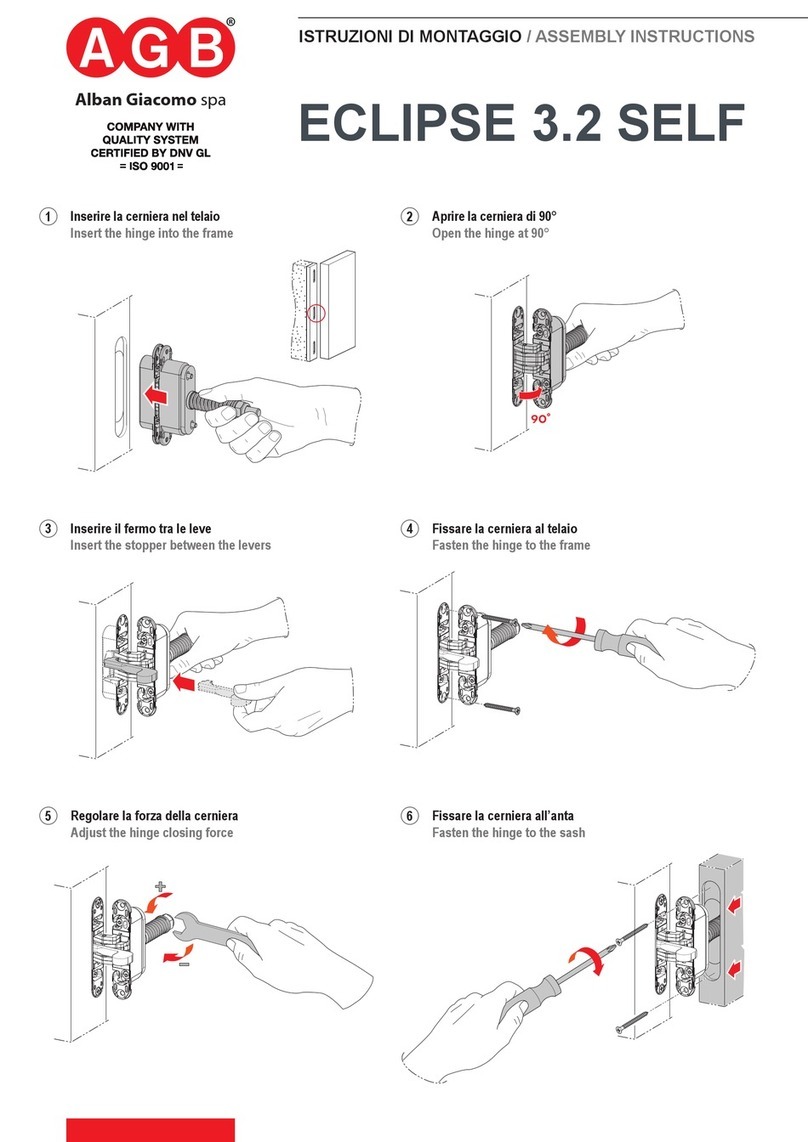

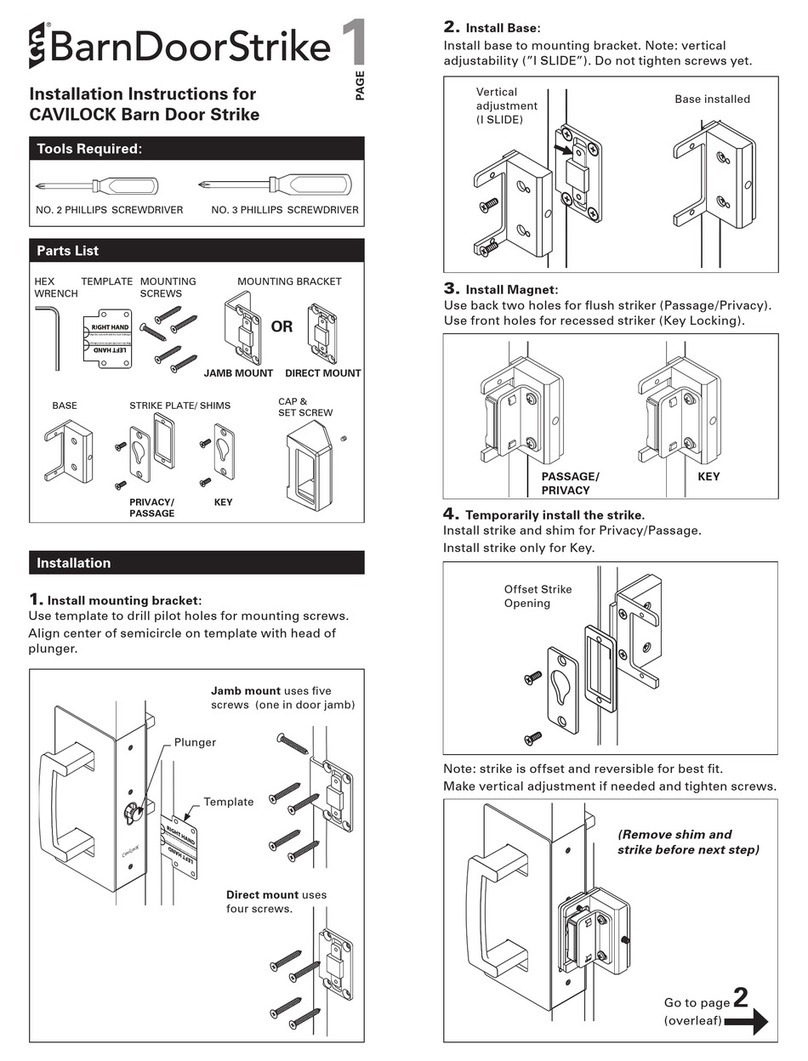

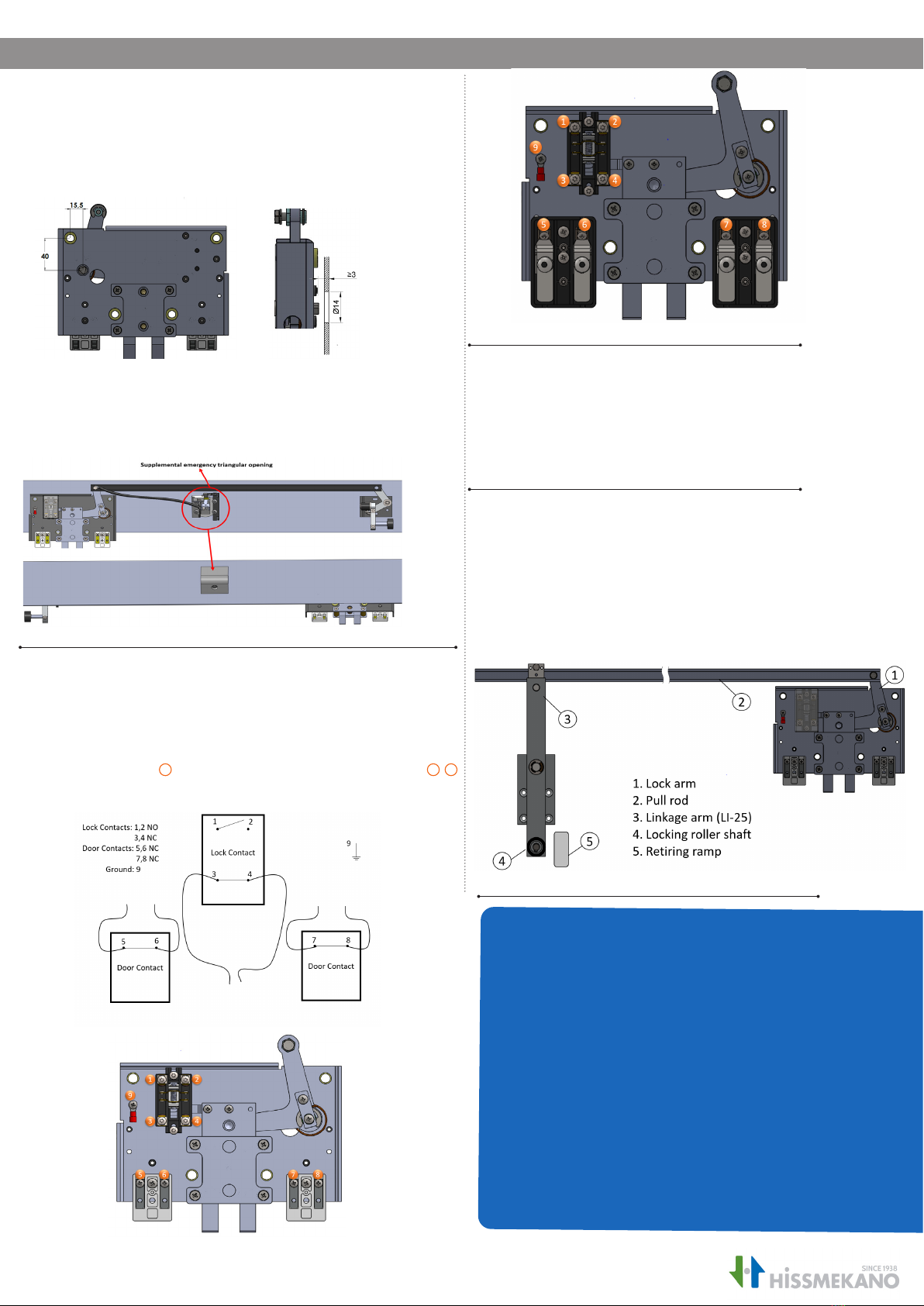

4. Connections of the contacts

LI-25-30 and LI25-R have door contacts, one for each door and a lock

contact. Below is the wiring diagram. LI-25-30 has KO-30 & LI-25-R has

KO-26 door contact.

Cables are attached between contact blades on locking contact and

door contacts. Ground 9is connected with cable lug.Rear contact 1, 2

is switched on if necessary.

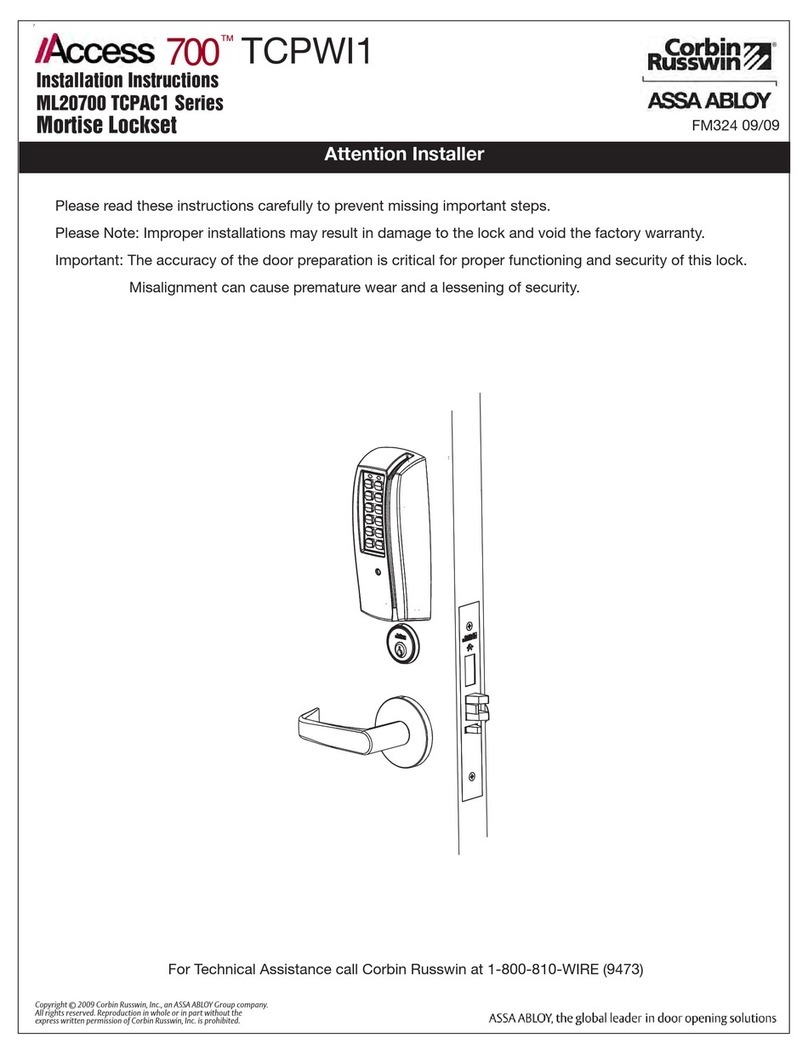

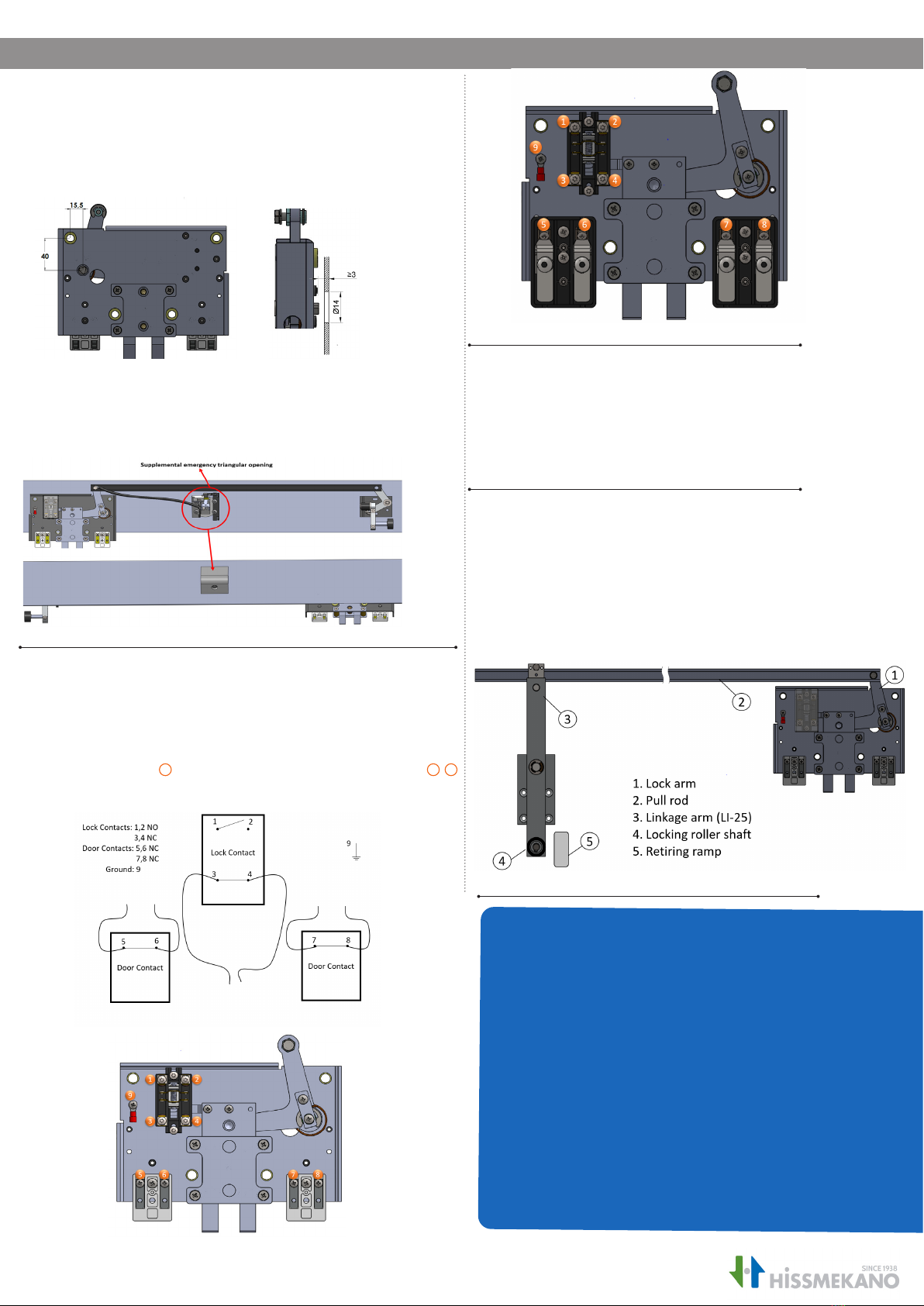

5. Magnet Switch (Valid only to locks with magnet

contact)

LI-25-30-M-H, freight lock with magnet switch for hidden Contact

230VAC 0.4A to prevent tampering/manupulation.

Magnet contact is just for monitoring and neither to put into door or

security circuit. Mandatory contact bridge with magnet included in

kit or ordered seperately Art.no:2400126-M.

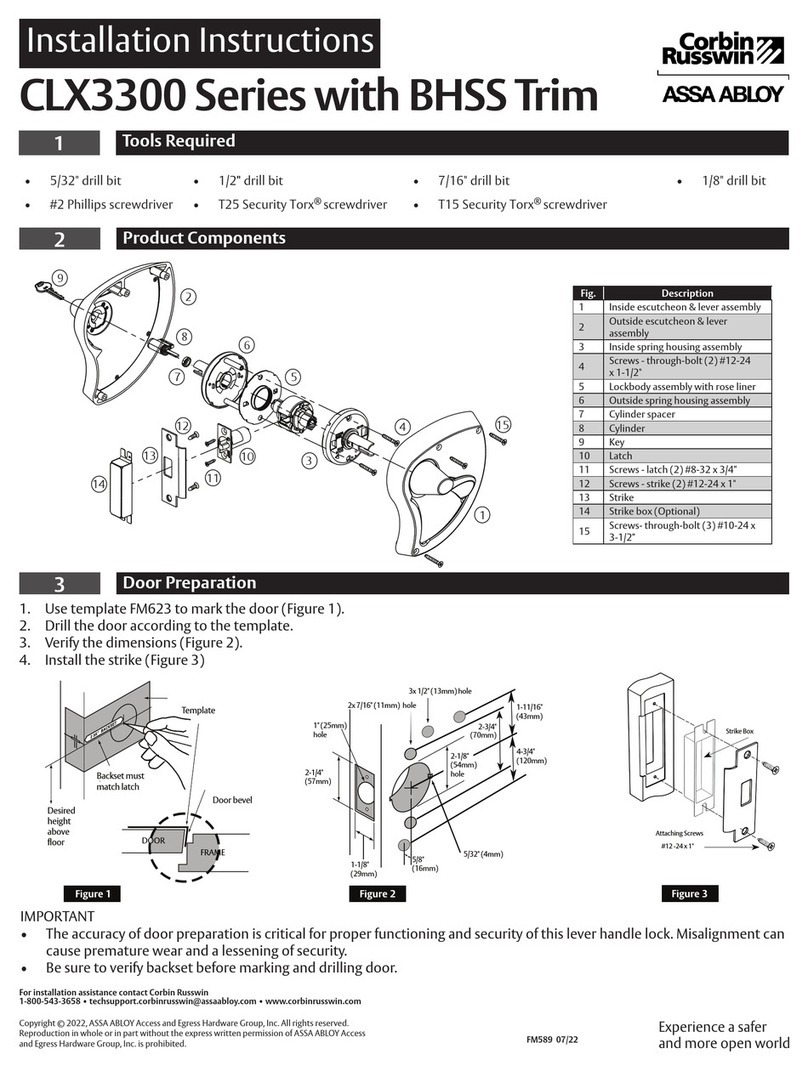

Figure 8 Mounting of the roller

REQUIREMENTS

The lock should not be lubricated. The European Standard EN 81-20 requires

a minimum lactching bolt engagement of 7mm before the lock contact closes.

RECOMMENDATIONS

we recommend to adjust the lactching bolt engagement to 15mm.

REGULATIONS

LI-25-30 & LI-25-R locks meets the requirements of EN81-20 with additional

hidden door contact. Installation is carried out according to European stan-

dards EN 81-20

CERTIFICATE

EU Certied, 20-GOT-LD-002, Kiwa Inspecta AB. Notied body No: 0409

TECHNICAL SPECIFICATIONS

Lock/Auxilary contact:

Voltage: 230VAC / 200VDC

Current: 2A AC/DC

INSTALLATION MANUAL 2 OF 2

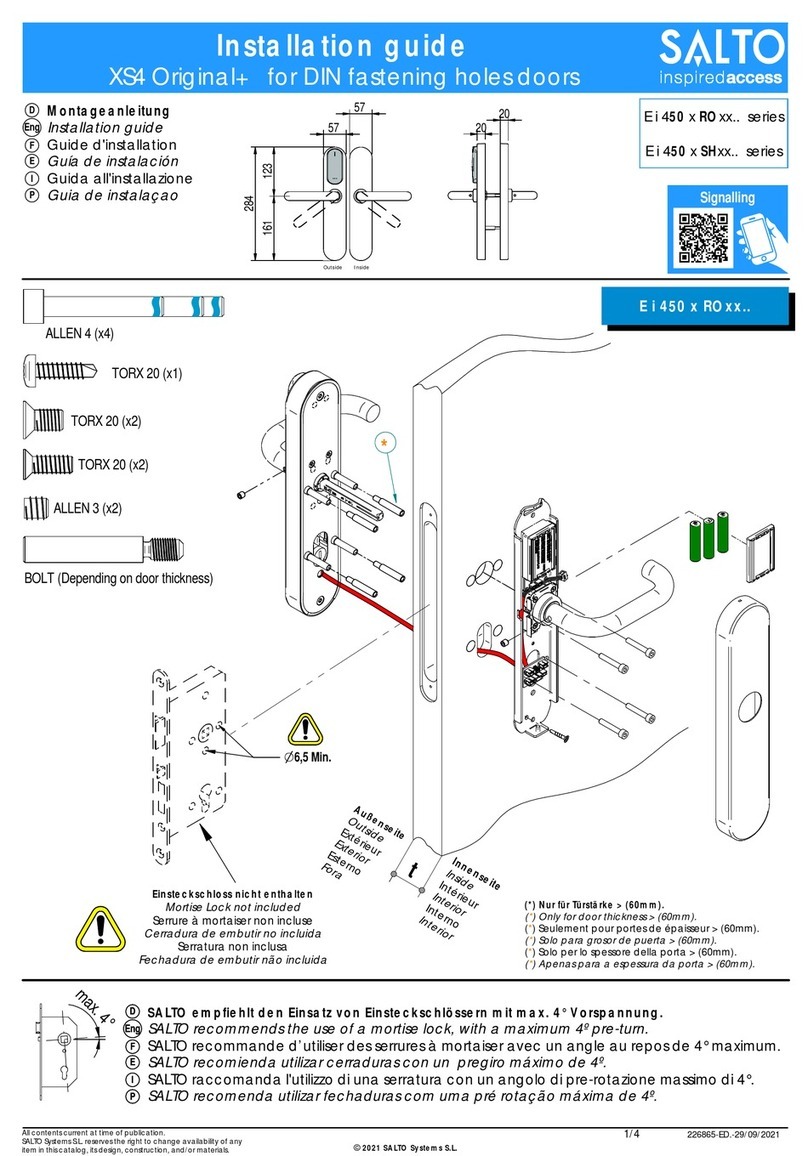

6. Mounting and adjustment of the roller

The pull rod 2 (1250mm- can be ordered in dierent lengths)

is mounted with lock arm 1. Linkage arm 3is mounted to

other end of pullrod. Locking roller shaft 4is mounted on lin-

kage arm and tightened. The roller should be centered over

the retiring ramp 5. The linkage arm is nally adjusted so that

the roller is about 2 mm from the retiring ramp when the ramp

is retracted.

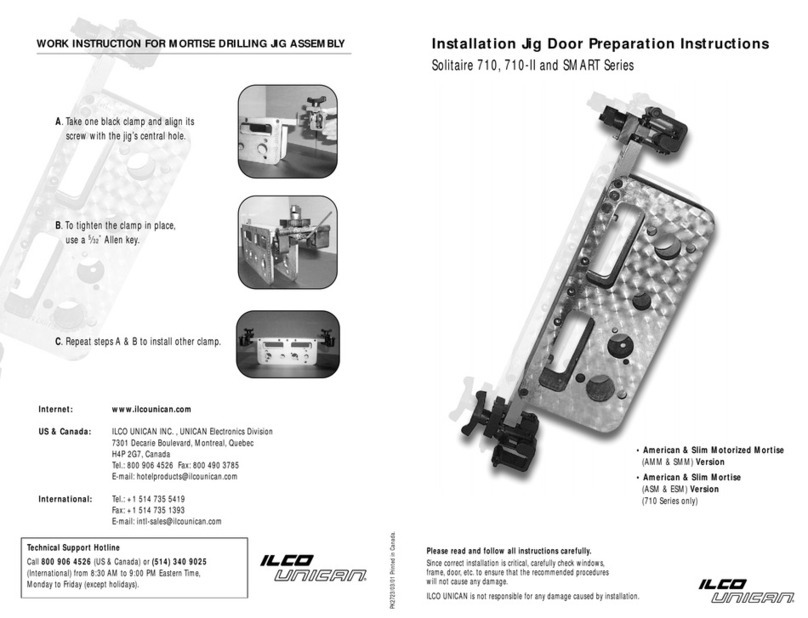

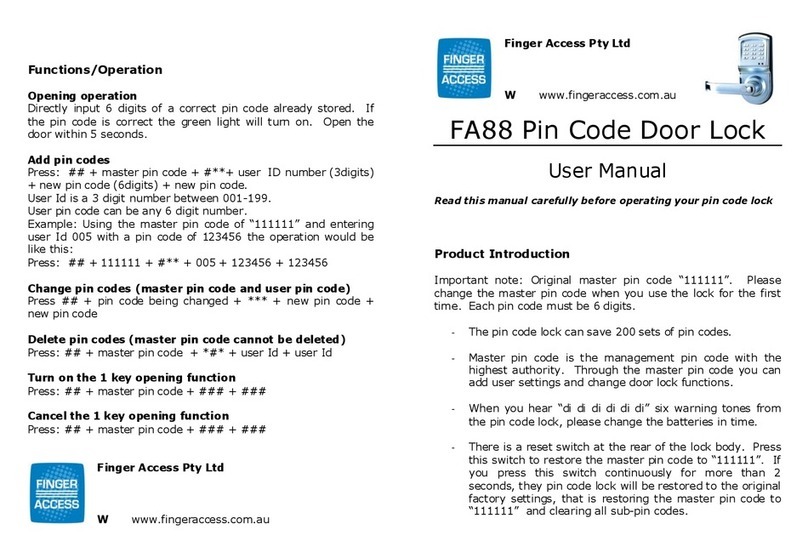

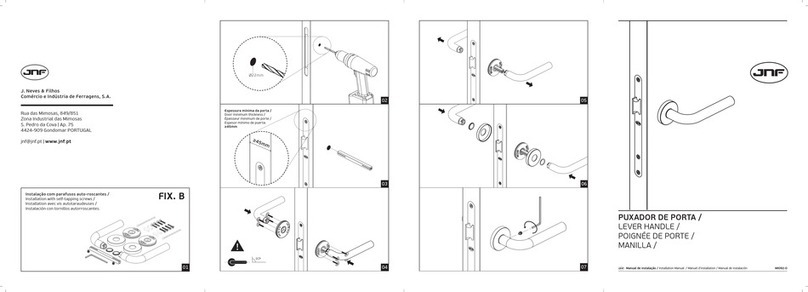

3. Emergency opening function

i. Valid only to locks with triangle opening

Holes are drilled in the door frame for the emergency opening function

as shown in the gure below. The hole should be at least 14mm in dia-

meter and the triangle should be recessed at least 3mm from the front

to meet the EN81-20 standard.

Figure 4 (i) Emergency unlocking

Figure 7 Picture showing connection numbers (LI-25-R)

Figure 5 connections for door and lock contacts

Figure 6 Picture showing connection numbers (LI-25-30)

ii. Emergency opening function (Supplemental)

Hole of 60mm diameter is drilled in the door frame to install supple-

mental emergency opening function. Bevel gear, lock and triagular

opening are connected with bowden cables as shown in Fig.4 (ii)

Figure 4 (ii) Supplemental emergency triangular opening