Hisun HS800 User manual

Forth version , May, 2014

Published by Chongqing

Huansong Industries

(Group) Co., Ltd and

Hisun Motors Corp USA.

Chongqing Huansong

Industries (Group)

Co., Ltd and Hisun

Motors Corp USA

holds the copy right.

No publishing and

reprinting without

permission

READ THIS

MANUAL

CAREFULLY

For questions regarding

this UTV, please

contact HISUN at:

(877) 838-6188

www.hisunmotors.com

REV. 06051401

SERVICE

MANUAL

HS800

Foreword

Brief introduction to maintenance handbook of

HS800UTV

The handbook is edited by Technical Center of Chongqing Huansong Industries (Group)

Co., Ltd., and is supplied to dealers and technicians as a docu ent of technique.

This anual gives ethods to check, aintain and repair utility terrain vehicles (UTV’s),

and supplies so e relevant techniques and perfor ance data. So e

techniques and ethods inside ay be used to check, aintain and repair other odels

of UTV, although it is ainly for the HS800UTV.

Please read the handbook through and fully understand it; otherwise, any i proper

repairing could bring you proble s, and or an accident ay occur.

Proper use and aintenance can guarantee the UTV being driven safely, reduce its

alfunctions, and help the vehicle re ain at its best perfor ance level.

The standards, procedures and specifications entioned in this anual are based on

the sa ple in design, and they are subject to changes according to the product’s

i prove ent without prior notice.

Third version , May, 2014

Published by Chongqing Huansong Industries (Group) Co., Ltd.

Chongqing Huansong Industries (Group) Co., Ltd holds the copy right.

No publishing and reprinting without per ission.

INDEX

Chapter 2

Specifications

Chapter 3

Periodic

Maintenance and

Adjustments

Chapter 4

Engine

Chapter

Chassis

Chapter 6

Electrical

Chapter 7

Engine

Management

System

Chapter 8

Troubleshooting

???

Wiring

Diagrams

Index

1.

2.

3.

Chapter 1

General

INDEX

INDEX

Chapter 1 General Information

Warnings, Cautions, Notes

Description, Location

Identification Code, Frame

Number, Engine Number

Safety

Handling Gasoline, cleaning parts

Warning Labels, Serial Numbers,

Fasteners, orque specs, Self

Locking fasteners

Washers, Cotter pins, Snap rings,

and E-clips

Shop Supplies, Lubricants, Engine

Oils

Greases, Brake Fluid, Coolant

Cleaners, Degreasers and

Solvents

Basic ools

Precision Measuring ools

Compression Gauge, Multimeter

Basic Service Methods

Storage

Chapter 2 Specifications

Conversion ables

General Specs

Engine Specs

Suspension Specs

Electrical Specs

Engine orques

Chassis orques

General orques

Lubrications

Chapter 3 Periodic Maintenance

and Adjustment

Maintenance Schedule

Valve Adjustment

Compression est

Engine Oil

Air Filter

Coolant Level

V-Belt

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-12

1-19

1-25

1-27

1-28

2-3

2-4

2-7

2-13

2-15

2-17

2-20

2-22

2-23

3-3

3-5

3-6

3-7

3-8

3-10

3-13

Spark Arrester

Brake Pedal

Brake Pads

Shift Lever Adjustment

Final Gear Oil

Steering System

Shock absorbers

ires

Headlight Adjustment

Chapter 4 Engine

Special notes

hrottle and Intake Manifold

Removal

Cylinder Head Cover and

Cylinder Head

Rocker Arms and Camshaft

Valves and Valve springs

Cylinder and Piston

Left Crankcase Cover and A.C.

Magneto

Starter motor and Oil Filter

Primary and Secondary Sheaves

Crankcase Cover and Oil Pump

Crankcase and Middle Driven

Shaft

Output Shaft

Gearcase Shift Lever and Oil

Pump

Gearcase ransmission

Chapter Chassis

Steering Assembly

Disc Brake components

Front Brake Caliper

Rear Brake Caliper

Parking Brake Caliper

Footrest

Front Wheel and ire

Rear Wheel and ire

Cv Axle, Front Axle

Front Bridge

Cv Axle, Rear Axle

Rear Bridge Reeducer

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-19

3-20

4-3

4-4

4-5

4-8

4-10

4-14

4-17

4-19

4-21

4-24

4-27

4-30

4-33

4-35

5-3

5-9

5-11

5-15

5-16

5-20

5-23

5-24

5-27

5-28

5-32

5-33

INDEX

Gear Shift Assembly

Front Swing Arm

Front Suspension

Rear Anti-roll Bar

Rear Swing Arm

Radiator and Oil Cooler

Water Pump

Seat

Fuel ank

Chapter 6 Electrical

Electrical Basics

Charging a Lead Acid Battery

Charging a Maintenance Free

Battery

Checking the Fuses

Electrical Components

Inspection of the Main Switch

Component Locations

roubleshoot (NO SPARK)

roubleshoot (Starter Motor

Failure)

Starter Motor Removal

roubleshoot (Battery is not

Charging)

Chapter 7 Engine Management

System

EMS Introduction, Components

Layout

ECU

Multec 3.5 Injectors

hrottle Body Assembly

Engine Coolant emp Sensor,

Oxygen Sensor

Fuel Pump Module

Fault Codes

5-36

5-39

5-40

5-43

5-44

5-47

5-51

5-56

5-59

6-3

6-4

6-6

6-7

6-8

6-10

6-11

6-12

6-15

6-16

6-17

7-3

7-4

7-4

7-5

7-7

7-8

7-9

7-12

Chapter 8 Troubleshoot

roubleshoot Basics

Principles and Requirements

Special Faults

Flooded Engine

Engine will not start

Spark est

Poor Engine Performance

Fuel System

Engine Smoke

Compression

Engine Lubrication

Cylinder Leak Down est

Electrical esting

est Equipment

Brake System

Headlight/ aillight

Lighting System

Brake Light

Reverse Indicator

Coolant emp Warning Light

4 Wheel drive Switch

Radiator Fan Motor

2/4WD Switch, Rear Differential

Fuel System, Electrical System

Starter Motor, Gear Shifting

8-3

8-4

8-4

8-6

8-6

8-7

8-8

8-12

8-13

8-14

8-16

8-17

8-20

8-22

8-27

8-30

8-31

8-32

8-36

8-37

8-39

8-42

8-44

8-45

8-46

General Information

1-1

Warnings, Cautions, Notes

Description, Location

Identification Code, Frame

Number, Engine Number

Safety

Handling Gasoline, cleaning

parts

Warning Labels, Serial Numbers,

Fasteners, orque specs, Self

Locking fasteners

Washers, Cotter pins, Snap

rings and E-clips

1-3

1-4

1-5

1-6

1-7

1-8

1-9

Shop Supplies, Lubricants,

Engine Oils

Greases, Brake Fluid, Coolant

Cleaners, Degreasers and

Solvents

Basic ools

Precision Measuring ools

Compression Gauge,

Multimeter

Basic Service Methods

Storage

1-10

1-11

1-12

1-12

1-19

1-25

1-27

1-33

General Information

1-2

General Information

1-3

This manual provides complete information on maintenance, tune-up, repair and

overhaul. Hundreds of photographs and illustrations created during the complete

disassembly of Utility Terrain Vehicles (UTV) guide the reader through every job.

ll procedures are in step by step format and designed for the reader who may

be working on the UTV for the first time.

Warnings, Cautions and Notes

The terms Warning, Caution and Note have specific meanings in this manual.

Warning

Emphasizes areas where injury or even death could result from

negligence.

Caution

Emphasizes areas where equipment damage could result.

Disregarding a Caution could cause permanent permanent

Mechanical damage, although injury is unlikely.

Note

Provides additional information to make a step or procedure easier

or clearer. Disregarding a Note could cause inconvenience, but

would not cause equipment damage or injury.

General Information

1-4

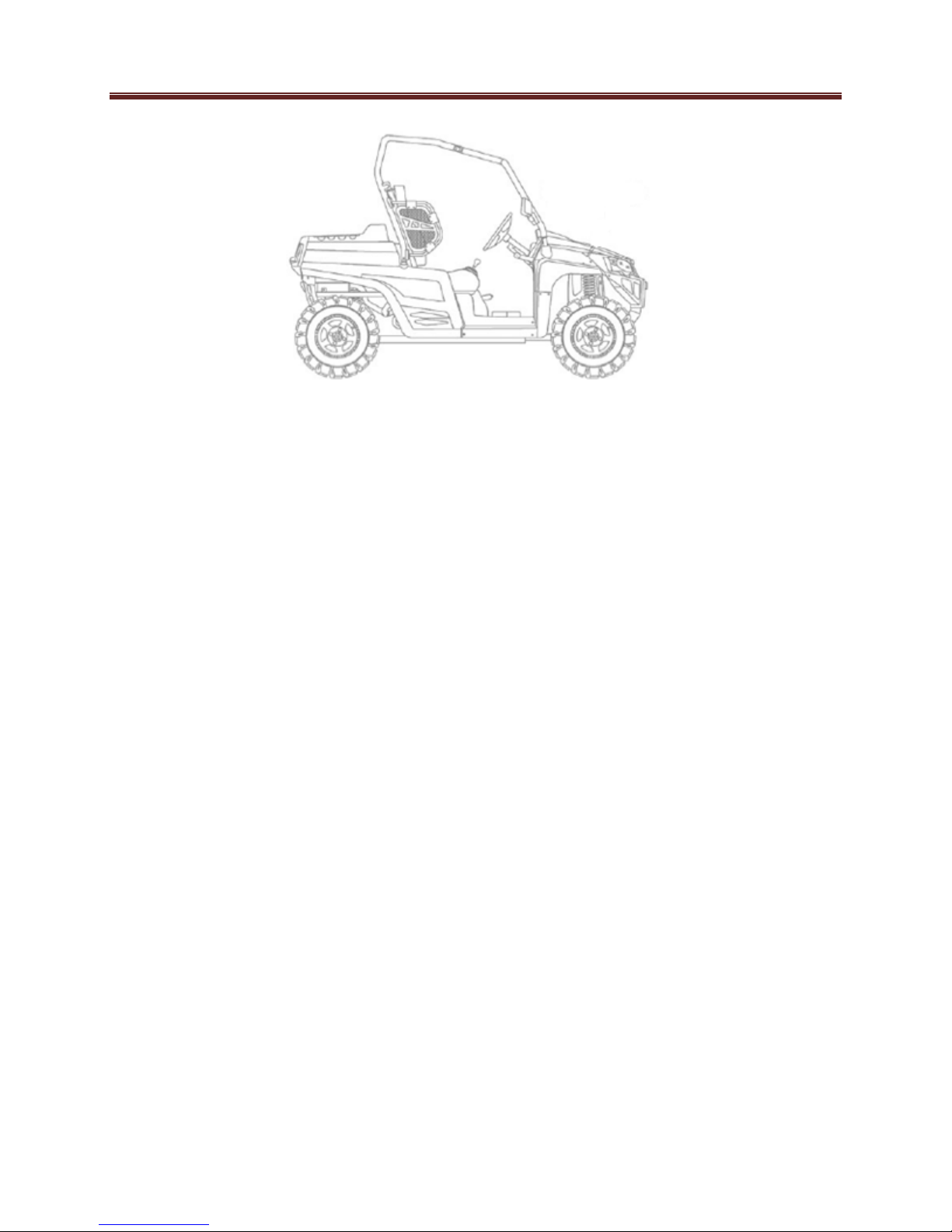

Description

1. Headlights/Front turning lights/

Position lights

2. Front shock absorber spring

preload djusting ring

3. Rear Brake Fluid Reservoir

4. Parking Brake Lever

5. Driver Seat

6. Battery

7. Fuses

8. Left shoulder protection plate

9. Driver’s seat belt

10. ir Filter case (Engine and ir

intake duct)

11. Cargo Bed

12. Tail light / Rear turning lights

13. Spark arrester

14. Rear Shock absorber assembly

adjusting ring

15. V-belt case

16. Passenger seat belt

17. Right shoulder protection plate

18. Spark plug

19. Oil filter

20. Fuel cap

21. Passenger seat

22. Rear view mirror

23. Coolant reservoir

24. Radiator cap

25. Steering wheel

26. Light switch

27. Main switch

28. On-Command four-wheel-drive

and differential lock switches

29. Multi-function Display

30. uxiliary DC jack

31. Brake pedal

32. ccelerator pedal

33. Drive select lever

34. Passenger handrail

Note:

The vehicle you have purchased

may differ slightly from those in the

figures of this manual.

General Information

1-5

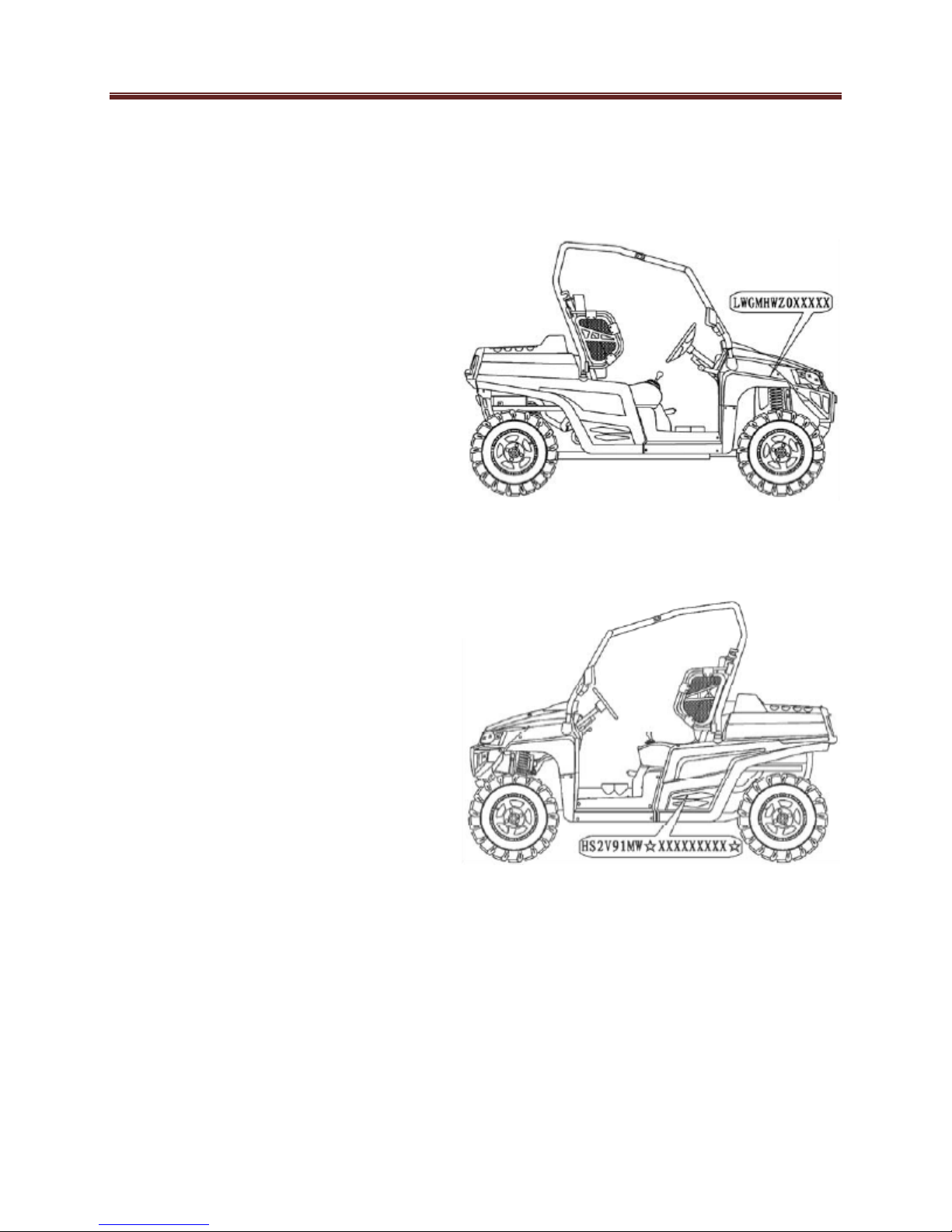

Identification Code

Frame No.

Frame No. is stamped on the right side

of the main frame.

Engine No.

Engine No. is stamped on the right side

of the engine.

General Information

1-6

Vehicle Identification Number

LWG MH WZ 44 E 123456

LWG Manufacturer

MD UTV below 750 cc

MH UTV above 750 cc

SD TV below 750 cc

SH TV above 750 cc

SZ 400 cc

TZ 500 cc

YZ 700 cc

WZ 800 cc

44 DOT Check Digits

2010 Model Year

B 2011 Model year

C 2012 Model Year

D 2013 Model Year

E 2014 Model Year

Manufacturing Plant

B Manufacturing Plant B

123456 Sequential Serial Number

General Information

1-7

Safety

Professional mechanics can work for

many years and never sustain a serious

injury or mishap. Follow these

guidelines and practice common sense

to safely service the utility terrain

vehicle.

1. Do not operate the utv in an

enclosed area. The exhaust

gasses contain carbon monoxide,

which is an odorless, colorless

and tasteless poisonous gas.

Carbon monoxide levels build

quickly in small confined areas

and can cause unconsciousness

and death in a short time. Make

sure to properly ventilate the

work area operate the UTV

outside.

2. Never use gasoline or any

extremely flammable liquid to

clean parts. Refer to cleaning

parts and handling gasoline

safely in this section.

3. Never smoke or use a torch in

the vicinity of flammable liquids,

such as gasoline or cleaning

solvents.

4. If welding or brazing on the UTV

move the fuel tank to a safe

distance, at least 50ft away.

5. Use the correct type and size

tools to avoid damaging

fasteners.

6. Keep tools clean and in good

condition. Replace or repair worn

or damaged equipment.

7. When loosening a tight fastener,

be guided by what would happen

if the tool slips.

8. When replacing fasteners, make

sure the new fasteners are the

same size and strength as the

original ones.

9. Keep your work area clean and

organized.

10. Wear eye protection anytime the

safety of the eyes is in question.

This includes procedures that

involve drilling, grinding,

hammering, use of compressed

air, and chemicals.

11. Wear the correct clothing for the

job. Tie up or cover long hair so it

does not get caught in moving

equipment.

12. Do not carry sharp tools in

clothing.

13. lways have an approved fire

extinguisher available. Make sure

it is rated for gasoline (class B)

and electrical (class C) fires.

14. Do not use compressed air to

clean clothing, the UTV, or the

work area. Debris may be blown

into the eyes or skin. Never direct

compressed air at anyone. Do

not allow children to use or play

with any compressed air

equipment.

15. When using compressed air to

dry parts, hold the part so it does

not rotate. Do not allow the force

of the air to spin the part. The air

jet is capable of rotating parts at

extreme speed and the part may

disintegrate or become damaged

possibly causing injury.

16. Do not inhale the dust created by

brake pad and clutch wear.

These particles may contain

asbestos. Some types of

insulating materials and gaskets

may also contain asbestos.

Inhaling asbestos particles is

hazardous to your health.

General Information

1-8

Handling Gasoline

safely

Gasoline is a volatile flammable liquid

and is one of the most dangerous items

in the shop. Because gas is used so

often, many people forget about the

hazards associated with its use. Gas

should only be used for fuel in a

gasoline internal combustion engine.

Keep in mind when working on the UTV

that gasoline is always present in the

fuel tank, fuel lines and carburetor. To

avoid an accident when working around

a fuel system, carefully observe the

following precautions.

1. Never use gas to clean parts.

Refer to cleaning parts in this

section.

2. When working on the fuel

system, work outside or in a well

ventilated area.

3. Do not add fuel to the fuel tank or

service the fuel system while the

UTV is near open flames, sparks

or where someone is smoking.

Gasoline vapor is heavier than air

and it collects in low areas, and is

more easily ignited than liquid

gasoline.

4. llow the engine to cool

completely before working on any

fuel system component.

5. Do not store gasoline in glass

containers. If the glass breaks, a

serious explosion or fire may

occur.

6. Immediately wipe up spilled gas

with rags. Store the rags in a

metal container with a lid until

they can be properly disposed of,

or washed.

7. Do not pour water onto a

gasoline fire. Water spreads the

fire and makes it more difficult to

put out. Use a class B, BC or

BC fire extinguisher to

extinguish the fire.

8. lways turn off the engine before

refueling. Do not spill fuel onto

the engine or exhaust system. Do

not overfill the fuel tank. Leave an

air space at the top of the tank to

allow room for the fuel to expand

due to temperature fluctuations.

Cleaning Parts

Cleaning parts is one of the more

tedious and difficult service jobs

performed in the home garage. Many

types of chemical cleaners and solvents

are available for shop use. Most are

poisonous and extremely flammable. To

prevent chemical exposure, vapor

buildup, fire and serious injury, observe

each product warning label and note the

following.

1. Read and observe the entire

product label before using any

chemical. lways know what type

of chemical is being used and

whether it is poisonous and or

flammable.

2. Do not use more than one type of

cleaning solvent at a time. If

mixing chemicals is required,

measure the proper amounts

according to the manufacturer.

3. Work in a well ventilated area.

4. Wear chemical resistant gloves.

5. Wear safety glasses

6. Wash hands and arms thoroughly

after cleaning parts.

7. Keep chemical products away

from children and pets.

8. Wear a vapor respirator if the

instructions call for it.

General Information

1-9

9. Thoroughly clean all oil, grease

and cleaner residue from any part

that must be heated.

10. Use a nylon brush when cleaning

parts. Metal brushes may cause

a spark.

11. When using a parts washer, only

use the solvent recommended by

the manufacturer. Make sure the

parts washer is equipped with a

metal lid that can lower in case of

fire.

Warning Labels

Most manufacturers attach information

and warning labels to the UTV. These

labels contain instructions that are

important to safety when operating,

servicing, transporting and storing the

UTV. Refer to the owner’s manual for

the description and location of labels.

Order replacement labels from the

manufacturer if they are missing or

damaged.

Serial Numbers

Serial and identification numbers are

stamped on various locations on the

frame, engine and carburetor body.

Record these numbers in the quick

reference data section in the front of the

manual. Have these numbers available

when ordering parts.

Fasteners

Proper fastener selection and

installation is important to ensure the

UTV operates as designed and can be

serviced efficiently. The choice of

original equipment fasteners is not

arrived at by chance. Make sure

replacement fasteners meet all the

same requirements as the originals.

Many screws, bolts and studs are

combined with nuts to secure particular

components. Marking will indicate the

strength or hardness. Manufacturers

specify the internal diameter and thread

pitch. The measurement across two flats

on a nut or bolt indicates the wrench

size.

Warning

Do not install fasteners with a

strength classification lower than

what was originally installed by the

manufacturer. Doing so may cause

equipment failure and or damage.

Torque Specifications

The material used in the manufacturing

of the UTV may be subjected to uneven

stresses if the fasteners of the various

subassemblies are not installed and

tightened correctly. Fasteners that are

improperly installed or work loose can

cause extensive damage. It is essential

to use an accurate torque wrench as

described in this chapter.

Self-Locking Fasteners

Several types of bolts, screws and nuts

incorporate a system that creates

interference between the two fasteners.

Interference is achieved in various

ways. The most common types are the

nylon insert nut and a dry adhesive

coating on the threads of a bolt. Self-

locking fasteners offer greater holding

strength than standard fasteners, which

improves their resistance to vibration. ll

self-locking fasteners cannot be reused.

The materials used to from the lock

General Information

1-10

become distorted after the initial

installation and removal. Discard and

replace self-locking fasteners after

removing them. Do not replace self-

locking fasteners with standard

fasteners.

Washers

The two basic types of washers are flat

washers and lock washers. Flat washers

are simple discs with a hole to fit a

screw or bolt. Lock washers are used to

prevent a fastener from working loose.

Washers can be used as spacers and

seals, or can help distribute fastener

load and prevent the fastener from

damaging the component. s with

fasteners, when replacing washers

make sure the replacement washers are

of the same design and quality.

Cotter Pins

cotter pin is a split metal pin inserted

into a hole or slot to prevent a fastener

from loosening. In certain applications,

such as the rear axle on an UTV or

motorcycle, the fastener must be

secured in this way. For these

applications, a cotter pin and castellated

(slotted) nut is used. To use a cotter pin,

first make sure the diameter is correct

for the hole in the fastener. fter

correctly tightening the fastener and

aligning the holes, insert the cotter pin

through the hole and bend the ends

over the fastener, Unless instructed to

do so, never loosen a tightened fastener

to align the holes. If the holes do not

align, tighten the fastener enough to

achieve alignment. Cotter pins are

available in various diameters and

lengths. Measure the length from the

bottom of the head to the tip of the

shortest pin.

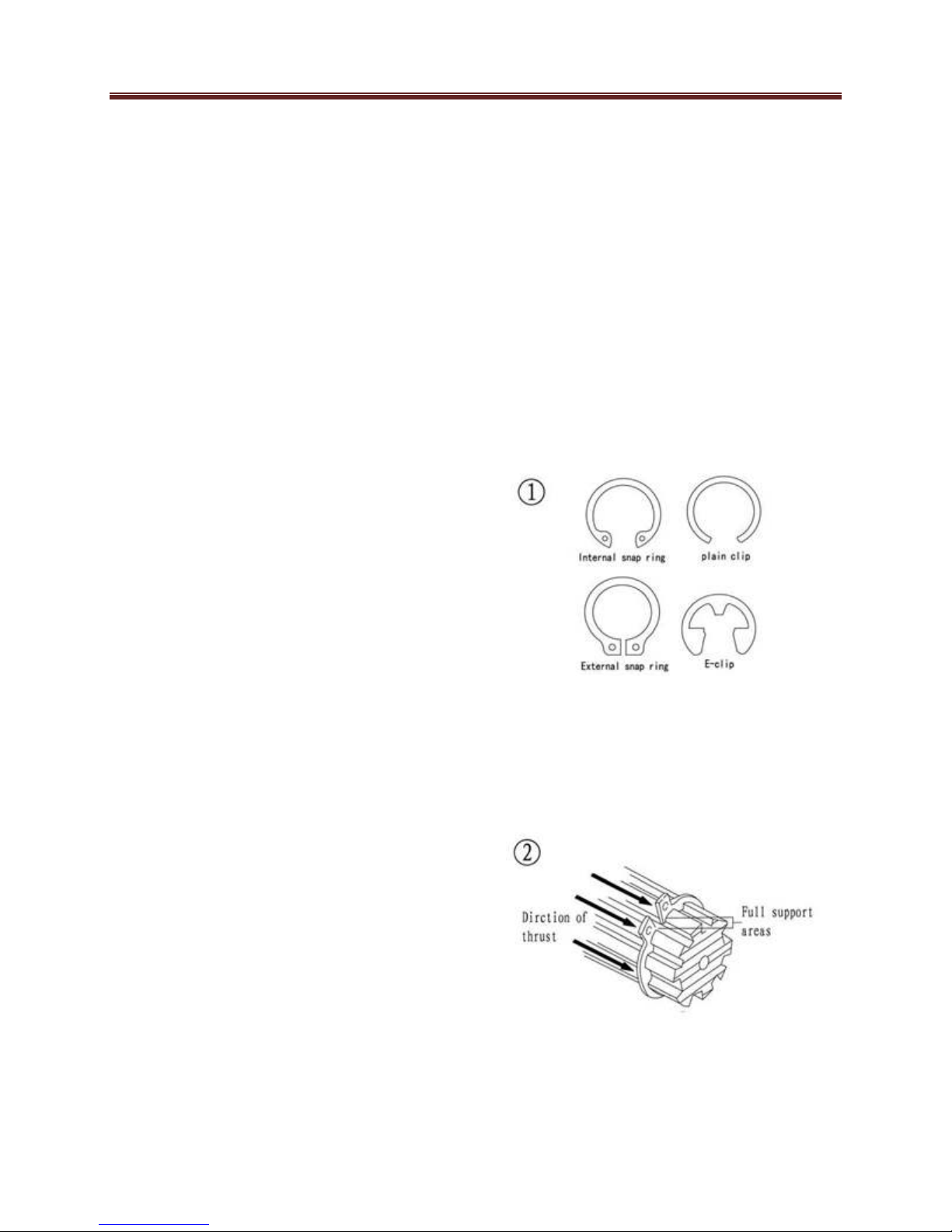

Snap Rings and E-clips

Snap rings (Figure 1) are circular-

shaped metal retaining clips. External

type snap rings are used to retain items

on shafts. Internal type snap rings

secure parts within housing bores. In

some applications, in addition to

securing the component(s), snap rings

of varying thicknesses also determine

endplay. These are usually called

selective snap rings.

The two basic types of snap rings are

machined and stamped snap rings.

Machined snap rings (Figure 2) can be

installed in either direction, because

both faces have sharp edges.

Stamped snap rings (Figure 3) are

manufactured with a sharp and a round

edge. When installing a stamped snap

General Information

1-11

ring in a thrust application, install the

sharp edge facing away from the part

producing the thrust.

Observe the following when installing

snap rings:

1. Remove and install snap rings

with snap rings pliers. Refer to

Basic Tools in this chapter.

2. In some applications. it may be

necessary to replace snap rings

after removing them.

3. Compress or expand snap rings

only enough to install them. If

overly expanded they lose their

retaining ability.

4. fter installing a snap ring. Make

sure it seats completely

5. Wear eye protection when

removing and installing snap

rings

E-clips are used when it is not practical

to use a snap ring. Remove E-clips with

a flat blade screwdriver by prying

between the shaft and E-clip. To install

an E-clip, center it over the shaft groove

and push or tap it into place.

Shop Supplies

Lubricants and Fluids

Periodic lubrication help ensure a long

service life for any type of equipment.

Using the correct type of lubricant is as

important as performing the lubrication

service. lthough in an emergency the

wrong type is better than not using one.

The following section describes the

types of lubricants most often required.

Make sure to follow the manufacturer’s

recommendations for lubricant types

Engine Oils

Engine oil for the UTV four stroke

engine is classified by two standards:

the merican Petroleum Institute ( PI)

service classification and The Society of

utomotive Engineers (S E) viscosity

rating Standard classification. The PI

and S E information is on all oil

container labels. Two letters indicate the

PI service classification. The number

or sequence of numbers and letter

(10W-40SG for example) is the oil’s

viscosity rating. The PI service

classification and the S E viscosity

index are not indications of oil quality.

The PI service classification standards,

the first letter in the classification S

indicates that the oil is for gasoline

engines. The second letter indicates the

standard the oil satisfies. The

classifications are: M (high friction

applications) and MB (low frication

applications)

Note:

efer to Engine Oil and Filter in

Chapter Three for further information

on API, SAE classifications.

General Information

1-12

lways use oil with a classification

recommended by the manufacturer,

using an oil with a different classification

can cause engine damage. Viscosity is

an indication of the oil’s thickness. Thin

oils have a lower number while thick oil

has a higher number. Engine oils fall

into the 5-to50-weight range for single-

grade oils. Most manufacturers

recommend multi-grade oil. These oils

perform efficiently across a wide range

of operating conditions. Multi-grade oils

are identified by a W after the first

number, which indicates the low-

temperature viscosity. Engine oils are

most commonly mineral (petroleum)

based, but synthetic and semi-synthetic

types are used more frequently. When

selecting engine oil, follow the

manufacturer’s recommendation for

type, classification and viscosity.

Greases

Grease is lubricating oil with thickening

agents added to it. The National

Lubricating Grease Institute (NLGI)

grades grease. Grades range from

No.000 to No.6, with No.6 being the

thickest. The most typical multipurpose

grease is NLGI No.2. For specific

applications, manufacturers may

recommend water-resistant type grease

or one with an additive such as

molybdenum disulfide (MoS2).

rake Fluid

Brake fluid is the hydraulic fluid used to

transmit hydraulic pressure (force) to the

wheel brakes. Brake fluid is classified by

the Department of Transportation

(DOT). Current designations for brake

fluid are DOT 3, DOT 4 and DOT 5, this

classification appears on the fluid

container. Each type of brake fluid has

its own definite characteristics. Do not

mix different types of brake fluid as this

may cause brake system failure. DOT 5

brake fluid is silicone based. DOT 5 is

not compatible with other brake fluids

may cause brake system failure. When

adding brake fluid, only use the fluid

recommended by the manufacturer.

Brake fluid will damage any plastic,

painted or plated surfaces it contacts.

Use extreme care when working with

brake fluid and remove any spills

immediately with soap and water.

Hydraulic brake systems require clean

and moisture free brake fluid. Never

reuse brake fluid. Keep containers and

reservoirs properly sealed.

Warning

Never put mineral based petroleum

oil into the brake system. Mineral oil

causes rubber parts in the system to

break down which could cause

complete brake failure.

Coolant

Coolant is a mixture of water and

antifreeze used to dissipate engine heat.

Ethylene glycol is the most common

form of antifreeze. Check the UTV

Manufacturer’s recommendations when

selecting antifreeze. Most require one

specifically designed for aluminum

engines. There are types of antifreeze

have additives that inhibit corrosion.

Only mix antifreeze with distilled water.

Impurities in tap water may damage

internal cooling system passages.

General Information

1-13

Cleaners, Degreasers

and Solvents

Many chemicals are available to remove

oil, grease and other residue from the

UTV. Before using cleaning solvents,

consider how they will be used and

disposed of, particularly if they are not

water-soluble. Local ordinances may

restrict types of cleaning chemicals.

Refer to Safer in this chapter. Use brake

parts cleaner for brake system

components. Brake parts cleaner leaves

no residue. Electrical contact cleaner is

a powerful solvent used to remove fuel

deposits and varnish from fuel system

components. Use this cleaner carefully,

as it may damage finishes. Most

solvents are designed to be used with a

parts washing cabinet for individual

component cleaning. For safety, use

only nonflammable or high flash point

solvents.

Gasket Sealant

Sealant is used in combination with a

gasket or seal. In other applications,

such as between crankcase halves, only

a sealant is used. Follow the

manufacturer’s recommendation when

using a sealant. Use extreme care when

choosing a different sealant based on its

resistance to heat, various fluids and its

sealing capabilities.

Gasket Remover

erosol gaskets remover can help

remove stubborn gasket. This product

can speed up the removal process and

prevent damage to the mating surface

that may be caused by using a scraping

tool. Most of these types of products are

very caustic. Follow the gasket remover

manufacturer’s instructions for use.

Thread locking

Compound

thread locking compound is a fluid

applied to the threads of fasteners. fter

tightening the fastener, the fluid dries

and becomes a solid filler between the

threads. This makes it difficult for the

fastener to work loose from vibration or

heat expansion and contraction. Use

thread locking compound sparingly.

Excess fluid can run into adjoining parts.

Caution

Thread locking compounds are

anaerobic and will stress, crack and

damage most plastics. Use caution

when using these products in areas

where there are plastic components.

Thread locking compounds are available

in a wide range of compounds for

various strengths, temperature and

repair applications. Follow the

manufacturer’s recommendations

regarding compound selection.

asic Tools

Most of the procedures in this manual

can be carried out with basic hand tools

and test equipment familiar to the home

mechanic. lways use the correct tools

for the job. Keep tools organized and

clean. Store them in a tool chest with

related tools organized together.

Quality tools are essential. The best are

constructed of high-strength alloy steel.

These tools are light, easy to use and

resistant to wear. Their working surface

General Information

1-14

is devoid of sharp edges and carefully

polished. They have an easy-to-clean

finish and are comfortable to use.

Quality tools are a good investment.

Some of the procedures in this manual

specify special tools. In many cases the

tools is illustrated in use. Those with a

large tool kit may be able to perform the

jobs, However, in some cases, the

specialized equipment or expertise may

make it impractical for the home

mechanic to attempt the procedure.

When necessary, such operations are

recommended to have a dealership or

specialist perform the task. It may be

less expensive to have a professional

perform these jobs, especially when

considering the cost of equipment.

When purchasing tools to perform the

procedures covered in this manual,

consider the tool’s potential frequency of

use. If a tool kit is just now being

started, consider purchasing a basic tool

set from a quality tool supplier and they

may offer substantial savings when

complicated, specialized tools need to

be added.

Screwdrivers

Screwdrivers of various lengths and

types are mandatory for the simplest

tool kit. The two basic types are the

slotted tip (flat blade) and the Phillips tip.

These are available in sets that often

include an assortment of tip size and

shaft lengths. s with all tools, use a

screwdriver designed for the job. Make

sure the tool fits the size of the fastener.

Use them only for driving screws. Never

use a screwdriver for prying or chiseling

metal. Repair or replace worn or

damaged screwdrivers. worn tip may

damage the fastener, making it difficult

to remove.

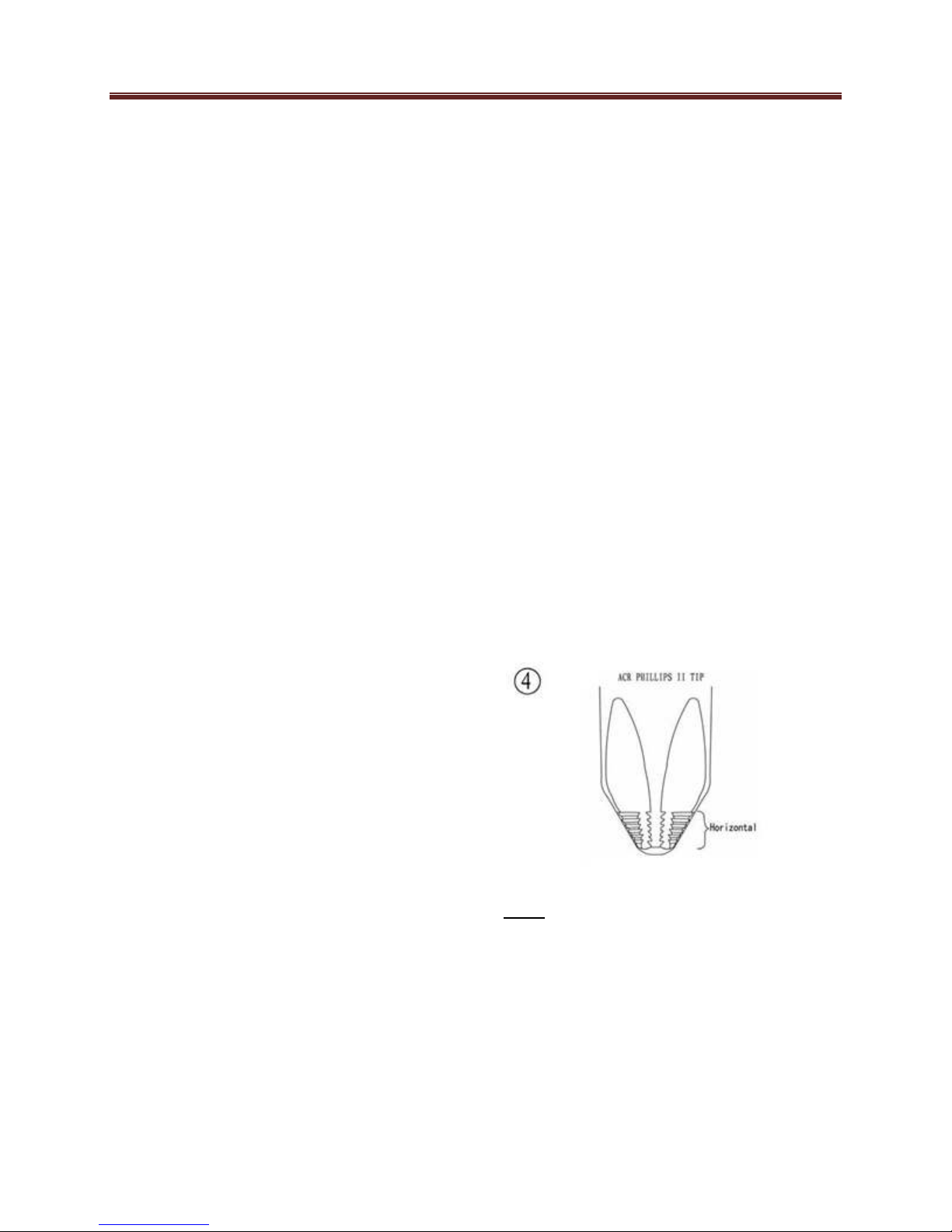

Phillips-head screws are often damaged

by incorrectly fitting screwdrivers.

Quality Phillips screwdrivers are

manufactured with their crosshead tip

machined to Phillips Screw Company

specifications. Poor quality or damaged

Phillips screwdrivers can back out and

round over the screw head. Weak or

soft screw materials can make removal

more difficult. The best type of

screwdriver to use on Phillips screw is

the CR Phillips II screwdriver, patented

by the horizontal anti-cam out ribs found

on the driving faces or flutes of the

screwdriver’s tip (figure 4). CR Phillips

II screwdrivers were designed as part of

a manufacturing drive system to be

used with CR Phillips II screws, but

they work well. Tool suppliers offer CR

Phillips II screwdrivers in different Tip

size and interchangeable bits to fit

screwdriver bit holders.

Note

Another way to prevent the

screwdriver from rounding out the

head of the screw is to apply valve

grinding compound onto the tip. After

loosening or tightening the screw,

clean the screw recess to prevent

engine oil contamination.

Table of contents

Other Hisun Utility Vehicle manuals

Hisun

Hisun HS700UTV-4 Manual

Hisun

Hisun HS500UTV User manual

Hisun

Hisun Strike 250 User manual

Hisun

Hisun HS164-4 User manual

Hisun

Hisun HS500UTV User manual

Hisun

Hisun HS1P65MM User manual

Hisun

Hisun HS294-2 Owner's manual

Hisun

Hisun STRIKE 800 User manual

Hisun

Hisun HS250UTV Owner's manual

Hisun

Hisun SECTOR 1000 User manual