HOCHIKI AMERICA CORPORATION

7051 Village Drive Suite 100 * Buena Park, CA 90621-2268

Phone: 714/522-2246 * Fax: 714/522-2268

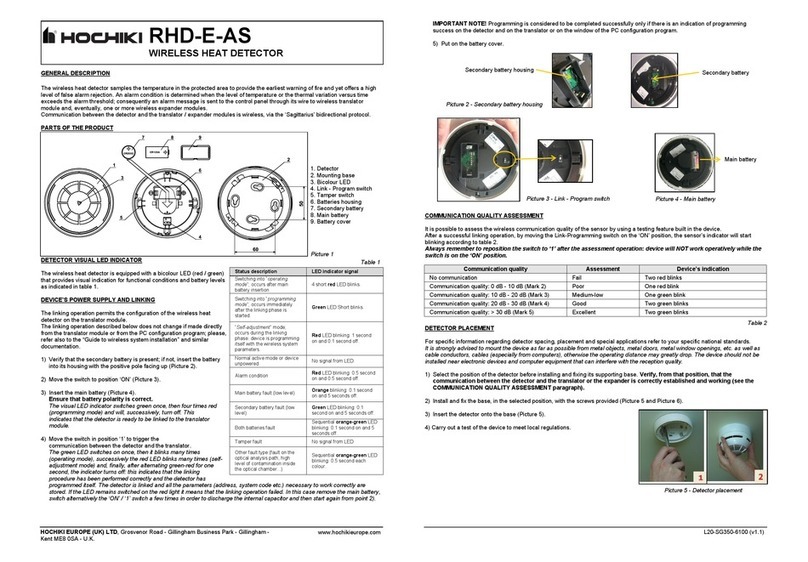

II. MOUNTING THE DETECTOR

The sampling tubes may be ordered to a desired length or ordered in one of 3 standard

lengths and cut per requirements. The intake sampling tube consists of a piece of steel

piping with a series of holes drilled the entire length of the tube and should extend the

entire width of the duct. The holes must be facing into the air flow (see Figure 2). The

exhaust tube consists of a piece of steel piping approximately 7-1/2" long.

1. Remove paper backing from mounting template (packaged in installation kit) and affix to duct at desired location on the side or top of duct.

2. Using template as a guide, drill 4 mounting holes (3/32" diameter) for duct mounting screws (4 #12 x 1/2" sheet metal screws packaged in installation kit).

Drill or punch holes for sampling tubes in air ducts (1-3/8" diameter), using template as a guide. Clean all holes.

To prevent false alarms the detectors should not be mounted in areas of extreme high or low temperatures, in areas where

high humidity exist, or in areas where duct air may contain gases or excess dust. The duct detector should, when possible, be

located a minimum of six duct widths downstream from a source of turbulence (bends, inlets, or deflection plates). At these

locations, air flow is less turbulent and the air/smoke mixture should be more homogenous.Refer to NFPA 90A, 72, and 101

for more information. See Figure 1.

Exception: Where it is physically impossible to locate the duct detector accordingly, the duct detector can be

positioned closer than six duct widths, but as far as possible from inlets, bends, or deflection plates.

These are Installation Instructions (DWG.# HA-06-249) for the DH-100-P Duct Detector configured as follows:

Duct Housing with the SOC-24DH Conventional Photoelectric Smoke Detector

INSTALLATION INSTRUCTIONS: DH-100-P FOUR-WIRE DUCT SMOKE DETECTOR

A. DUCT PREPARATION

The Duct Detectors are designed for use in ducts where the air velocities are from 1,000 to

4,000 feet per minute. See Figure 2 for sampling tube orientation to air flow direction.

DH-100-P

With power source de-energized, wire all connections per instructions on pages 2-3. The wiring access

hatch cover can be stored at the top of the unit. Return cover before restoring power.

Wiring must conform to applicable local codes, ordinances and regulations covering these types of devices.

Wire the detectors according to the engineering drawings for the particular job requirements. These detectors

are not intended for open area protection, nor should they be used for open air protection. Refer to NFPA 90A

and NFPA 72 for general and additional information on Duct Smoke Detectors concerning operation and

installation. Terminals are suitable for up to #14 gauge wire.

To verify proper sampling of air, use a Dwyer Model 4000 differential pressure gauge (or equivalent). See Figure 5

for gauge connections (SOC-24DH detector not shown). The pressure differential between input sampling tube

and exhaust tube should be greater than 0.01" of water and less than 1.2" of water. Return cover and tighten captive

screws. Ensure the catch is engaged by pushing from the outside. There should be a solid green pilot indication.

Indication is independent of seal integrity.

Move duct housing/sampling tube assembly to desired location. Use 4 mounting screws

(4 #12 x 3/4") sheet metal screws, packaged in installation kit) to secure the housing to

the air duct.

1. Sampling tube connectors are equipped with set screws, which allow the tubes to be

mounted only in directions shown in Figure 2. Establish proper orientation

considering airflow direction.

2. Insert intake and exhaust tubes into connectors, align set screw to set screw hole in

tubes and tighten firmly.

1. Cut the intake sampling tube to the desired length.

2. Firmly insert the stopper (packaged in installation kit) in the end of the INTAKE sampling tube.

INTAKE SAMPLING TUBES STANDARD LENGTHS:

III. ELECTRICAL INSTALLATION

FIGURE 5. AIR SAMPLING VERIFICATION

For duct widths of 1.0' to 2.5'

For duct widths of 2.5' to 5.0'

For duct widths of 5.0' to 10.0'

EXHAUST TUBE

HOLE &

CONNECTOR

LOW

PRESSURE

STS-2.5

STS-5.0

STS-10.0

HIGH

PRESSURE

INTAKE TUBE

HOLE &

CONNECTOR

Hochiki America Corporation *DH-100-P Installation Instructions (HA-06-249. P/N 1700- 12442, Page 1 of 2) 04/20

B. VERIFY AIR FLOW AND DIRECTION

C. SAMPLING TUBE ASSEMBLY (See Figure 2)

D. MOUNT SAMPLING TUBES (See Figure 2)

E. MOUNT THE DUCT HOUSING (See Figure 1B & 2)

G. VERIFY AIR SAMPLING (See Figure 3)

A. GENERAL INFORMATION

B. DETECTOR WIRING

I. LOCATION REQUIREMENTS

Remove the access hatch cover by removing tamper screw if installed, and depressing the tab.

Unscrew the 4 screws on the top of the duct housing, screws are captive in the housing. Push

the catch inside the access cover down to release the cover.

F. COVER REMOVAL (See Figure 1B & 2)