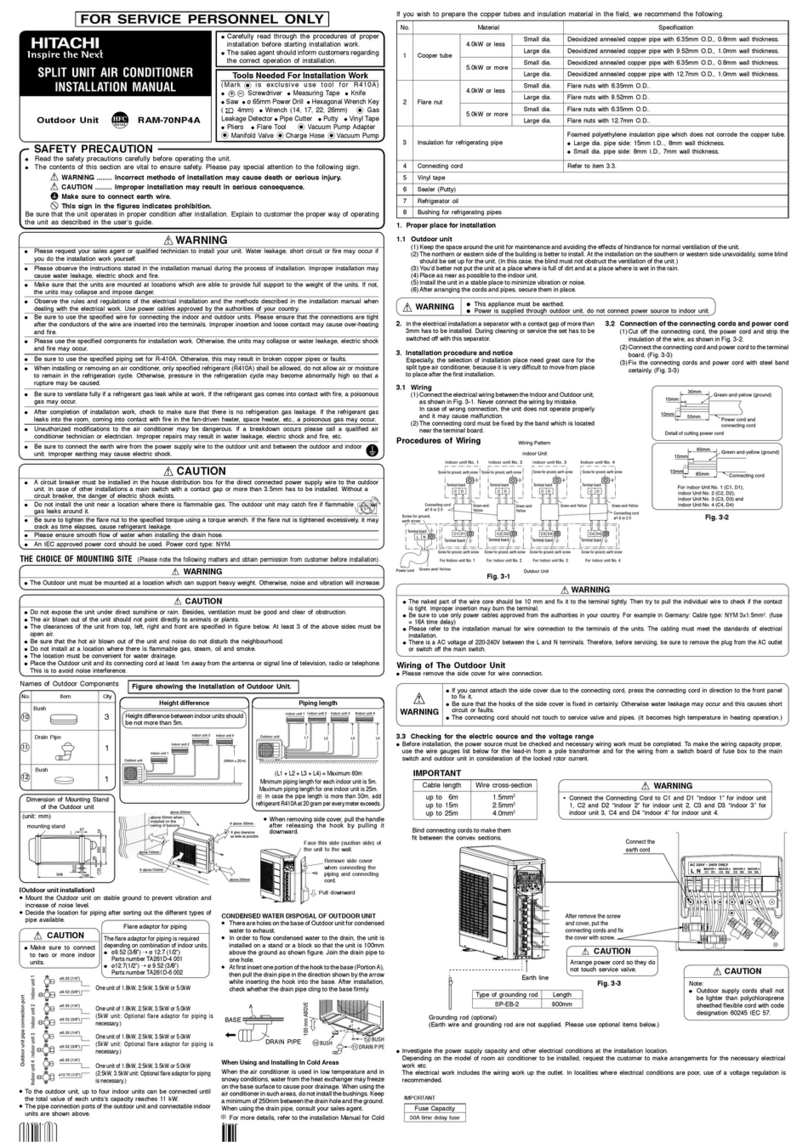

To prevent current leakage:

⚫To avoid carelessness from power companies or other accidents that cause over current to get into the unit via the earth

wire resulting in damage to the unit, be sure to install a circuit breaker. Refer to the dealers (the qualified technicians) for

details.

⚫To prevent electric shock in case of current leakage, the outdoor unit must be connected with an earth wire with wire

specification of 2.5mm2to 6mm2.

(When hooking up the earth wire, the installer must first handle the end tip of the wire. After crimping the wire with a ring

terminal, make sure to screw down the earth wire tightly to complete grounding at the place marked with a grounding

sign near the access panel combination or the valve base combination.)

⚫When installing near places with high humidity such as bathing facilities, damp, humid places, basements, and places

with frequent water accumulation, be sure to install a circuit breakers preventing leakage. Refer to the dealers (the

qualified technicians) for details.

1. To ensure your safety, this product must not be used in the highly humid areas such as laundry room and bathroom,

etc.

2. The earth wire must not be connected to the following positions:

⚫Water pipes: If there is a plastic pipe in the pipelines, do not connect the earth wire to the pipeline.

⚫Gas pipes: There is risk of explosion after ignited.

⚫Ungrounded neutral lines in the electrical circuit panel, earth wires of the telephone line and lightning rods, etc, which

may have large amount of current flowing through tending to cause danger when lightning strikes or by other factors.

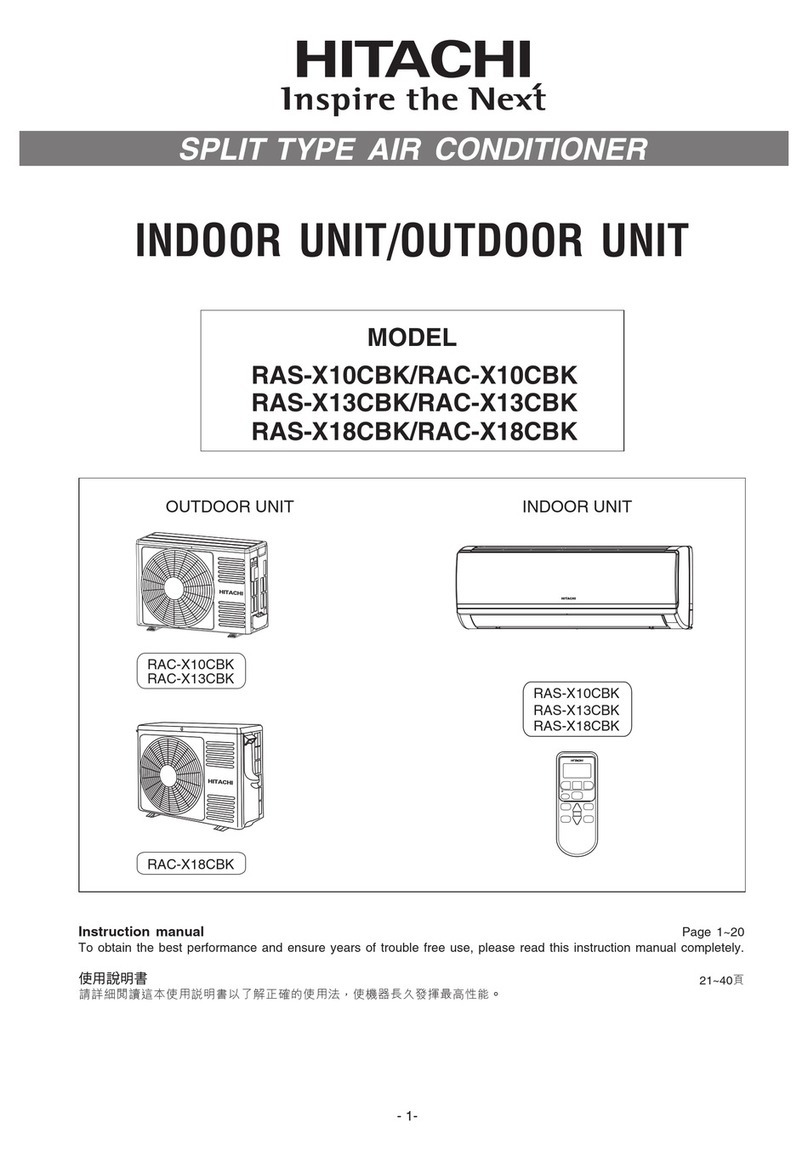

⚫The units must be installed at the places where sufficient

supports are available, vibration-free, firm and stable places.

⚫There are no heat sources, fumes in the vicinity and no barriers

around the air outlet.

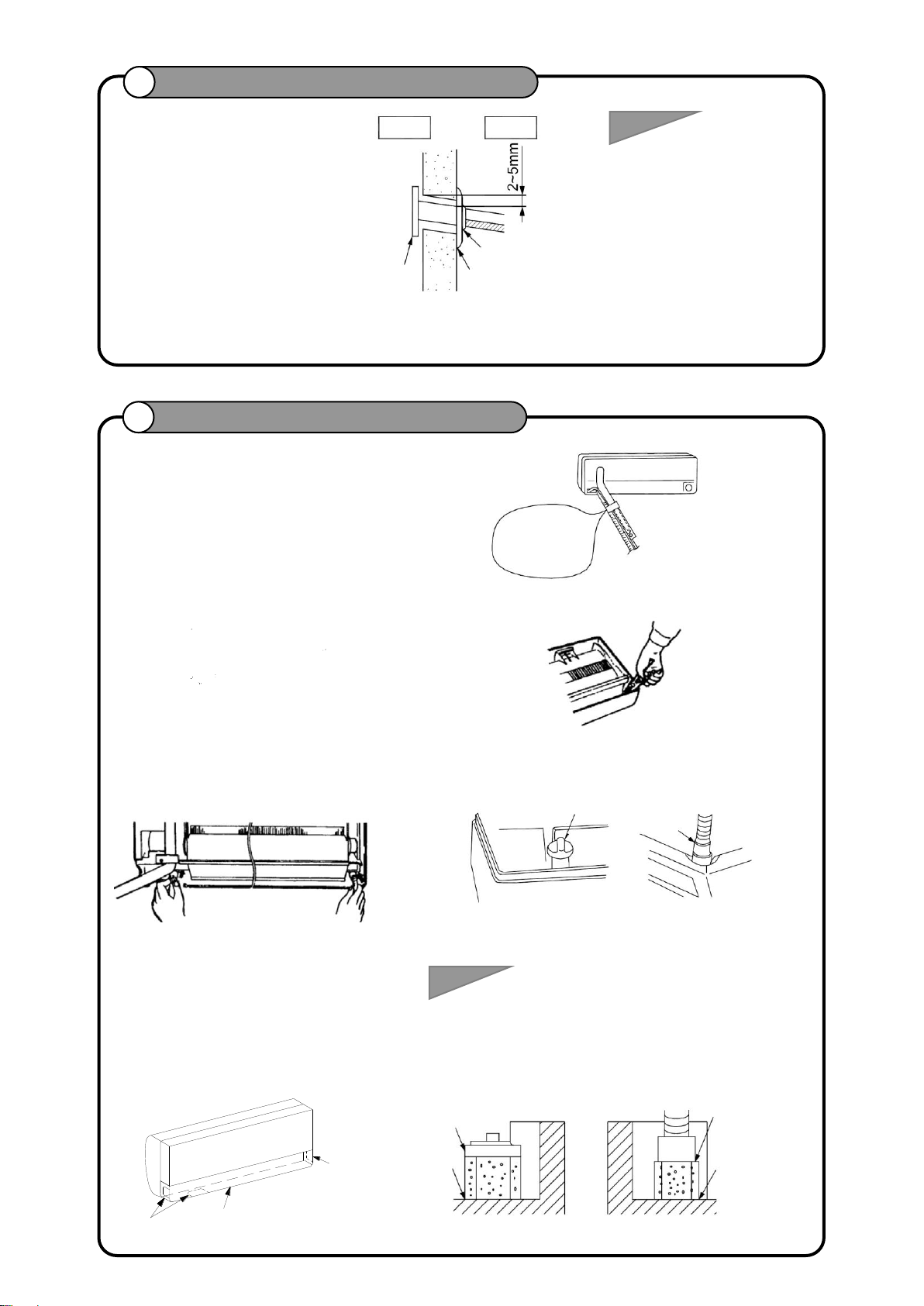

⚫There should have some clearance in the distance as indicated

by in the diagram ( page 4) on the top, left and right

sides of the unit.

⚫Places where it is convenient for the unit to drain water and to

connect piping of the outdoor units

⚫To avoid noise effect, keep the unit and the remote controller

1m or above away from TV and radio, etc.

⚫To avoid errors in the remote controller; keep the controller

away from high frequency machines and wireless machines

with high power output.

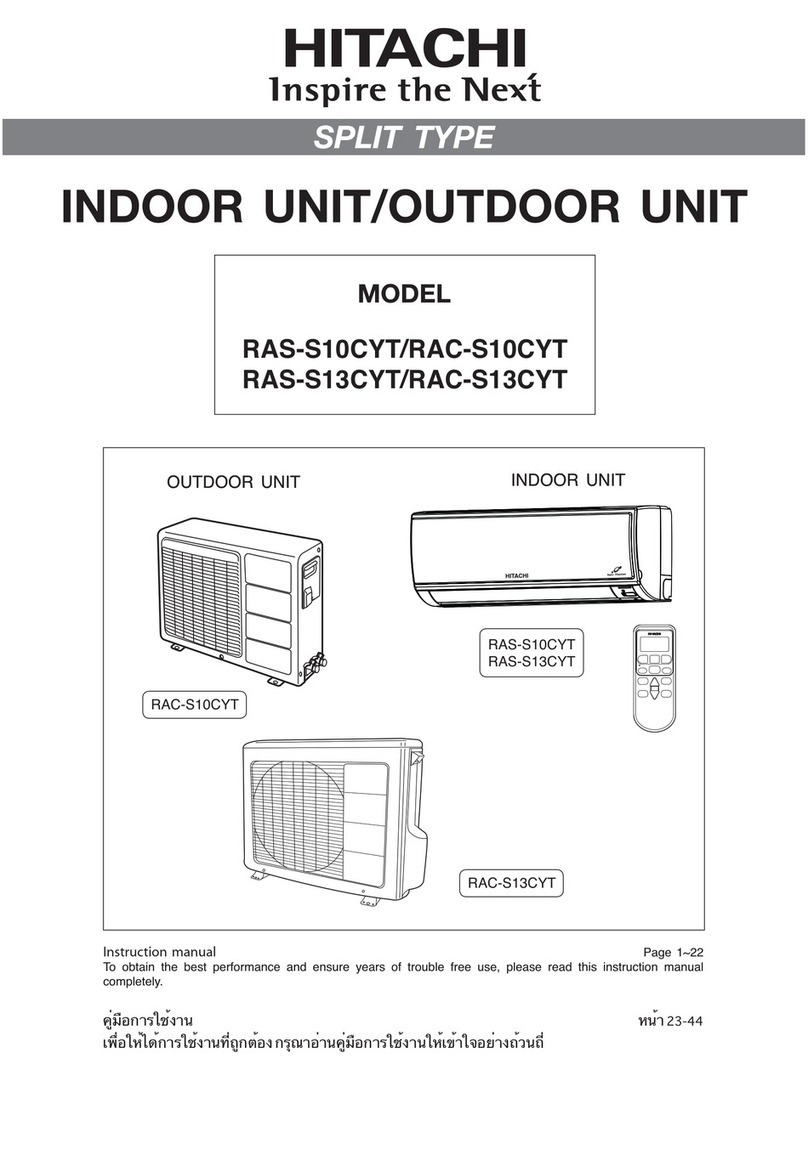

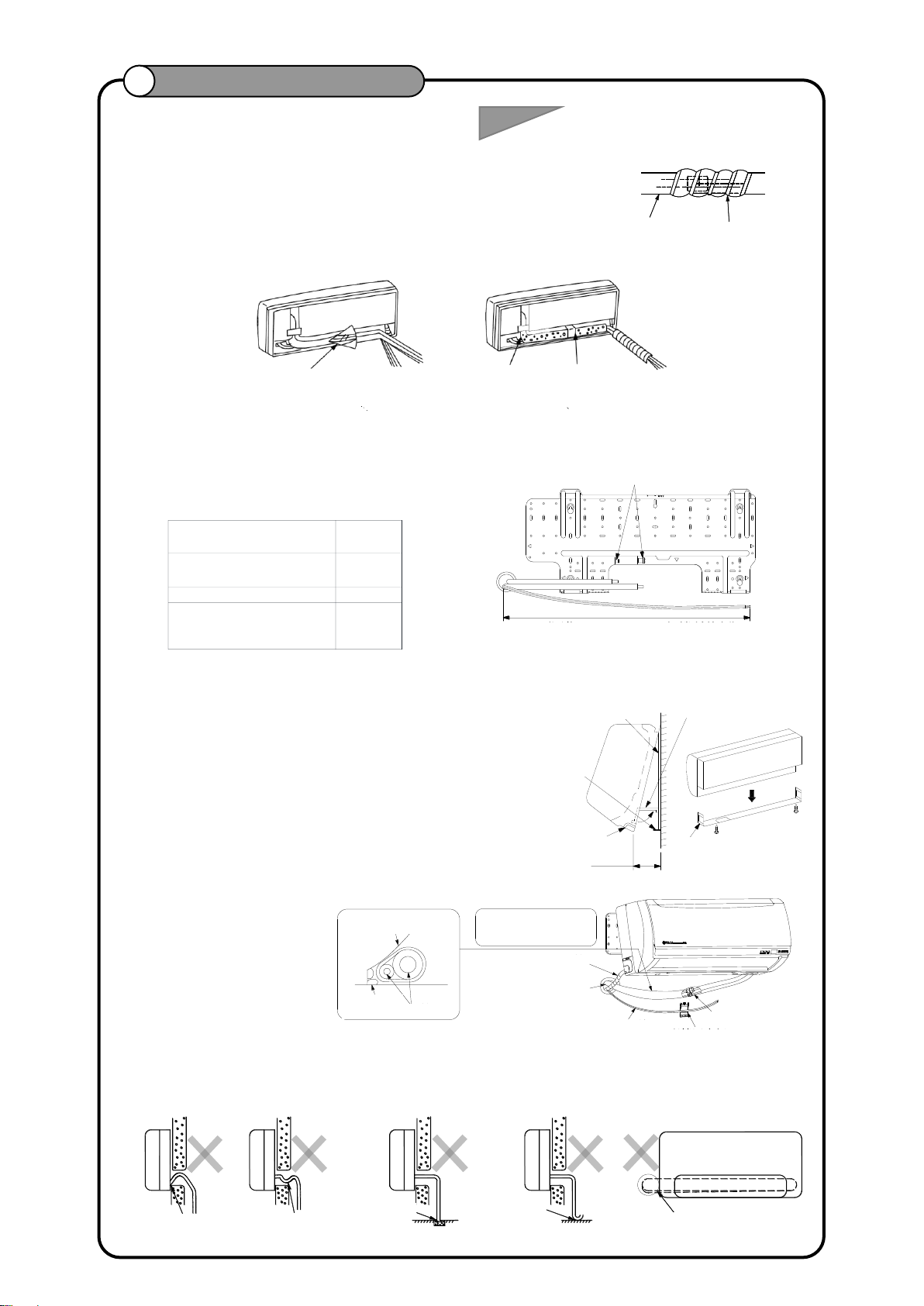

⚫Make sure the pullout direction of the pipes:

There are four pullout

directions for the pipes -

straight backward,

downward, leftward and

rightward.

⚫Do not install the unit at the places easy to expose rain or

direct sunlight, but at the places where there are frequent

airflows.

⚫The airflow must not face directly to animals and plants.

⚫On the top, left, right, front and rear sides of the unit, there

must leave clearance in the distance as indicated in the

diagram ( page 4). At least two sides should be open,

where one side is for the outflow.

⚫The outflow air and noises must not annoy neighbors.

⚫The units must not be installed at the places where flammable

gas, vapor, dust and fumes are available.

⚫The drain hose must be kept unclogged.

⚫The outdoor units must be installed at the places capable of

sustaining heavy weight, otherwise, the noise and vibration will

be amplified, tending to cause the unit to fall or personal injury.