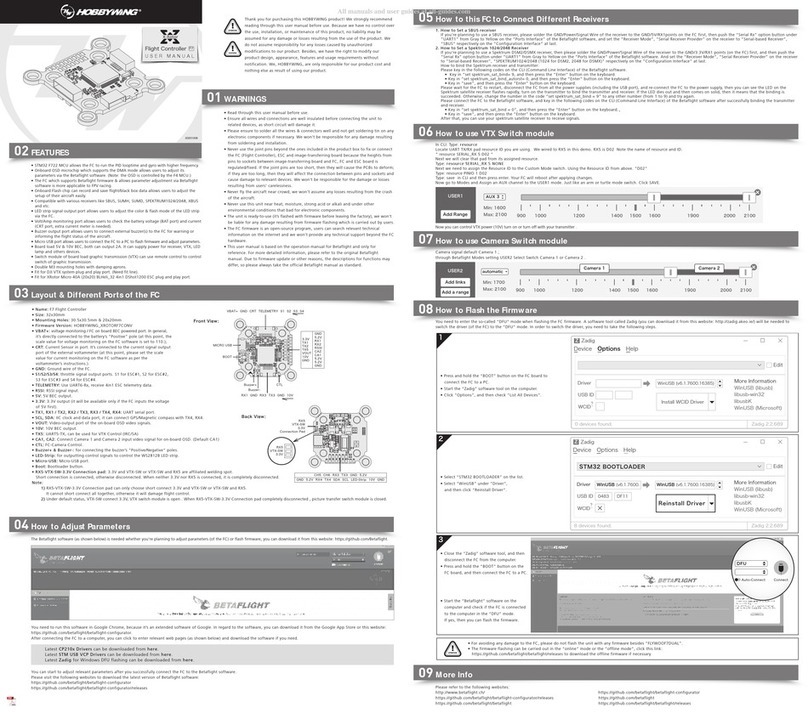

User Manual of XRotor Series Controllers for Multi-rotors HW-SM015DUL-20150203

Thank you for purchasing the product! Brushless power system can be very dangerous, any improper use may

cause personal injury and damage to the product and related devices. Therefore, we strongly recommend reading

through this user manual before use. In that we have no control over the use, installation and maintenance of this

product, no liability may be assumed for any damages, losses resulting from the use of the product. Besides, we

don’t shoulder any responsibility for any losses caused by unauthorized modifications to our product.

【Features】

Special core program for multi-rotor controllers greatly improves the throttle response;

Specially optimized software for excellent compatibility with disc-type motors;

Highly intelligent and adaptive, all settings except "Timing" are preset and that makes the usage really simple;

Compatible with various flight-controllers and supports the signal frequency of up to 621Hz (Notes: the throttle

signals over 500Hz are non-standard signals.).

【Specifications】

Model Con.

Current

Peak

Current

(10 sec)

BEC Lipo Programmable Item Weight Size (L*W*H)

XRotor

80A-HV 80A 100A No 4-12S

Timing

(Intermediate/High)106g 77*35*21

XRotor

100A-HV 100A 120A No 4-12S

Timing

(Intermediate/High)106g 77*35*21

XRotor

100A 100A 150A No 4-6S

Timing

(Intermediate/High)104g 70*35*21

【User Guide】

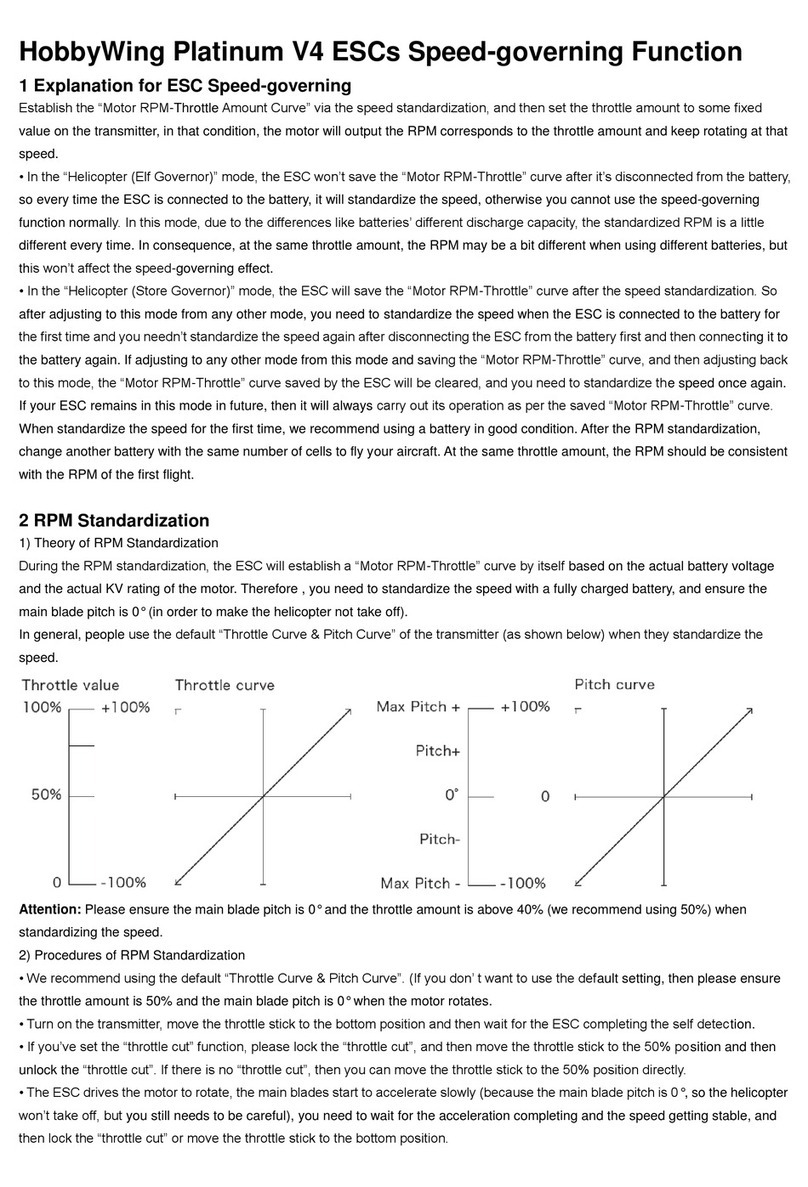

Throttle Calibration & ESC Programming

User needs to calibrate the throttle range when he starts to use a new XRotor brushless ESC or another transmitter;

User can change the Timing setting when some abnormality occurs in ESC driving the disc-type motor or need the

motor to reach a higher RPM. (Note: Intermediate Timing is the default setting.)

Step 1: Motor Wiring

Warning! This is an extremely powerful brushless motor system. We strongly recommend removing your propellers for

your own safety and the safety of those around you before performing calibration and programming operations.

Note: The 3pin JR connector beside the throttle signal cable is ONLY used to provide power supply to the cooling fan for

the ESC (The cooling fan is an optional accessory).

Step 2: Radio Calibration

Step 3: ESC Programming

Notes: Generally speaking, intermediate timing is applicable for most motors and it brings higher efficiency but less heat to

the power system. High timing can increase the RPM of the motor, but it also increase the motor temperature. Therefore,

please have a test flight on the ground and ensure everything is ok first, and then you can fly the aircraft into the sky.

【Normal Start-up Process】

【Protections】

【Troubleshooting】

Trouble Warning Tone Possible Cause Solution

The ESC was unable

to start the motor.

(The motor beeps rapidly)

Move the throttle stick to the

bottom position or recalibrate the

The ESC was unable

to start the motor.

Check if the transmitter and

Check if the throttle wire has been

properly plugged into the throttle

The ESC was unable

to start the motor.

Refer to the transmitter instructions

and correctly set the "Normal/

Reverse" direction of the throttle

The ESC is specially designed for multi-rotors, so it hasn't the LVC(Low Voltage Cutoff) protection or

Start-up Protection: The ESC will shut down the motor after it fails to start the motor normally in 2 seconds by

increasing the throttle value. In this case, you need to move the transmitter throttle stick back to the bottom position

and restart the motor. (Possible causes to this problem: poor connection or disconnection between the ESC and

motor wires; propellers are blocked or others.)

Over-load Protection: The ESC will cut off the power/output when the load suddenly increases to a very high value

and it won’t get back to normal operation until the throttle stick is moved back to the bottom position. Besides, the

ESC will automatically attempt to restart when the motor and the ESC are out of sync.

Throttle Signal Loss Protection: When ESC detects loss of signal for over 0.25 second, it’ll cut off the output

immediately to avoid even greater loss which may be caused by the continuous high-speed rotation of propellers or

rotor blades. And the ESC will resume the corresponding output after usual signals are received normally.

Turn on the

transmitter, and

then move the

throttle stick to

the top position.

“Beep-beep-” Throttle Calibration

“Beep-beep-beep-” Intermediate Timing

“Beep-beep-beep-beep-” High Timing

If move the throttle stick to the bottom

position in 3 seconds after you heard the

corresponding beeps, then the

programming of that item is completed.

The motor

will beep

different

tones

circularly.

Connect the receiver to

the battery and ensure

the transmitter and

receiver are well bound,

and then turn on the

ESC.

Programming is completed; and the

ESC is ready to go.

Turn on the transmitter

and move the throttle

stick to the bottom

position.

The motor will emit a long “beep----”1

second after the system is connected to the

battery indicating the ESC is armed and the

multi-rotor is ready to go.

Turn on the

transmitter, move

the throttle stick to

the top position.

Connect the receiver to the

battery, ensure the transmitter

and receiver are well bound,

and then turn on the ESC.

After the motor emits two short

“beep-beep”, move the throttle

stick to the bottom position in 3

seconds.

Throttle

Calibration

completed