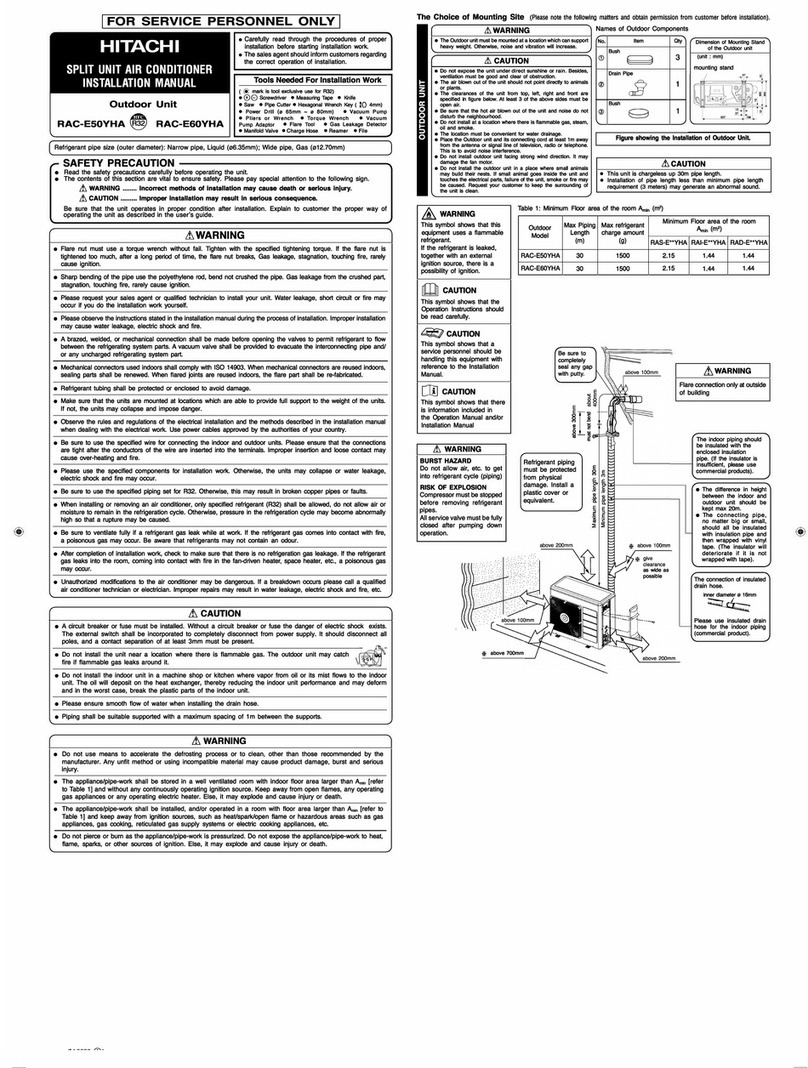

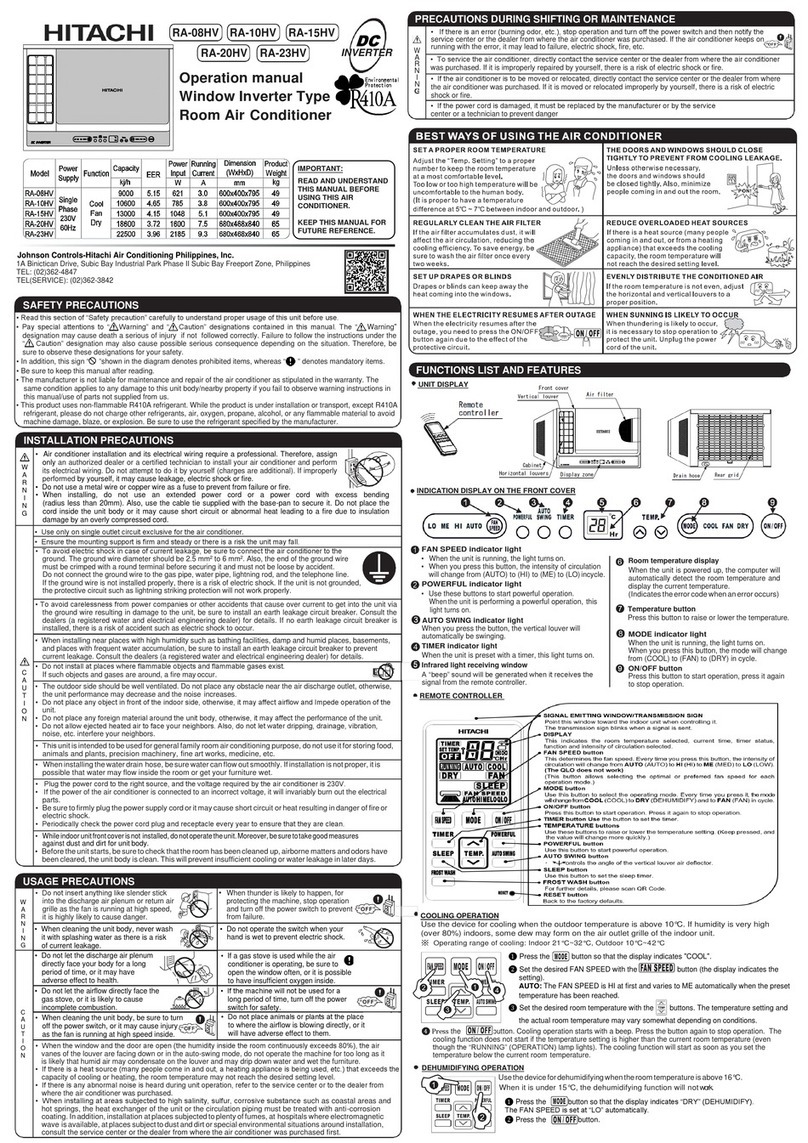

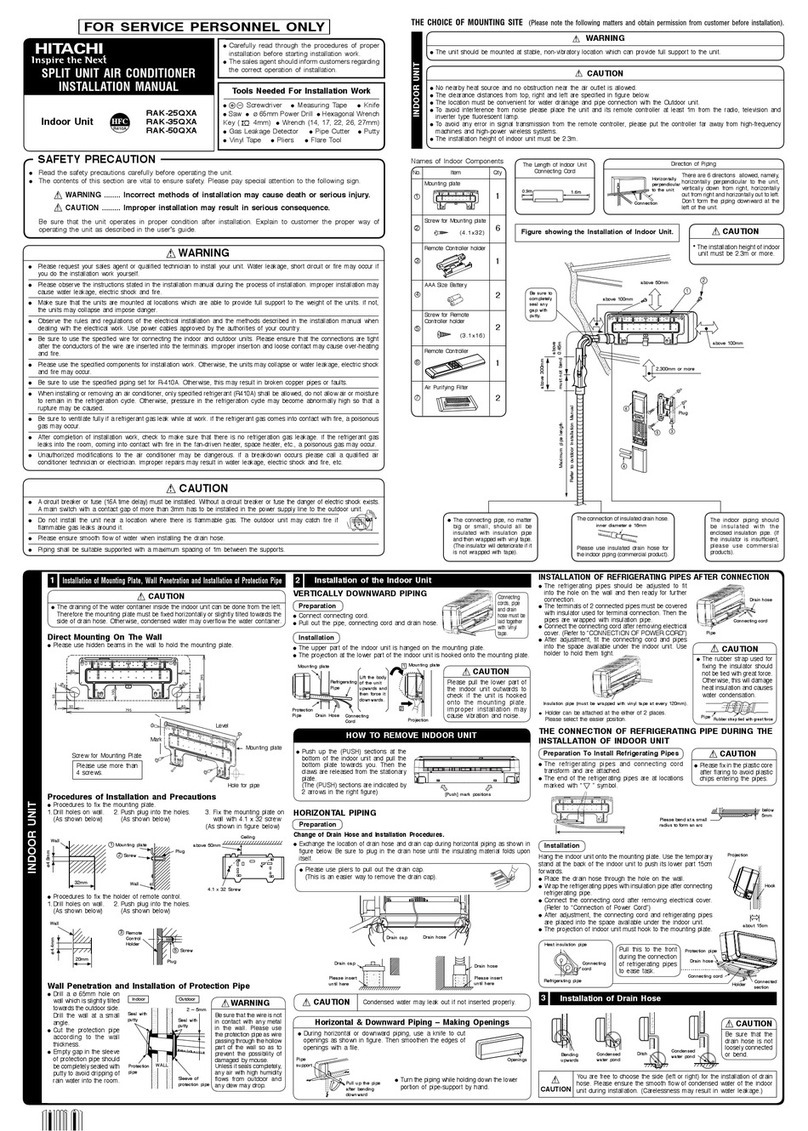

THE CHOICE OF MOUNTING SITE (Please note the following matters and obtain permission from customer before installation).

WARNING

zThe unit should be mounted at stable, non-vibratory location

which can provide full support to the unit.

CAUTION

zNo nearby heat source and no obstruction near the air outlet

is allowed.

zThe clearance distances from top, right and left are specified

in figure below.

zThe location must be convenient for water drainage and pipe

connection with the Outdoor unit.

zTo avoid interference from noise please place the unit and its

remote controller at least 1m from the radio, television and

inverter type fluorescent lamp.

zTo avoid any error in signal transmission from the remote

controller, please put the controller far away from high-

frequency machines and high-power wireless systems.

INDOOR UNIT

!

Accessories to indoor Unit:

Other optional parts for display panel

wired remote controller & wireless remote

controller SPX-URFG & SPX-RKD800

Display panel

Panel installation plate

Panel cover

Remote controller kit (wireless)

Remote controller kit (wired)

Item QuantityNo.

1

2

3

4

5

1

1

1

1

1

zInstall the indoor unit

with a proper clearance

around it for operation and

maintenance working space.

zIn case that the ceiling

board can not be detected

for servicing, prepare a

service access door below

the indoor unit for removing

the indoor unit.

Electrical Box

Service Access

Door (Min. 450)

Rear Side

Front Side

Min.

1000

Min.

1000

(130)

Min. 600

View from Top

Min.

600

1

2

3

4

5

6

7

8

Figure showing the Installation of Indoor Unit.

CAUTION

!

The indoor piping should be insulated with the

enclosed insulation pipe. (If the insulator is

insufficient, please use commercial products.)

zNeed a connect for refrigerant pipe, drain pipe and F cable in the ceiling after suspending the indoor unit. Arrange the

drain pipe, refrigerant pipe and F cable in their installation position.

zFor finishing the opening on the ceiling, arrange with the builder in detail.

zIf the ceiling is already completed, connecting cables between indoor and outdoor, piping and drain piping must be done

before the fitting indoor unit.

Opening on ceiling & suspension bolt

1

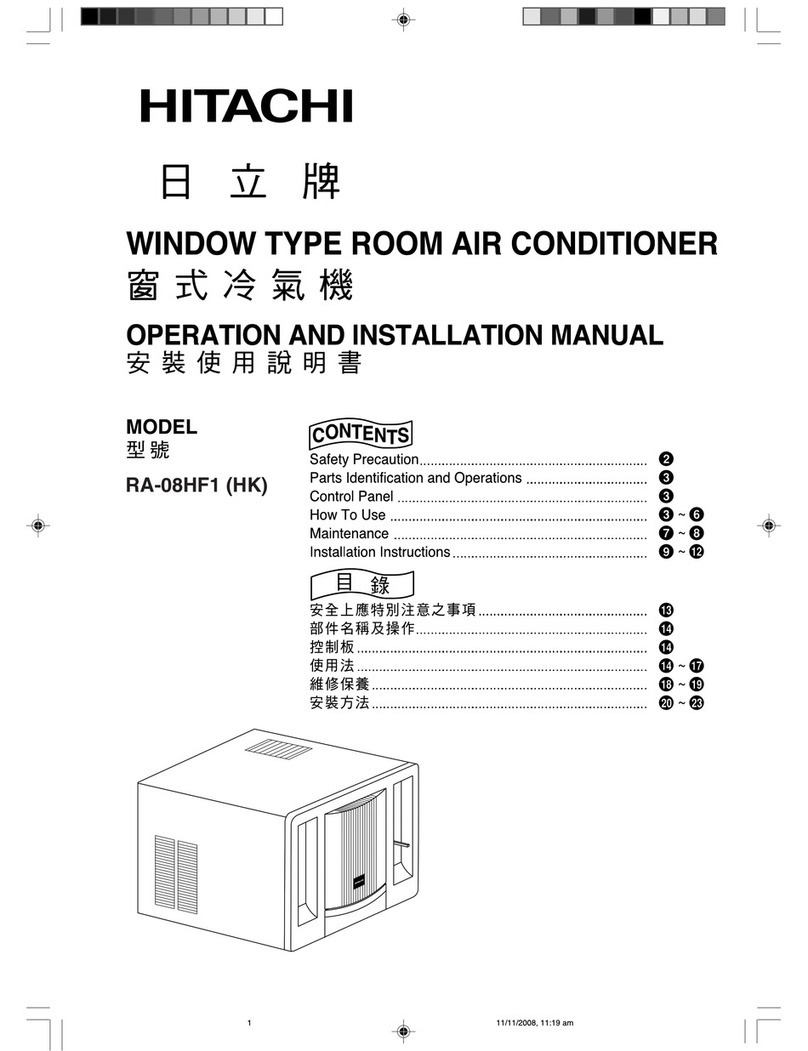

Wall Penetration and Installation of Protection Pipe

zDrill a ø 65mm hole on wall which is slightly tilted towards the outdoor side. Drill the wall at a small angle.

zCut the protection pipe according to the wall thickness.

zEmpty gaps in the sleeve of protection pipe should be completely sealed with putty to avoid dripping of rain water into the

room.

Make sure that the wire is not in contact

with any metal in the wall. Please use

the protection pipe as wire passing

through the hollow part of the wall so

as to prevent the possibility of damaged

by mouse.

Preparation for installing indoor unit

2

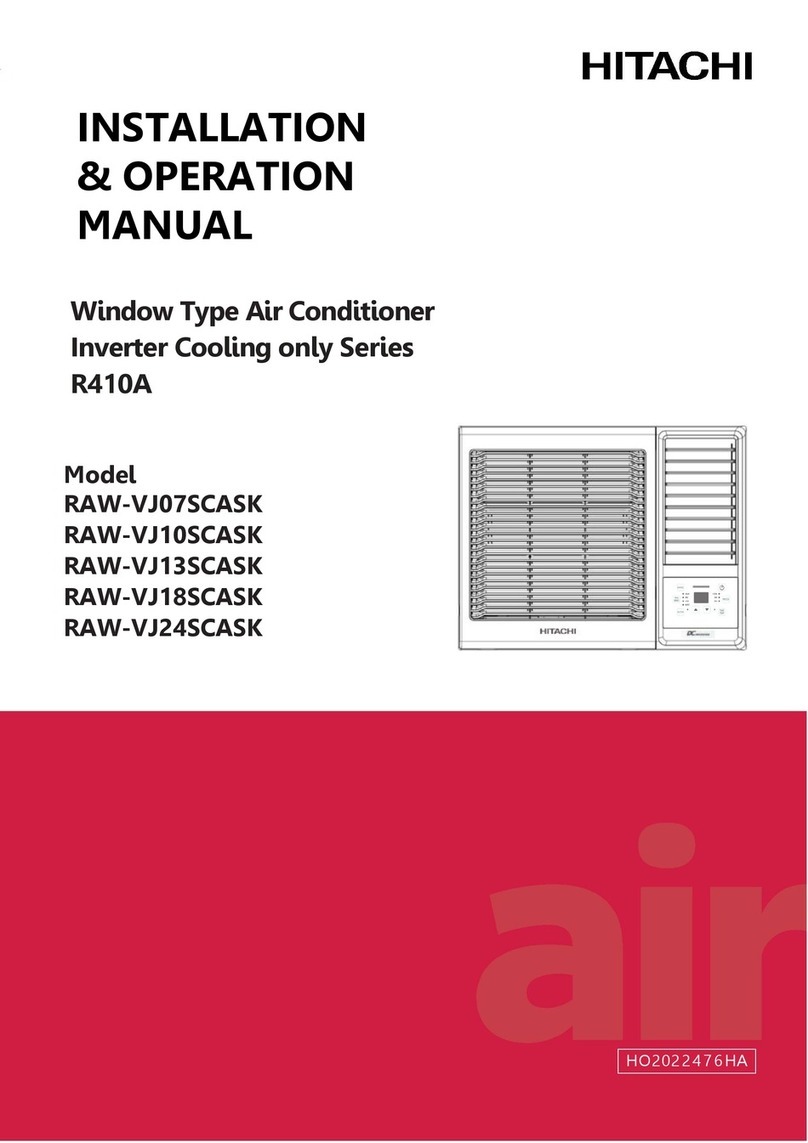

Installation of suspension bolts

zMake sure to reinforce furring of ceiling (frame : ceiling joints and supporter) to maintain level of ceiling and prevent vibration

of ceiling plate.

zSuspension bolts should be purchased in the field.

zRefer to diagrams shown below for length of suspension bolts.

zIn case of wooden frame zIn case of steel frame

Use a protection pipe (commercial product) to protect

against the following:

-Connecting cables touching the metal lath inside

the wall.

-A possibility where a mouse can bite the cables, as

these can cause an electrical shock or fire.

-Incomplete sealing, as high humidity can cause

the water to drip.

zIn case drain piping cannot be done smoothly due to obstacles, it can also be arranged outside of the main unit as shown

in the drawing below.

zMaximum drain-up length shall not more than 500mm height.

zWhen the relative humidity of inlet or ambient air exceeds 80%, apply an (field-supplied) auxiliary drain pan beneath the

indoor unit as shown below:

Drain pipe installation

zPrepare polyvinyl chloride pipe with a 32mm outer diameter.

zBe sure to roll an insulation (thickness 10mm or more) for the drain pipe at indoor side.

zAlways draw the drain pipe downward so that water flows smoothly. Fix it (ex. by hanger) to prevent a peak and trap.

!

!

CAUTION

No. Component’s Name

Washer (M10)

Screw (4mm)

Hose Clamp

Insulation (22IDx130)

Insulation (43IDx130)

Binder

Filter Holder

Screw for Filter Holder

8

16

1

1

1

10

2

2

Q’ty

CAUTION

Always install the indoor

unit level. Units not

installed level may leak.

!

CAUTION

zDischarge grille and suction

grille shall be covered by

insulation material to prevent

water drop.

!

Downward 1/25 ~ 1/100

Seal

Trap

Stagnant water

No insulation

Insulation (Thickness

10mm or more)

Suspension Bracket

Drain Piping (PVC Tube, VP25)

1/25 to 1/100 Down-Slope

(Field-Supplied)

(Field-Supplied)

(Field-Supplied)

(Field-Supplied)

(Field-Supplied)

90° Elbow Pipe (VP25)

Lift Piping For Drain-Up

(PVC Tube, VP25)

90° Elbow Pipe (VP25)

Indoor Unit

Drain Pan

Drain Pump Hose Clamp

To the Atmosphere

Auxiliary Drain Pan

(Field-Supplied)

(Max.) 374 to 500 (Drain-Up Length)

60 ~ 90mm square piece of lumber Insert 980 ~ 1470N

150 ~ 160mm (100 ~ 150kgf)

Reinforcing

bar

Concrete

Bend slip-

preventive metal

C type

metal

Long nut

Suspension bolt

(M10)

Suspension bolt (M10)

Suspension

bolt (M10)

Suspension

bolt (M10) Suspension

bolt (M10)

Hanger bolt

Angle

Angle

Nut

Nut

About 75

About 75

Angle

Ceiling Ceiling

H beam

Indoor Outdoor

WALL

Protection pipe

2 ~ 5mm

Seal with putty Seal with

putty

Sleeve of

protection pipe

(Unit : mm)

WARNING

CAUTION

CAUTION

CAUTION

This symbol shows that this equipment uses a

flammable refrigerant.

If the refrigerant is leaked, together with an external

ignition source, there is a possibility of ignition.

This symbol shows that the Operation Instructions

should be read carefully.

This symbol shows that a service personnel should

be handling this equipment with reference to the

Installation Manual.

This symbol shows that there is information

included in the Operation Manual and/or Installation

Manual.

Refrigerant piping must be protected

from physical damage. Install a plastic

cover or equivalent.

Be sure to

completely

seal any

gap with

putty.

Drain pipe

Must be installed separately.

Insulate indoor part of pipe

to prevent condensation.

zThe difference in height

between the indoor and

outdoor unit should be

kept below 20m.

zThe connecting pipe,

no matter big or small,

should all be insulated

with insulation pipe and

then wrapped with vinyl

tape. (The insulator will

deteriorate if it is not

wrapped with tape).

<

SIA2371: A

>

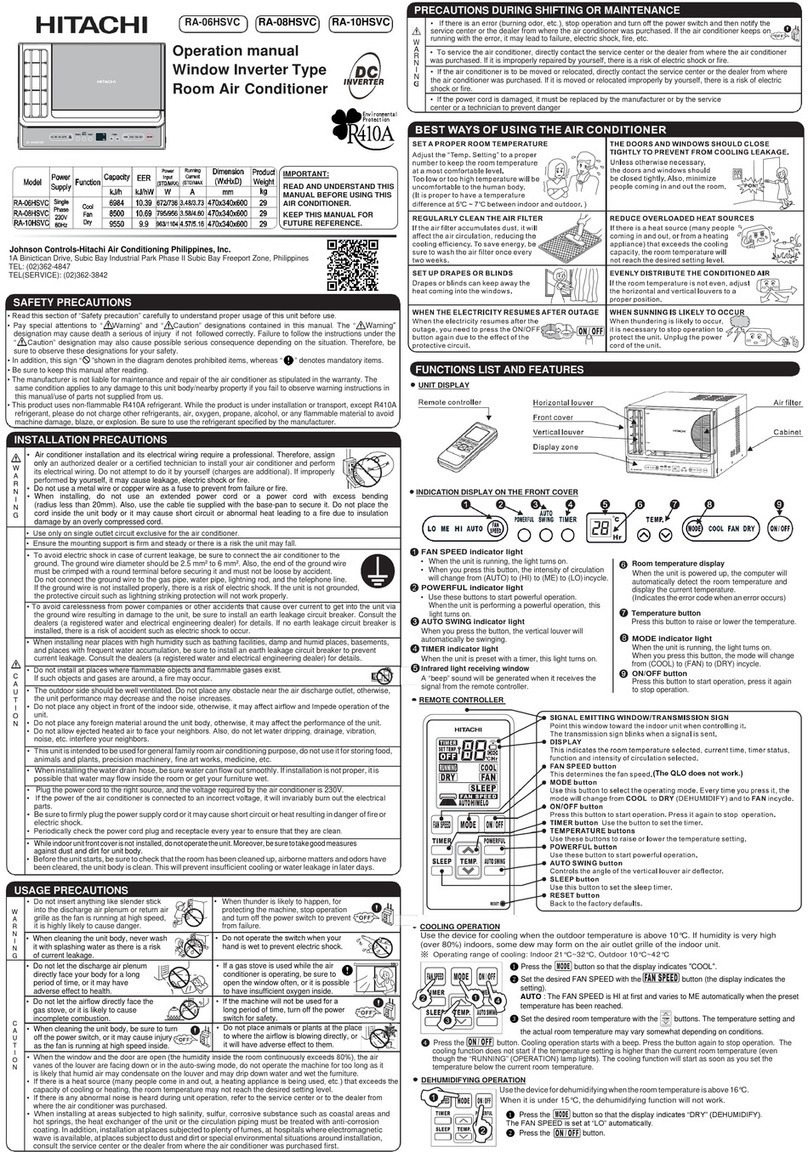

SAFETY PRECAUTION

zRead the safety precautions carefully before operating the unit.

zThe contents of this section are vital to ensure safety. Please pay special attention to the following sign.

WARNING ........ Incorrect methods of installation may cause death or serious injury.

CAUTION ......... Improper installation may result in serious consequence.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper way of

operating the unit as described in the user’s guide.

(50/60QHAE) Refrigerant pipe size (outer diameter): Narrow pipe, Liquid (ø6.35mm); Wide pipe, Gas (ø12.70mm)

(70QHAE) Refrigerant pipe size (outer diameter): Narrow pipe, Liquid (ø6.35mm); Wide pipe, Gas (ø15.88mm)

z

Flare nut must use a torque wrench without fail. Tighten with the specified tightening torque. If the flare nut is

tightened too much, after a long period of time, the flare nut breaks, Gas leakage, stagnation, touching fire,

rarely cause ignition.

z

Sharp bending of the pipe use the polyethylene rod, bend not crushed the pipe. Gas leakage from the crushed

part, stagnation, touching fire, rarely cause ignition.

z

Please request your sales agent or qualified technician to install your unit. Water leakage, short circuit or fire

may occur if you do the installation work yourself.

z

Please observe the instructions stated in the installation manual during the process of installation. Improper

installation may cause water leakage, electric shock and fire.

z

A brazed, welded, or mechanical connection shall be made before opening the valves to permit refrigerant to

flow between the refrigerating system parts. A vacuum valve shall be provided to evacuate the interconnecting

pipe and/or any uncharged refrigerating system part.

z

Mechanical connectors used indoors shall comply with ISO 14903. When mechanical connectors are reused

indoors, sealing parts shall be renewed. When flared joints are reused indoors, the flare part shall be re-fabricated.

z

Refrigerant tubing shall be protected or enclosed to avoid damage.

z

Make sure that the units are mounted at locations which are able to provide full support to the weight of the

units. If not, the units may collapse and impose danger.

z

Observe the rules and regulations of the electrical installation and the methods described in the installation

manual when dealing with the electrical work. Use power cables approved by the authorities of your country.

z

Be sure to use the specified wire for connecting the indoor and outdoor units. Please ensure that the connections

are tight after the conductors of the wire are inserted into the terminals. Improper insertion and loose contact

may cause over-heating and fire.

z

Please use the specified components for installation work. Otherwise, the units may collapse or water leakage,

electric shock and fire may occur.

z

Be sure to use the specified piping set for R32. Otherwise, this may result in broken copper pipes or faults.

z

When installing or removing an air conditioner, only specified refrigerant (R32) shall be allowed, do not allow

air or moisture to remain in the refrigeration cycle. Otherwise, pressure in the refrigeration cycle may become

abnormally high so that a rupture may be caused.

z

Be sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact with

fire, a poisonous gas may occur. Be aware that refrigerants may not contain an odour.

z

After completion of installation work, check to make sure that there is no refrigeration gas leakage. If the refrigerant

gas leaks into the room, coming into contact with fire in the fan-driven heater, space heater, etc., a poisonous

gas may occur.

z

Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call a qualified

air conditioner technician or electrician. Improper repairs may result in water leakage, electric shock and fire, etc.

z

A circuit breaker or fuse must be installed. Without a circuit breaker or fuse the danger of electric shock exists.

The external switch shall be incorporated to completely disconnect from power supply. It should disconnect all

poles, and a contact separation of at least 3mm must be present.

z

Do not install the unit near a location where there is flammable gas. The outdoor unit may catch fire if flammable

gas leaks around it.

z

Do not install the indoor unit in a machine shop or kitchen where vapor from oil or its mist flows to the indoor

unit. The oil will deposit on the heat exchanger, thereby reducing the indoor unit performance and may deform

and in the worst case, break the plastic parts of the indoor unit.

z

Please ensure smooth flow of water when installing the drain hose.

z

Piping shall be suitable supported with a maximum spacing of 1m between the supports.

CAUTION

!

!

Tools Needed For Installation Work

●Carefully read through the procedures of

proper installation before starting installation

work.

●The sales agent should inform customers

regarding the correct operation of installation.

z+ – Screwdriver ●Measuring Tape

●Knife ●Saw ●ø 65mm Power Drill

●Allen Key ( 4mm)

●Wrench (14, 17, 19, 22, 24, 27mm)

●Gas Leakage Detector ●Pipe Cutter

●Plastic Tape ●Pliers ●Flare Tool

Wireless remote controller

(optional)

Wired remote controller

(optional)

Refrigerant Gas Pipe Connection

Refrigerant Liquid Pipe Connection

Drain Pipe Connection

(Gas pipe)

(Drain pipe)

(Liquid pipe)

980 (for Suspension Bolt)

(for Suspension Bolt)

Unit : mm

(for Suspension Bolt)

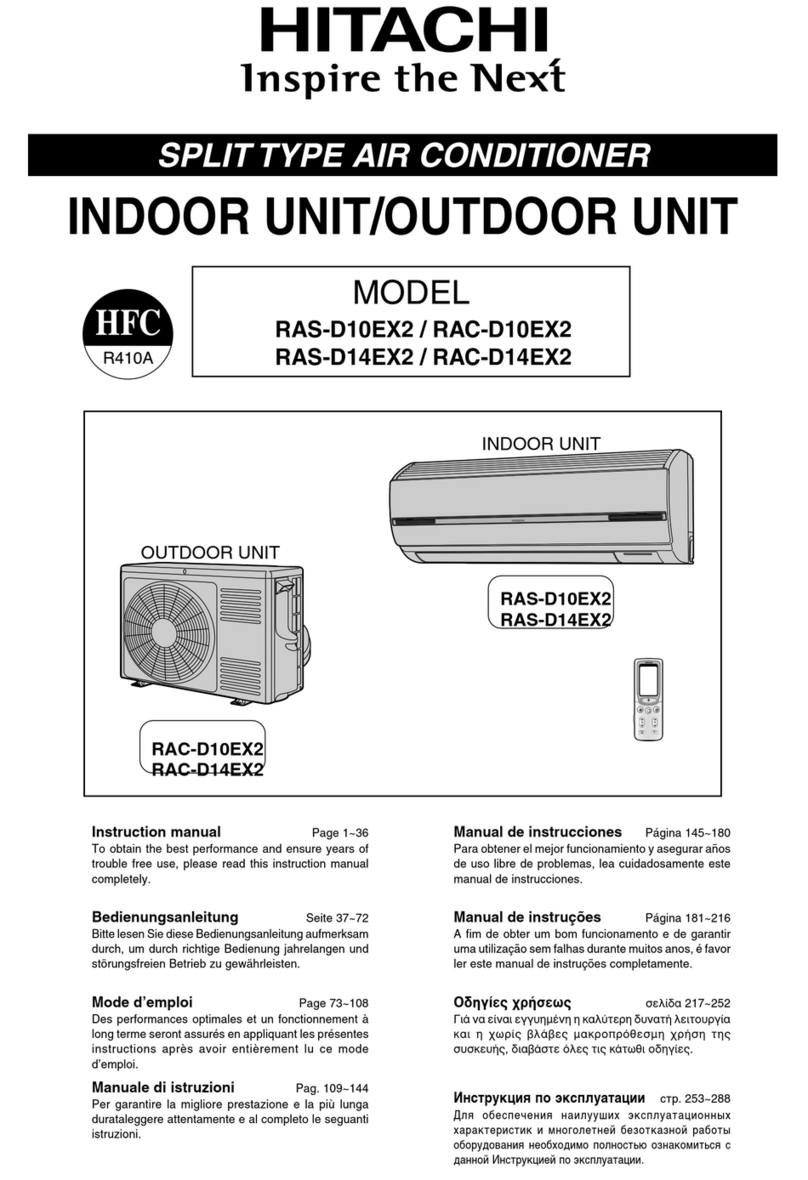

INSTALLATION

MANUAL

SPLIT UNIT AIR CONDITIONER

INDOOR UNIT

RAD-DJ50QHAE

RAD-DJ60QHAE

RAD-DJ70QHAE

EN INSTRUCTION MANUAL

FOR SERVICE

PERSONNEL ONLY