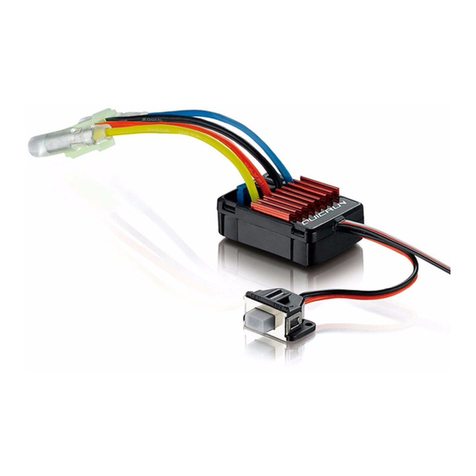

Model QUICRUN WP Crawler Brushed

Cont. / Peak Current

Motor Type

Applications

80A / 400A

Brushed Motor (540 / 550 / 775 size motors)

1/10th Rock Crawler

LiPo / NiMH Cells

BEC Output

Connectors

Size / Weight

Programming Port

2-3S LiPo / 5-9S NiMH

6V / 7.4V@ 3A (Switch-mode)

Input End: XT60; Output End: No Connectors

36.2 x 31.6 x 17.0 mm / 58.5g

Separate Port

Motor

Limit

Brushed Motor Limit with 2S LiPo / 6S NiMH: ≥10T or RPM<[email protected] (540/550 size motors)Brushed

Motor

Limit

with

3S

LiPo

/

9S

NiMH:

≥16T

or

RPM<

[email protected] (540/550

size

motors)

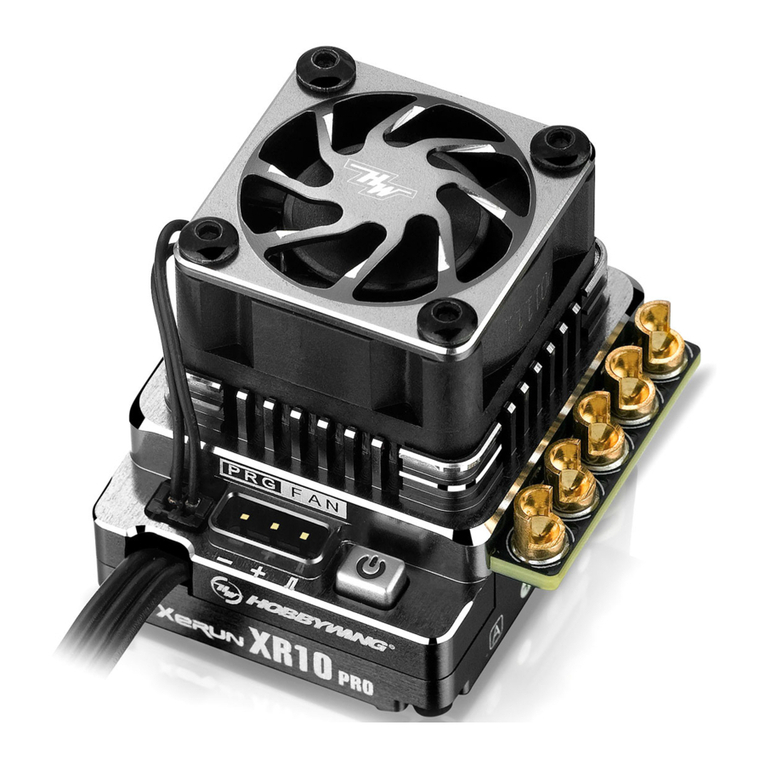

• Fully waterproof design for all conditions. (Note: please clean and dry it after use for avoiding rusty connectors)

• HOBBYWING patented copper heat-conductive plates attached to the MOSFET board allows the internal heat to be quickly transferred to the CNC-machined aluminum reticular heat sink for

great heat dissipation.

• High reliable electronic switch design prevents mechanical switch failure due to dirt, water, dust and etc.

• Built-in switch-mode BEC with switchable voltage of 6V/7.4V and cont. /peak current of 4A/6A for usage with high torque and high voltage servos.

• Tunable drag brake and drag brake rate for different vehicles, tracks and control feel. Adjustable PWM frequency combined with advanced freewheeling (/DEO) technology guarantees great

throttle linearity and driving feel.

• 9 levels of acceleration/pun from soft to aggressive for different vehicles, tires and tracks.

• Proportional brake with 9 levels of initial brake force, maximum brake force and drag brake force.

• Multiple protections: low-voltage cutoff protection, thermal protection, and throttle signal loss protection.

• Separate programming port to easily connect the LED program card to the ESC.

• Single-button ESC programming and factory reset.

• ESC programming via Hobbywing LED program card.

• Motor Wiring

There is no polarityon the M+/M- two ESC-to-motor wires, hence, do not worry on how you connect them initially. You may find it necessary to swap two wires if the motor runs in reverse.

• Receiver Wiring

Plug the throttle control cable on the ESC into the throttle (TH) channel on receiver. The throttle control cable will output the voltage of 6V/7.4V to the receiver and steering servo. Hence, no

separate battery can be connected to the receiver. Otherwise, your ESC may be damaged.

• Battery Wiring

Proper polariy is esential. Please ensure positive (+) connects to positive (+), and negative (-) connects to negative (-) when plugging in the battery! When reverse polarity is applied to your ESC

from the battery, it WILL damage your ESC. This WILL NOT be covered under warrranty!

Congratulations and thank you for your trust in Hobbywing product. By purchasing

the QuicRun WP-Crawler-Brushed, you have chosen a high performance sensored

brushed electronic speed controller! This speed controller is equipped with

high-tech features to enhance your experience with Hobbywing brushed power

systems. Improper usage and unauthorized modification to our product is extremely

dangerous and may damage the product and related devices. Please take your time

and read the following instructions carefully before you start using your speed

control. We have the right to modify our product design, appearance, features and

usage requirements without notification.

This is an extremely powerful brushed

motor system. For your safety and the

safety of those around you, we

strongly recommend removing the

pinion gear attached to the motor

before performing calibration and

programming functions with this

system. It is also advisable to keep the

wheels in the air when you turn on

the ESC.

ATTENTION

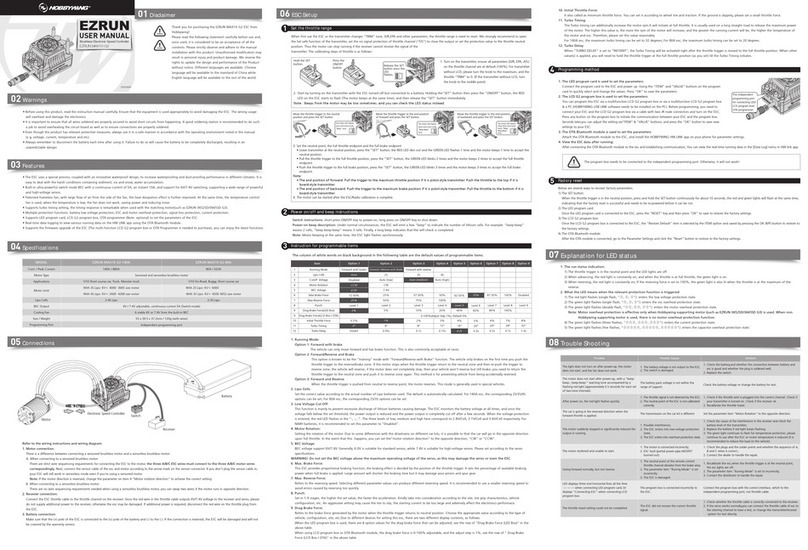

Begin using your ESC by calibrating with your tramistter. We strongly recommend Hobbywing users to use the “Fail Safe” function on the radio system and set (F/S) to “Output

OFF” or “Neutral Position”. Example of calibrating Neutral range and Endpoint.

IMPORTANT

Radio Calibration

1

• Power ON/OFF:

(Start with the ESC turned off), press the ON/OFF button to turn on the ESC.

(Start with the ESC turned on) press and hold the ON/OFF button to turn off the ESC.

• Warning Tones:

With the ESC is turned on in the normal way (that is turn it on without pressing and holding the SET button): if you set the “Battery Type” to “LiPo”, the motor will beep N (number)

beeps to indicate the number of LiPo cells you have plugged in (i.e. 2 beeps indicates a 2S LiPo, 3 beeps indicates a 3S LiPo.) and then a long beep to inform you that your ESC is

ready to work. If you set the “Battery Type” to “NiMH”, the motor will only beep a beep to indicate the ESC is in NiMH mode and then another beep to inform you that your ESC is

ready to function.

Power ON/OFF & Warning Tones

2

1. Turn on the transmitter, ensure all parameters (D/R, Curve, ATL) on the throttle channel are at default (100%). For transmitter

without LCD, please turn the knob to the maximum, and the throttle “TRIM” to 0. Please also turn the corresponding knob to the

neutral position. For FutabaTM transmitter, the direction of throttle channel shall be set to “REV”, while other radio systems shall be set

to “NOR”. Please ensure the “ABS/braking function” of your transmitter must be DISABLED.

2. Start with transmitter on and the ESC turned off but connected to a battery. Holding the SET button and press the ON/OFF button to

turn on the ESC, the RED LED on the ESC starts to flash (Note: the motor beeps at the same time), and then release the SET button

immediately(The ESC will enter the programming mode if the SET button is not released in 3 seconds, please restart from step 1.).

Note: Beeps from the motor may be low sometimes, and you can check the LED status instead.

Move the throttle stick to the neutral position and

press the set button.

Release the set

button once the

LED flashes.

3. Set the neutral point, the full throttle endpoint and the full brake endpoint.

• Leave transmitter at the neutral position, press the SET button, the RED LED flashes 1 time and the motor beeps 1 time to accept the neutral position.

• Pull the throttle trigger to the full throttle position, press the SET button, the RED LED blinks 2 times and the motor beeps 2 times to accept the full throttle endpoint.

• Push the throttle trigger to the full brake position, press the SET button, the RED LED blinks 3 times and the motor beeps 3 times to accept the full brake endpoint.

4. The motor can be started 3 seconds after the ESC/Radio calibration is complete.

The RED LED

flashes once and

motor emits

“Beep” tone.

Move the throttle stick to the end position of

forward and press the set button.

The RED LED flashes

twice and motor emits

“Beep-Beep”

tone.

Move the throttle stick to the end position of

backward and press the setup button.

The RED LED flashes

twice and motor emits

“Beep-Beep-

Beep” tone.

1. Program your ESC with the SET Button

2. Program your ESC with a LED program card

• For easy recognition, the motor beeps at the same time when the Red LED

flashes.

• When “N” (the number) is equal to or bigger than 5, we use a long flash

to represent “5”. For example, the Red LED flashes a long flash (and the

motor beeps a long beep at the same time) indicating you are in the 5th

programmable item; if the Red LED flashes a long flash and a short flash

(and the motor beeps a long beep and a short beep at the same time)

indicating you are in the 6th programmable item; a long flash and two

short flashes ( a long beep and two short beeps at the same time)

indicating you’re in the 7th programmable item and so on.

• Restore the default values with the SET button

Press and hold the SET button for over 3 seconds anytime when the throttle is at the neutral position (except during the ESC calibration and programming) can factory reset your ESC. The Red LED flahses

a long flash (the motor beeps a long beep at the same time) and then a short, single flash that repeats indicating that you have successfully restored all the default values within your ESC. Once you power

the ESC off, and then back on, your settings will be back in the default mode.

• Restore the default values with a LED program card.

After connecting the LED program card to the ESC, press the “RESET” button and the “OK” button to factory reset your ESC.

• The Red LED dies out when the throttle trigger is in throttle neutral zone.

• The Red LED flashes when your vehicle runs forward and it turns solid Red when you pull the throttle trigger to the full throttle endpoint.

• The Red LED flashes when your vehicle brakes and it turns solid Red when you push the throttle trigger to the full brake endpoint and set the “maximum brake force” to 100%.

• The Red LED flashes when your vehicle runs backward and it runs solid Red when you push the throttle trigger to the full brake endpoint and set the “maximum reverse force” to 100%.

A standard LED program card is also included in the product box.

Its friendly interface makes the ESC programming easy and quick.

Before the programming, you need to connect your ESC to the

program card via a White/Red/Black PVC cable with two JR male

connectors (one end of the cable to the separate programming port

on the ESC and the other end to the port marked with “-/+/S” on

the program card), and then turn on the ESC, all programmable

items will show up a few seconds later. You can select the item by

choosing via “ITEM” & “VALUE” buttons on the program card.

Press the “OK” button to save all new settings to your ESC.

ATTENTION

Enter the 2nd item

"Battery Type"

Hold the SET key

Switch on the ESC

Red LED flashes

Red LED flashes

once

Red LED flashes

twice

Red LED flashes

3 times

Red LED flashes

N times

Release

SET kye

Release

SET kye

Press

SET kye

Press

SET kye

Press

SET kye

Press

SET kye

Release

SET kye

Release

SET kye

Red LED flashes once, choose "LiPo"

Red LED flashes twice, choose "NiMH"

Red LED flashes once, choose

"Disabled"

Red LED flashes twice, choose

"Auto (Low)"

Red LED flashes 3 times, choose

"Auto (Medium)"

Red LED flashes 4 times, choose

"Auto (High)"

Red LED flashes once to choose

Red LED flashes twice to choose

Red LED flashes 3 times to choose

"Forward with brake"

"Forward / Reverse with brake"

"Forward / Reverse"

Enter the 3rd

item"Cutoff Voltage"

Enter the Nth item

Enter the 1st item

"Running Mode"

Turn off the ESC

Turn on the transmitter

Hold SET key for 3 seconds

Hold SET key for 3 seconds

Hold SET key for 3 seconds

Hold SET key for 3 seconds

......The following steps are just like the above setps......

Finish programming, switch off the ESC, and then switch it on

Click the SET button to choose the

option, the times the red LED

blinks indicates the option number

you are going to select.

After entering the

corresponding item, the

red LED starts to blink,

the times it blinks

represents the current

option number.

Press SET key to choose the value,

the flash times of the RED LED

means the option number.

(Once means the 1st option,

twice means the 2nd option, etc.)

External Programming

Port for Connecting

Program Card.

1.Running Mode

2.Battery Type

3.Cutoff Voltage

4. Initial Start Force

5.Max. Forward Force

6.Max.Reverse Force

7. Max. Brake Force

8.Initial Brake Force

9. Drag Brake

10.Drag Brake Rate

11.Neutral Range

12. Start Mode/Punch

13.PWM Frequency

14.BEC Voltage

15.Freewheeling

Option 1

Fwd/Brk

LiPo

Disabled

0%

25%

25%

0%

0%

0%

Level 1

0.02ms

Level 1

1K

6V

Enabled

Option 2

Fwd/Rev/Brk

NiMH

Auto (Low)

2%

50%

50%

12.5%

6.25%

5%

Level 2

0.03ms

Level 2

2K

7.4V

Disabled

Option 3

Fwd/Rev

Auto (Medium)

4%

75%

75%

25%

12.5%

10%

Level 3

0.04ms

Level 3

4K

Option 4

Auto (High)

6%

100%

100%

37.5%

18.75%

50%

Level 4

0.05ms

Level 4

8K

Option 5

8%

50%

25%

60%

Level 5

0.06ms

Level 5

16K

Option 6

10%

62.5%

31.25%

70%

Level 6

0.07ms

Level 6

Option 7

12%

75%

37.5%

80%

Level 7

0.08ms

Level 7

Option 8

14%

87.5%

43.75%

90%

Level 8

0.10ms

Level 8

Option 9

16%

100%

50%

100%

Level 9

0.12ms

Level 9

Programmable Item

07

Explanation for LED Status

08

Troubleshooting

03

Features

02

Warnings

04

Specifications

05

Begin to Use a New Brushed ESC

06

ESC Setup

Programmable Items

3

ESC Programming

4

Factory Reset

5

CAUTIONS

ATTENTION

01

Introduction

USER MANUAL

QuicRun WP Crawler Brushed

Brushed Electronic Speed Controller

Those “black background and white text” options are the factory default settings.

1. Running Mode

Option 1: Forward with Brake. It’s a racing mode. It has only forward and brake functions.

Option 2: Forward/ Reverse with Brake. This option is known to be the “training” mode with “Forward/ Reverse with Brake” functions. Hobbywing has adopted the “DOUBLE-CLICK” method, that is

your vehicle only brakes on the 1st time you push the throttle trigger forward (brake) (1st push). The motor stops when you quickly release the throttle trigger and then re-push the trigger quickly (2nd

push), only then the vehicle will reverse. The reverse function will not work if your car does not come to a complete stop. The vehicle only reverses after the motor stops. This method is for preventing

vehicle from being accidentally reversed.

Option 3: Forward and Reverse. This mode is often used by special vehicles (rock crawler). It adopts the “SINGLE-CLICK” method. The vehicle will brake immediately when you push the throttle trigger

forward (brake).

2. Battery Type

Option 1: LiPo. Select this option when you use a LiPo battery and set the cutoff voltage accordingly.

Option 2: NiMH. Select this option when you use a NiMH battery and set the cutoff voltage accordingly.

3. Cutoff Voltage

Sets the voltage at which the ESC lowers or removes power to the motor in order to either keep the battery at a safe minimum voltage (for LiPo batteries). The ESC monitors the battery voltage all the

time; it will immediately cut off the output when the voltage goes below the cutoff threshold. The RED LED will flash a short, single flash that repeats (☆-, ☆-, ☆-) to indicate the low-voltage cutoff

protection is activated.

Option 1: Disabled. The ESC does not cut the power off due to low voltage. Please pay attention to the power change of your vehicle. In general, the battery voltage gets pretty low when your vehicle is

severely losing power, then you should stop using that pack.

Option 2: Auto (Low). Low cutoff voltage, difficult to get the LVC protection activated, is applicable to batteries with poor discharge capability. The corresponding cutoff voltage is 4.5V for a NiMH pack.

Option 3: Auto (Medium). Medium cutoff voltage, prone to getting the LVC Protection activated, is applicable to batteries with ordinary discharge capability. The corresponding cutoff voltage is 5.0V

for a NiMH pack.

Option 3: Auto (High). High cutoff voltage, very prone to getting the LVC Protection activated, is applicable to packs with great discharge capability. The corresponding cutoff voltage is 5.5V for a NiMH pack.

4. Initial Start Force

It’s the initial force when you pull the throttle trigger from neutral position toward non-throttle throttle position. A suitable start force can effectively prevent vehicle from sliding when you apply a low

throttle amount.

5. Max. Forward Force

It’s the force when throttle trigger is at the full throttle position. It’s adjustable among 25%, 50%, 75% and 100% (by default). You can lower down the value for better driving feel/control when you

drive a crawler (simulation model) over difficult terrains (and don’t have any requirement against the maximum speed).

6. Max. Reverse Force

Different reverse amount will bring different reversing speed. For the safety of your vehicle, we recommend using a low amount.

7. Max. Brake Force

The ESC provides proportional braking function; the braking effect is decided by the position of the throttle trigger. It sets what percentage of available braking power when full brake is applied. Large

amount will shorten the braking time but it may damage your pinion and spur. Please select the most suitable brake amount as per your car condition and your preference.

8. Initial Brake Force

It is also known as “minimum brake force”. It is the force when pushing throttle trigger from neutral zone to the initial brake position. To get a smoother braking effect, the default is equal to the drag brake.

9. Drag Brake

Drag brake is the braking power produced when releasing the throttle trigger from full speed to neutral zone.

Attention! Drag brake will consume much power, so apply it cautiously.

10. Drag Brake Rate

It’s the rate at which the drag brake increases from zero to the pre-set value when the throttle trigger enters the neutral range. A suitable rate can make the vehicle stop stably. You can choose the drag

brake rate from level 1 (very soft) to level 9 (very aggressive) as per the track, tires’ grip, and etc.

11. Neutral Range

As not all transmitters have the same stability at “neutral position”, please adjust this parameter as per your preference. You can adjust to a bigger value when this happens.

12. Start Mode / Punch

You can choose the punch from level 1 (very soft) to level 5 (very aggressive) as per the track, tires, grip, your preference and etc. This feature is very useful for preventing tires from slipping during the

starting-up process. In addition, “level 4” and “level 5” have strict requirement on battery’s discharge capability. It may affect the starting-up if the battery discharges poorly and cannot provide large

current in a short time. The car stutters or suddenly loses power in the starting-up process indicating the battery’s discharge capability is not good, and then you need to reduce the punch or increase the

FDR (Final Drive Ratio).

13. PWM Drive Frequency

The acceleration will be more aggressive at the initial stage when the drive frequency is low; a higher drive frequency is smoother but this will create more heat to the ESC.

14. BEC Voltage

Option 1: 6.0V. It’s applicable to ordinary servos. Do not use this option with high voltage servos; otherwise your servos may not function normally due to insufficient voltage.

Option 2: 7.4V. It’s applicable to high voltage servos. Do not use this option with ordinary servos; otherwise your servos may be burnt due to high voltage.

15. Freewheeling

For regular vehicles, we recommend disabling this function. With it disabled, your vehicle can have quick acceleration. For a crawler (simulation model), we suggest enabling it. With it enabled, you

crawler can have better linearity during a low-speed running and also less heat.

Trouble(s) Solution(s)Possible Causes

1. No power was supplied to the ESC.

2. The ESC switch was damaged

The throttle control cable was reversely plugged in or in the

wrong channel on the receiver.

The throttle range was not calibrated properly.

1. The ESC-to-motor wiring order was incorrect.

2. Incorrectly set the direction of the throttle channel.

1. The receiver was influenced by some foreign interference.

2. The LVC protection was activated.

3. The ESC thermal protection was activated.

The throttle neutral position on your transmitter was actually

in the braking zone.

1. Check if all ESC & battery joints or connections have been well soldered or firmly connected.

2. Replace the broken switch.

Please plug the throttle control cable in the TH channel (usually CH2) on receiver

or recalibrate the throttle range.

Please recalibrate the throttle range or fine-tune the neutral position on the transmitter.

1. Swap motor wires.

2. Change the direction of the throttle channel from “NOR” to “REV” or “REV” to “NOR”.

1. Check all devices and try to find out all possible causes, and check the transmitter’s battery voltage.

2. The Red LED keeps flashing indicating the LVC protection is activated, so please replace your battery pack.

3. The Red LED keeps flashing indicating the ESC thermal protection is activated, please let your ESC cool

down before using it again.

Recalibrate the throttle neutral position. No LED on the ESC will come on when

the throttle trigger is at the neutral position.

The ESC was unable to start the motor (but the Red status

LED flashed) after it was powered on

The vehicle moved forward or backward slowly

when the throttle trigger was at the neutral position

The ESC was unable to start the status LED;

the motor after it was powered on

The vehicle ran backward when you pulled the

throttle trigger towards you

The vehicle could run forward but could not reverse

The motor suddenly stopped or significantly

reduced its output in operation

• To avoid short circuits, ensure that all wires and connections must be well insulated before connecting the ESC to related devices.

• Ensure all devices are well connected to prevent poor connections and avoid damages to your electronic devices.

• Read through the manuals of all power devices and chassis and ensure the power configuration is rational before using this unit.

• Please use a soldering iron with the power of at least 60W to solder all input/output wires and connectors.

• Do not hold the vehicle in the air and rev it up to full throttle, as rubber tires can “expand” to extreme size or even crack to cause serious injury.

• Stop immediate usage once the casing of the ESC exceeds 90℃/194℉ as this may cause damages to both the ESC and motor. Hobbywing recommends setting the “ESC Thermal Protection” to

105℃/221℉ (this refers to the internal temperature of the ESC).

• Users must always disconnect the batteries after use as the current on the ESC is consuming continuously if it is connected to the batteries (even if the ESC is turned off). The battery will

completely be discharged and may result in damage to the battery or ESC when it is connected for a long period of time. This WILL NOT be covered under warranty.

Battery

Motor

Receiver

Switch

Electronic Speed Controller

Press and hold

the SET button

Press the ON/OFF button