1. Contents

2. Introduction

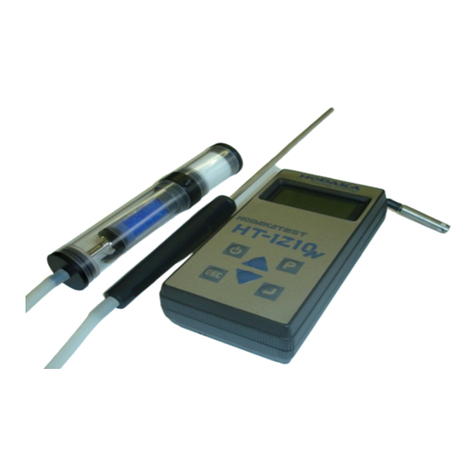

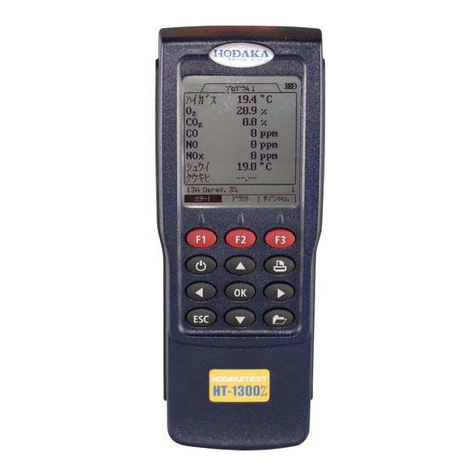

2.1 The flue gas analyzer HT-1200N

2.2 Important instructions regarding the Operating Manual

3. Safety Regulations

3.1 Safety Instructions

3.2 Specific Safety Instructions

4. Device illustrations

4.1 Perspectiv View

4.2 Connection plate

4.3 Lower part

4.4 Keyboard

5. Power supply

5.1 Prepare measurement

5.2 Interface RS 232

6. Operating

6.1 Switch ON the unit

6.2 Gas measurement

6.3 Last values

6.4 Zero setting

6.5 Extension menu

6.5.1. Stored data

6.5.1.1 View stored data

6.5.1.2 Delete data

6.5.1.3 Measurement HT-1200N to PC

6.5.2 Device settings

6.5.2.1 Date/ Time

6.5.2.2 Parameter

7. Calculation basis

7.1 Analysis and calculation

8. Technical Specifications

9. Storage

9.1 Operating and storage temperature

10. Guarantee

1

2

2

3

4

5

12

13

14

114

9. Storage

9.1 Operating amd storage temperature

Operating temperature 0 to 45℃

-20 to 60℃

Long term non-operating and storage:

1, charge battery every 3 weeks at the line power

2, store in a dry place

Recommendation :

Discharge battery before charging (turn power on of unit and wait until

auto shut-down before charging.)

Storage temperature

Guarantee period : 12months from date of dispatch.

Guarantee: During guarantee period, if your instrument brakes down although

correct usage based on this user manual,

we will repair it by free of charge.

In case you have trouble, firstly please contact to HODAKA CO., LTD.

(+81-(0)6-6922-5501), then send your instrument to HODAKA CO., LTD.

HODAKA CO., LTD shall not be liable for any loss or damage whatever arising

from content errors or any mis-use of this instrument.

HODAKA CO., LTD.

1-6-17 Asahiku Takadono Osaka Japan 535-0031

TEL: +81-(0)6-6922-5501

FAX: +81-(0)6-6923-1617

Traceability certification can be issued at HODAKA.

( Additional cost will be required)

10. Guarantee

Option Description Art. No.

Air temp. sensor

Ambient air temp. sensor

Battery charger

Hard case

Measurement software

Measurement software

Infrared printer

Roll paper for infrared printer

* Fuel data might slightly differ depend on location, therefor calculated data also might have difference.

0~100℃、for air temp.

0~100℃

AC100~240V

Aluminum, dimentino:350×460×155 weight:2.9kg

Online View 2000(OS Windows XP/7) with RS232cable

Online View 2000(OS Windows XP/7)with RS232cable,USBcable

with roll paper×1 , AAbattery x 4

5rolls

HT-1382

HT-1321

HT-1318

HT-1315

HT-2094

HT-2084

HT-1610

HT-1636

2.Introduction

3.Safety Regulations

The following Safety instructions have to be strictly observed.

They are an essential and indispensable part of the user documentation.

Not observing can mean loss of warranty claims.

3.1 Safety Instruction

The device HT-1200N is only to be used for its indicated purpose:

The measurement of flue gases, of combustion air and gas temperature.

3.2 Specific Safety Instructions

The device is only to be used with the supplied AC adapter (HT1301) for

power supply.

Should the battery catch fire due to an operating error or a technical defect,

the fire should only be extinguished with the corresponding fire extinguishing

equipment.

The metal tube of the probe as well as any other metal parts / accessories are

not to be used as electric conductors.

The device is not to be used in and under water.

The device is not to be placed near or directly at open fire or heat.

The indicated range of temperature of the probe is not to be exceeded,

as the probe, temperature sensory mechanism and sensor could be destroyed.

Plugs of the electronic measuring device have to be avoided.

Caution: Moisture, being evacuated out of the condensate trap can be

slightly acidic.

In case of skin contact IMMEDIATELY: clean respective parts of the body!

Avoid contact of eyes with liquid!

After measurement, vent the device with fresh air and see to it that the probe is

getting cold.As long as it is hot, the tube of the probe could burn persons or cause

fire damages on inflammable underground.

The exhalations of alcoholic combinations(f.ex.attenuation, petrol, spirit,

varnish.....) may be damage the sensor of the analyzer. Therefore it’ s forbidden

to preserve or use these fluids near by the device.

2.1 The flue gas analyzer HT-1200N

The Flue Gas analyzer HT-1200N is used for the following purposes:

Precise control and adjustment measurement for gas and oil firings

Inspection of gas firing locations

Control of modern combustion boilers

2.2 Important Instructions regarding the Operating Manual

The operational manual is an important part of the scope of supply and assures

not only the correct operation and use of the measuring device,but also the safety

of the user and the environment.

Therefore,every user is obliged to read carefully the operation manual and to strictly

observe all instructions regarding safety.

Additional instructions in other chapters are marked through Caution signs.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

2