FIRElink-100 – Installation Manual Page 3 of 40

©2010 Hochiki Europe (UK) Ltd 9-5-0-345/ISS4/OCT10

Table of Contents

1Introduction.................................................................................................................................... 5

1.1 Indicators............................................................................................................................... 6

1.2 Inside the Detector................................................................................................................. 7

1.3 Detector Terminal Block Connections..................................................................................... 8

1.4 Programming the Detector...................................................................................................... 9

1.5 Time and Date Tab................................................................................................................. 9

1.6 Alarm Levels and Delays Tab............................................................................................... 10

1.6.1 Alarm Levels - (Level subgroup)....................................................................................... 10

1.6.2 Alarm Delays - (Delay subgroup)...................................................................................... 10

1.6.3 ClassiFire® Override........................................................................................................ 10

1.6.4 Alarm Factor....................................................................................................................10

1.6.5 LDD Enable ..................................................................................................................... 11

1.6.6 FastLearn Enable............................................................................................................. 11

1.6.7 Auto FastLearn Enable..................................................................................................... 11

1.6.8 ClassiFire 3D...................................................................................................................11

1.6.9 Demo Mode ..................................................................................................................... 11

1.7 Day/Night Switching Tab...................................................................................................... 12

1.7.1 Day Start / Night Start –.................................................................................................... 12

1.7.2 Disable Day / Night Switching........................................................................................... 12

1.8 Alarm Actions Tab................................................................................................................ 12

1.8.1 Remote Functions (Remote Input subgroup) .................................................................... 12

1.8.2 Programmed Isolate......................................................................................................... 12

1.8.3 Latching Alarms............................................................................................................... 12

1.8.4 Latching Faults.................................................................................................................12

1.8.5 Cascading Alarms............................................................................................................ 12

1.9 Device Information Tab ........................................................................................................ 13

1.9.1 Device Type.....................................................................................................................13

1.9.2 Firmware Version............................................................................................................. 13

1.9.3 Run-time Hours................................................................................................................ 13

1.9.4 Watchdog Count .............................................................................................................. 13

1.9.5 Device Text...................................................................................................................... 13

1.10 Referencing Tab................................................................................................................... 13

1.10.1 Reference Detector.......................................................................................................... 13

1.10.2 Reference Enable ............................................................................................................ 13

1.10.3 Reference Level............................................................................................................... 13

1.10.4 Reference Back-off .......................................................................................................... 13

1.11 Flow Monitoring Tab.............................................................................................................14

1.11.1 Flow Rate......................................................................................................................... 14

1.11.2 Flow High Limit ................................................................................................................ 14

1.11.3 Flow Low Limit................................................................................................................. 14

1.11.4 Flow Fault Delay.............................................................................................................. 14

1.12 Miscellaneous Tab ............................................................................................................... 14

1.12.1 Access Code.................................................................................................................... 14

1.12.2 Chart Recording Rate....................................................................................................... 15

1.12.3 Separator Condition ......................................................................................................... 15

1.12.4 Separator Change Date.................................................................................................... 15

1.12.5 Factory Default.................................................................................................................16

1.13 Other Remote Software Features......................................................................................... 16

1.13.1 Reset............................................................................................................................... 16

1.13.2 Histogram Screen ............................................................................................................ 16

1.14 Chart Recording................................................................................................................... 18

1.15 Load / Save Function Settings.............................................................................................. 18

2Design Limitations....................................................................................................................... 20

2.1 System Design..................................................................................................................... 21

2.2 EN54-20 Compliance........................................................................................................... 22

3Installation.................................................................................................................................... 24

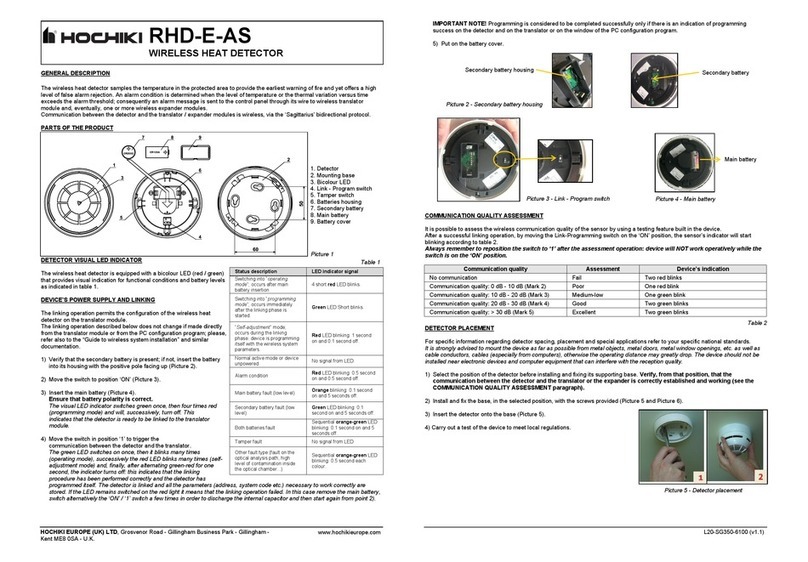

3.1 Docking Station.................................................................................................................... 24