User Manual of “SEAKING V3 RTR”Series Brushless Speed Controller for Boat HW-SM704DUL-V2-20180111 Page - 2 -

voltage the moment it is connected to the controller, then the ESC counts the cells number. For example, if the battery voltage is lower than

8.8V, it will be identified as 2S Lipo battery. In order to ensure the ESC calculate the cells number correctly, please always use a fully charged

battery to connect the ESC. If the battery is not fully charged or partly discharged, then the “Auto Calculate” may get a wrong result.

Hint: In the startup process, the motor will emit several “Beeps” to indicate the Lipo cells number; it is helpful for you to check if it is

consistent with the actual cells number in your battery pack. If you often use Lipo battery packs with the fixed number of cells, then we

strongly suggest you to set the “Lipo Cells”to a fixed value instead of using the “Auto Calculate”, as this can ensure the low-voltage cutoff

protection works normally all the time.

3. Low-voltage Cutoff Threshold: This function prevents the Lipo battery pack from over-discharging. The ESC detects the battery voltage all

the time, if the voltage goes below the threshold for 2 seconds, the output power will be cut off, then the Red LED blinks slowly. The controller

can be re-operated at the halved power after the throttle returns to zero. then please replace the battery pack as soon as possible.

Warning! If you ignore the low voltage cutoff warning and keep running, the Lipo battery will be damaged irreversibly!

a) How to calculate the cutoff threshold of a whole battery pack:

The cutoff threshold of a battery pack = the threshold of each cell x cells number

For example, if the threshold of each cell is set to “3.2V/Cell”, and the battery pack is a 3S (3 Cells), then the cutoff threshold of this

battery pack is 3.2x3=9.6V.

b) If you are using a NiMH battery:

NiMH battery is not easy to be damaged, so you needn’t worry about the over-discharging problem, you can set this programmable item

to “No Protection”.

4. Timing: Please select the most suitable timing option according to the motor you are using. The correct timing makes the motor run

smoothly. Generally speaking, higher timing brings out higher output power, higher speed and also higher temperature.

【Program the ESC】

1. Program the ESC with your transmitter

By 4 Steps: Enter the programming mode →Select programmable item(s) →Choose a new value for the selected item →Exit

2. Program the ESC with a Program Card

Program card is an optional equipment for boat ESCs, it has 3 digital LEDs to display the programmable items and corresponding parameter

values, so the user interface is very intuitive. It’s quite easy to program ESCs with this small equipment. For more detailed information, please

read its operation manual.

【Multiple Protections】

1. Low Voltage Cutoff Protection:when the battery voltage falls below the preset cutoff threshold for over 1 second, the ESC will cut off the

output and stop working, then the Red LED blinks slowly. The controller can be reoperated at the halved power after the throttle returns to

zero.

2. Overheat Protection:when the ESC temperature goes above the factory preset value (100℃or 212 ℉), the ESC will cut off the output and

stop running, then the Green LED flashes slowly. The controller can be reoperated at the halved power after the throttle returns to zero, the

output will resume if the temperature decreases below 80℃(176℉) .

3. Throttle Signal Loss Protection:when the receiver detects no throttle signal (from the transmitter) for over 0.1 second, the ESC will cut off

the output. The controller will not resume running until the signal is detected again. Hereby, we suggest users setting the no signal protection

(or F/S Protection) on the Throttle channel (on the transmitter) to “Output off” or “Neutral position” to ensure that the motor can be stopped

when the throttle signal is lost.

【LED Indications】

There are two LED indicators in the ESC,a Green one and a Red one.

1. When the throttle is above the zero-speed position, the Red LED will come on and the motor starts to spin; while pushing the throttle to the

maximum position (/ full throttle), the motor runs at its full speed and both the Red & Green LEDs light up.

2. When setting the throttle range and parameters of the ESC, the motor beeps and Red LED flashes simultaneously for easy observation.

3. Green LED blinks slowly denoting the ESC has entered the overheat protection, Red LED flashes slowly means the Low-Voltage Cutoff

Protection is activated.

【Troubleshooting】

After powered on, the motor doesn’t emit any

beep tone and the LED doesn’t light up.

No battery voltage is inputted to the ESC or

got the polarity reversed.

Check the connection between the battery

and ESC, please re-solder if poor soldering

exists.

If the polarity is reversed, please cut off the

power immediately. Otherwise, the ESC

will be damaged irreversibly.

After powered on, the motor doesn’t work, but

the following alert tone is emitted:

“beep-beep-, beep-beep-”(here the time interval

is 1 second).

The battery voltage is abnormal; or the

startup temperature of the ESC is above 80℃

(176℉).

Check the battery voltage;

Check whether the water cooling system

runs smoothly or not, or change another

ESC with greater amperage capability.

Pulling the throttle trigger, while the boat goes

backward.

Wrongly connected the ESC and motor wires.

Swap any two wires connections between

the ESC and the motor.

The boat cannot run backward.

The ESC is not set to “Forward and

Backward” running mode;

The ESC cannot recognize the throttle neutral

point.

The throttle range is set to "Full-Range" mode

for a stick transmitter.

Set the running mode to “Forward and

Backward”;

Recalibrate the throttle range according to

instructions on page 1.

Set the throttle range to "Half-Range "

mode for the stick transmitter.

The output power suddenly weakens.

The Low-Voltage Cutoff Protection or the

Overheat Protection is activated.

Replace another fully-charged battery;

Cool the ESC down before using it again.

The motor cannot be started normally, and it

only stutters.

The ESC and motor wire are not well

connected or the ESC / motor is damaged

Check all the connections; replace the ESC

or the motor. (Note: please test with a

small throttle value first, then increase the

value after the motor returns to normal.

Otherwise, the ESC/motor may get

damaged again.

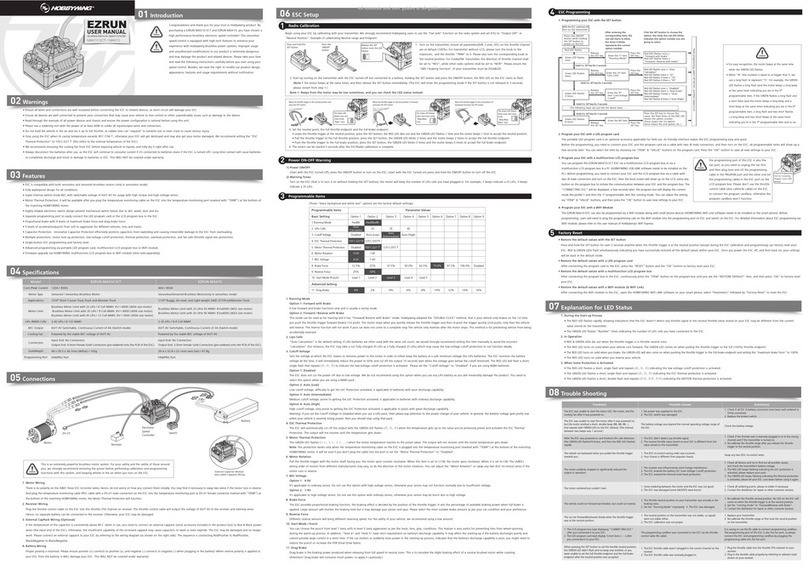

STEP 1. Enter the programming mode

1. Switch on the transmitter, move the throttle stick to the top position (/full throttle).

2. Connect the battery pack to the ESC, wait for 2 seconds, the motor emits “Beep-Beep-” tone.

3. Wait for 5 more seconds, the motor emits a special tone “♪”, that means the controller enters the programming mode.

STEP 2. Select programmable items

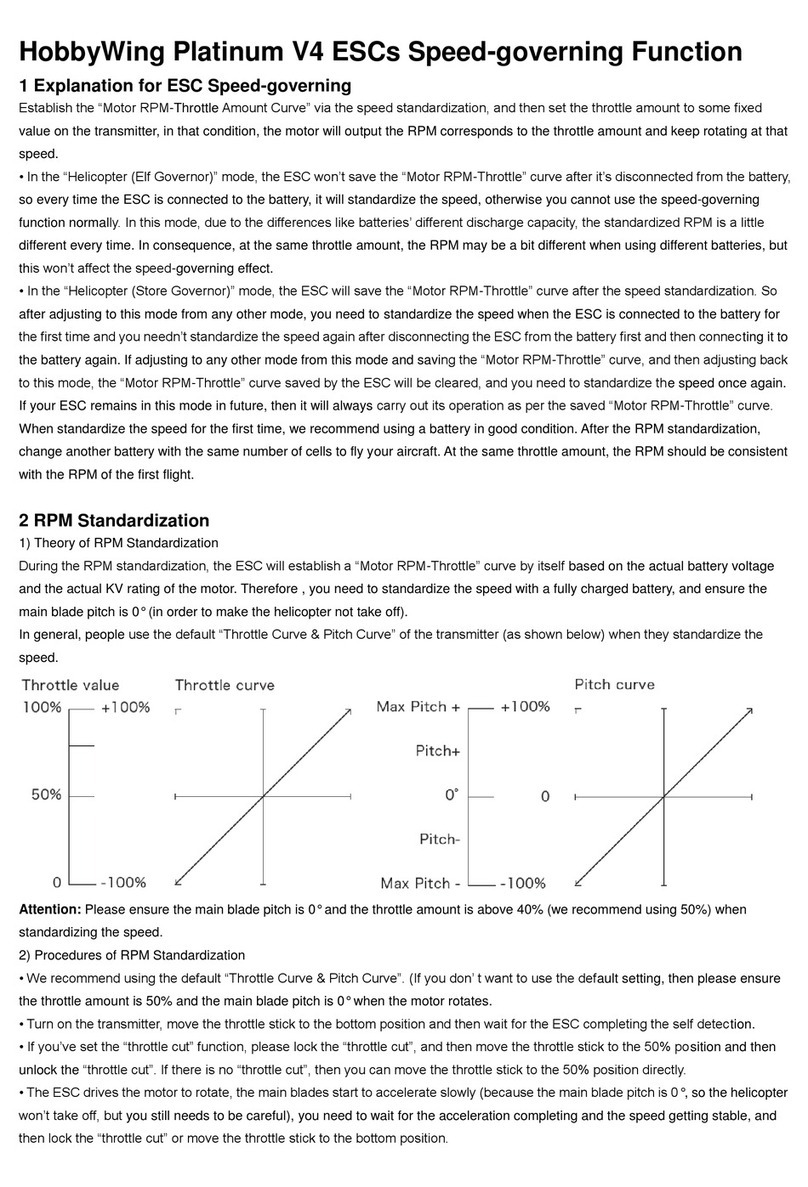

After entered the programming mode, you will hear the following 4 kinds of “Beep” tones circularly. If move the throttle stick to the bottom

position (/full brake) within 3 seconds after one kind of “Beep” tone emits, then the corresponding item will be selected.

1. “Beep-” Running Mode (1 short “beep”)

2. “Beep-Beep-” Lipo Cells (2 short “beeps”)

3. “Beep-Beep-Beep-” Low-voltage Cutoff Threshold (3 short “beeps”)

4. “Beep-Beep-Beep-Beep” Timing (4 short “beeps”)

STEP 3. Choose a new value for the selected item

After entered a certain item, the motor will beep in a loop. Set the corresponding value by moving the throttle stick to the top position

(/full throttle) when you hear the tone, then a special tone “♪” emits, which means the value has been chosen and saved into the ESC.

(If keep the throttle stick at the top position (/full throttle) for over 2 seconds, you can return to STEP 2 and set other items; if move the

stick to the bottom position (/full brake) within 2 seconds, then you will exit this programming mode directly.)

“Beep—B”

1 long +

1 short

“Beep—BB”

1 long+

2 short

“Beep—BBB”

1 long+

3 short

Low-voltage

Cutoff Threshold

Note5: One long “Beep—” = 5 short “Beep”. For example, “Beep—Beep” tone means the No.6 value.

(

5+1

=

6

)

STEP 4. Exit the programming mode

There are 2 methods to exit the programming mode:

1. In STEP 3, the motor emits the special tone “♪”after chosen the value, at this moment user can move the throttle stick to the

bottom position (/full brake) in 2 seconds to exit the programming mode.

2. Disconnect the battery pack from the ESC to exit the programming mode forcibly.