HTM-

30N Se

upper or the lower limit, respectively. The level switch can be

so it is applicable to ferrous or nonferrous tanks

consider the following

■

When installation, the process connection should be screw or flange type

length

of the screw should not be over 24mm. Otherwise, dust or

enter,

resulting in a malfunction. For horizontal

drawing

facing upward and installing

■

To prevent buildup, the product should be installed at an inclination of

In addition, the wing of the sensor must be installed ve

■

Sensor shall be installed at the place far from inlet of the tank and protector shall be

installed in order to protect the sensor from damage by falling medium if it is installed

at the inlet. The protector shall have sufficient area to protect

m

edium and be installed at a distance that does not affect sensor operation.

■

■

If the housing temperature rises because of direct sunlight, install a sun

prevent such occurrence

Precautions

for Installation

AMP & Wiring

■

Connect AC (90~240V) or DC (24V) according to the power specifications.

■

Make sure to connect the power with the correct polarity (+,

■ Do not

connect the wire with the power connected.

■

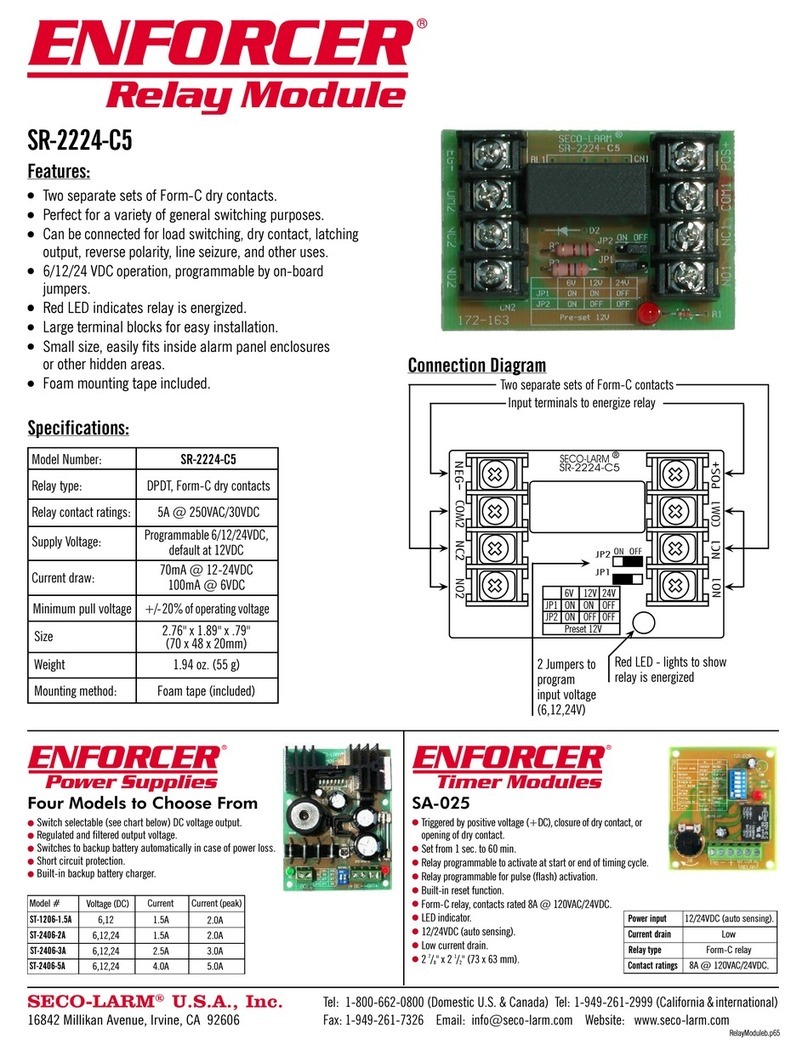

This product provides DPDT. Wire it with COM and NO Terminal to use High Contact.

■

Make sure to connect it to an external ground.

ries

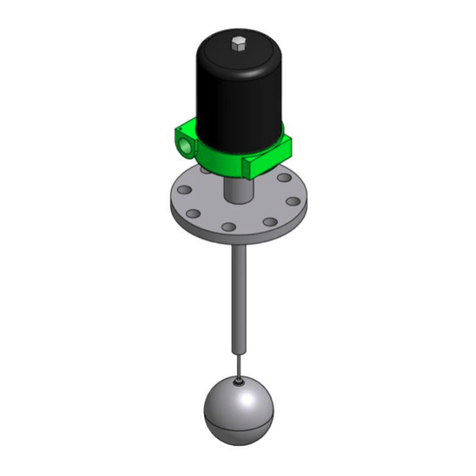

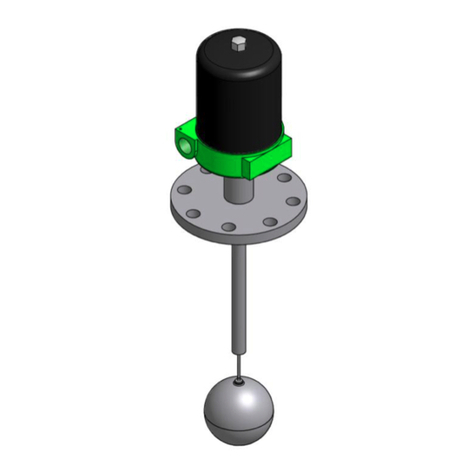

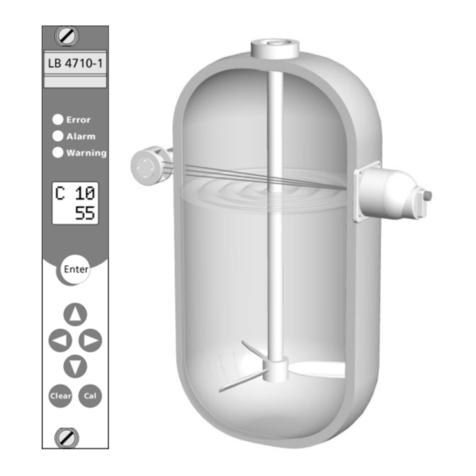

is installed on the top or the side of a container and silo to

upper or the lower limit, respectively. The level switch can be

so it is applicable to ferrous or nonferrous tanks

and silos.

When

consider the following

:

When installation, the process connection should be screw or flange type

of the screw should not be over 24mm. Otherwise, dust or

resulting in a malfunction. For horizontal

installati

on, mark indicated in below

facing upward and installing

the wide surface of the fork vertical.

To prevent buildup, the product should be installed at an inclination of

In addition, the wing of the sensor must be installed vertically.

Sensor shall be installed at the place far from inlet of the tank and protector shall be

installed in order to protect the sensor from damage by falling medium if it is installed

at the inlet. The protector shall have sufficient area to protect

edium and be installed at a distance that does not affect sensor operation.

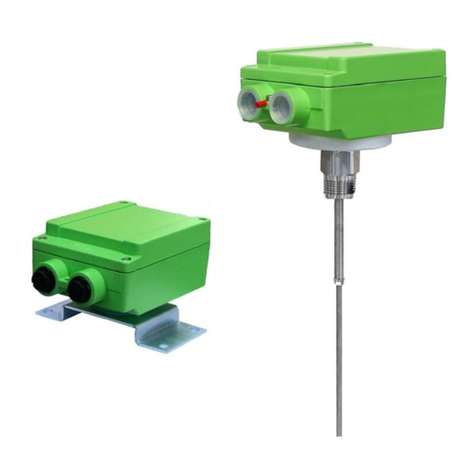

Cable lead

-

in inlet must face the direction shown in the figure.

If the housing temperature rises because of direct sunlight, install a sun

prevent such occurrence

.

Set

Connect AC (90~240V) or DC (24V) according to the power specifications.

Make sure to connect the power with the correct polarity (+,

connect the wire with the power connected.

This product provides DPDT. Wire it with COM and NO Terminal to use High Contact.

Make sure to connect it to an external ground.

-

proof products, apply power after tightening the

The direction of the tuning fork can be checked from the outside.

HTM-30N Series

7

is installed on the top or the side of a container and silo to

detect the

installed on any material,

installing this product,

When installation, the process connection should be screw or flange type

, and a

of the screw should not be over 24mm. Otherwise, dust or

foreign matter may

on, mark indicated in below

the wide surface of the fork vertical.

To prevent buildup, the product should be installed at an inclination of

15° or more.

Sensor shall be installed at the place far from inlet of the tank and protector shall be

installed in order to protect the sensor from damage by falling medium if it is installed

the sensor from incoming

edium and be installed at a distance that does not affect sensor operation.

in inlet must face the direction shown in the figure.

If the housing temperature rises because of direct sunlight, install a sun

cover to

Connect AC (90~240V) or DC (24V) according to the power specifications.

Make sure to connect the power with the correct polarity (+,

-).

This product provides DPDT. Wire it with COM and NO Terminal to use High Contact.

proof products, apply power after tightening the

cover.

The direction of the tuning fork can be checked from the outside.