User Manual of Series Brushless Speed Controller HW-SM100DUL-20161226

Page 2

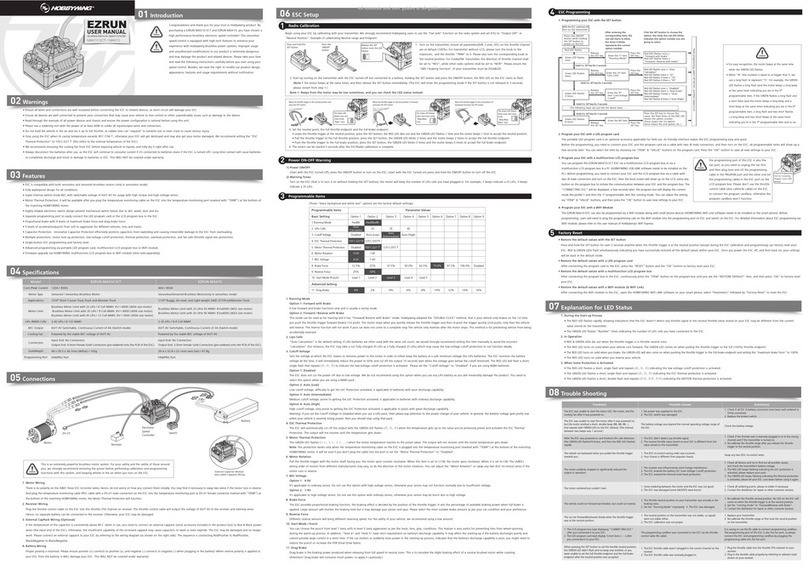

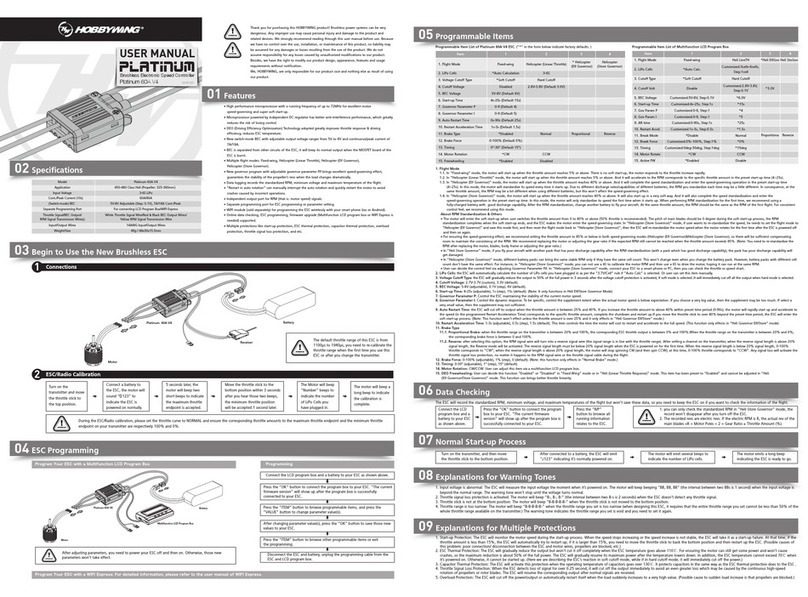

06 Programmable Items

Values

1 2 3 4

1 Brake Type *Disabled Normal Reverse

2 Brake Force *Low Medium High

3 Voltage Cutoff Type *Soft Hard

4 LiPo Cells *Auto Calc. 3S 4S

5 Cutoff Voltage Disabled Low *Medium High

6 Start-up Mode *Normal Soft

7 Timing Low *Medium High

8 Active Freewheeling *On Off

Note: Those values marked with * in the form below are the factory default settings.

1. Brake Type

1.1 Normal Brake

After selected this option, the brake function will be activated when you move the throttle stick to the bottom position. In this mode, the brake amount

equals to the brake force you’ve preset.

1.2 Reverse Brake

After selected this option, the Reverse Brake signal wire (its signal range must be the same as the throttle range) must to be plugged into any vacant channel

on the receiver, and you can control the motor direction via that channel. The channel range of 0-50% is the default motor direction, and the channel range

of 50% to 100% will cause the motor to spin counterclockwise. The channel stick should be within the channel range of 0-50% (0 would be better) when

the first time you power on the ESC. After the Reverse function is activated, the motor will stop first and then spin in the reversed direction and then

increase to the speed corresponding to the throttle input. Either signal loss, no matter reverse brake signal loss or throttle signal loss during the flight, can

cause the throttle signal loss protection to be activated.

2. Brake Force

This item is only effect in the “Normal brake” mode ,The higher the level, the stronger the braking effect , where the low/medium/high corresponds to the

braking force: 60/80/100%

3. Voltage Cutoff Type

3.1 Soft Cutoff

After selected this option, the ESC will gradually reduce the output to 50% of the full power in 3 seconds after the low-voltage cutoff protection is

activated.

3.2 Hard Cutoff

After selected this option, the ESC will immediately cut off the output when the low-voltage cutoff protection is activated.

4. LiPo Cells: The ESC will automatically calculate the number of LiPo cells you have plugged in as per the “3.7V/Cell” rule if “Auto Calc.” is selected, or

you can set this item manually.

5. Cutoff Voltage

If set off, the low-voltage protection function is disabled. In addition, the protection voltage value of the low-voltage protection function corresponding to

the low/medium/three modes is about 2.9V/ section, 3.2V/ section and 3.5V/ section. This value is the voltage of a single battery, multiplied by the number

of lithium batteries automatically identified by the electronic governor or the number of lithium batteries manually set, which is the protection voltage value

of the battery. (For example, if the low voltage protection threshold of 3 lithium batteries is medium, the protection voltage of the batteries is 3X3.2=9.6V)

6. Start-up Mode

6.1 Normal Start-up

After selected this option, the motor will immediately start spinning and then quickly reach to the corresponding speed when you move the throttle stick

from bottom position to top position.

6.2 Soft Start-up

After selected this option, the motor will slowly start spinning and then quickly reach to the corresponding speed when you move the throttle stick from

bottom position to top position.

7. Timing

Can adjust the drive motor timing value. The low / Medium and high are respectively: 5°/15°/22°.

8. Active Freewheeling (DEO)

This item is adjustable between “Enabled” and “Disabled”, and it is enabled by default. With it enabled, you can have better throttle linearity or smoother

throttle response.

07 Troubleshooting & Multiple Protections

Troubleshooting

Troubles Warning Tones Causes Solutions

The ESC didn’t work after it was

powered on while the motor kept

beeping.

“BB, BB, BB……”

The input voltage was beyond

the operating voltage range of

the ESC.

Adjust the power-on voltage and ensure

it’s in the operating voltage range of the

ESC.

The ESC didn’t work after it was

powered on while the motor kept

beeping.

“B-, B-, B-, B-……” The ESC didn’t receive any

throttle signal from the receiver.

Check if the transmitter and receiver are

well bound, if any poor connection exists

between the ESC and receiver.

The ESC didn’t work after it was

powered on while the motor kept

beeping.

“B, B, B, B……” The throttle stick has not been

moved to the bottom position.

Move the throttle stick to the bottom

position and calibrate the throttle range.

The ESC didn’t work after the throttle

calibration while the motor kept beeping.

“B, B, B, B……” The throttle range you set was

too narrow. Re-calibrate the throttle range.

The ESC output suddenly reduced to

50% during the flight, the motor kept

beeping after the flight completed but the

battery was still connected to the ESC.

“BB, BB, BB……” The ESC thermal protection has

been activated

Improve the heat dissipating condition (i.e.

add a cooling fan) or reduce the ESC load.

The ESC output suddenly reduced to

50% during the flight, the motor kept

beeping after the flight completed but the

battery was still connected to the ESC.

“BBB, BBB, BBB……” The low-voltage cutoff

protection has been activated.

Change another pack; lower down the

cutoff voltage or disable the LVC

protection (we do not recommend this).

Multiple Protections

1. Start-up Protection:

The ESC will monitor the motor speed during the start-up process. When the speed stops increasing or the speed increase is not stable, the ESC will take it

as a start-up failure. At that time, if the throttle amount is less than 15%, the ESC will try to restart automatically; if it is larger than 20%, you need to move

the throttle stick back to the bottom position first and then restart the ESC. (Possible causes of this problem: poor connection/ disconnection between the

ESC and motor wires, propellers are blocked, etc.)

2. ESC Thermal Protection:

The ESC will gradually reduce the output but won’t cut it off when the ESC temperature goes above 110℃. For ensuring the motor can still get some power

and won’t cause crashes, so the maximum reduction is about 50% of the full power. The ESC will gradually resume its maximum power after the

temperature lowers down. In addition, the ESC temperature cannot exceed 70℃ when it’s powered on. Otherwise, it cannot be started up. (Here we are

describing the ESC’s reaction in soft cutoff mode, while if in hard cutoff mode; it will immediately cut off the power.)

3. Throttle Signal Loss Protection:

When the ESC detects loss of signal for over 0.25 second, it will cut off the output immediately to avoid an even greater loss which may be caused by the

continuous high-speed rotation of propellers or rotor blades. The ESC will resume the corresponding output after normal signals are received.

4. Overload Protection:

The ESC will cut off the power/output or automatically restart itself when the load suddenly increases to a very high value. (Possible cause to sudden load

increase is that propellers are blocked.)

III. Select Parameter Values

The motor will beep different kinds of beeps

circularly, move the throttle stick to the top

position after you hear some kind of beeps will

get you to the corresponding parameter value,

then you’ll hear the motor emit “ ” to

indicate the value is saved, then get back to

VI. Exit the

Programming

Move the throttle

stick to the bottom

position within 3

seconds after you

hear two long beeps