3

■ Amplifier Specification

Module M-95P

Enclosure Weather Proof

Housing Material P.B.T / AL.C

Mounting Compact

Microprocessor 16 Bit Microprocessor

Supply Voltage AC Free (90V ~ 240V @ 50/60Hz)

DC+17V ~ +35V @ Typ.+24V

Power Consumption

AC Free

(90~240V)

Stand-by ■ AC 220V @ 7W

■ AC 110V @ 3.1W

Active ■ AC 220V @ 7.6W

DV+24V Stand-by ■ DC + 24V @ 0.2W

Active ■ DC + 24V @ 0.96W

Oscillation Frequency 1MHz

Sensitivity Resolution 0.1pF

Dielectric Constant 2 @ Min. (Powder/Liquid)

Function (Adjustment)

■ Sensitivity

■ Relay Delay Time

■ Relay Return Time

■ Relay Contact Control (Normal/Reverse)

Sensitivity

■ RANGE: Measurement Sensitivity Adjustment Range

▶ Sensitivity Setting Range: 10pF ~ 150pF

▶ Sensitivity Setting Method: BCD DIP Switch

■ SEN. : Measurement Sensitivity Fine Adjustment

▶ Dry Contact Adjustment Range: Δ10pF

▶ Wet Contact Adjustment Range: Δ-5pF

Relay Delay Time Range 0.5Sec. @ Min / 1Sec. ~ 10Sec. @ 0.1Sec. Resolution

Relay Return Time Range 0.5Sec. @ Min / 1Sec. ~ 10Sec. @ 0.1Sec. Resolution

Relay Contact Out Control Normal Close @ Default

Relay Contact Rating DPDT : AC250V/5A, DC30V/5A

Status Indicator Bi-Color LED [Green / Red / Orange]

Detection Indicator Red LED

Relay Control Indicator Green LED

UART Monitoring

Ambient Temperature -20℃ ~ +80℃

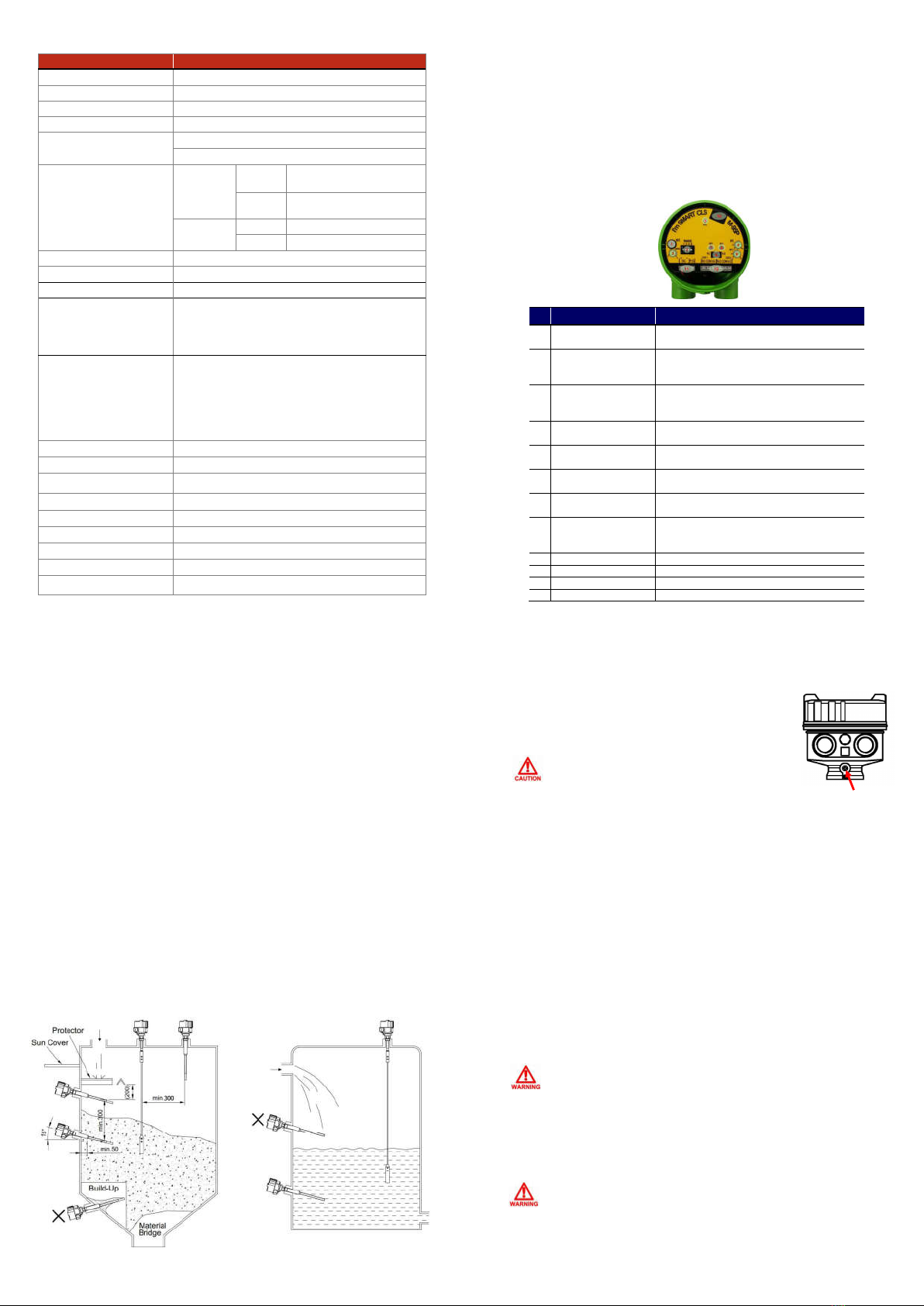

4

Refer to Instruction Manual for Setting Guide.

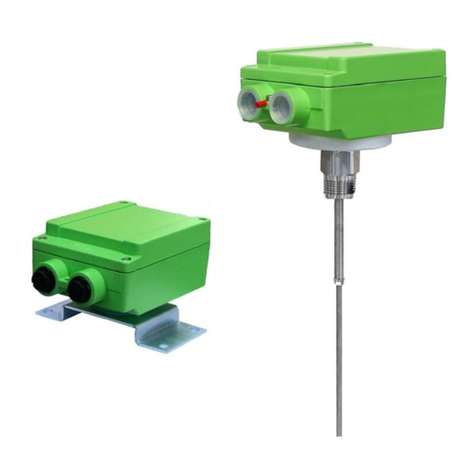

4. Wiring and Amplifier Composition

■ Wiring

- Connect correctly AC (90~240V) or DC (+24V) power to the power specification.

- Make sure to connect the DC power with correct polarity (+, -).

- Do not connect the wire with the power connected.

- It provides DPDT output by default, wired COM and N.O terminals when

using the high alarm.

- External grounding shall be completed.

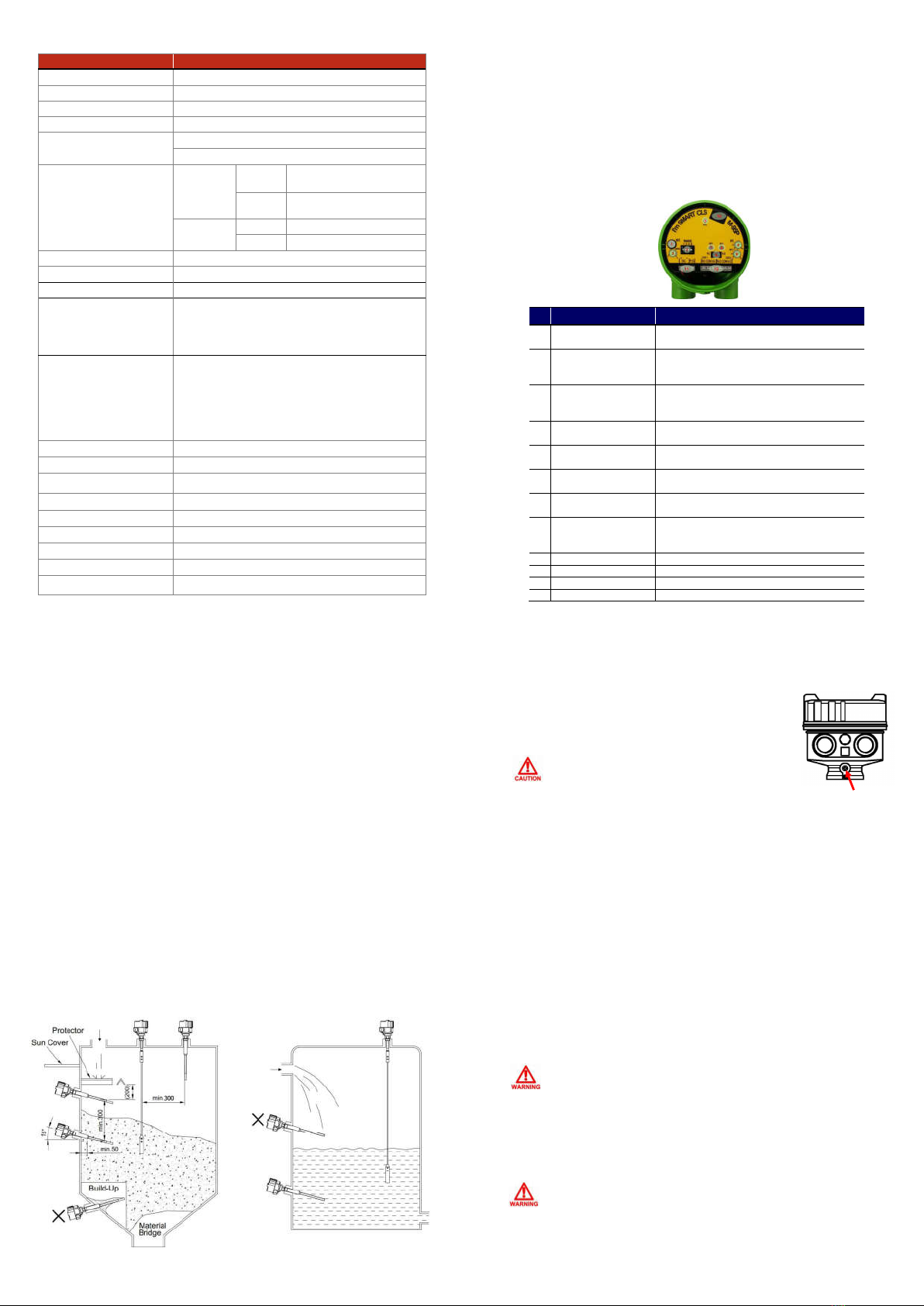

No Configuration Function

1 SET. ■ Autoset

○ Automatic Measurement and Standard of Capacitance on Tank

2 RANGE

■ Capacitive Measurement Sensitivity Range Setting

○ Sensitivity Setting Range: 10pF ~ 150pF

○ Sensitivity Setting Range: BCD Dip Switch

3 SEN.

■ Fine Tuning of Capacitance Measurement Sensitivity

○ Dry Contact Sensitivity Fine Adjustment Range: △10pF

○ Wet Contact Sensitivity Fine Adjustment Range: △-5pF

4 DT. ■ Relay Delay Time Adjustment

○ Time Range: 0.5s, 1s ~ 10s @ Adjustment 0.1s

5 RT. ■ Relay Return Time Adjustment

○ Time Range: 0.5s, 1s ~ 10s @ Adjustment 0.1s

6 Fail Safe Mode ■ Relay Transformation Adjustment

○ N.C ↔ N.O

7 DET. ■ Measurement Status LED

○ OFF → Red

8 RLY.

■ Relay Status LED

○ N.C: OFF → Green

○ N.O: Green → OFF

9 PWR ■ Power & Status Display

10 UART ■ M-95P Status Setting and Status Communication Port

11 Power ■ Power Connector (AC / DC)

12 Relay Out ■ Relay Contact Out (DPDT)

5

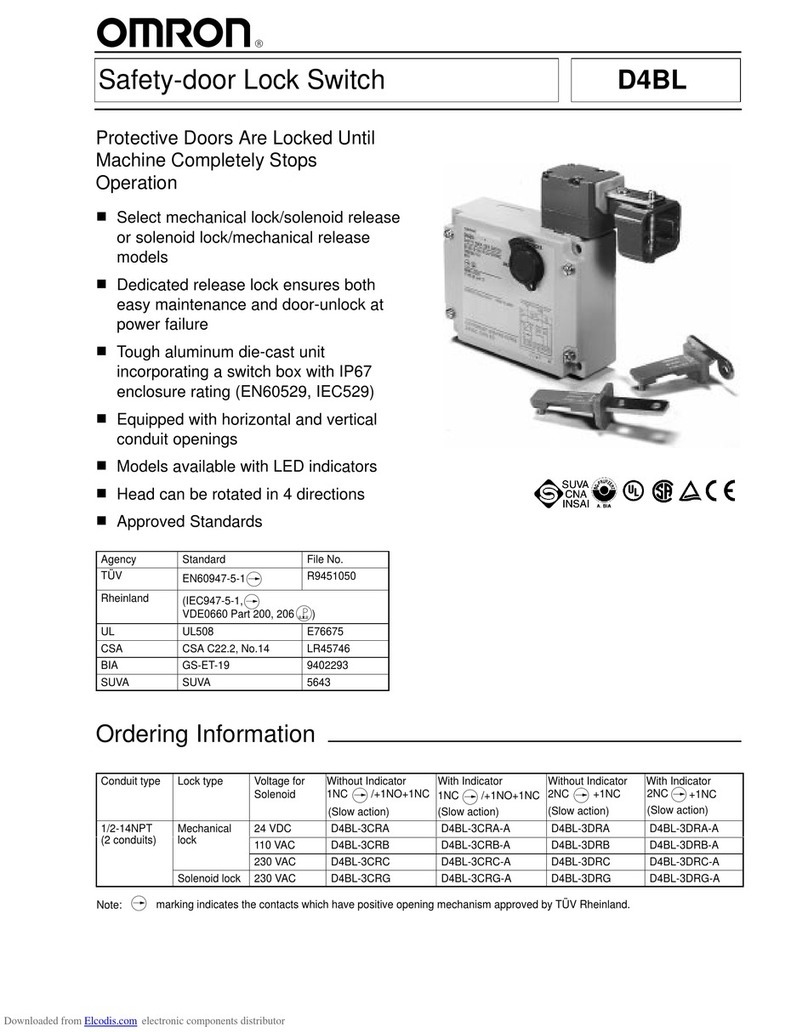

5. Precautions

■ Precautions for Installation

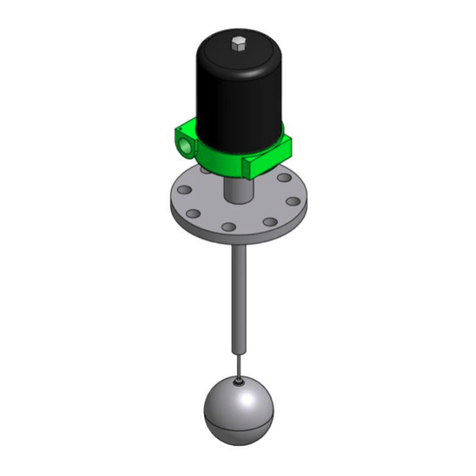

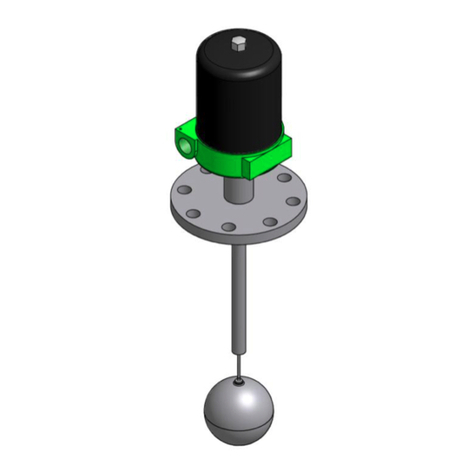

The capacitance type level switch can be installed in screw (PT, NPT, PF, etc.) and

flange (ANSI, JIS, DIN, etc.) as well as tri-clamp and other various locations.

Pay attention to the following matters during installation.

▶ Side Mounting Installation

Highly sensitive measurement is available because it measures the level by

whole of probe but it shall be installed slopingly, forwarding of sensor to

the bottom in order to avoid a malfunction caused by build-up of the

medium on the sensing probe.

▶ Top Mounting Installation

This installation is not much affected by build-up of the medium on the

probe but the sensitivity is lower than side mounting because it measures

the level by the end of probe only, and it is not suitable to detect a level of

the medium which has a lower dielectric constant.

6

■ Precautions for Grounding

▶ When connecting to an external ground, the ground

wire shall be 4 ㎟(4mmSQ).

■ Failure Check & Maintenance

▶ Inspection of Product

The life span of key parts depends on user’s environment and can be used optimally

through periodic check. Therefore, regular inspection ensures optimal performance of

product, so take regular inspection and maintenance at least every year. Inspection of the

appearance of the product shall be visually checked to see if there is any damage, and

the attachment of the medium or foreign substances to the sensor will make it worse, so

they shall be removed regularly. Be careful not to damage Teflon part during removal.

▶ Failure Check

1) Is power voltage connected correct?

2) Is power voltage supplied according to specifications correct?

3) Is cable wiring correct?

4) Is the Fail-Safe Mode setting correct?

5) Does the green LED turn on?

■ User Training

Make sure that the ambient temperature of housing is kept at -20℃ ~ +60℃. Ex-proof

products are designed according to Article 34 of the Industrial Safety and Health Act and

Article 58.4 of the Enforcement Rules of the same Act. (Refer to Instruction Manual for details.)

◈ More product information can be acquired at our website. (www.hitrol.com)

Make sure to insert a washer if the terminal lug is

removed from ground terminal and then re-connected.

(Loosening prevention)

Turn off the power of the product for maintenance.

In an explosion area, do not disassemble when power is supplied.

Do not apply a non-ex-proof product in an Ex-proof zone. Ex-proof

products can only be installed at zone 1 and 2 of environment. It shall

be installed in compliance with the ex-proof temperature rating and

the applied fluid temperature.

External Grounding