Do not place the piping

directly on the ground.

Straight length

min 0.5 m

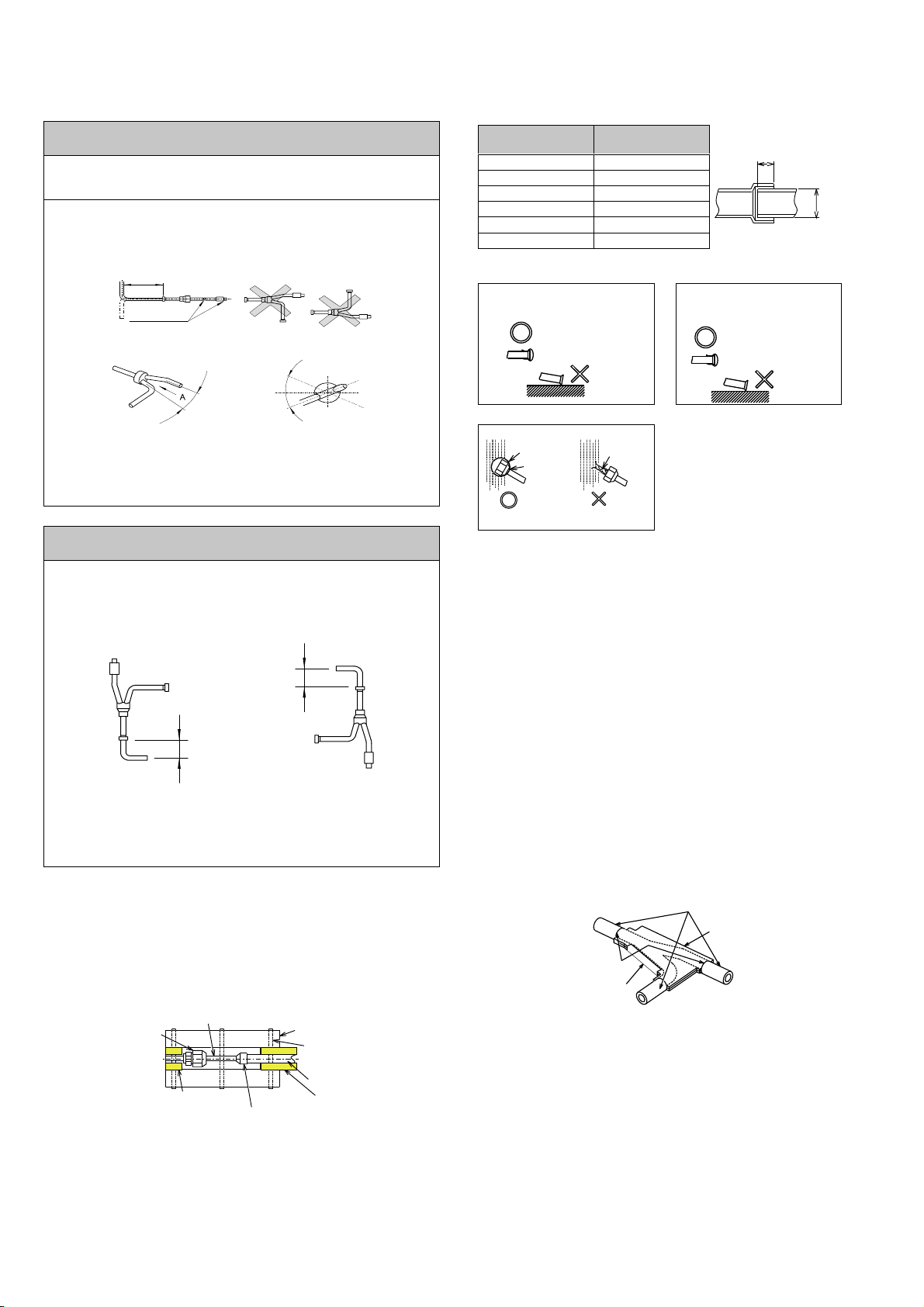

4.2. Installation Position

Horizontal Installation

Locate the branch pipes on the same horizontal plane. (Inclination

Max. 30°) Make the straight length a minimum of 0.5 m after the

vertical bend.

Vertical Installation

4.3. Piping Connection

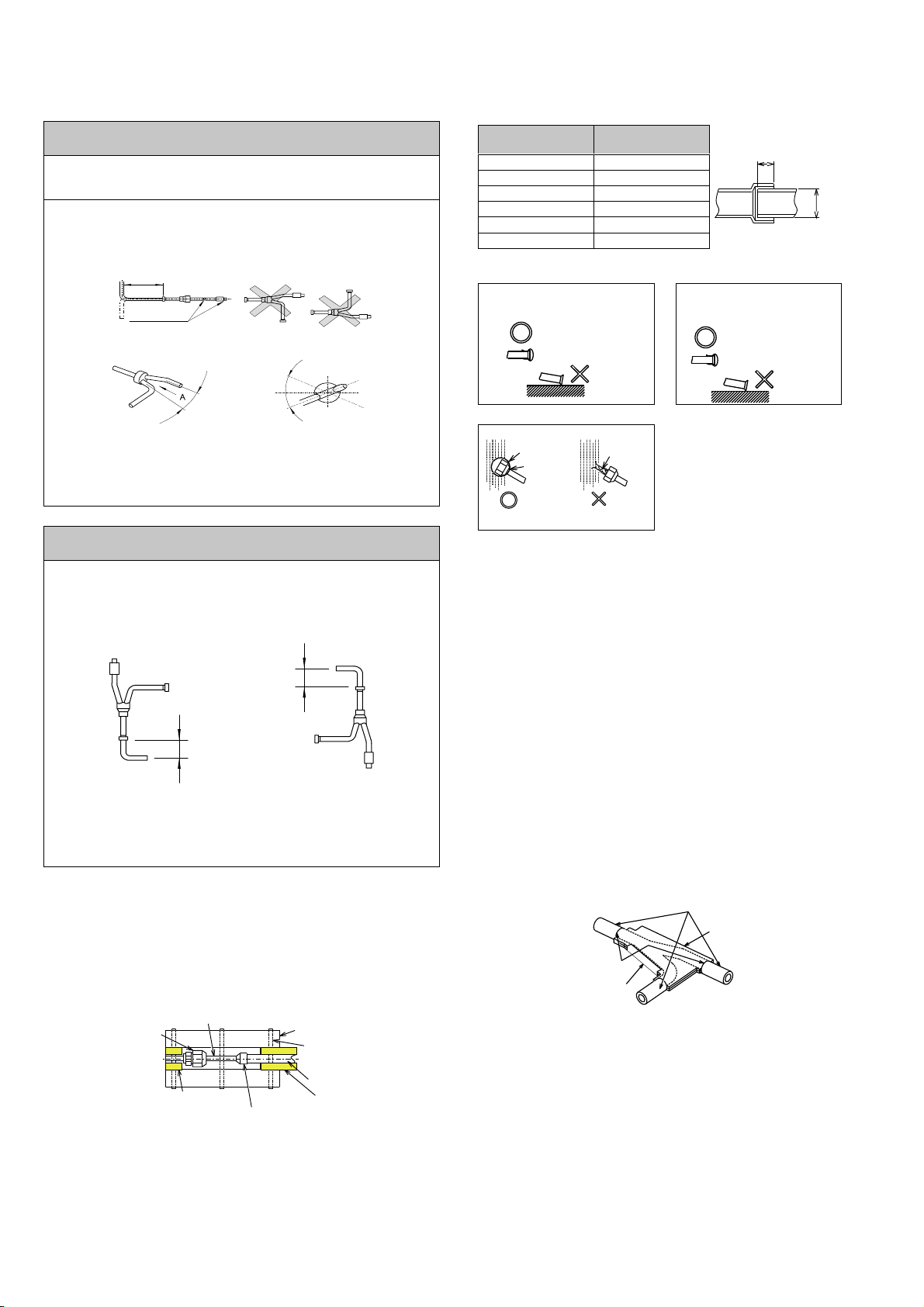

■When connecting liquid piping for the unit with a capacity of 2HP or

smaller and with the length of piping is 15 meters or longer, apply a

piping size of φ9.53mm. Fix the connecting pipe as shown in the

figure below. Utilize the insulation attached to the Multi-Kit.

Make flares after attaching flare nut to

the connecting pipe. (Accessory) Insulate this part with insulation.

Fix this part with the

cord band or vinyl tape.

Field-supplied refrigerant piping.

Field- upplied insulation

Utilize the flare nut

of the indoor unit.

Indoor Unit

Brazing

Insulation attached

to indoor unit.

(Accessory)

□(1) Utilize clean copper pipes without any moisture and foreign

materials on the interior surface of pipes.

When connecting refrigerant piping, cut copper pipes with a pipe

cutter and blow the pipes with nitrogen, remaining no dust inside the

pipe. Do not utilize a saw and a grindstone and others which

causes a great amount of powder.

□(2) When cutting the pipe, secure the part for brazing as shown in

the following table.

A: Outer

Diameter

B: Minimum

Depth

5 O.D. <8 6

8 O.D. <12 7

12 O.D. <16 8

16 O.D. <25 10

25 O.D. <35 12

35 O.D. <45 14

B

A

Cautions for Refrigerant Piping

Put the cap

or vinyl tape.

Incorrect

Correct

Put the cap

or vinyl tape.

Incorrect

Correct

Cap or Vinyl

Bag Rubber

Rain

IncorrectCorrect

Rain can

invade.

Band

□(3) Make sure that the stop valves are closed completely.

□(4) Blow the inside of the pipes with nitrogen when brazing.

#

DANGER:

Check for the refrigerant leakage in detail. If a large refrigerant

leakage occurs, it will cause difficulty with breathing or harmful

gases would occur if a fire were being used in the room.

□(5) An air tight test pressure of this product is 4.15MPa.

□(6) Attach insulation packed with Multi-Kit to each branch utilizing

a vinyl tape.

Also attach insulation to piping supplied in the field.

Set up the insulation closely by field supplied tape.

!

NOTE:

When polyethylene foam is applied, a thickness of 10mm for

the liquid piping and 15mm to 20mm for the gas piping is

recommended. (Utilize insulation for gas piping with a heat

resistance of 100℃)

Field upplied Insulation

Factory upplied Insulation

Tape (Accessory)

Do not make a space.

"

CAUTION:

(1) When the temperature of the piping decrease to room

temperature, perform insulation work. If insulation work is

performed immediately after brazing, insulation can melt.

(2) If the ends of piping system are open to the atmosphere for

a while after accomplishing piping work, securely put caps

or vinyl bags to the ends of the piping, avoiding the intrusion

of moisture and dust.

After installing work has been finished, it is recommend that

this manual shall be retained carefully by a customer.

ENG -P5413706, PMML0099A-rev.2-10/04

When installing the pipe

through the wall, secure a

ca

at the end of the

i

e.

INCORRECT

Upward

Upward

Downward

Downward

CORRECT

Inclination

Max. ±30°

Inclination

Max. ±30°

CORRECT CORRECT

Straight length

min 0.5 m

Straight length

min 0.3 m

Downward

Downward Branch

Downward

Upward Upward

Downward Branch