HiTECH Technologies TC-136 User manual

HiTECH Technologies, Inc.

OPERATING MANUAL

Model TC-136

THERMOELECTRIC MODULE

TEMPERATURE CONTROLLER

HiTECH Technologies, Inc.

301 Oxford Valley Road

Yardley, PA 19067-7706

Tel: 215. 321. 6012 - Fax: 215. 321. 6067

Technical support: 800.755. 4507 or 888. NIVELCO

Email: [email protected]

Copyright©2002

HiTECH Technologies, Inc.

NOTES:

16

Features ................................................................................... 1

Description ................................................................................... 2

Block Diagram ................................................................................. 4

RS232 Communications Connections ............................................... 5

Mechanical Package Drawing ........................................................... 6

Customer Hook-Up Drawing ............................................................ 7

Expansion Connector Wiring Diagram .............................................. 8

Menu Tree with Factory Default Settings ........................................... 9

Set-Up Instructions ........................................................................... 10

Appendix A - Troubleshooting Communications Port ........................ 13

Application Note 353 (5 Minutes to PID Tuning) ............................... 14

TABLE OF CONTENTS

In no event shall HiTECH be liable for any damages whatsoever (including without limitation, damage for

loss of business profits, business interruption, loss of business information, or any other pecuniary loss)

arising out of the use or inability to use this HiTECH product, even if HiTECH has been advised of the

possibility of such damages.

Integral Reset monitors the difference between the set point and the actual temperature. Its

function is to slowly change the output power until the delta between actual temperature and

set temperature is zero.

The function works by integrating the error signal at fixed intervals. These intervals are

expressed in repeats/minute. The acceptable range for the TC-136 is 0.01 to 10 repeats /minute.

Start with a setting determined by the following formula.

Integral Reset = 1/ 2(period)

Note: Period is expressed in minutes.

Example: The system‘s period of oscillation with narrow bandwidth was 75 seconds.

Therefore the suggested Integral Rate is

Integral Reset = 1/ 2(1.25 minutes)

Integral Reset = 0.625 repeats/minute

For slower response reduce the number of repeats per minute.

NOTE: DERIVATIVE RATE IS DIFFICULT TO APPLY. IF YOU ARE NOT EXPERIENCED

IN PROCESS CONTROL, ASK FOR HELP NOW!

Derivative Rate senses the rate of change of the temperature and allows the controller to

anticipate power needed to compensate for rapid changes in system loading. This term is

generally used only on very sluggish systems or where very quick response is necessary.

The acceptable range for the TC-136 is 0.01 to 10 cycles/minute.

To determine an appropriate derivative rate, use the following formula.

Derivative Rate = Integral Reset / 10

For the example above the Derivative Rate would be .06 cycles per minute.

The Derivative function is difficult to use and often causes more trouble than it is worth!

15

Page

••

••

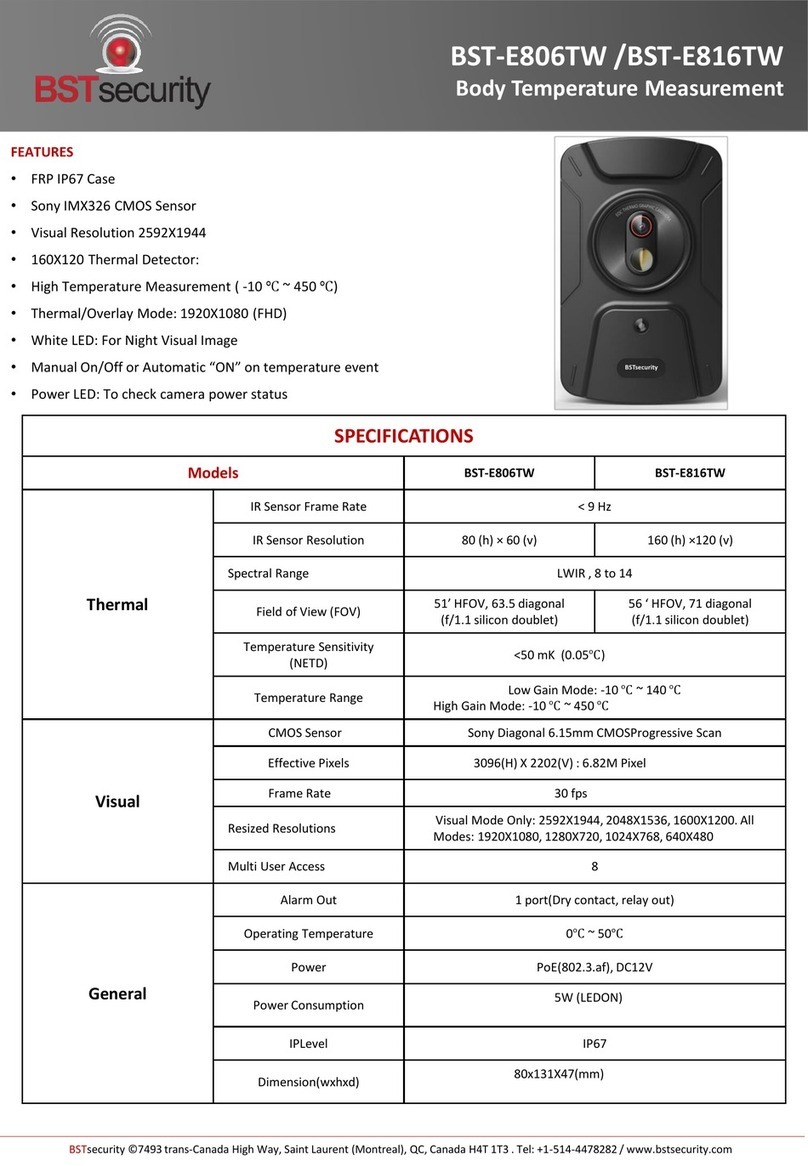

•INPUT VOLTAGE FROM 12 TO 28 VOLTS DC

••

••

•SELF-CONTAINED, 0.1 TO 25 AMPERE LOAD RATING

••

••

•PC PROGRAMMABLE VIA RS232 COMMUNICATIONS PORT

••

••

•BI-DIRECTIONAL CONTROL FOR HEATING AND COOLING APPLICATIONS

••

••

•SOLID STATE “H” BRIDGE OPERATION

••

••

•CONTROLTEMPERATUREOF-20° TO 100°C WITHTS67 SERIESTHERMISTOR SENSORS

-40°TO 70°C WITH TS141 SERIES THERMISTORSENSORS

••

••

•PROPORTIONAL(P), INTEGRAL (I),AND DERIVATIVE(D)CONTROL THATCAN BE

SELECTED AS P, PI, PD, OR PID; ON/OFF WITH AN ADJUSTABLE HYSTERESIS

••

••

•TEMPERATURE RESOLUTION OF 0.05°C.

••

••

•PULSE WIDTH MODULATION OF OUTPUT

••

••

•SELECTABLE MODULATION FREQUENCY OF 675 Hz OR 2700 Hz

••

••

•CONTROL STABILITY OF ±0.05°C.

••

••

•1500 VAC ISOLATION OF RS232 COMMUNICATIONS INTERFACE

••

••

•CONTROLS UP TO 680 WATTS

••

••

•SET TEMPERATURE SELECTABLE

••

••

•PC SET WITH CONTROLLER STAND-ALONE OPERATION

••

••

•REMOTE USER SET TEMPERATURE POTENTIOMETER

••

••

• 0 V TO 5 V ADJUSTABLE RANGE

••

••

•4 TO 20 MA CURRENT LOOP

••

••

•DIFFERENTIAL TEMPERATURE CONTROL

••

••

•NO COMPUTER PROGRAMMING EXPERIENCE IS REQUIRED TO USE THE COMMUNICATIONS

SOFTWARE PROGRAM

••

••

•COMMAND SET IS PROVIDED SO PROGRAMMERS MAY CREATE THEIR OWN SOFTWARE

INTERFACE OR EMBEDDED CONTROLLER APPLICATIONS

••

••

•PC CONFIGURABLE ALARMS FOR 5 VOLTS DC AT 25 MA

••

••

•ALARM CANCEL: SELECTABLE VIA PC OR REMOTE CONTACTS

••

••

•NON-VOLATILE MEMORY RETENTION OF PARAMETERS

FEATURES:

1

APPLICATION NOTE 353

5 Minutes to PID Tuning of the TC-136 Controller

TuningtheModel TC-136 temperaturecontrollerinvolvesthreevariables.(P)ropotional

bandwidth, (I)ntegral action, and (D)erivative rate.

The control algorithm sums the three values of these terms to determine the output power.

P + I + D = % Power Applied

Most applications work satisfactorily with only the “P” and “I” values used.

Start the tuning process by setting the Integral and Derivative functions to zero.

Proportional Bandwidth is defined as the temperature range around the setpoint where the

controller modulates (proportions) the output power. In a heating application, if the temperature

is above the proportional band, the controller output is OFF. If the temperature is below the

proportional band, the controller output is ON.

Each thermal system has its own time constants determined by the thermal mass of the

components and the placement of the sensor relative to the load. To tune the system the

bandwidth must be wide enough that the controller can sense a change and react to it before the

temperature drifts outside the bandwidth. If the bandwidth is too small the output will oscillate

above and below the setpoint, never settling into control.

The bandwidth range of the TC-136 is 1°C to 100°C. The units are shipped with a default setting

of 20°C.

Assuming the controller is configured for your requirements, start the tuning process by

applying power with the default settings and observing the system’s response. If the system

comes into the proportional band and maintains a steady temperature near setpoint, without

over shoot, the bandwidth setting is satisfactory or too large. Reduce the bandwidth setting until

the system just begins to oscillate. At this point, the bandwidth is too small. Note the bandwidth

setting that just caused the system to oscillate, record the period of oscillation for use in

determining the Integral Reset setting. To set the proportional bandwidth, multiply the current

bandwidth setting by 1.5 and use it as your new bandwidth setting. The system should come into

control and maintain a steady temperature near the setpoint.

14

GENERAL DESCRIPTION

Model TC136 is a bi-directional control for independent thermoelectric modules or in conjunction

with auxiliary or supplemental resistive heaters for both cooling and heating applications. The “H”

bridge configuration of the solid state MOSFET output devices allows for the bi-directional flow of

currentthrough thethermoelectric modules. Highly efficientN-channel outputdevices are usedfor

thiscontrol mode.

This controller is PC programmable via an RS232 communication port for direct interface with a

compatible PC. The RS232 communications interface has 1500 VAC isolation from all other

electronic circuitry minimizing interference from noise or errant signals caused by common ground

loops. The easily accessible communications link permits a variety of operational mode configu-

rations. Field selectable parameters or data acquisition in a half duplex mode can be performed.

This controller will accept a communications cable length in accordance with RS232 interface

specifications.

Once the desired set parameters are established, the PC may be disconnected and Model TC-136

becomesaunique,stand-alone controller. Allparametersettingsareretainedinnon-volatile memory.

The user friendly, communications software requires no prior programming experience to estab-

lish operation. A command set is provided for qualified personnel to program a software inter-

face or use as an embedded control.

Mechanically, the control printed circuit board is mounted to a metal bracket that is suitable for

either horizontal or vertical orientation. Input and output connections are accessible via screw

type terminal strips, fast-on terminals, and a .100 center connector.

TECHNICAL DESCRIPTION

ModelTC-136 iscapable of operatingfrom an inputsupply voltageof 12 through28 VDC,common

tomany available thermoelectricmodules. Theself-contained MOSFEToutputdevices deliver load

currents from 0.1 to 25 amperes (NOTE: consult appropriate installation instructions for power

supply and heat sinking requirements for high current operation). This unit will control total load

power up to 680 watts with a finite temperature resolution of 0.05°C.

The output signal to the thermoelectric module is Pulse Width Modulated and is PC selectable for

either 675 Hz or 2700 Hz operation. Pulse Width Modulation averages the amount of energy

provided to the module and reduces the extreme temperature excursions that are experienced

with an “on / off” system. This tends to extend the life and reliability of the thermoelectric devices.

The PWM control scheme affords control accuracy to within ±0.05°C. at the control sensor.

Thecontroller tuningstructure allows designationof a varietyof controlfeatures. Thecomputer set

2

APPENDIX A

Troubleshooting Communications Port

Error Message Cause Solution

Comm Port Timeout No power to TC-136 Apply power to TC-136, review

Customer Drawing for proper hookup.

Comm Port Timeout Wrong Comm Port Selected Check Computer hardware settings

and set to the correct Comm Port.

Comm Port Timeout Incorrect wiring of the Comm Port

to the Computer.

Check for the correct wiring from

JP3 to the Computer.

Comm Port Open Error No Comm Port available at this

port setting

Check Computer hardware setting

and set to the correct Comm Port.

13

value provides for manual control of the output, either polarity, from 0% to 100% of load power.

Proportional bandwidth (P) in degrees, integral reset (I) in repeats per minute, and the derivative

rate (D) in minutes may be configured for P, PI, PD, or PID control. In addition, a deadband control

(on/off) with an adjustable hysteresis may be selected. Differential temperature control is offered

when two input sensing thermistors are chosen.

Acontrol temperaturerange of –20°Cto 100°C (TS67series probe)or-40°C to70°C (TS141series

probe) is standard when using an HiTECH thermistor sensor for the PC’s primary set temperature.

Additional external set temperature input types may be selected. They include a remote set tem-

peraturepotentiometer,a0to 5 VDCsignal, and a0 to 20ma current loop. Thesesecondary inputs

are used to define and “map” the secondary input to an adjustable temperature range. Differential

settemperaturecontrol may alsobeselected from thisconfigurationmenu. All temperatures maybe

consistently displayed in °C. or °F.

Differential control is accomplished by selecting the primary set temperature with the second

thermistor input and establishing the offset with the computer set temperature. The unit will

control the differential between Input 2 (reference temperature) and Input 1 (actual system tem-

perature).

Two types of control output modes may be selected. This determines the direction of the current

flow through the thermoelectric module during the heat cycle. This current flow may be from Wire

Point WP1 (+) to Wire Point WP2 (-). Alternatively, this current flow may be reversed from WP2

(+) to WP1 (-) as selected in the configuration menu.

Several alarm types may be selected which provide a 5 VDC output, rated for 25 ma of current.

They consist of no alarm function, tracking alarm, and fixed value alarm. Alarm set temperature

values are entered in the setup menu. The computer-controlled selection is available for addi-

tional embedded controller input/output options. The alarm setup menu also provides for selec-

tion of an alarm latching condition. The alarm sensor may be either the control temperature

sensor or a secondary thermistor sensor.

The various alarms have the ability to determine the status of the output power to the thermoelec-

tric module or auxiliary heater. Power may be maintained during an alarm condition or the main

power may be shut down.

3

24. NOTE: Refer to the Menu Tree in this manual for the factory default settings for the following parameters.

25. The FIXED SET TEMP is the set temperature value entered in degrees. This temperature is one within the range

ofthe inputsensor orthe limitsof lowand highset rangesfrom the controllerconfiguration setup. TheCOMPUTER

CONTROLselection inthe CONTROLTYPE configurationprovides a fixedpercentage ofpower tothe load. This

power resolution with an entry of 0.0 is equal to 0% power and +12.0 equals 100% power and -12.0 equals -100%

power.

26. PROPORTIONALBANDWIDTH is the temperature bandin which0% to100% power willbe appliedto theload.

The acceptable bandwidth values that may be entered are 1° to 100°.

27. INTEGRAL GAIN shifts the proportional bandwidth with respect to the set point to compensate for droop. This

value is expressed in repeats per minute and the acceptable values that may be entered are .01 to10 repeats per

minute.

28. DERIVATIVE GAIN senses the rate of rise or fall of the system temperature and adjusts the cycle time of the

controller to minimize overshoot or undershoot. This value is expressed in cycle rates per minute and the

acceptable values that may be entered are .01 to 10 cycles per minute.

29. CONTROL DEADBAND is the temperature band where the controller is turned on and off by either rising or

falling temperatures where no heating or cooling takes place. This band is expressed in °F. and the acceptable

values that may be entered are 0.1°F. to 100°F.

30. Review the tuning parameters for correctness and then select the Send Box Values button to download these

constants to the controller.

31. The CALIBRATE box provides additional variables that can be used to fine tune your system’s operation. You

may want to try controlling with the initial settings prior to entering values in this section.

32. INPUT1 OFFSETis amanual methodof compensatingfor thesensor 1temperature andactual controltemperature.

33. INPUT 2 OFFSET is a manual method for compensating for the sensor 2 temperature and actual temperature.

34. HEAT SIDEMULTIPLIERis a0.01 to2.00 numericalmultiplierthat compensatesfor thenon-symmetrical response

of the thermoelectric module between the heat and cool modes.

35. If you have entered values in the CALIBRATE box and they are the desired settings, select the Send Box Values

button to download these constants to the controller.

36. Initial set-up of your Model TC-136 controller is complete.

12

4

13. Now, click on the CONTROL TYPE menu key and select which type is appropriate for your application. The

DEADBANDCONTROL is anon/off controland PIDCONTROL is aproportional/integral/derivative control. The

COMPUTERCONTROL acts likean electronicvariac inthat afixed percentage of power maybe appliedto theload.

14. Clickingon theCONTROL MODEmenu keypermits theselection ofeither HEATWP1+ andWP2- orHEAT WP2+

and WP1-. This selection establishes the polarity for the heating mode of the thermoelectric module. (i.e. If the

positive side of the module is connected to WP1 and the negative side to WP2, the module will heat when power is

applied to the module, and vice versa if the wiring is reversed.) This selection allows you to reverse the current flow

in the thermoelectric module without changing the wiring.

15. The ALARM TYPE setting permits the selection of available alarm options with this controller. The drop down

menu allows for four selections. NO ALARM PICKED indicates that no alarm parameters are desired. SET

TRACKINGALARMS allows analarm tobe setwith respect tothe settemperature andwill move,accordingly,with

a change of the temperature setting. This option can be used for a high alarm, low alarm, or both settings. FIXED

VALUEALARMS permitsthe setting ofa fixed,absolute temperatureeither aboveor belowthe setpoint temperature

orboth. COMPUTER CONTROLLEDALARM is notan actualalarm, buta useractivation ofthe alarmrelay viathe

PC.

16. The POWER OUT SHUT DOWN IF ALARM menu key provides two selections. NO SHUT DOWN IF ALARM

which will let the power output stage of the controller to continue to function or MAIN OUT SHUTDOWN IF

ALARM which disables the power output stage under an alarm condition.

17. Associatedwith theALARM TYPEconfiguration arethe HIGHALARM SETTING,LOW ALARMSETTING, and

theALARM DEADBAND selections. Ifan alarmtype has been selected, enterthe desiredhigh and lowtemperature

values. The ALARM DEADBAND option is to set the hysteresis of the alarm values from 0.1°F. to 100°F.

18. TheALARM LATCHoption permitsthe selectionof anALARM LATCH OFFwherethe controllerwill automatically

reset if the alarm condition is self-correcting or ALARM LATCH ON which will maintain that an alarm condition

existed and must be manually cleared.

19. TheCHOOSE SENSORFORALARM optionallows forthe selectionofeither thethermistor CONTROLSENSOR or

theINPUT 2 SENSORbe used forthe alarm.

20. TheCHOOSE DEGC ORDEG Fmenu keypermits theselection ofdisplaying DEGF or DEGC.

21. Review all of your controller configuration selections. If all the configuration selections are correct for your

application, select the Send Box Values button to download these settings to the controller.

22. You are now ready to tune the controller. All selections for this portion will occur in the menu tree TUNING box

displayed on the monitor.

23. The various constants required by the controller to optimize the system performance are entered in this section.

11

TC-136

TS67 at -20°C to 100°C

TS141 at -40°C to 70°C

RS232 COMMUNICATIONS CONNECTIONS

FOR MODEL TC-136

JP3 1 2 3

RS232

TX RX COMMON

PC CONNECTION TABEL

PC CONNECTOR PC FUNCTION* CONTROLLER

9 PIN 25 PIN

PIN 2 3 RECIVE (RX) TRANSMIT (TX)

PIN 3 2 TRANSMIT (TX) RECEIVE (RX)

PIN 5 7 COMMON SHIELD

*Functionsnormallyassigned topins.

Check yourPCmanual toconfirm.

RX TX SHLD

5

SET-UP INSTRUCTIONS FOR MODEL TC-136, THERMOELECTRIC MODULE,

PC PROGRAMMABLE, TEMPERATURE CONTROLLER

1. Connect the appropriate DC power (12 to 28 volts) to the controller between WP3 (+) and WP4 (-) and the

thermoelectric module between WP1 and WP2 in accordance with the customer hook-up drawing. Note: the DC

power supply must also match the voltage and current ratings of the thermoelectric module configuration.

(Reference Application Note 351).

2. Connect the RS232 Communications Port from the controller (JP3) to the RS232 input on the PC. Pin 1 of JP3 is the

controller’s RX, Pin 2 of JP3 is the controller’s TX, and Pin 3 of JP3 is the controller’s Shield.

3. Turn power on to both the PC and controller. The on-board green LED will flash at a steady rate to indicate the

controller is energized correctly.

4. Insert the TC-136 software disk into the computer A:\ drive. To install the software from the floppy disk, select

“START”, “RUN”from yourWindowsDesktop andthen enterA:\Oi362.exe and OK. Thiswill loadthe PCinterface

into your computer’s RAM.

5. NOTE: Refer to the Model TC-136 Menu Tree in this manual for factory default settings.

6. The Menu Tree screen will appear on your PC monitor.

7. NOTE: If you receive an error message, please refer to Appendix A.

8. All selections are made from this menu screen. In the PC COMMUNICATIONS box, select the “COMM PORT” (1

through 4) which will be your communications link to the controller. After making this selection, click on the

INITIALIZEbutton.

9. In the CONFIGURE box, the various menu selections are used to establish the custom operating criteria for the

controller. NOTE: To avoid damage to the thermoelectric module, confirm that the OUTPUT ON/OFF is in the

OFF position prior to proceeding!!

10. First,click onthe PWMOUTPUT TIMEBASE (pulse width modulated)menu key, optionsfor “SLOWTIMEBASE

675Hz” or “FAST TIMEBASE 2700Hz” will appear. Select the option that is appropriate for your thermoelectric

module(s).

11. Next,click onthe SETTEMP TYPEINPUT 2menu keyto revealthe optionsavailable. COMPUTER SETVALUE is

to be set for the desired control set temperature. The other selections, POTENTIOMETER SET, 0 to 5 vdc SET, and

0 to 20 ma SET, are for external set temperature adjustments. The controller default setting for these options is the

fullrange of thethermistor inputsensor. TheDIFF.SET=INP2+COMPSET establishesan actualset temperaturethat

is the sum of the optional thermistor input sensor and the temperature selected as the COMPUTER SET VALUE.

12. Associated with the external set temperature adjustments are the SET TEMP HIGH RANGE and SET TEMP LOW

RANGE selections. These permit the selection of limitations on the temperature range of the external adjustments.

Enter the desired values for these settings. These set limit values must be within the -20°C. and 100°C. range

specified for the controller.

10

6

9

MECHANICAL PACKAGE DRAWING

NOTE: THE FACTORY DEFAULT VALUES ARE SHOWN IN RED.

S

LOW TIMEBASE 675Hz

FAST TIMEBASE 2700Hz

C

OMPUTER SET VALUE

POTENTIOMETER SET

0 TO 5vdc SET

0 TO 20ma SET

DIFF. SET=1NP2+FIXED SET TEMP

D

EADBAND CONTROL

PID CONTROL

C

OMPUTER CONTROL

H

EAT WP1+ AND WP2-

HEAT WP2+ AND WP1-

N

O ALARMS PICKED

SET TRACKING ALARMS

FIXED VALUE ALARMS

COMPUTER CONTROLLED

N

O SHUTDOWN IF ALARM

MAIN OUT SHUTDOWN IF ALAR

C

ONTROL SENSOR

I

NPUT2 SENSOR

UTPUT

OWER %

Model 5C7-362 Menu Tree

R

S-232 Communications

C

OM1

COM2

COM3

COM4

A

LARM LATCH OFF

A

LARM LATCH ON

D

EG F

DEG C

T

S67 Sensor –20°C to 100°C

T

S141 Sensor –40°C to 70°C

TC-136

N/A

HiTECH

Technologies, Inc.

7 8

CUSTOMER HOOK-UP DRAWING EXPANSION CONNECTOR WIRING DIAGRAM

TC-136

Table of contents

Popular Temperature Controllers manuals by other brands

Multipipe

Multipipe Rio Quantum quick guide

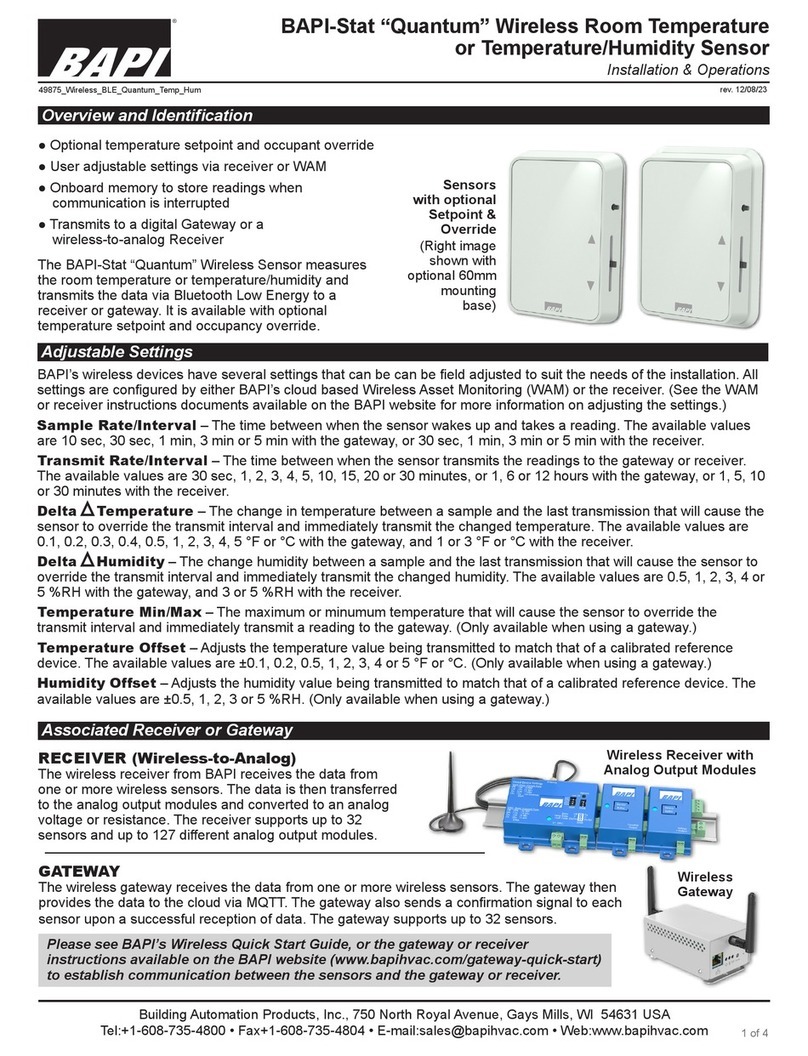

BAPI

BAPI BAPI-Stat Quantum installation & operations

Solidyne

Solidyne WTS-DB quick start guide

Elsist

Elsist SENSIT TG68 DS 18B20 instruction manual

Ascon tecnologic

Ascon tecnologic e34B operating instructions

American Standard

American Standard ZZSENSAL0400AA Installer's guide