INSTALLATION INSTRUCTIONS FOR HOCHIKI ANALOGUE SENSORS

TYPE: ACC, ATJ, ALN

INTRODUCTION

Analogue Multi sensor ACC-ASN

Analogue Heat sensor ATJ-ASN

Analogue Smoke sensor ALN-ASN

Analogue Sensor Base YBN-R/3, YBN-R/3(SCI), YBO-R/SCI,

YBO-BS, YBO-BSB, YBO-BSB2

Other combinations of sensor and base are also possible.

Please confirm with Hochiki or the appointed sales agent.

Ensure that the following items are inspected before installation and maintenance.

Hochiki cannot warrant a sensor’s performance if such items are neglected.

CAUTION

・This sensor cannot be used to prevent FIRE itself, it is only intended to detect a certain characteristic of fire.

・When installing this sensor, ensure that the location of each sensor has been planned in accordance with appropriate local

and National fire regulations or recommendations.

・The detector shall not be installed in the following environmental conditions:

-Situations in which condensation exists.

-Situations in which corrosive gases exist.

-Situations in which dust or steam exist.

-Situations in which obstacles exist, which could impede airflow to the detector.

・Certain actions can cause permanent damage to the sensor and therefore if the sensor is subjected to any of the following

actions it should not be used:

-Disassembly and reassembly.

-Impact or shock or drop.

-Touching the thermistors of the sensor(the thermistors is orange color and located in sides of smoke chamber). (only

ACC and ATJ)

・The sensor should therfore be replaced after a fire has occurred if damage is suspected.

・After installation, all sensors on the fire alarm system should be tested to verify correct operation.

・Installation and maintenance should only be carried out by suitably trained personnel.

・The sensor must be subject to periodic maintenance during regular service visits, which should be as recommended by

appropriate local and National Standards or recommendations. In the event of no such Standards existing, Hochiki

recommend that the minimum period of maintenance should be 1 year and that the following items should be taken into

account:

-In cases where there are excess built up of dust on the smoke chamber or the thermistors, the sensitivity of the sensor

could be affected.

-A regular operational test should be performed.

-A visual check for staining and mechanical damage should be made.

-If the Testifire, Solo or an equivalent heat detector tester is being used to test the ACC/ATJ, please ensure that the

main duct of the tester is aligned with one of the thermistors on the sensor, incorrect alignment could result in a

failed test or damage to the sensor.

・Sensor operation should not be verified by the use of a naked flame or open fire.

Operation should only be checked by equipment that is capable of exceeding the required detection threshold by a small

amount sufficient to guarantee a fire signal is produced by the sensor.

・A dust cover is included on the sensor to ensure that contamination cannot affect the correct operation for the sensor. The dust

cover must be removed for the sensor to operate. (only ACC and ALN)

・The correct operation and function for each sensor must be checked during installation. Regular checks of each device's

operation should be made to ensure that the system continues to operate correctly.

・Compliance with AS 7240.5 and 7240.7 is achieved at Table.1 setting. Other settings do not comply with AS 7240.5 and AS

7240.7.

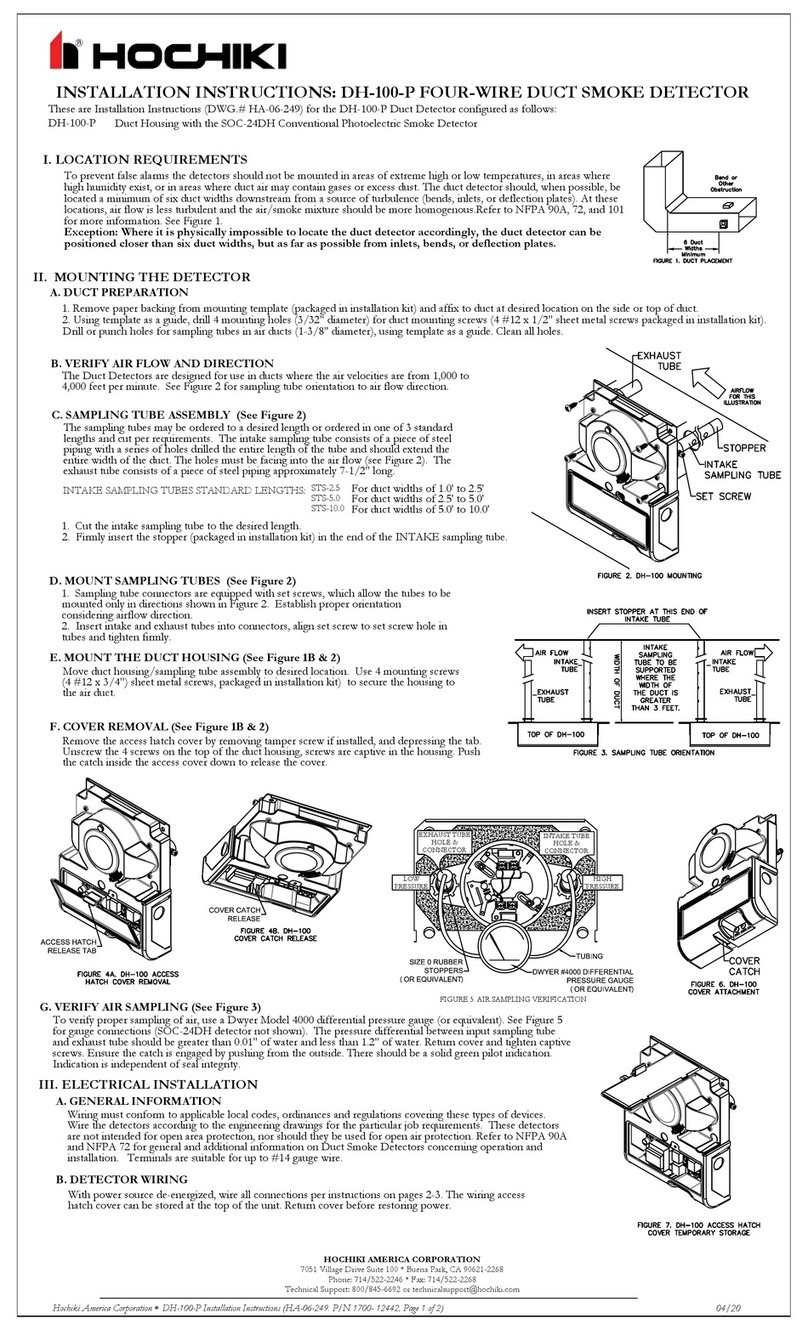

EXTERNAL VIEW

REF.No.:7-0-000-3207-722

Fig.1

SMALLER HOLE

ACC:DOUBLE

ALN:NO CIRCLE

LAGER HOLE

SMOKE CHAMBER(ACC/ALN)

THERMISTOR(ACC/ATJ)

CONTACT BLADE

NAME LABEL

PRONG

MARKING

ATJ:SINGLE