Hjelpemiddelspesialisten DELTA BUGGY User manual

Hjelpemiddelspesialisten AS, Rosenholmveien 22, 1252 Oslo

Telefon: +47 66 81 60 70 - Telefaks: +47 66 81 60 71

E-post: [email protected] - Internett: www.hm-spes.no

DELTA BUGGY

INSTRUCTION

MANUAL

PLEASE READ THIS BEFORE USING YOUR DELTA

BUGGY AND KEEP IN A SAFE PLACE FOR FUTURE

REFERENCE

♦ ALWAYS DEPLOY THE ANTI-TIPPER AND THE BRAKES

WHEN PARKED AND BEFORE TRANSFERRING IN OR OUT OF

THE BUGGY. The Delta buggy is designed to be easy to tip

backwards for improved manoeuvrability and easier handling. NB.

THE ANTI-TIPPER WILL NOT BE AS EFFECTIVE ON SOFT

GROUND LIKE SAND.

♦ DO NOT HANG ANY LUGGAGE ON THE HANDLE OR

BACKREST FRAME. This can cause the buggy to tip backwards.

♦ WHEN ASSEMBLING THE BUGGY CHECK THAT QUICK

RELEASE WHEELS ARE SECURELY ATTACHED.

♦ READ THE INSTRUCTIONS BEFORE USE; PAY

PARTICULAR ATTENTION TO ITEMS WITH THE WARNING

TRIANGLE.

♦ ALWAYS HOLD ON TO THE BUGGY IN USE. TAKE

EXTRA CARE ON INCLINES. A wrist strap is provided for extra

security.

♦ ALWAYS USE THE LAP BELT TO KEEP THE CHILD SAFE.

The shoulder and groin straps of the harness can be removed if not

required.

♦ WHEN OPERATING THE PARK BRAKES CHECK THAT

THEY ARE WORKING EFFECTIVELY AND DEPLOY THE ANTI-

TIPPER BEFORE RELEASING THE BUGGY.

♦ Do not allow the child to climb into the buggy unassisted.

♦ Attempting to negotiate steps and stairs is dangerous, be sure

that you and your helper can support the weight of the buggy and

occupant. Do not attempt more than a short run of steps without at

least two carers.

♦ The handle mounting is flexible to reduce hand/wrist fatigue.

Do not lift the buggy by the handle when occupied; use the frame or

section of tube between the handle adjusters and frame.

IMPORTANT SAFETY NOTES

Pg.22

IMPORTANT SAFETY NOTES

♦FOLLOW THE PRE-USE SAFETY CHECKS BEFORE USE, REFER TO

THE CARE AND MAINTENANCE INSTRUCTIONS.

♦If any part is damaged or fails to operate correctly do not continue to

use the buggy. Read the care and maintenance instructions and contact

Delichon for advice if necessary.

♦Take care when the rear wheels are removed to avoid damage to the

brake mechanisms; use the protective discs provided.

♦Never leave a child unattended in the buggy.

♦Do not overload the buggy with additional children or luggage. See

dimension and limits table on page 6.

♦Do not allow children to play with or climb on the buggy.

♦No adaptations or modifications must be made to the buggy without

approval from the manufacturer.

♦Do not place heavy objects on top of the frame when it is being stored or

transported.

♦Keep your buggy clean and in good condition for optimum performance

–see maintenance instructions.

♦THE DELTA BUGGY IS NOT SUITABLE FOR TRANSPORTING THE

OCCUPANT IN A MOTOR VEHICLE.

Pg.3

Description

The Delta Buggy is designed to enable access to areas where most wheelchairs would

be unsuitable; countryside paths for example.

The fabric seat of the Delta is designed to provide comfort and support to the user; it

is not however intended as a primary seating system but for occasional use.

When in the buggy the occupant should be supervised at all times by a carer.

All attendants/carers should be familiar with the user instructions before use.

A lap belt and shoulder straps are provided, the lap belt should be used at all times for

safety. Foot straps and groin pad may also be provided.

The rear wheels have drum brakes operated by hand levers on the push handle, these

act to slow down the buggy or stop it from rolling back on a hill. The brake levers are

fitted with a lock that allows brakes to be used for parking by keeping them on when

the carer lets go of the handle.

The design allows easy and compact folding and (optionally) quick release removal of

the wheels for transit; discs are provided to protect the brakes when the wheels are

removed. The large frame is available with two sizes of fabric seat which are

interchangeable.

The centre of gravity of the buggy and occupant is close to the rear axle to make

tipping back for steering and negotiating obstacles easier. The axle position can be

adjusted to fine tune the balance for the individual user. A foot-operated stabiliser,

which must be deployed when parked, is mounted on the rear of the frame to

prevent tipping.

A luggage carrier under the seat may be provided. Do not hang luggage on the handle.

Accessories

A transport bag is available as an extra, to help to protect the buggy during storage or

transit. A wedge shaped seat cushion is available to reduce hip flexion and raise the

occupant in the seat. Rain covers are available for the small and medium Delta Buggy

only and must be used in conjunction with a sun-hood. Sun-hoods are available for all

sizes. Double width rear wheels are available to make pushing the buggy easier on soft

ground.

Pg.4

Bungee cord

Lap belt strap

Shoulder

strap

Side of seat

hammock

FIG. 24

The lap belt and shoulder straps are threaded through a three bar buckle on the back

corner of the seat (see fig. 24).

Remove the adjustable (pronged)

part of the buckles from the straps

and the bungee cords from the

hammock before washing.

Pg.21

Shoulder Strap

Attach with

Velcro®

Slide Pad Up

Over Buckle

FIG. 23 Fitting the Shoulder

Straps and Pads

FIG. 25

Medium bungee

attachment

Large bungee

attachment

point

Regular Checks

The Delta buggy should be inspected by a competent person every 6 months for

adjustment and wear. The following items should be checked:

♦Park brake adjustment, brake cable and brake pad wear or damage.

♦Anti-tipper function and secure locking into place; when deployed the end of

anti-tipper should be approx. 22mm from the ground.

♦Security of the quick release wheel attachments.

♦Wear to folding joints. If there is excessive movement in the joints, take out a

stainless steel screw to inspect the polymer bearing that protects the aluminium

joint from the fixing screw. The bearings can be replaced if necessary.

♦Wear to the handle adjusters clutch mechanism. When the handle does not lock

securely the adjusters should be replaced.

♦That all screws and fixings are secure; folding joint fixings should not be over

tightened.

♦Condition and secure attachment of the foam that covers the handle to backrest

frame joint.

♦Tyre wear and inflation pressure.

♦Secure attachment of footrest; adjust height if required.

♦Check condition of harness and foot-straps; replace if necessary.

Spares are available from Delichon and are supplied with fitting instructions.

If any part is damaged, loose or not working correctly do not

continue to use the buggy until rectified.

To remove seat hammock for washing or replacement;

Look carefully at how the seat is attached to the frame before and during removal to

make replacing it easier, in particular take note of how the straps and the bungee

cords are threaded.

The top of the fabric seat fits over the frame, most of the occupants weight is

supported through this section. The sides and front of the fabric seat are attached to

the frame by poppers, the number of these varies with the size of the frame.

Between the front corners of the seat there is a 40mm wide webbing strap which

must pass around the frame and fasten tightly underneath.

The rear corners are held in place with bungee cords which pass through the webbing

loops on the seat and hook onto slots in the frame brackets. The slots are in the axle

adjuster plate on the medium Delta and on the rear frame bracket of the large Delta

(see fig. 25)

Pg.20

Dimensions and Limits

NOTE: the fabric seat dimensions change when someone sits in it; a larger

range of occupants can be comfortably accommodated than is suggested

by the seat width and depth measurements.

SMALL DELTA

Approx. dimensions in mm

Length

Width

Height

Overall dimensions

1080 - 1280

570

930 - 1040

Overall folded dimensions

850

540

300

Maximum occupant weight

40kg

Maximum occupant height

1.3m

Maximum luggage weight

6kg

Seat to footrest height

240 - 360

Push handle height

665 - 1030

Rear wheel diameter

305

Front wheel diameter

305

Buggy weight

13kg

FIG. 2 –FOLDED DELTA BUGGY

FIG. 1 –MEDIUM DELTA BUGGY

Pg.5

MEDIUM DELTA

Approx. dimensions in mm

Length

Width

Height

Overall dimensions

1220-1270

625

1020-1050

Overall folded dimensions

880

560

240

Maximum occupant weight

55kg

Maximum occupant height

1.5m

Maximum luggage weight

10kg

Seat to footrest height

275- 420

Push handle height

880-1050

Rear wheel diameter

395

Front wheel diameter

305

Buggy weight

13.5kg

INTERMEDIATE DELTA

Approx. dimensions in mm

Length

Width

Height

Overall dimensions

1390-1430

695

1170

Overall folded dimensions

1100

620

250

Maximum occupant weight

60kg

Maximum occupant height

1.65m

Maximum luggage weight

10kg

Seat to footrest height

380 - 550

Push handle height

900-1070

Rear wheel diameter

395

Front wheel diameter

305

Buggy weight

14kg

LARGE DELTA

Approx. dimensions in mm

Length

Width

Height

Overall dimensions

1390-1430

695

1170

Overall folded dimensions

1100

620

250

Maximum occupant weight

70kg

Maximum occupant height

1.8m

Maximum luggage weight

10kg

Seat to footrest height

340 - 510

Push handle height

900 - 1070

Rear wheel diameter

395

Front wheel diameter

305

Buggy weight

14kg

Pg.6

Care & Maintenance Instructions

Cleaning

The fabric seat, the harness pads, the luggage carrier, the transport bag, the sun-hood

and storm-cover are constructed mainly of waterproofed fabrics that can be sponged

with warm soapy water, brushed with a soft brush and/or hosed down. Rinse off any

soap with clean water. DO NOT IRON.

The removable webbing straps can be machine-washed at 30°C to 40°C –remove the

parts of the buckles that are not stitched on first.

The frame, wheels and footrest can be cleaned by sponging with warm soapy water,

brushing with a soft brush and/or hosing down. Rise with clean water and remove the

rear wheels to allow the brakes to dry.

If the buggy should be exposed to salt water wash off as soon as possible with fresh

water to reduce corrosion.

Protecting the metal parts of the brake mechanism with a water repellent agent such

as Duck Oil® is advised to prolong their life and aid cleaning but avoid getting this on

the brake pads or drums.

Tyres

Standard tyres should be inflated to between 20 and 30p.s.i. (1.4 and 2 bar). Beach

wheel tyres should be inflated to between 10 and 15 p.s.i. (0.7 and 1 bar approx). A

car foot pump or bicycle pump with the correct adaptor (similar size to mountain

bike) can be used. A puncture protection material such as ‘Green Slime®’, available

from most cycle shops, can be used. Spare tyres and inner tubes can be purchased

from cycle shops or Delichon Limited.

Adjusting the Brakes

As the brake pads wear, adjustment will be necessary. To adjust the brakes release

the lock nut on the park brake adjuster (see fig. 22) and screw the adjuster out

slightly, re-check the brakes and adjust further if needed. When satisfactory park

brake function has been attained tighten the lock nut taking care not to move the

adjuster.

Pg.19

Park Brake

Adjuster

FIG. 22

Warranty

Your Delta Buggy is guaranteed for one year from delivery.

The warranty does not cover tyres, inner tubes, brake pads/shoes or damage caused

by misuse or neglect.

Spare parts and advice are available from Delichon Limited. Moving parts subject to

wear and most likely to need replacement are tyres, brake components, polymer

bearings in the frame joints, webbing straps and the handle adjuster mechanisms.

Pre-use Safety Checks

BEFORE EACH USE CHECK THE FOLLOWING ITEMS

♦That the wheels are securely attached (see pages 7 & 8)

♦That the anti-tipper is operating correctly, and is deployed before transferring

anyone into the seat.

♦That the park brakes are working; try by pushing the buggy with the brakes on.

♦That no parts appear broken or loose.

♦That the tyres are inflated to the correct pressures. Low tyre pressure will cause

instability and make pushing the buggy more difficult.

Pg.18

Instructions for Use

See Pre-Use Safety Checks Before Use.

To unfold the Delta Buggy; place the folded frame on the ground with the handle

uppermost, unclip the retaining strap. Put the wheels to one side.

Unfold the handle first, by pushing in the buttons on the inside of the handle hinge

and rotating the handle upwards.

Lift the top of the backrest and push down the sliders on the side of the frame as far

as they will go (see fig. 8). Clip the ends of the retaining strap together under the seat.

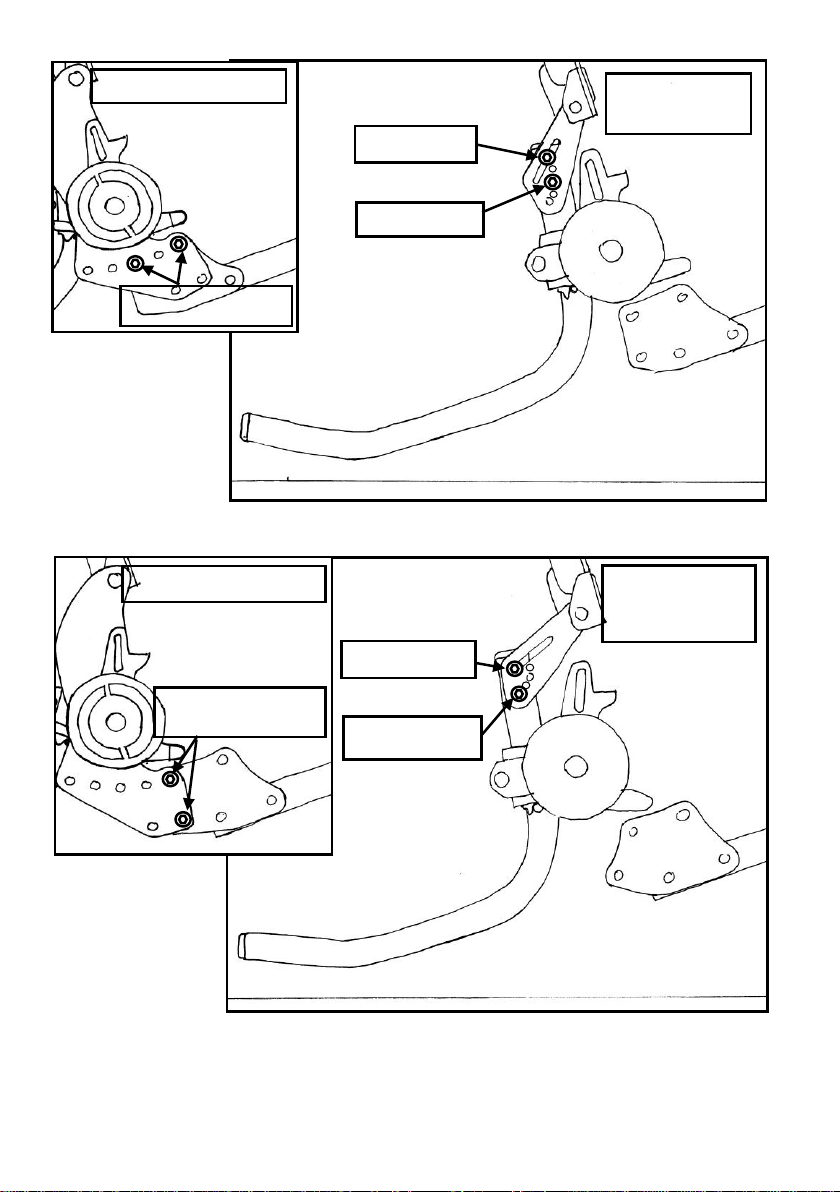

To fit the rear wheels; first check that the park brakes are not on. Take one wheel,

push and hold down the button on the centre of the hub and insert the axle as far as

it will go into the hole in the middle of the rear brake. Release the button.

PULL THE WHEEL TO CHECK THAT IS SECURELY ATTACHED. Repeat with

the other wheel.

Handle Adjuster

Button

FIG. 3

Wheel Release

Button

FIG. 4

Pg.7

Locating

Pins

FIG. 6

To fit the front wheel; first check that the quick release lever on the front wheel

axle is released (see fig. 5). Locate the ends of the axle into the front forks and lock

the quick release lever.

PULL THE WHEEL TO CHECK THAT IT IS SECURE.

DEPLOY THE ANTI- TIPPER AND ENGAGE THE PARK BRAKES

BEFORE PUTTING SOMEONE INTO THE BUGGY.

To deploy the anti-tipper; push down gently with your foot on the stainless steel

tube and flip it into the centre where it clicks into place; push down near to the bend

in the tube not on the end.

To fold down the footrest; pull the two rings on the underside of the footplate to

retract the spring loaded locating pins and fold down –the pins should release easily

do not force them. Let go of the rings to lock the footrest in place.

The height of the footrest may need to be adjusted

before use - see instructions below.

The footrest can be removed to make more

space during transfer in or out of the buggy.

To remove the footrest pull on the locating

pins and fold the footrest up as far as it will go;

keeping hold of the rings lift the footrest

upwards parallel to the frame tube.

The foot-straps are designed to be long

enough to remain under the loops on the

footrest while positioning the foot.

Pg.8

Quick Release

Lever in Locked

Position

FIG. 5

Screw C

Screw D

Screw E

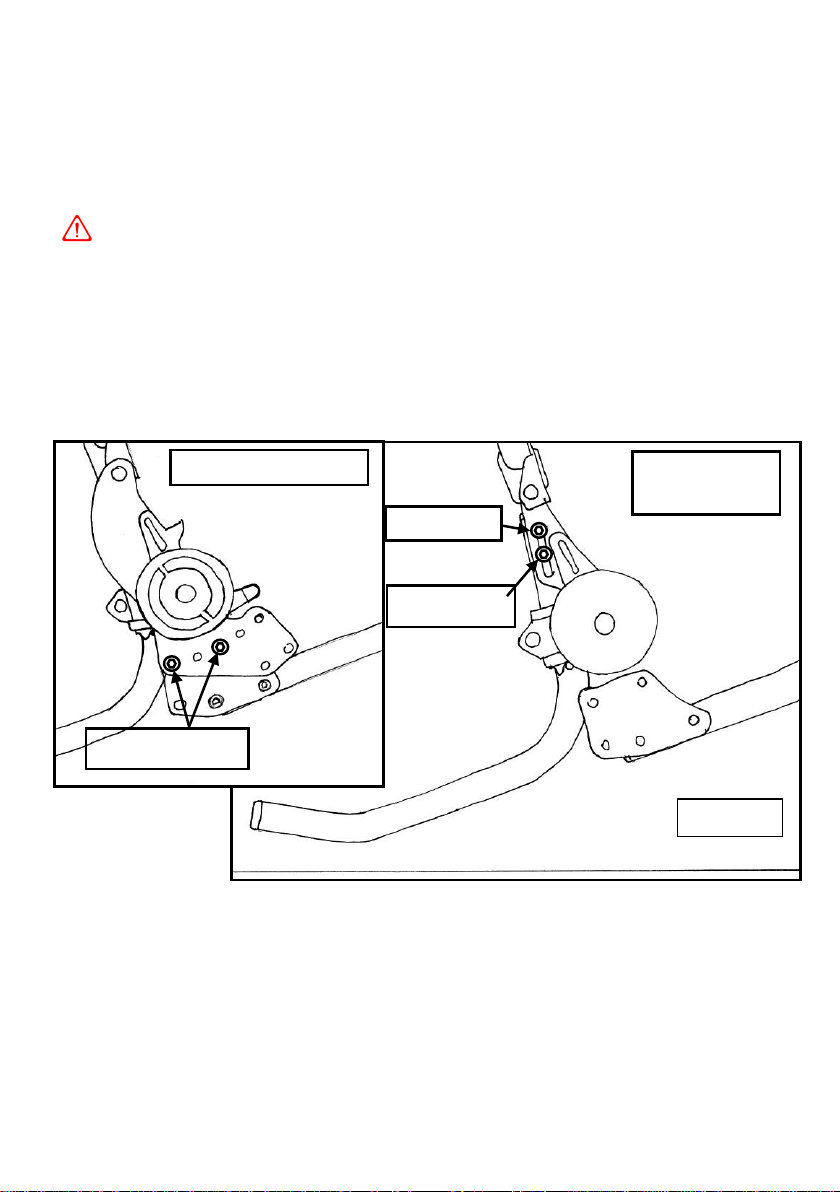

To adjust the anti-tipper position; first; loosen screws C & E. Then remove

screw D; be careful not to lose the washers. Rotate the anti-tipper assembly around

the axle to position 1 - 5 to suit the axle setting. Line up the appropriate hole or slot

in the adjuster plates and replace screw D; there should be spring washers between

the plates and the tube and plain washers under the screw head and the nut (see

diagram below). The end of the anti-tipper tube should be approximately 22mm from

the floor when deployed on a level surface.

Pg.17

Spacing

Plates

Flat

Washers

FIG.21

FIG. 20

Pg. 16

AXLE POSITION 3

SCREWS A & B

ANTI-TIPPER

SETTING 3

SCREW D

SCREW E

AXLE POSITION 5

SCREWS A & B

ANTI-TIPPER

SETTING 5

SCREW D

SCREW E

FIG. 18

FIG. 19

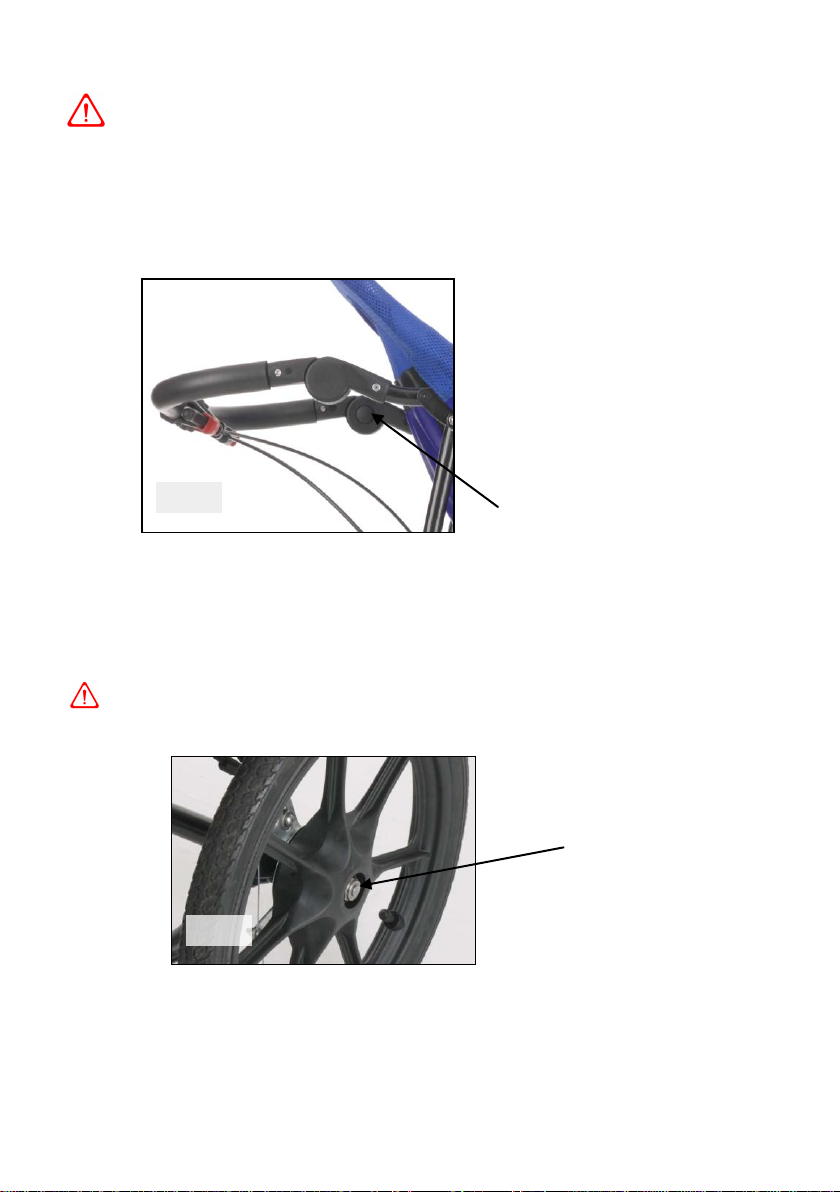

FIG 8.

Lap Pad

Park-Brake Latch

FIG. 7

To engage the park brakes;

pull the brake levers and engage

the red latch into the last notch on

the brake lever housing.

TO TEST THAT THE PARK-

BRAKES ARE WORKING TRY

PUSHING THE BUGGY; THE

REAR WHEELS SHOULD BE

LOCKED

Adjusting the Harness

The harness is attached to two buckles at the back corners of the seat; the length of

the two sides of the lap belt can be adjusted via these buckles. The lap belt is

tightened by using the centre buckle on the lap pad. The lap belt should be used at all

times to keep your child safely in the buggy.

The shoulder straps automatically adjust to the correct height when tightened by

sliding up or down the backrest.

The shoulder straps can be removed if not required by pulling the pad over the buckle

and undoing the Velcro® fastening. The bottom part of the shoulder strap can be

tucked out of the way under the seat.

The straps can be secured out of the way when transferring someone into and out of

the seat by using the Velcro® on the ends of the straps and under the lap pad buckle

to attach them to the side pads and the Velcro® patch on the right hand side of the

cover (see fig. 12).

The groin strap is

positioned by passing one

end of the lap belt through

the webbing loop on the

front of the pad before

fastening the lap belt. The

groin strap is attached to

the seat canvas the strap

passing through the

required loop on the canvas

and securing with the buckle

(see Fig 13).

Pg.9

Footrest Clamp

FIG. 9

Footrest Hook

Footrest

Adjusting

Screws

To adjust the footrest height;

first remove the footrest (see

page 8). Loosen the footrest

adjusting screws (see fig. 9) and

slide the footrest clamps up or

down the frame tubes to the

desired height.

Adjust the position of the clamps

so that they are at equal heights

and the footrest hooks are in line

with the frame.

Tighten the screws and check that

the footrest fits securely. There

should be about 1mm clearance

between the brackets on the

footrest and the footrest hooks.

The foot-straps are designed to be

long enough to remain under the

loops on the footrest while

positioning the foot.

To attach the sun-hood; with the sun-hood folded, fit the back of the hood

over the top of the backrest. Carefully insert the ends of the wire frame into the

holes in the handle bracket and push them in as far as they go. Hook the ends of the

bungee cords onto the slot in the rear frame bracket.

Pg.10

Attach bungee to slot in

frame bracket.

Frame of hood fits into

holes in handle bracket.

FIG. 10

Fitting the Beach Wheels

The beach wheels are attached to the buggy with quick release axles similar to the

standard wheels (but longer). The release button is deeper below the outside of the

hub.

Make sure that the axles are fully pushed down into the hub - they may be quite tight.

ENSURE THAT THE WHEELS ARE SECURE BEFORE USE.

ADJUSTING THE REAR AXLE POSITION OF THE DELTA BUGGY

The new Delta buggy has an adjustable axle position to change the balance of the

buggy making it less or more ‘tippy’. The Delta buggy is designed to be balanced so

that it is easy to manoeuvre. The default axle setting is in the most forward position.

For some occupants whose centre of gravity is further back in the buggy due to body

shape the axle can be moved further back.

To adjust the axle position; lay the buggy on its side and remove the screws A & B

from both sides of the frame.

There are five possible positions; positions 1, 3 & 5 are shown in the diagrams. Rotate

the axle assembly to line up the holes in the desired position. Replace the screws with

their washers, one side at a time. The anti-tipper must be adjusted to the

correct position corresponding to the axle (see pg.16).

Pg.15

ANTI-TIPPER

SETTING 1

SCREW D

SCREW E

AXLE POSITION 1

SCREWS A & B

FIG. 17

Table of contents