FR15/25,FR18/26,&FR25/35SERVICEMANUAL

SAFETYPRECAUTIONS

SAFETY SIGNS AND SAFETY MESSAGES

Improper service operation can cause accidents. Don’t take chances with incorrect or damaged

equipment. Read and understand the procedures for safe driving and maintenance outlined

in the is manual. Don’t hesitate to ask for help. Stay alert! Follow safety rules, regulations, and

procedures. Avoid accidents by recognizing dangerous procedures or situations before they

occur. Drive and work safely and follow the safety signs and their messages on the truck and

in this manual.

Safety signs and messages are placed in this manual and on the truck to provide instructions

and identify specific areas where potential hazards exist and special precautions should be

taken. Know and understand the meaning of these instructions, signs, and messages. Damage

to the truck, death, or serious injury to you or other persons may result if these messages are

not followed. If warning decals are damaged, they must be replaced.

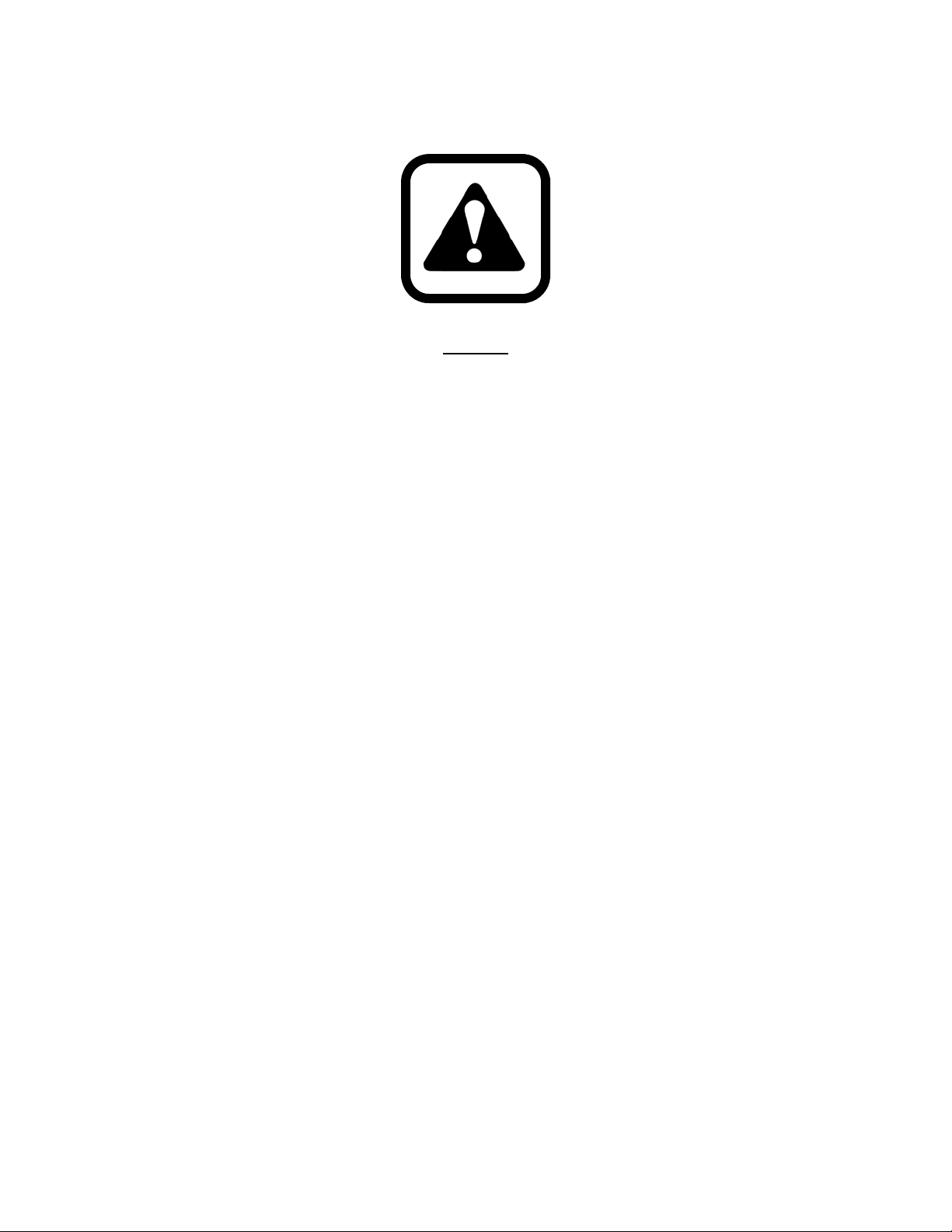

NOTICE

This message is used when special information, instructions, or identification

are required relating to procedures, equipment, tools, pressures, capacities,

and other special data.

IMPORTANT

This message is used when special precautions should be taken to ensure a

correct action or to avoid damage to or malfunction of the truck or a component

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

WARNING

Indicates a potentially hazardous situation which, if not avoided, may result in

death or serious injury.

DANGER

Indicates a potentially hazardous situation which, if not avoided, will result in

death or serious injury.