Hissmekano AB Reprovägen 7 SE-183 77 Täby Phone: +46-(0)8-586 272 00 Fax: +46-(0)8-732 51 26 E-mail: info@hissmekano.se

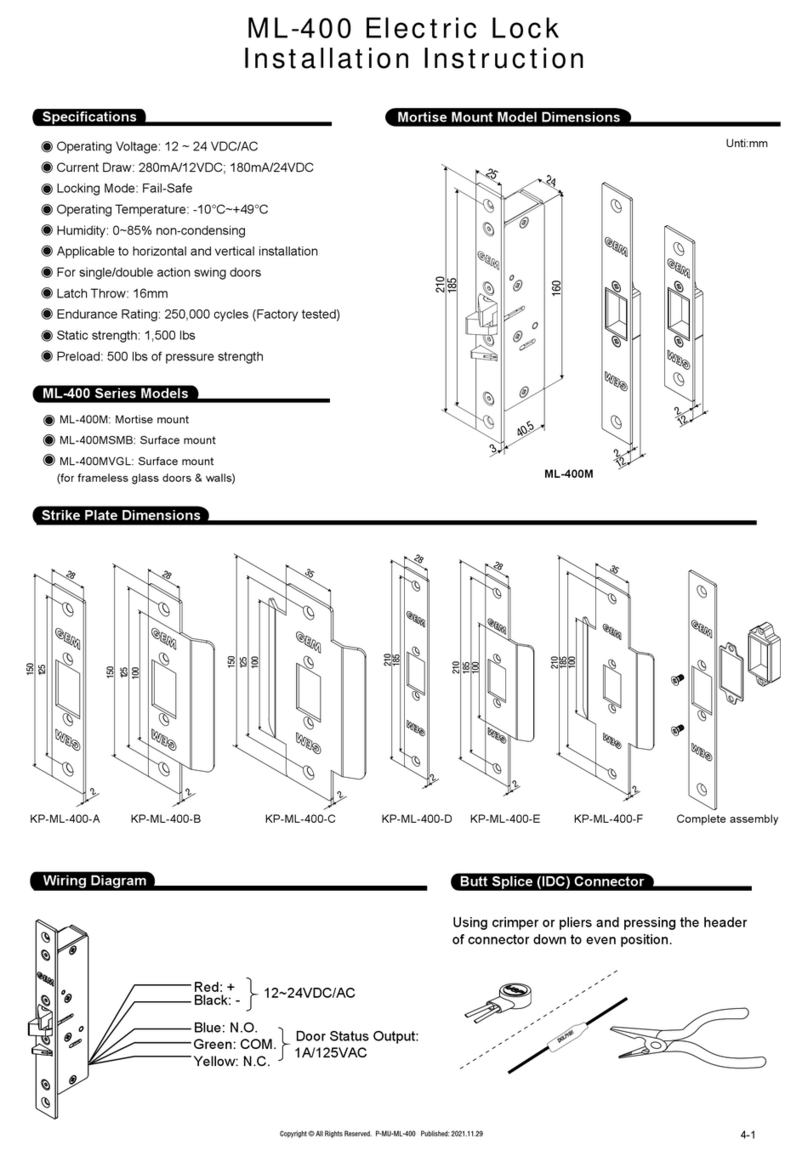

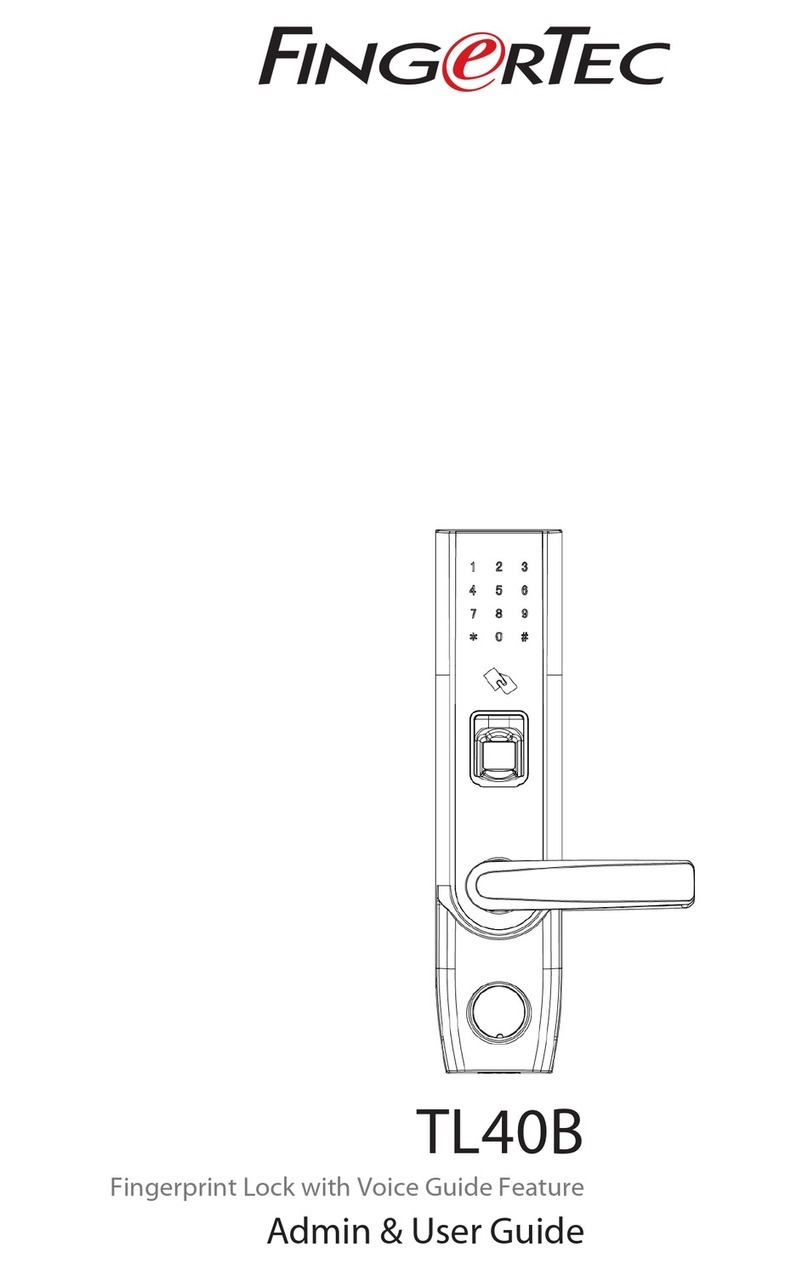

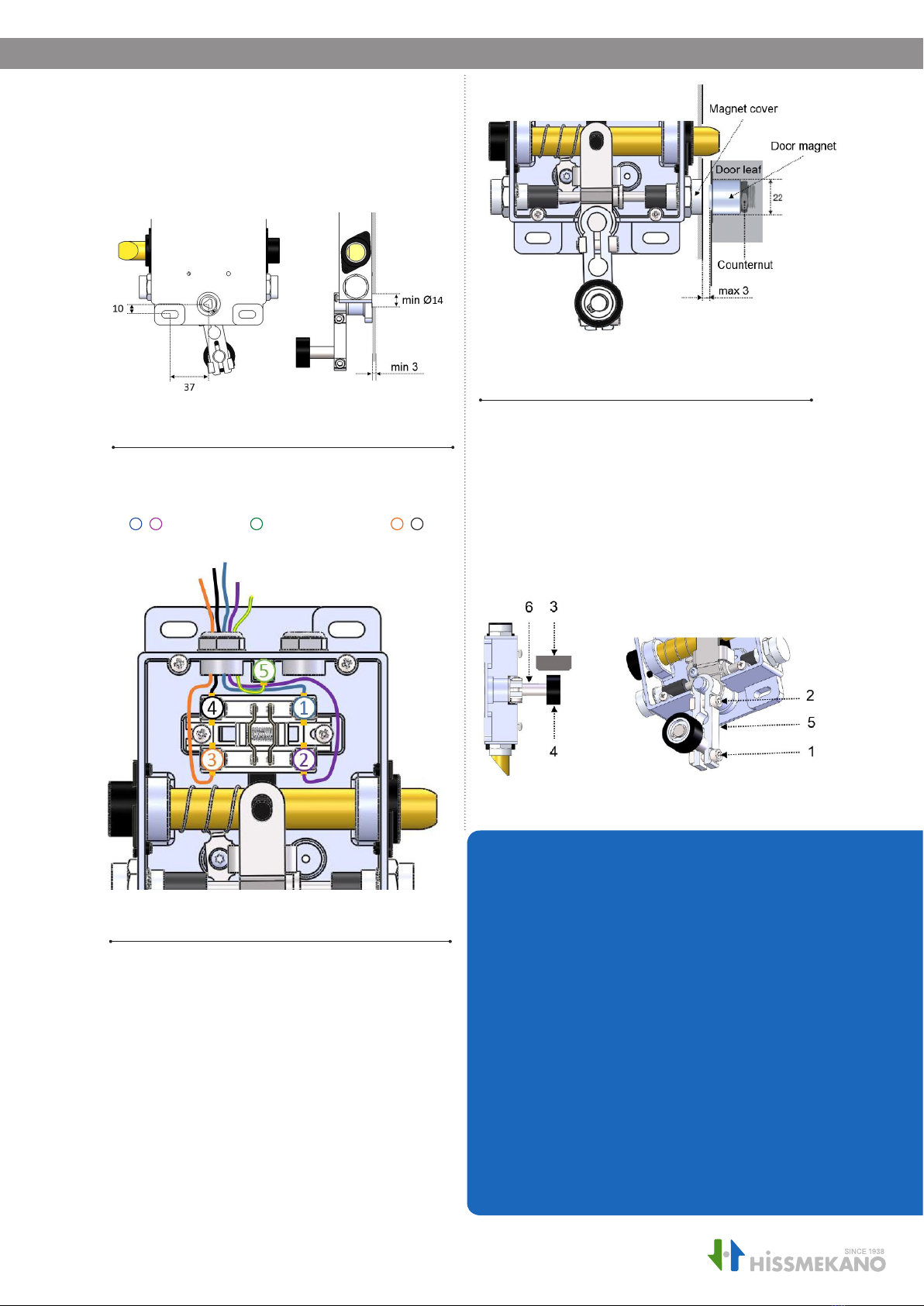

4. Connection of the contacts

Cables are connected to the terminal screw on lock contact

NC 1, 2and to ground 5. The auxiliary contact 3, 4is

connected if required.

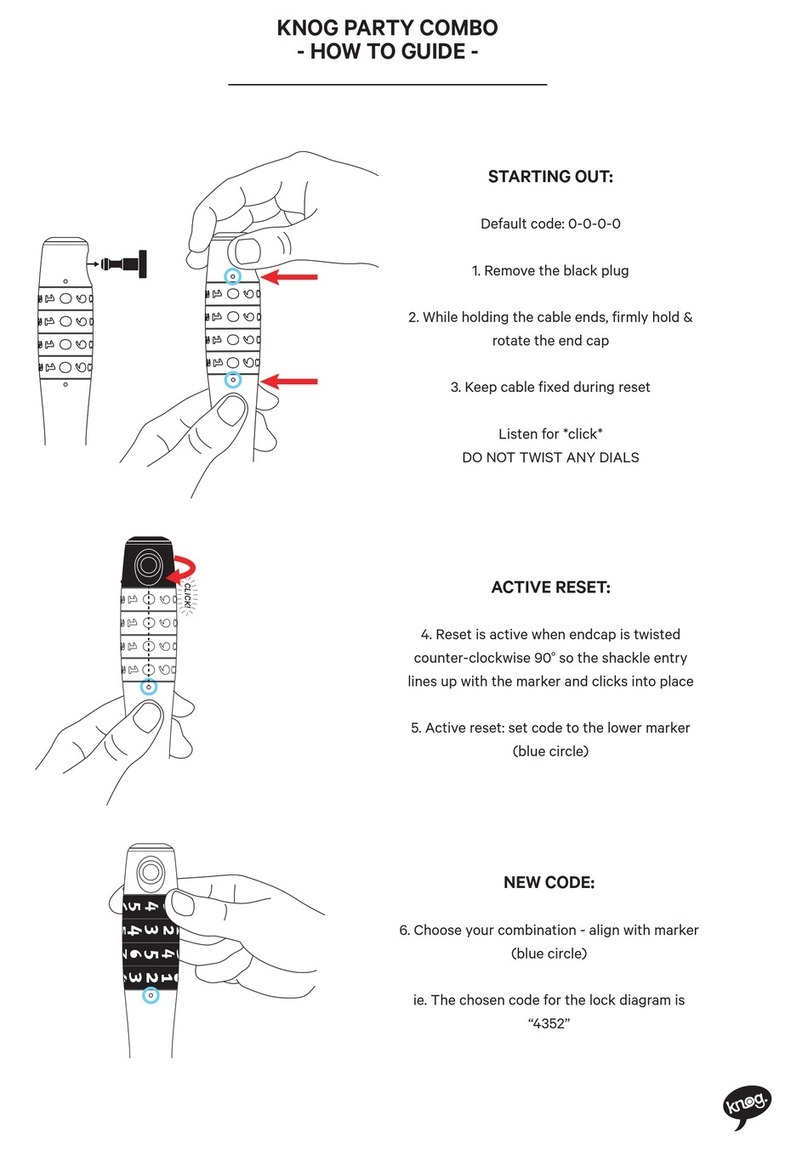

5. Mounting of door magnet

The door magnet is mounted in a 22mm hole in the door leaf.

After adjusting the distance, the door magnet is locked with

the counter nut. The door magnet should be centered in front

of the magnetic cover and adjusted so that the distance bet-

ween the door magnet and the magnet cover is at maximum

3mm. The door magnet is attached with epoxy glue or 2 pop-

nuts. If the door frame is of thick material, problems may arise

because the lock magnet is disturbed by the magnetic eld of

the door frame. Door magnet (article number: 2400242) with a

diameter of 30mm should be used.

Figur 6 Mounting of door magnet

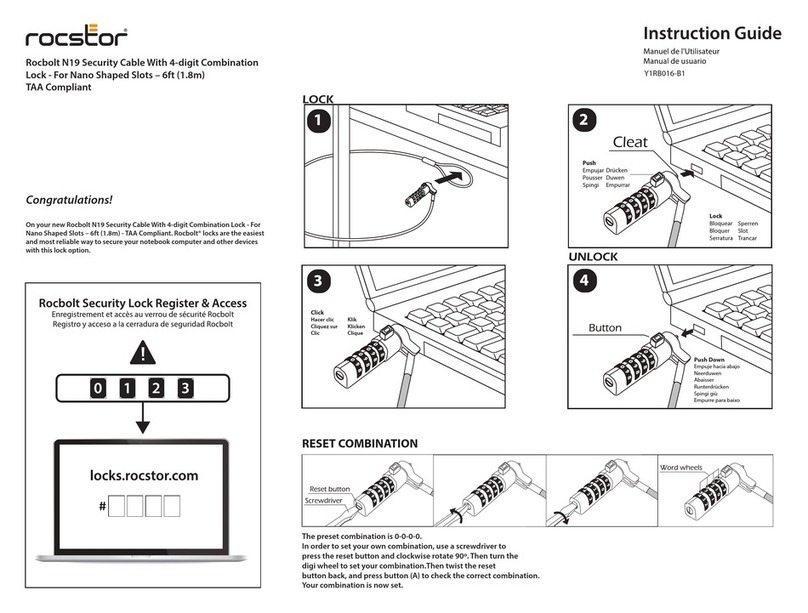

Figure 7 Mounting of the roller

REQUIREMENTS

The lock shall not be lubricated. The European Standard EN 81-20 requires a

minimum latching bolt engagement of 7mm before the lock contact closes.

RECOMMENDATIONS

We recommend to adjust the latching bolt engagement to 15mm.

REGULATIONS

LO-30S lock meets the requirements of EN 81-20 ”Common rules for checking

the door’s locked and closed position.” For the LO-30 type, additional compo-

nents are required to meet the requirements of EN81-20.

Installation is carried out according to European standards EN 81-20.

CERTIFICATE

EU certied, 17-NOR-LD-002, Kiwa Inspecta AB. Notied Body No: 0409

TECHNICAL SPECIFICATIONS

Lock/Auxiliary contact

Voltage: 230VAC / 200VDC

Current: 2A AC / 2A DC

2 OF 2

Figure 5

6. Mounting/adjustment of the roller

The locking roller shaft 6is mounted in the locking arm

5 and is tightened by screw 1. The locking arm 5is tur-

ned upwards by loosening screw 2if needed. The rol-

ler 4should be centered over the retiring ramp 3. The

locking arm is nally adjusted with screw 2so that the

roller is about 5 mm from the retiring ramp when the ramp

3is retracted. The shaft 6is cut if needed.

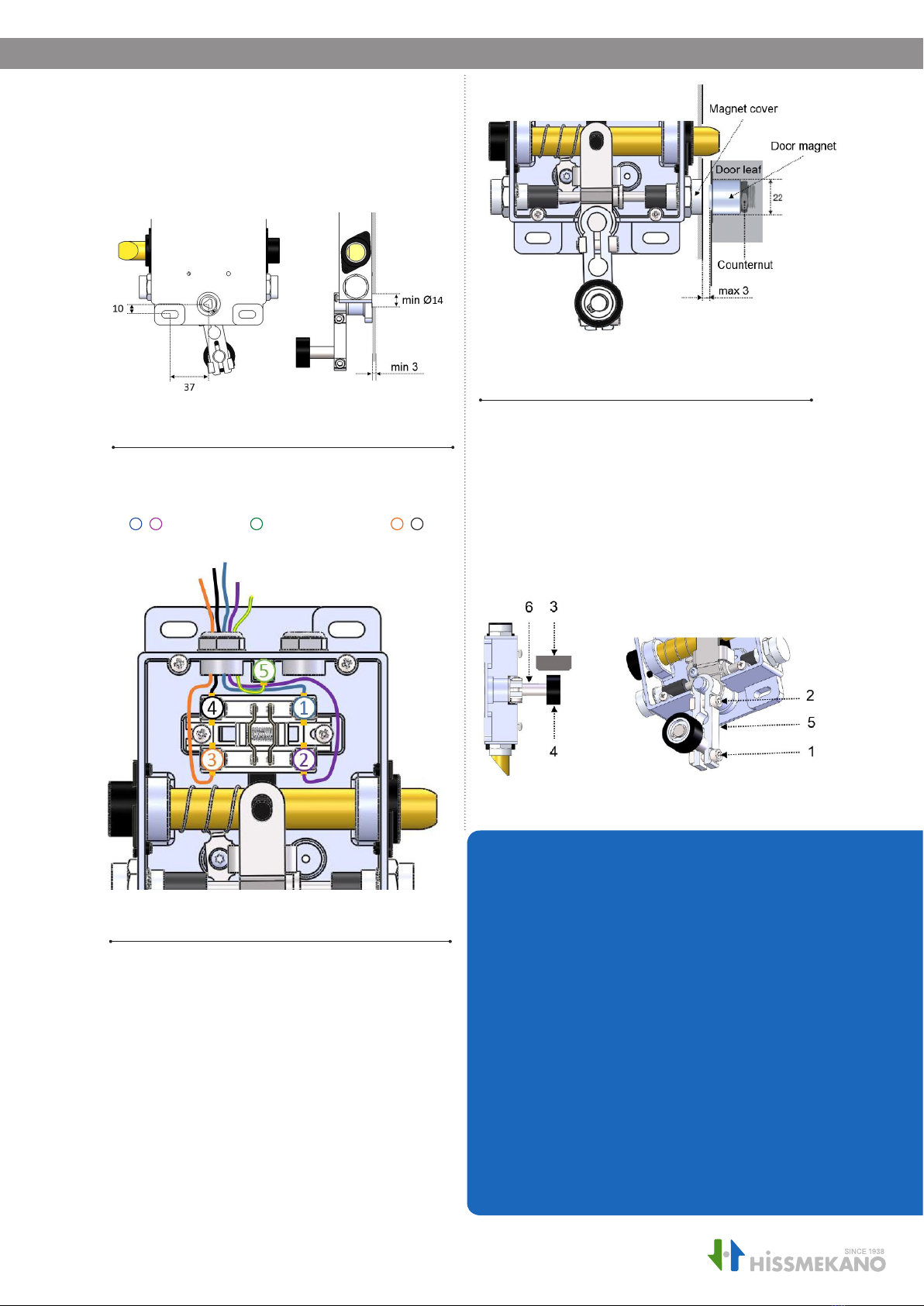

3. Emergency unlocking

Holes are drilled in the door frame for the emergency

opening function as shown in the gure below. The hole

must be at least 14mm in diameter and the triangle must

be recessed at least 3mm from the front to meet the

standard EN81-20.

Figure 4 Emergency unlocking

INSTALLATION INSTRUCTIONS