3

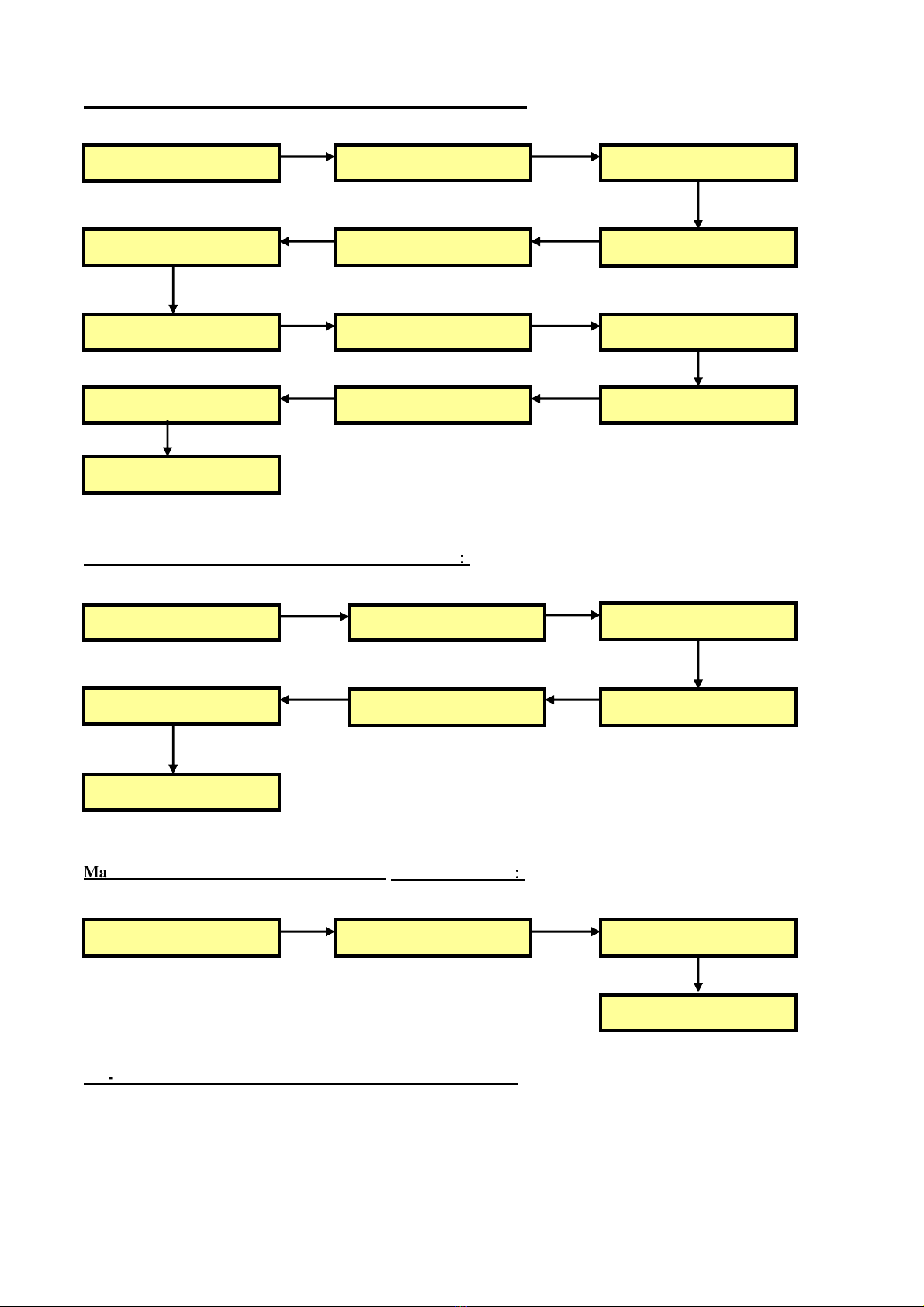

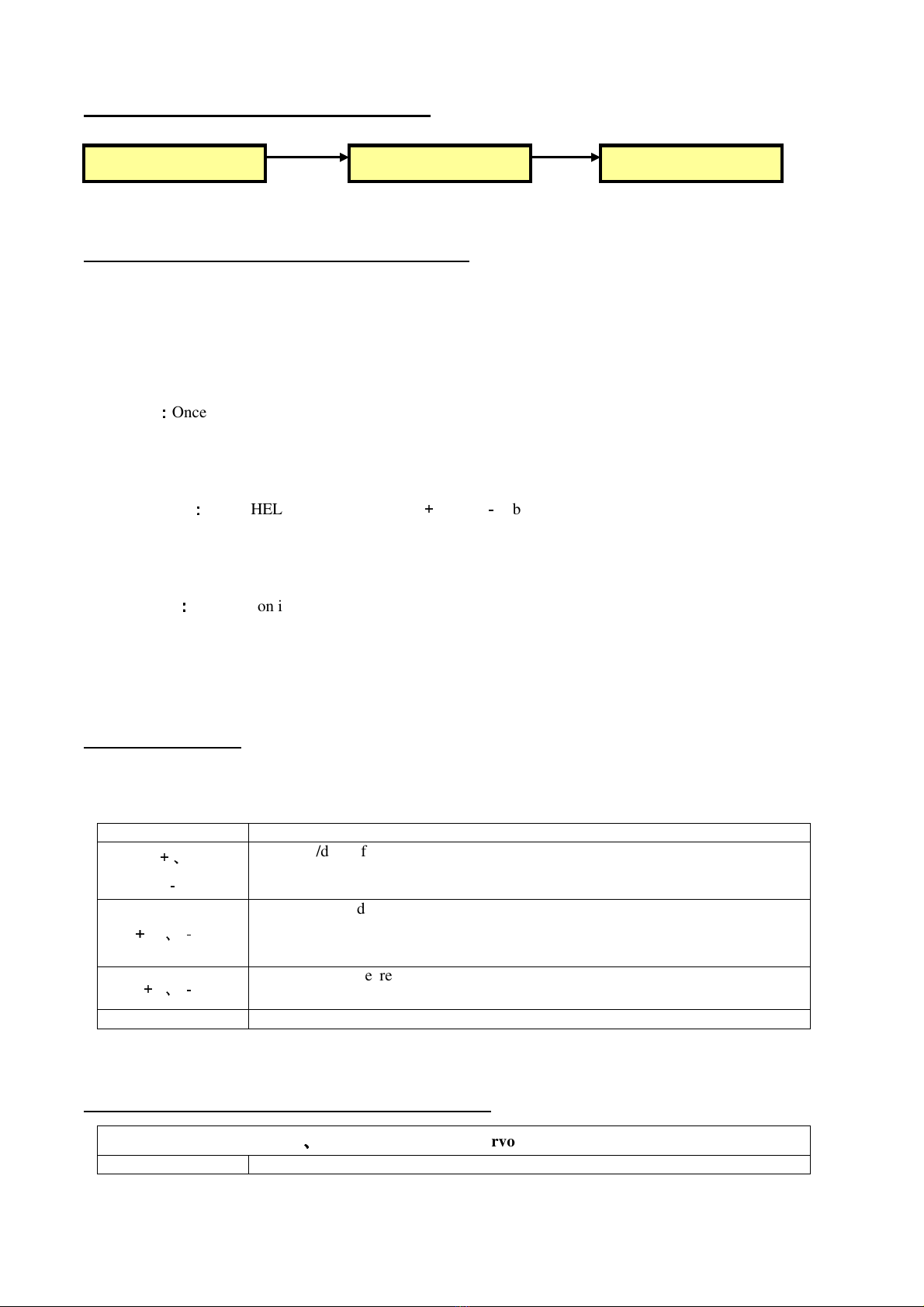

Please perform the following steps, to install the Turnigy® V-Bar 600.

●A rigid rotor head has no flybar, no washout assembly and no pitch mixer arms.

You must have a flybarless head with proper geometry installed

●Install Turnigy® V-Bar 600 correctly as illustrated above.

●Connect Turnigy® V-Bar 600 to receiver. Don not connect the servos to the Turnigy® V-Bar 600 at this

time.

●Ensure that the transmitter trims and sub-trims are set to zero, and that collective pitch to tail pitch mixing

is disabled.

●Ensure the swashplate type of transmitter is H1.

●Adjust the rudder, pitch, aileron and elevator servo travel (ATV, end point) to +/-100% in your transmitter.

●Set a gain switch in your transmitter for switching flight mode.

●Refer to the following LCD Setting Adaptor guide for detailed setting .

●Connect the servos(rudder,aileron, elevation,pitch) to Turnigy® V-Bar 600.

●Set the gain in your transmitter so that the Turnigy® V-Bar 600 is in memory bank 0, see page 5 before

continuing

●Set tail gyro gain in Turnigy® V-Bar 600 to be in normal mode (heading hold off).

●Select “READ DATA” menu and read the data under the flight mode

●If you switched gain switch, you must select “READ DATA” menu and read the data under the flight

mode.

●Rudder servo is in normal mode. Perform mechanical adjustment of the rudder servo horn and control

linkages to achieve approximately 8deg tail pitch.

●Confirm correct relationship of rudder stick and Turnigy® V-Bar 600 response to tail movement. Confirm

there is no mechanical binding.

●Confirm correct relationship of aileron stick and Turnigy® V-Bar 600 response to swashplate movement.

Confirm there is no mechanical binding.

●Confirm correct relationship of elevation stick and Turnigy® V-Bar 600 response to swashplate

movement. Confirm there is no mechanical binding .

●Confirm correct relationship of pitch stick and Turnigy® V-Bar 600 response to swashplate movement.

Confirm there is no mechanical binding.

In order to determine Turnigy® V-Bar 600’s Neutral Point, please don’t move the helicopter for

3 seconds

after powering on. Bind Turnigy® V-Bar 600 tightly with Velcro, avoiding that the helicopter body is

vibrated to cause Turnigy® V-Bar 600's shake.

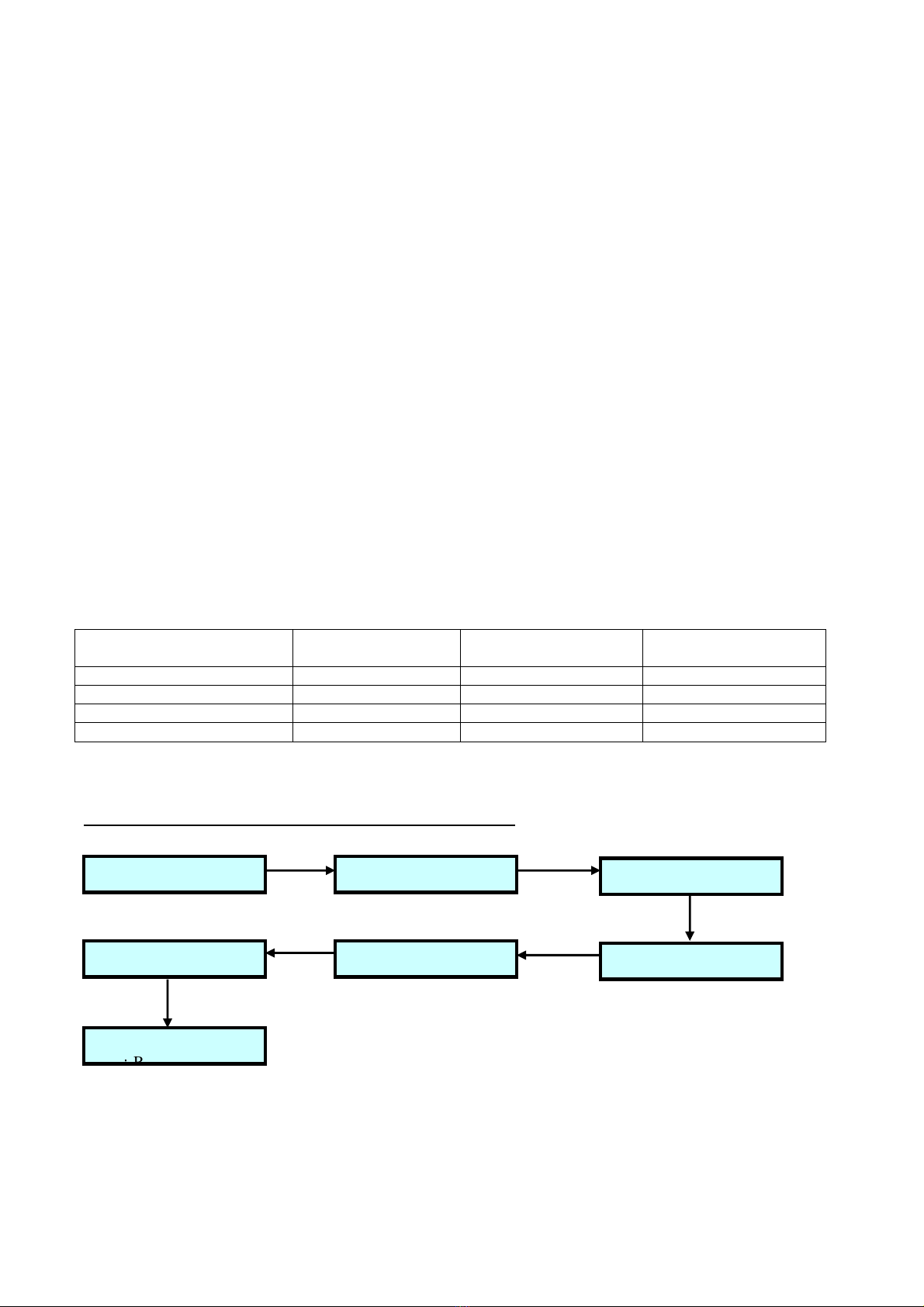

Power up Turnigy® V-Bar 600, and connect with LCD programmer.

Status LED:

During normal operation the LED provides simple status information for users.

On

:

AVCS and Normal mode. Rudder stick at neutral.

Off

:

Error. Gyro not receiving valid signal from the receiver or unable to calibrate

because the rudder stick is not centred.

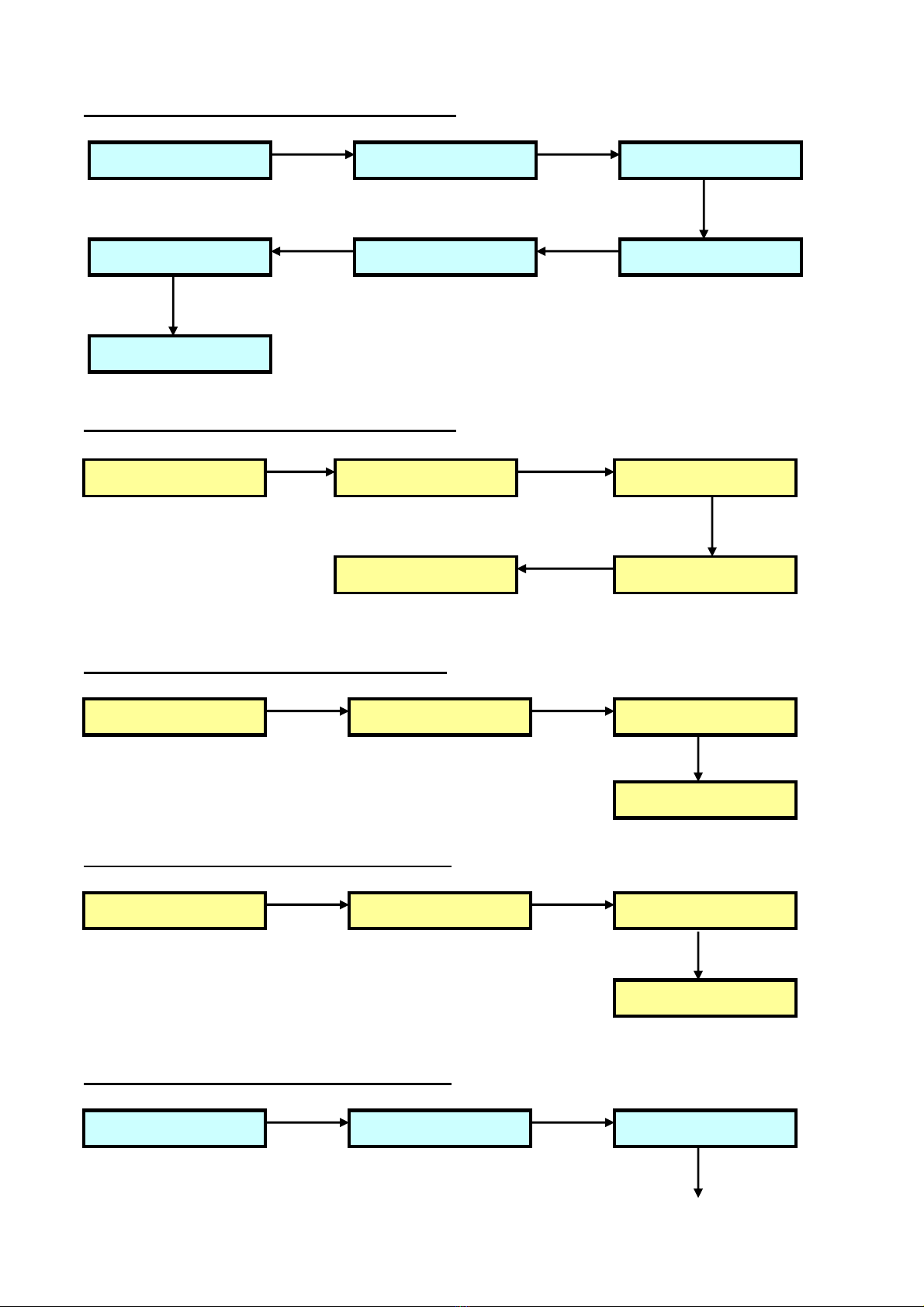

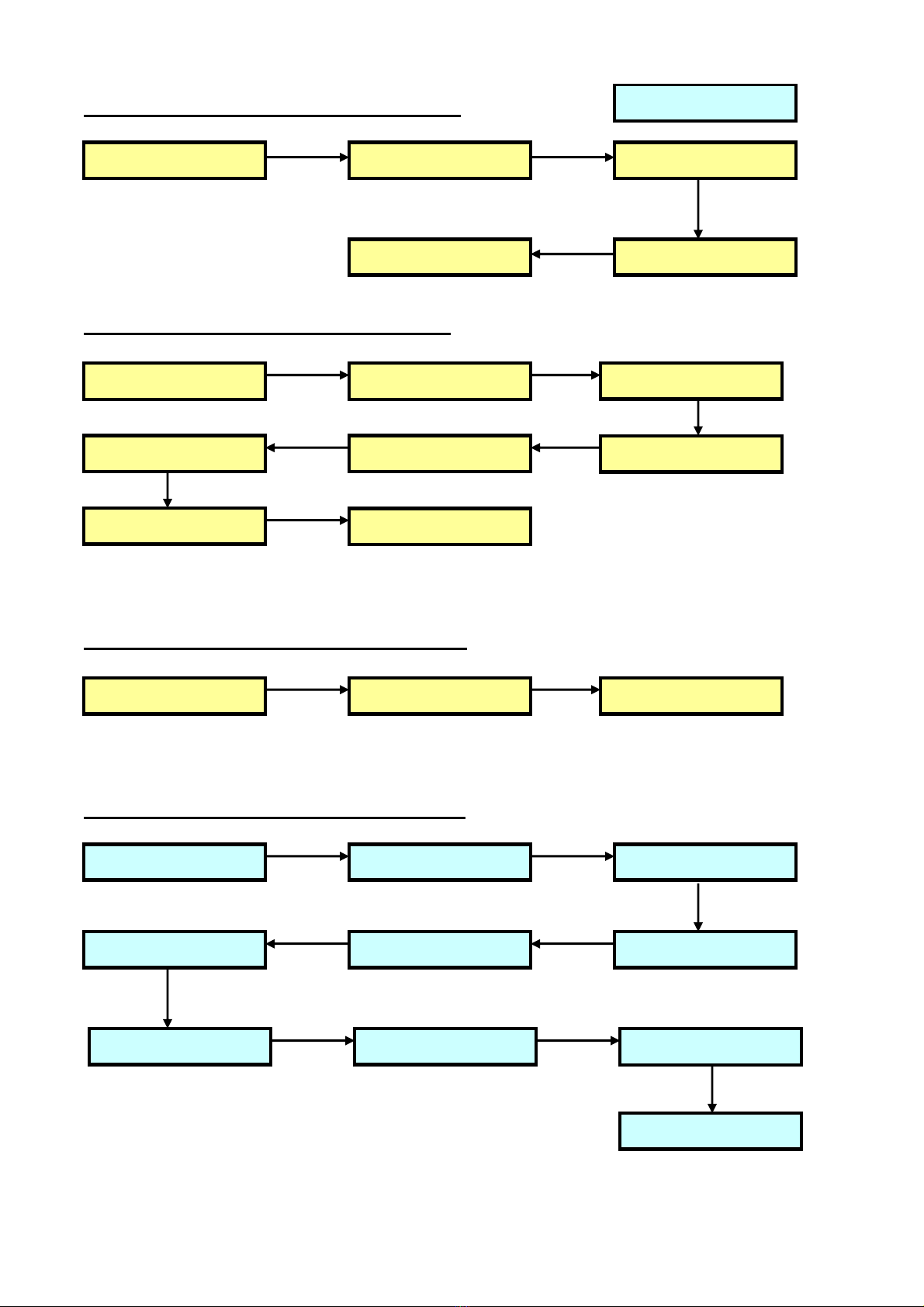

LCD Setting: