Assa Abloy Corbin Russwin CLX3300 Series User manual

Other Assa Abloy Door Lock manuals

Assa Abloy

Assa Abloy SARGENT IN Series User manual

Assa Abloy

Assa Abloy Corbin Russwin CLX3300 User manual

Assa Abloy

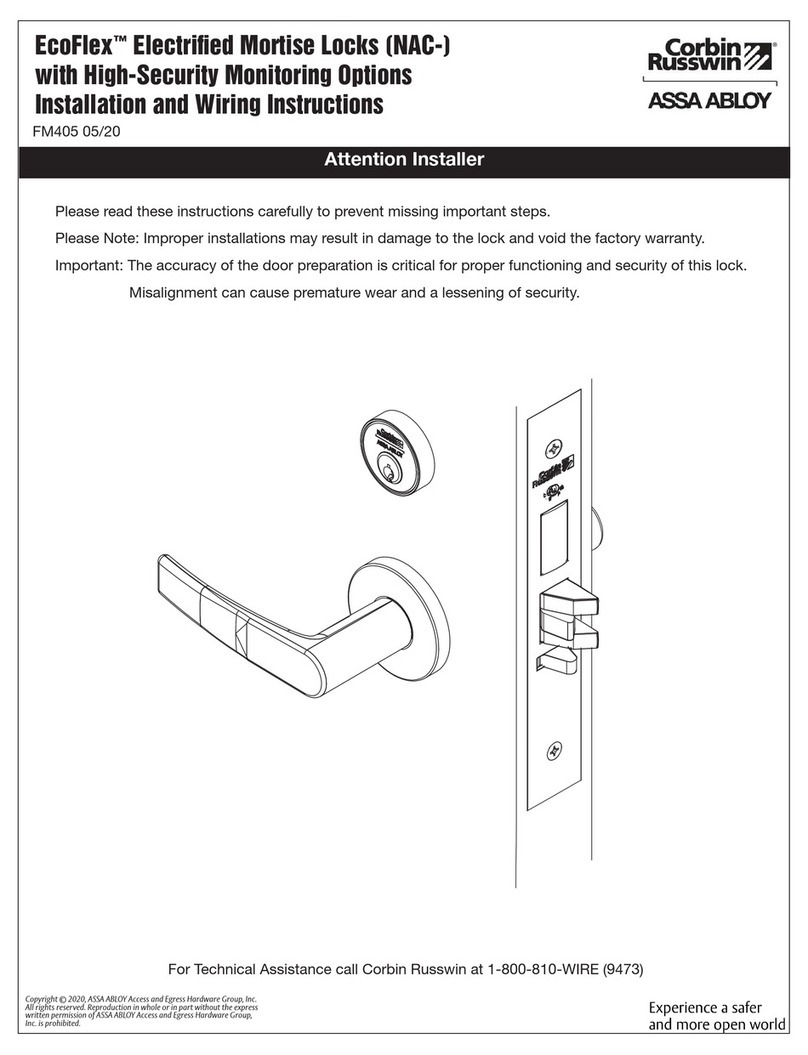

Assa Abloy Corbin Russwin EcoFlex NAC Series Assembly instructions

Assa Abloy

Assa Abloy Abloy EL648 User manual

Assa Abloy

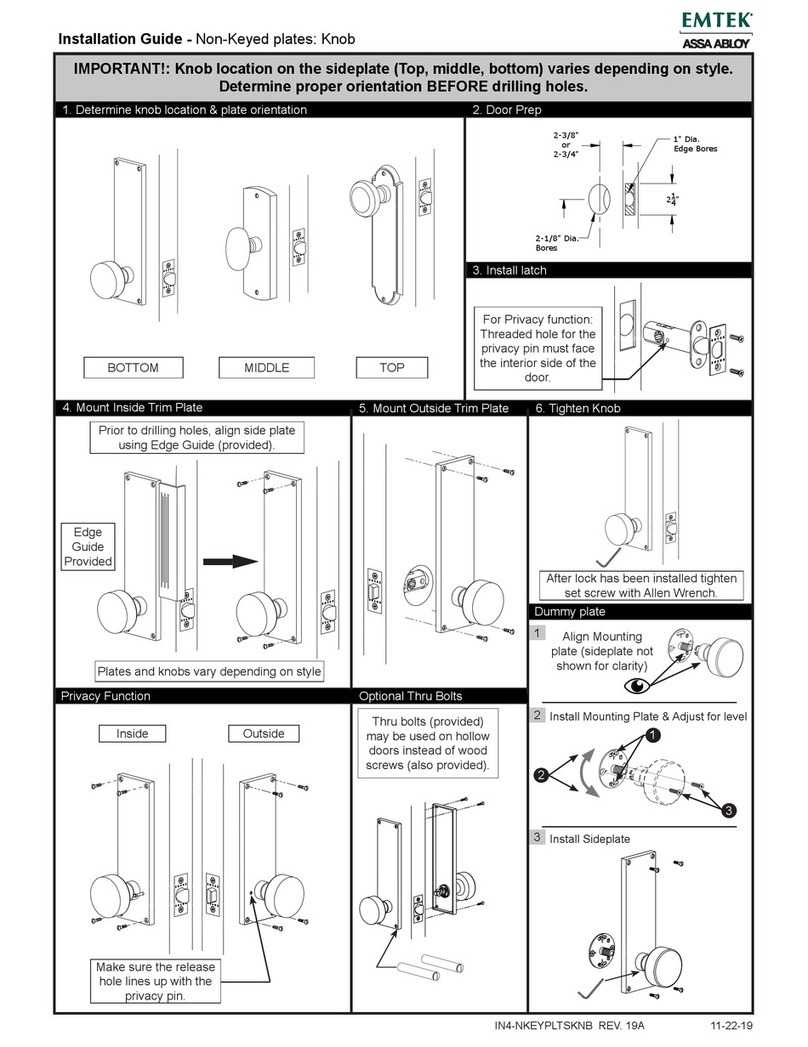

Assa Abloy EMTEK User manual

Assa Abloy

Assa Abloy Sargent PE8500 Series User manual

Assa Abloy

Assa Abloy Sargent 8200 Series User manual

Assa Abloy

Assa Abloy Yale Real Living Assure Lock YRD216-ZW3 Assembly Instructions

Assa Abloy

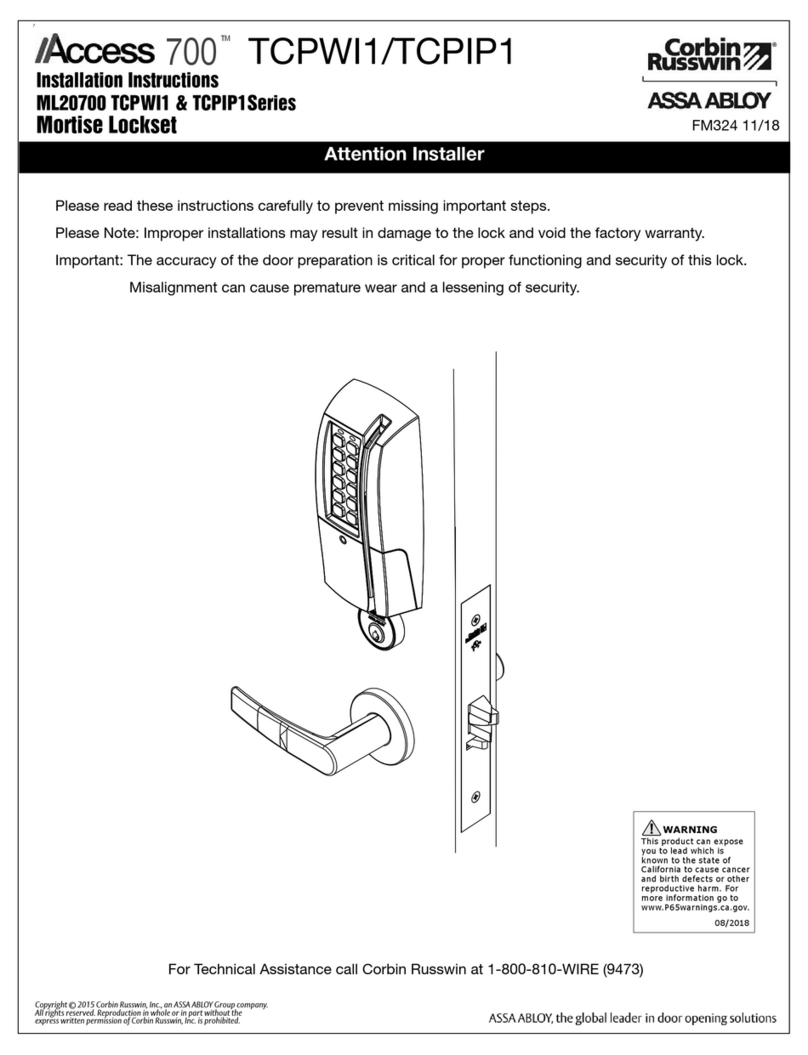

Assa Abloy Corbin Russwin Access 700 ML20700 TCPWI1... User manual

Assa Abloy

Assa Abloy MSL sFlipLock standard User manual

Assa Abloy

Assa Abloy SECURITRON DPA-12 User manual

Assa Abloy

Assa Abloy TD0192 User manual

Assa Abloy

Assa Abloy R10 User manual

Assa Abloy

Assa Abloy 8788 User manual

Assa Abloy

Assa Abloy Sargent BHL 8200 Series User manual

Assa Abloy

Assa Abloy Corbin Russwin ED5800 Series User manual

Assa Abloy

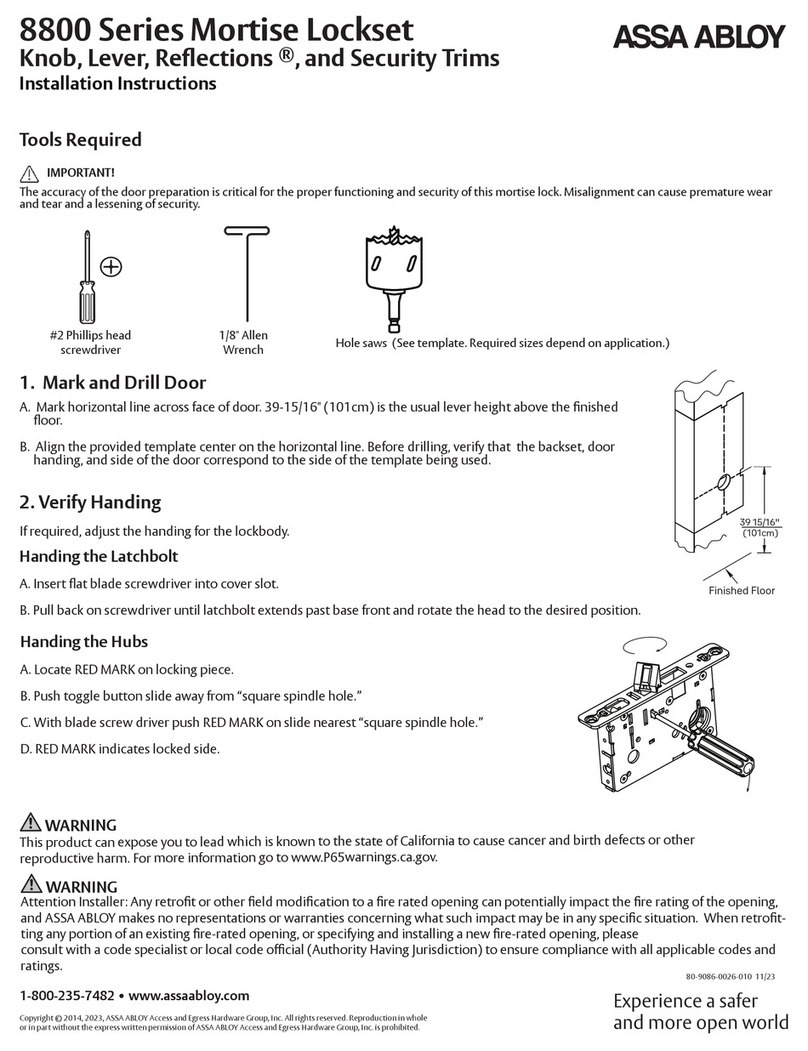

Assa Abloy 8800 Series User manual

Assa Abloy

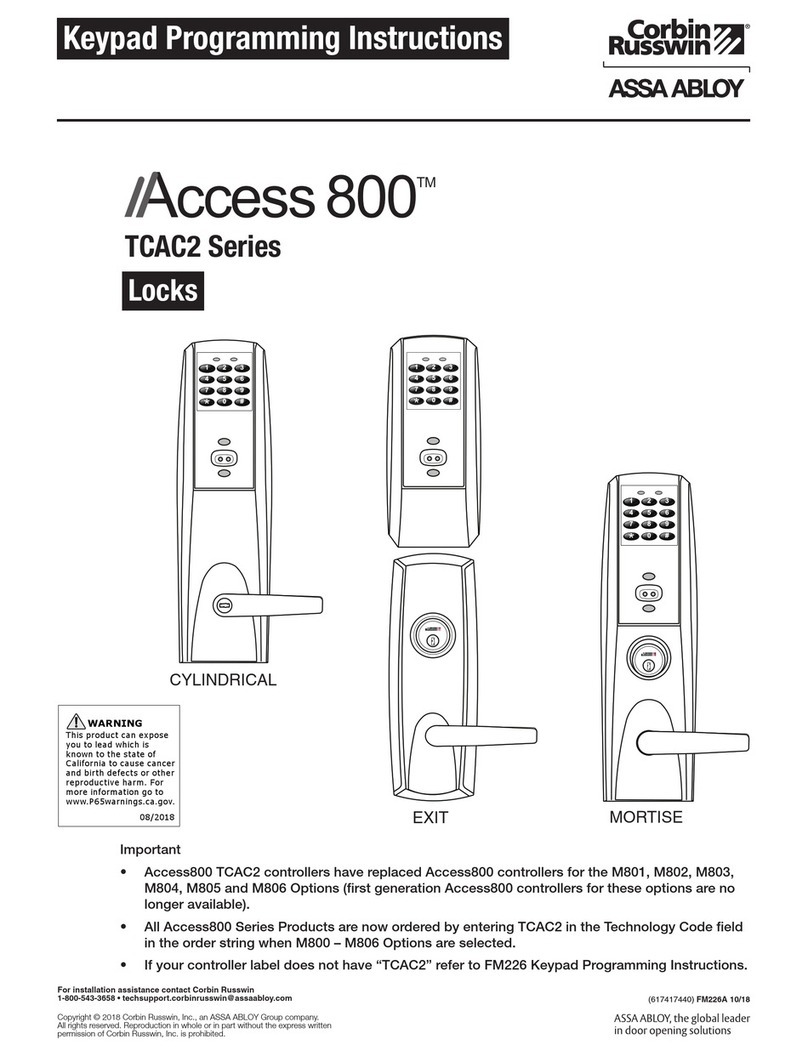

Assa Abloy Corbin Russwin Access 800 TCAC2 Series Installation manual

Assa Abloy

Assa Abloy HES 9400 Series User manual

Assa Abloy

Assa Abloy OneSystem N1940 User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

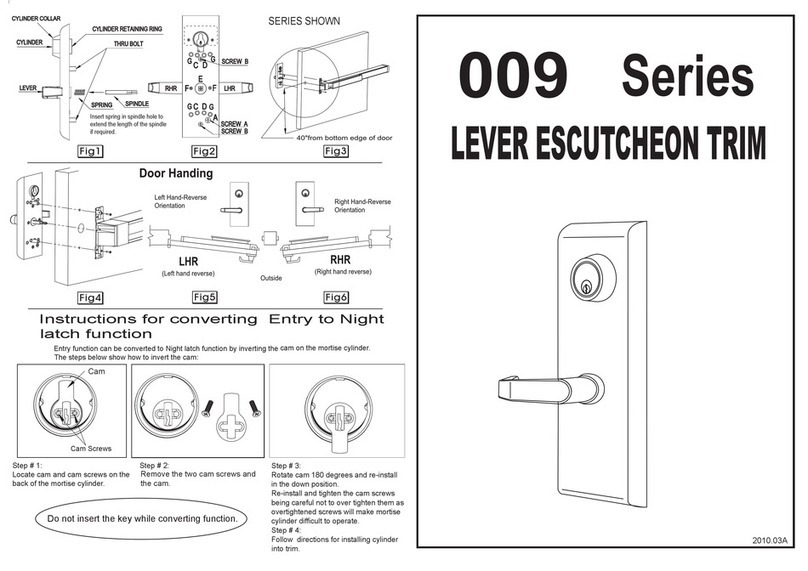

Baldwin

Baldwin 009 Series quick start guide