CANnector Installation Guide 4.01.0091.20000 1.3 en-US

Table of Contents Page

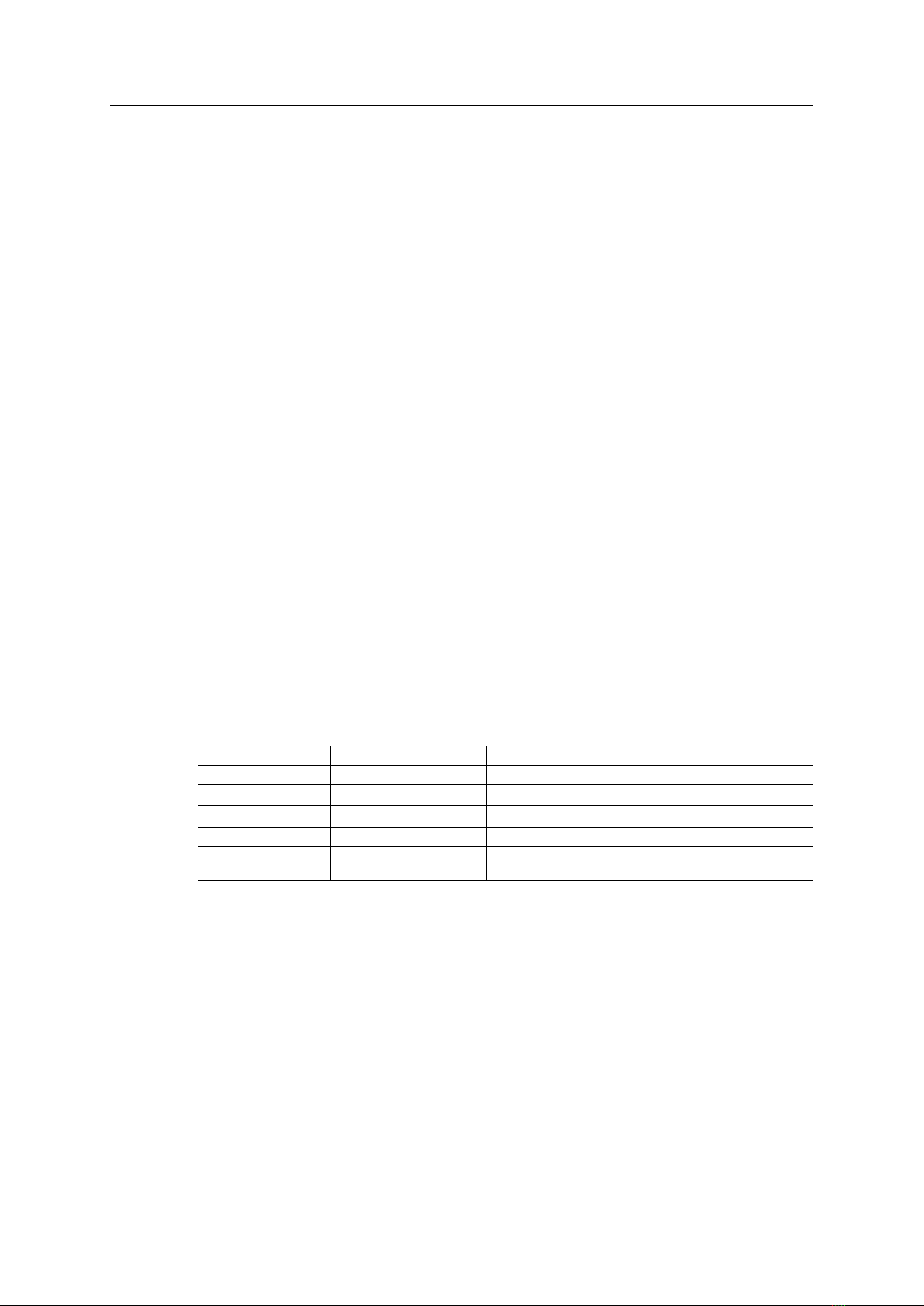

1 User Guide ........................................................................................................................... 3

1.1 Target Audience...............................................................................................................3

1.2 Related Documents ..........................................................................................................3

1.3 Document History ............................................................................................................3

1.4 Trademark Information.....................................................................................................4

1.5 Conventions....................................................................................................................4

2 Safety Instructions .............................................................................................................. 5

2.1 Information on EMC .........................................................................................................5

2.2 General Safety Instructions................................................................................................5

2.3 Intended Use...................................................................................................................5

2.3.1 CANnector Device Variants S, L, SE, LE, LA..................................................................... 5

2.3.2 CANnector Log, Range, Bridge .. .... .. .... .. .. .... .... .. .. .... .. .... .. .. .... .. .... .. .... .. .... .. .. .... .. .... .. ... 5

3 Scope of Delivery ................................................................................................................ 6

4 Product Description ............................................................................................................ 7

4.1 CANnector Device Variants S, L, SE, LE, LA ............................................................................7

4.1.1 Common Features.................................................................................................7

4.1.2 Device Variants.....................................................................................................7

4.1.3 Software for Configuration ....................................................................................... 7

4.2 CANnector Log, Bridge, Range ............................................................................................8

4.2.1 Common Features.................................................................................................8

4.2.2 Pre-Configured Product Variants .. .. .. .. ........... .. ........... .............. .............. ..... .. ... ..... .. .. . 8

4.2.3 Software for Configuration and Visualization ................................................................. 9

5 Installation......................................................................................................................... 10

5.1 Installing on DIN Rail....................................................................................................... 10

5.2 Installing the Adhesive Feet ............................................................................................. 10

6 Configuration..................................................................................................................... 11

6.1 Creating Configurations for CANnector S, L, SE, LE, LA .......................................................... 11

6.2 Selecting Pre-Configured Configurations for CANnector Log, Bridge, Range .............................. 12

6.2.1 Installing the Software .......................................................................................... 12

6.2.2 Connecting the Device .......................................................................................... 12

6.2.3 Selecting a Pre-Configured Configuration.................................................................... 13