Hog Slat Inc. Newton Grove, NC USA August 2016

3

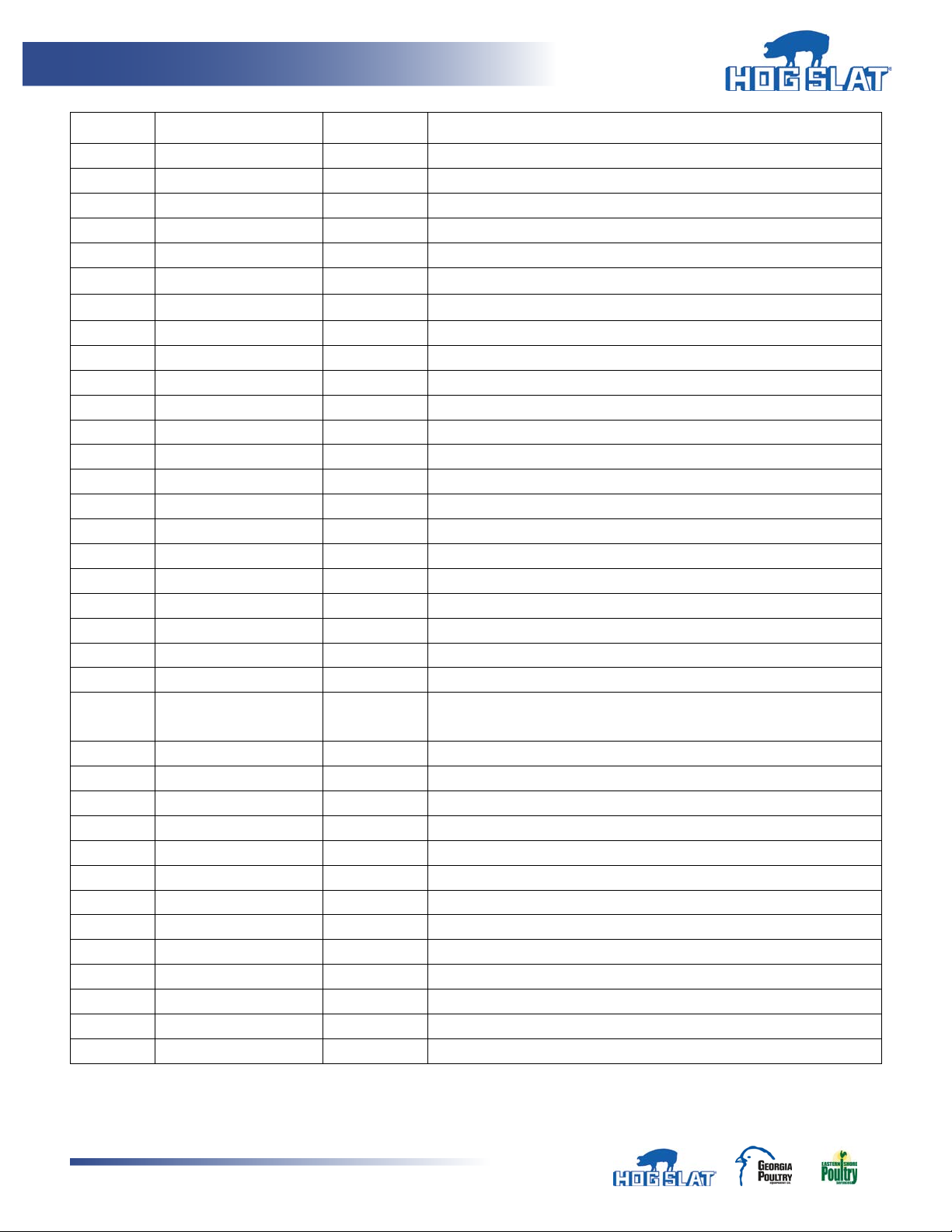

ITEM # PART # QTY PER DESCRIPTION

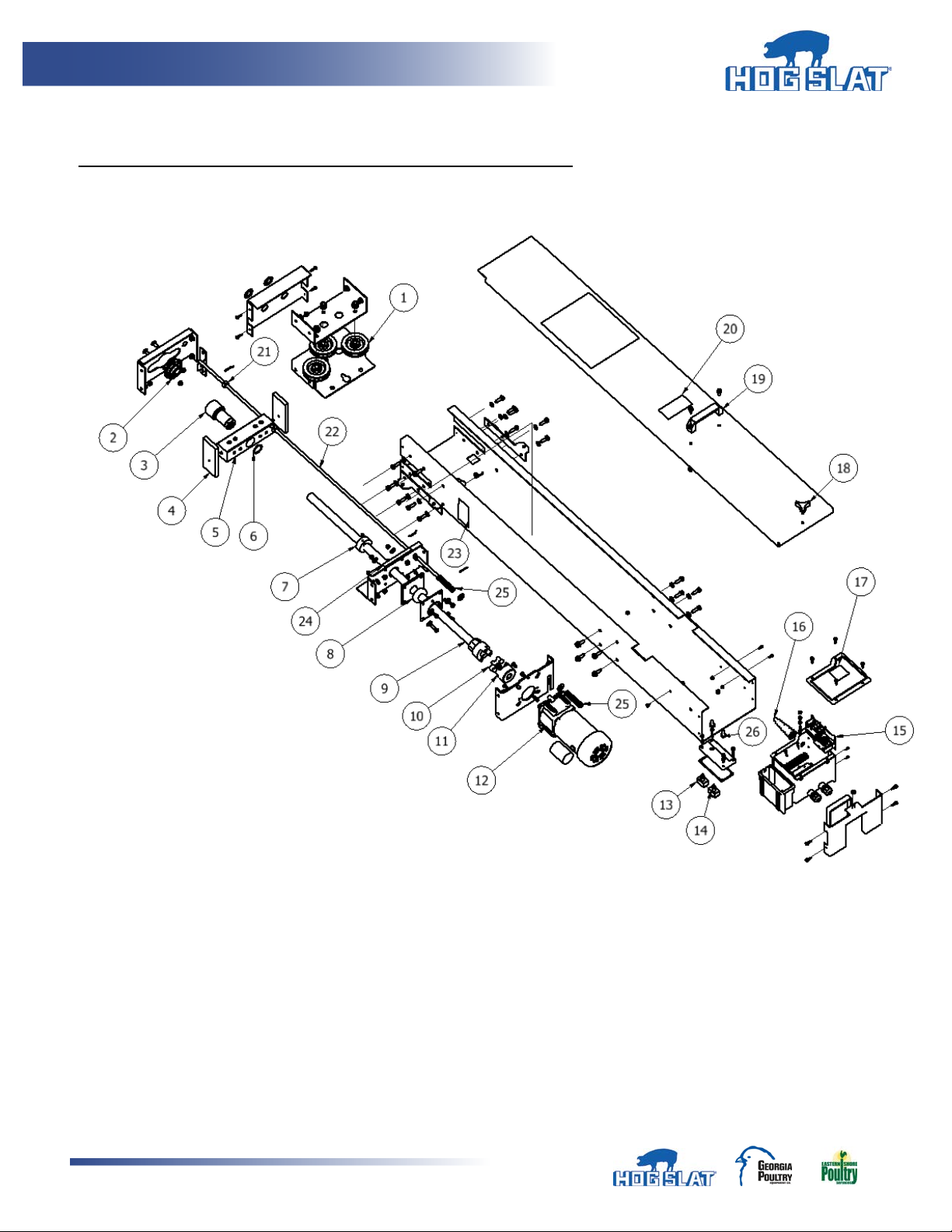

1 HS583-34 3 Pulley, Cast 3-1/2" with double ball bearings

2 HS583-42 1 Bearing Flange 1" I.D

3 HS583-8-2 1 Load Nut, nylon

HS583-8-2A 1 Load Nut Replacement Kit

4 HS583-9 2 Slide, load block

HS583-8 1 Kit, Complete Load Block Assembly including Load Nut

6 1 1 ¼” External snap ring, supplied with HS583-8-2A

7 HS583-41 1 Threaded collar, seal thrust bearing nylon

8 HS583-12 1 Thrust bearing, 1” ID, D9

9 HS583-11A24 1 ACME screw, 24” machine

HS583-11A36 1 ACME screw, 36” machine

Spider Gear-spacer Hytrel (white) L090/L095

Coupling Jaw L095 5/8" bore with keyway

Motor 1/8 HP, 115V AC, 60 Hz, 1.9A FL, 28RPM

Motor 1/8 HP 230V AC, 50/60Hz, 0.75/0.90A FL, 24/29 RPM

Motor 1/8 HP, 115V AC, 60 Hz, 1.65A FL, 16RPM

HS9053 1 Motor 1/8HP 115V 60Hz, 1.9A FL, 60RPM

HS9054 1 Motor 1/8HP 230V 50/60Hz, 0.75 / 0.90 FL, 60RPM

13 EL1001 1 Switch, Toggle SPDT , 10A @ 250 Volt, CTR OFF

14 EL1005 1 Switch, Toggle DPDT , 10A @ 250 Volt, CTR OFF

15 HS583E-31 1 Switch assembly with (6) EL1135 micro switches for enclosed

style only.

17 HSLABEL-008 1 Label, Warning-Shock Hazard

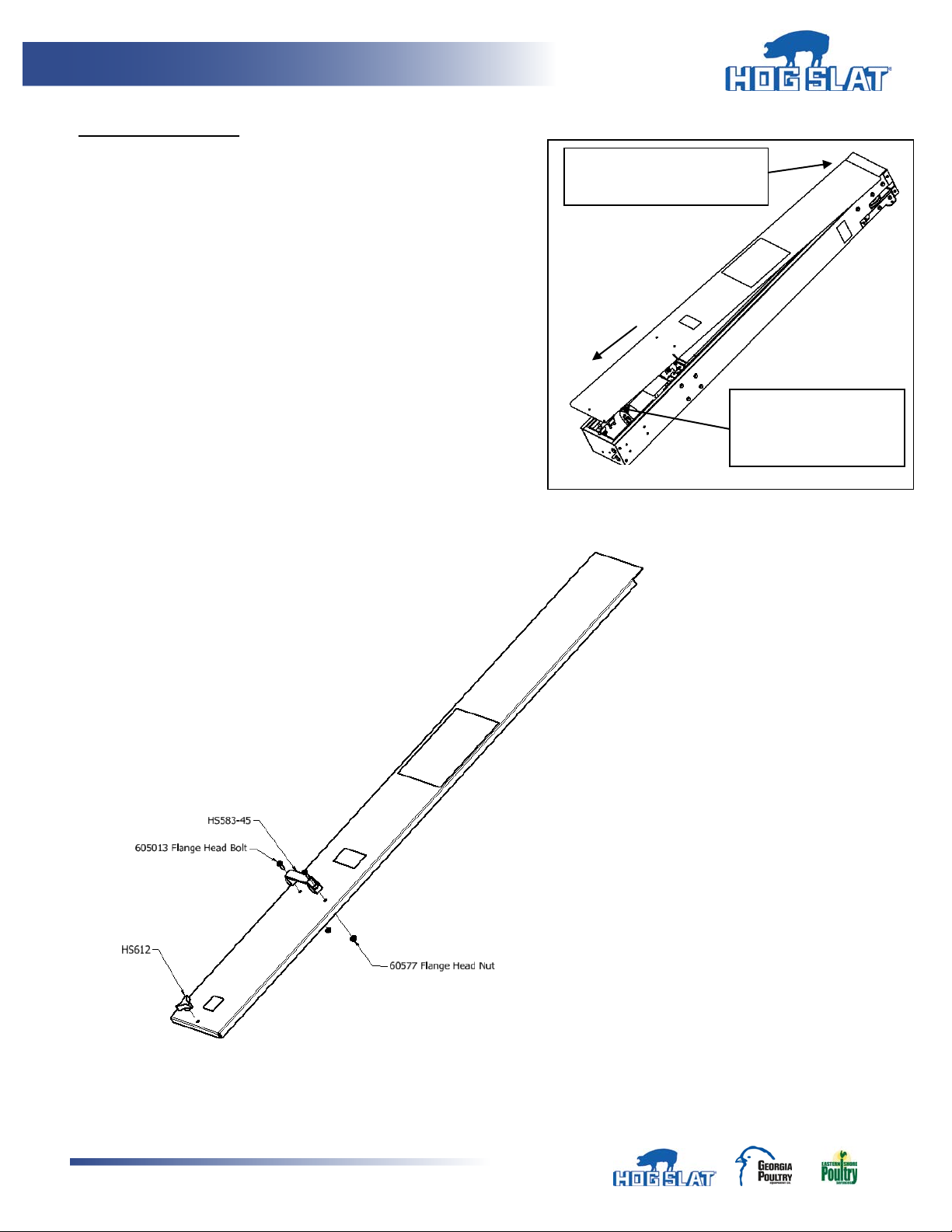

18 HS612 1 Knob, tri-handle, ¼-20 insert

19 HS583-45 1 Handle, Front door

20 HSLABEL-084 1 Label, “Caution Automatic Equipment”

21 HS583-28 2 Collar, steel 3/8'' w/ set screw

22 HS583-27-24 1 Limit rod, 24” machine

HS583-27-36 1 Limit rod, 36” machine

HS583-27-48 1 Limit rod, 48” machine

23 HSLABEL-083 2 Label, “Warning Moving Parts”

24 HSLABEL-087 1 Label, “Grease Location”

25 HS583-29 2 Spring, limit rod

26 EL1083 2 Rubber cover, toggle switch