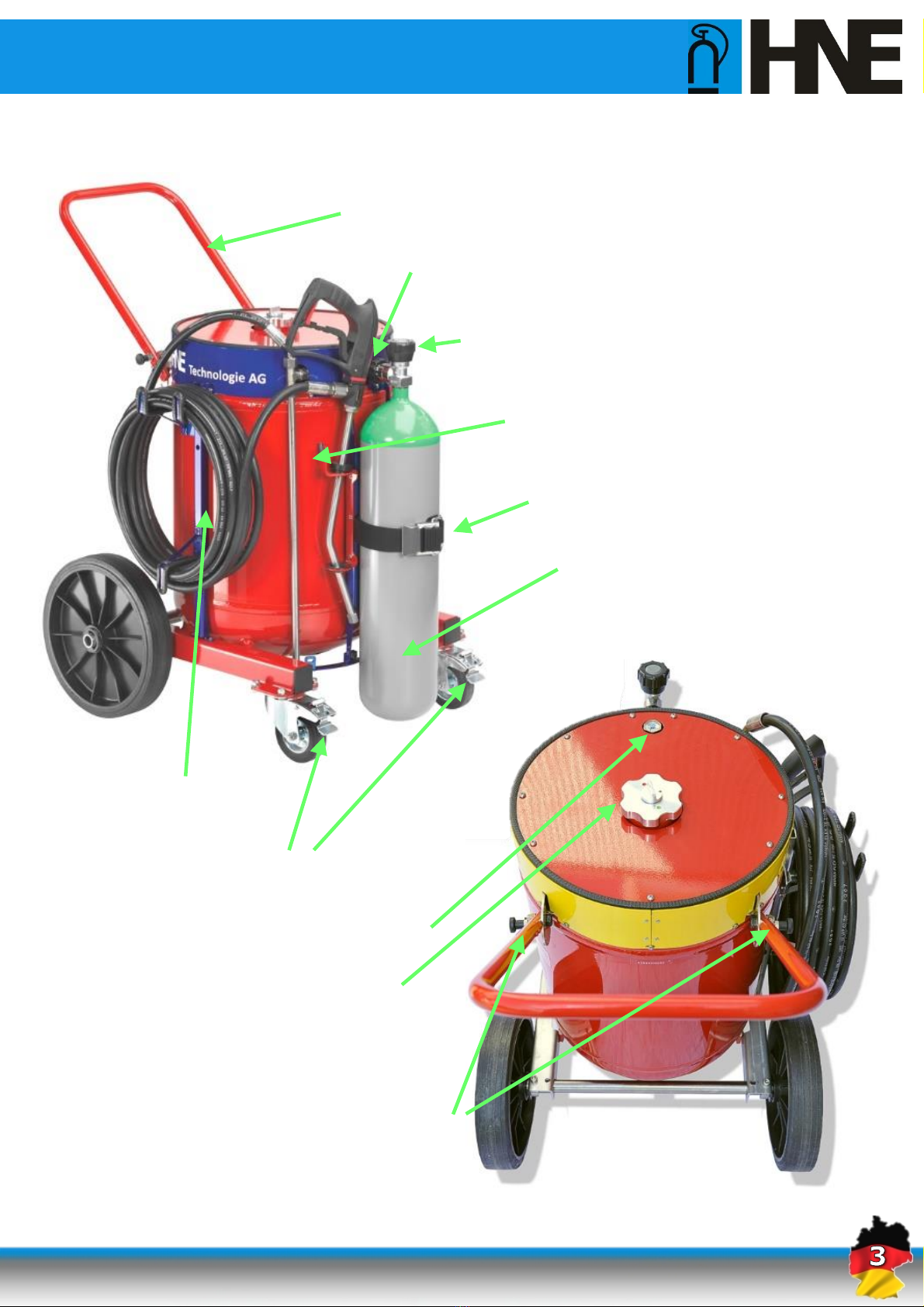

MADE IN GERMANY

www.hne.ag

Important basic information

thank you for choosing one of our products. You have acquired

a premium class fire fighting device, worldwide known for

superior performance and highest quality.

This manual will help you to keep operational readiness and

lifespan of your VARIO on highest level and to take full

advantage of its technical superiority. Please read it carefully

before using the extinguisher for the first time. In case of

questions or technical problems, please contact us.

Reliability and versatility of the HiPRESS/CAFS system exceed

even the toughest demands for professional use. The extra high

and constant working pressure offers excellent fire rating and

increased safety and capabilities for fire fighters during action.

Dear customer,

This manual is an important part of the extinguisher. It refers

to safe and proper use of the device in the interest of safety.

It has to be accessible for users and must be passed on in

case of sale.

We assume no liability for injuries, damage or malfunctions,

which arise due disregard of these user instructions.

The warranty for this device applies for flaws of material,

assembly, quality and function. It is void if the device is not

applied, operated and maintained as described.

Without our written permission, no content of this manual

shall be reproduced or forwarded to others. All technical

specifications and illustrations are subject to copyright.

Technical modifications are subject to change without notice.

HiPRESS 50 - COLD METAL