Hobby King Gulfstream G500 ARF User manual

Other Hobby King Toy manuals

Hobby King

Hobby King DH 82 Tiger Moth User manual

Hobby King

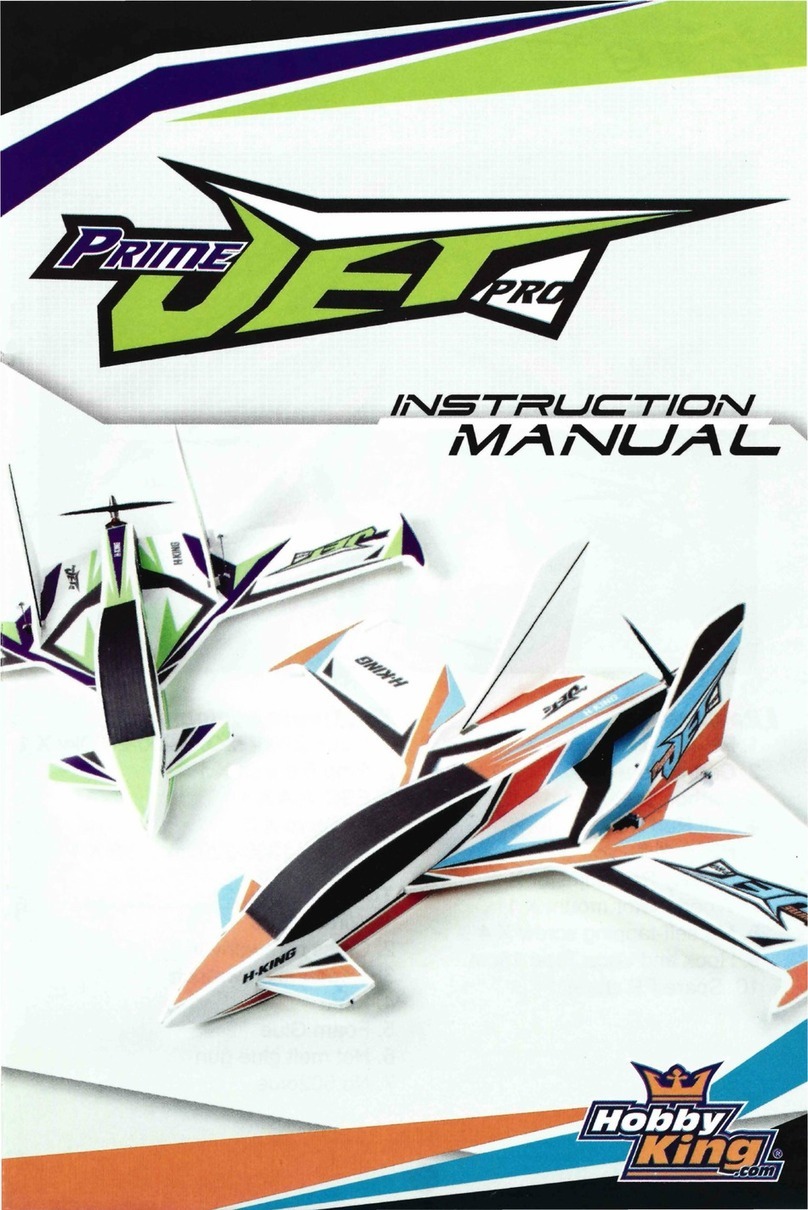

Hobby King Prime Jet Pro User manual

Hobby King

Hobby King YAK54 20CC EP User manual

Hobby King

Hobby King J3 CUB User manual

Hobby King

Hobby King Waco 30E User manual

Hobby King

Hobby King HUMMER EPP-3D User manual

Hobby King

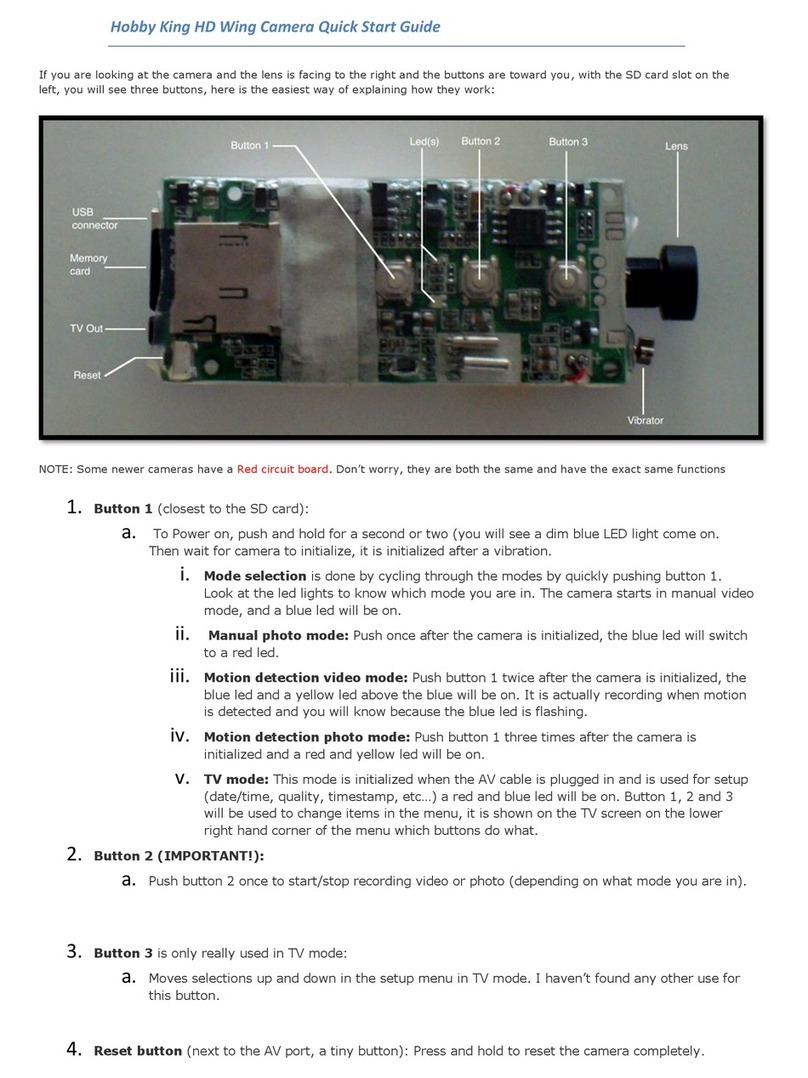

Hobby King HD Wing Camera User manual

Hobby King

Hobby King B-17 F User manual

Hobby King

Hobby King 450 User manual

Hobby King

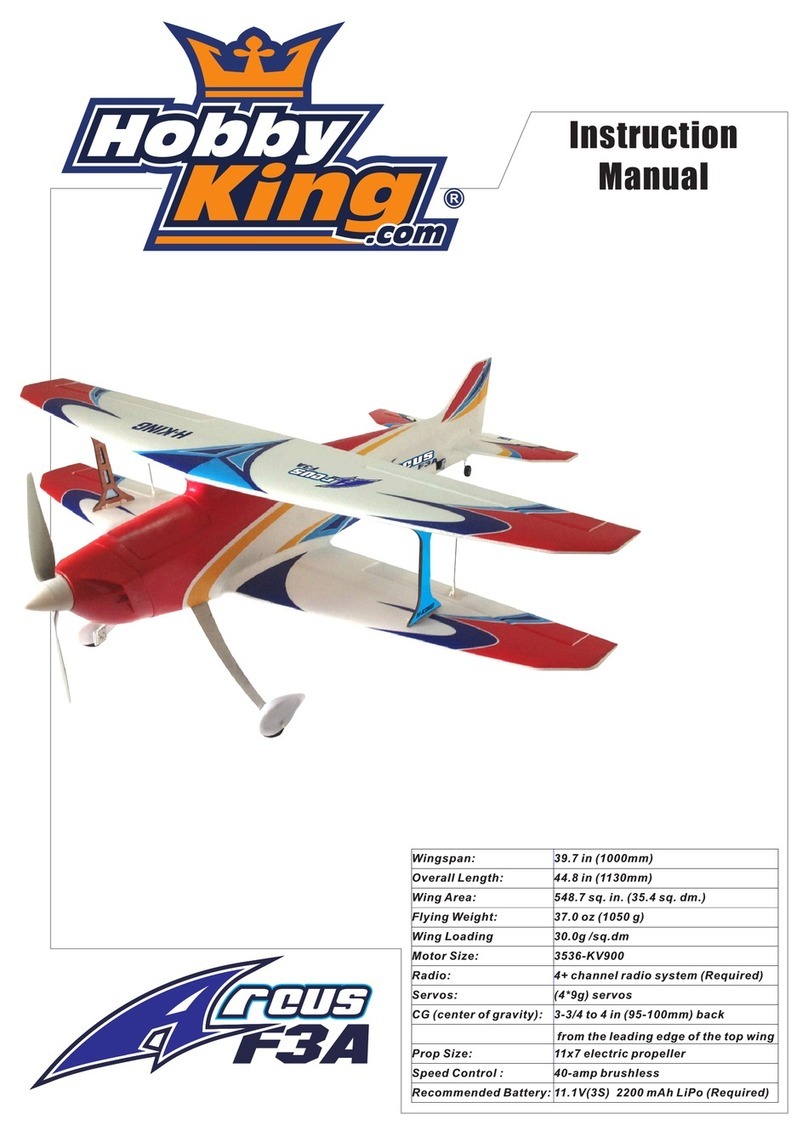

Hobby King Arcus F3A User manual

Hobby King

Hobby King WARGO YAK55 User manual

Hobby King

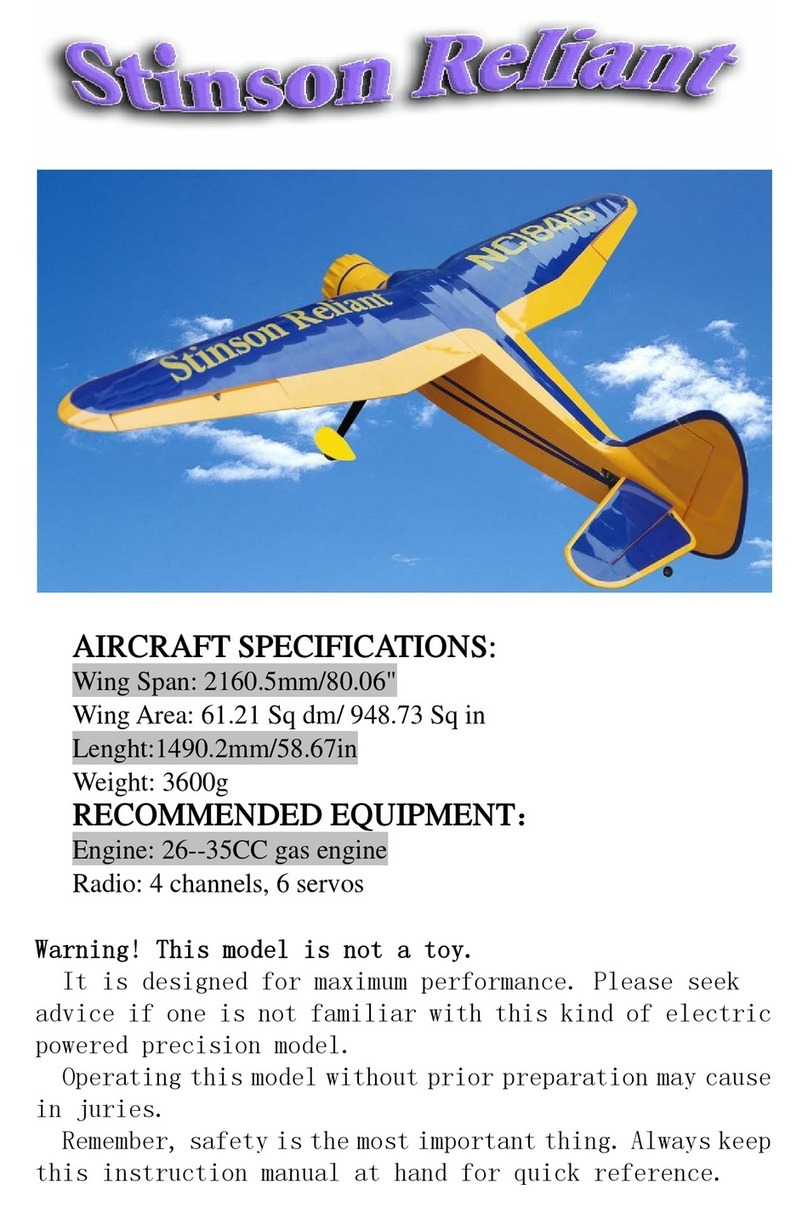

Hobby King Stinson Reliant User manual

Hobby King

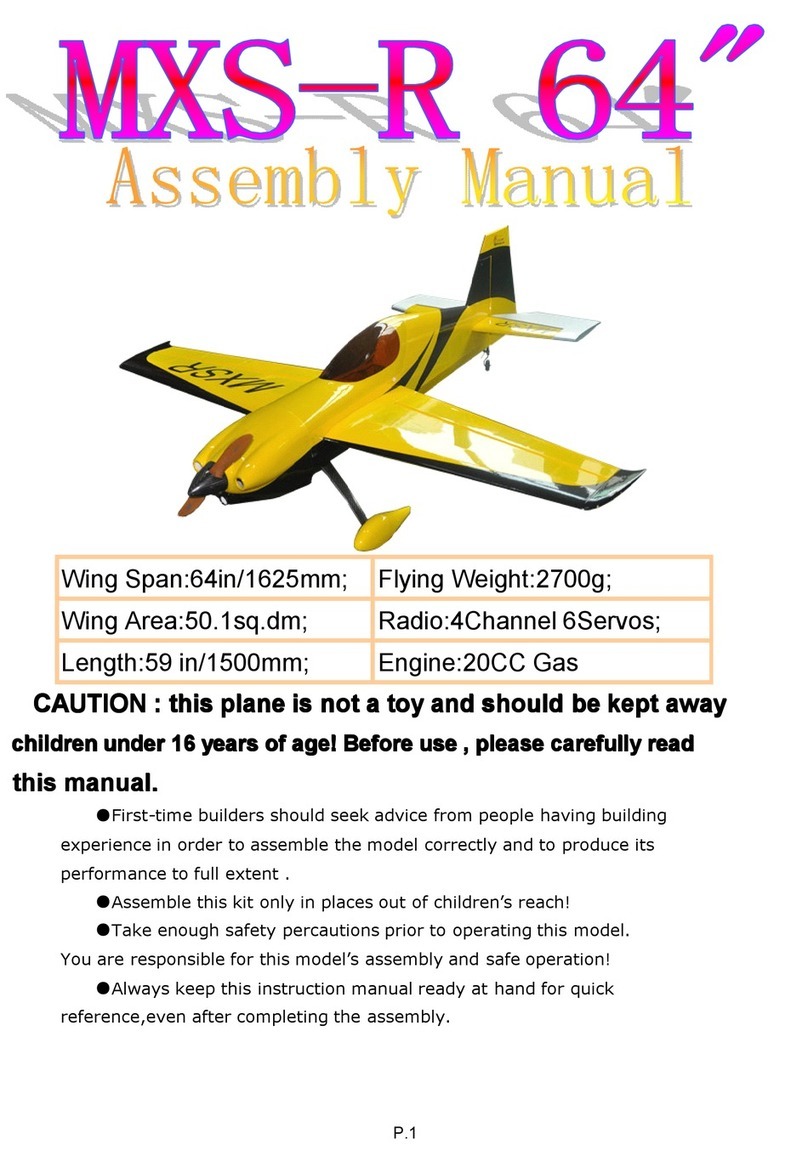

Hobby King MXS-R 64 User manual

Hobby King

Hobby King Aether 3700 EP User manual

Hobby King

Hobby King BAE Hawk User manual

Hobby King

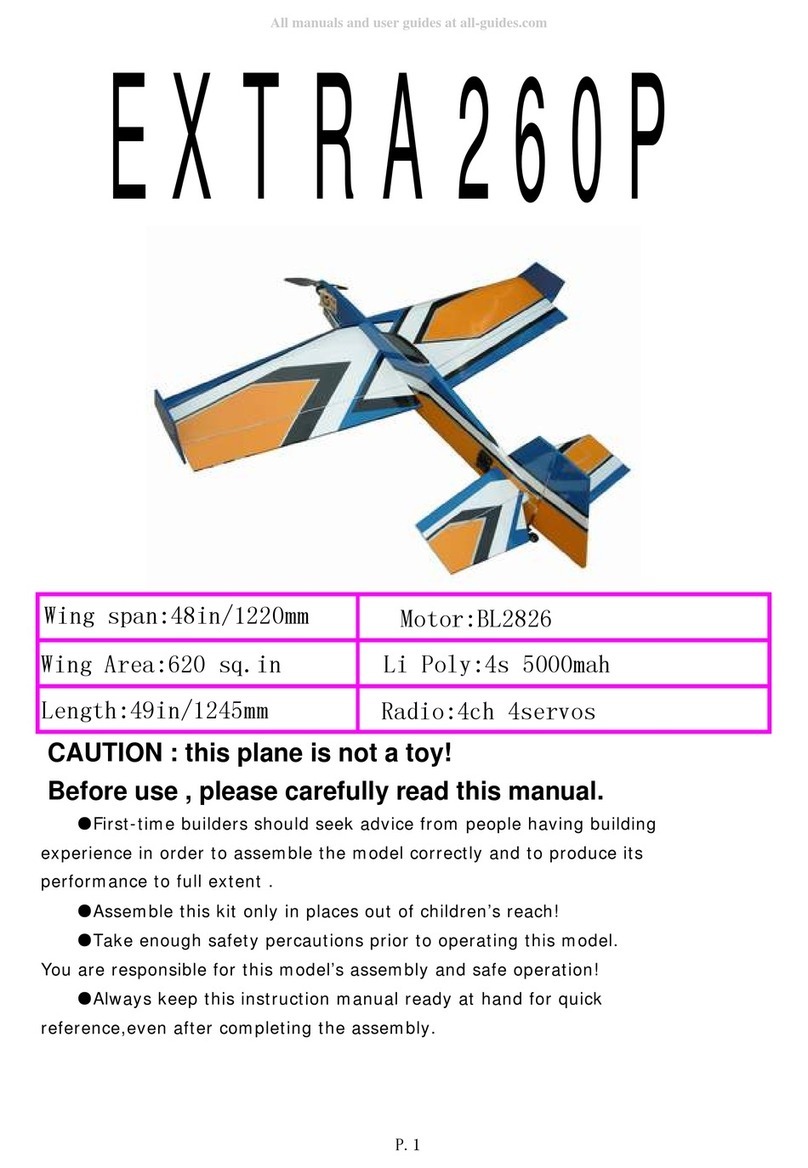

Hobby King EXTRA260P User manual

Hobby King

Hobby King H-KING Cri Cri User manual

Hobby King

Hobby King RYAN-STA User manual

Hobby King

Hobby King Maestro-46 User manual

Hobby King

Hobby King Micro SU-27 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions